quantitative estimation of minerals in iron ores using chemical

advertisement

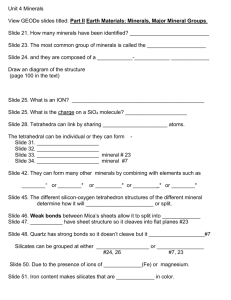

QUANTITATIVE ESTIMATION OF MINERALS IN IRON ORES USING CHEMICAL ASSAYS AND THERMO-GRAVIMETRY ANALYSIS DATA Venugopal Tammishetti*, Sivakumar Subramanian, Dharmendr Kumar, Beena Rai and Pradip Tata Research Development and Design Centre, Tata Consultancy Services Ltd., Pune, India *Email: venugopal.tammishetti@tcs.com ABSTRACT The separation efficiency in a mineral processing plant is generally assessed and reported in terms of elemental assays constituting the minerals of interest. However, different minerals comprising of same elements behave differently under similar process conditions and hence it is imperative to track the mineralwise composition of different streams in a processing plant. The availability of automated mineral analyzers such as QEMSCAN and TESCAN in recent times has made it possible; however, due to the higher cost as well as expertise required, their adaptation in day to day monitoring of operations is not yet a common place. X-ray diffraction (XRD) profile fitting (Rietveld Refinement) is another technique which can provide estimates of mineral proportions in a sample. The results of Rietveld Refinement however are affected by coating of fines on coarse particles, method of sample preparation, particle size distribution of sample, elemental substitution in mineral crystal lattice etc. In the present work, we propose a simple and efficient method for quantitative estimation of minerals in iron ores using elemental assays and thermo-gravimetry analysis data. The minerals (hematite, goethite, gibbsite, kaolin and quartz) are identified using powder XRD analysis. It is also observed that goethite phase contains Al substitution in the crystal lattice. The samples were analyzed for % Fe, % Al2O3 and % Silica using chemical analysis. The measured Loss on Ignition (LOI) in the sample is contributed from goethite, gibbsite and kaolinite phases. LOI from gibbsite and goethite occur in temperature range 250-3500C and LOI from kaolinite occur in temperature range 4007000C. According, LOI are determined in two different temperature ranges that are 100-4000C and 4008500C. We have used this data to successfully determine the mineral compositions of iron ore samples. We have also employed a data reconciliation algorithm on the calculated data for further improvement and consistency of our results. Our method is very convenient for quick estimation of mineral proportions in a sample. The proposed method can also be used for quantitative phase estimation in bauxite ores and red muds. Figure 1 – Estimated mineral compositions of streams of separation experiment KEYWORDS Mineral composition, Iron ores, Thermo-gravimetry, Data reconciliation and Phase analysis