Doc. - Global Mining Standards

advertisement

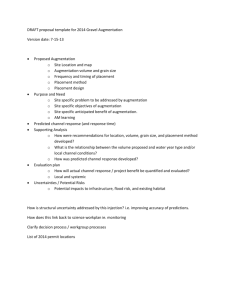

Detailed Programme Information for the EMESRT EQUIPMENT INTERACTION MANAGEMENT Workshop TUESDAY JUNE 10 AND WEDNESDAY JUNE 11 EMESRT WORKSHOP ON Day 1 – June 10 (10 am – 5 pm) Day 2 – June 11 (8 am to 4 pm) 1. Introductions 2. Update of EMESRT progress 3. Introduction to the workshop process 4. Definition of the Haul Truck collision problem using Interaction Analysis 5. The Equipment Interaction Control Model – from upstream to the collision 9. Review of Day 1 10. Interaction Control Failure Modes – the equipment 11. Interaction Control Failure Modes – the human factor 12. Finalisation of Interaction Management workshop outputs 13. Discussion about an EMESRT position on Interaction Management Afternoon 6. Exercise 1 – Objectives for operator & machine augmentation 7. Deriving Performance Requirements from Objectives 8. Exercise 2 – Performance Requirements for operator & machine augmentation 14. EMESRT 2014 – 2015 Work Plan meeting (EMESRT ADVISORY GROUP MEMBERS plus interested obervers) Morning Evening . EMESRT Dinner Programme detail. DAY 1 – Tuesday June 10 – 10 am to 5 pm (Sir James Foots Building (SMI), Uni of QLD – Brisbane) 1. Introductions – round table person and role introductions 2. Update of EMESRT progress – overview of past EMESRT work and current status – T Egan 3. Intro to the Workshop Process - introduction to the design for the two days that is intended to derive information on equipment interaction management that is suitable for inclusion in the EMESRT process of engaging with major OEMs. – J Joy Note that Equipment Interaction Management (EIM) will be used as the term to cover all controls intended to reduce risk of equipment collisions. Also the days processes will NOT include detailed operator or other personnel behaviour issues, but rather recognition of the assumption that humans will err. Therefore the EIM must be designed with recognition that people are inherently unreliable. 4. Definition of the Haul Truck collision problem using Interaction Analysis - the focus of the workshop with be EIM for surface haul trucks at this time to reduce complexity. The related problem that needs addressing will be defined using Interaction Analysis results – C Doran, Anglo American 5. The Equipment Interaction Management Control Model - from upstream to the collision – a model outlining the types of controls used in EIM with introduction of the focus on operator augmentation and machine augmentation to avoid collisions and minimise collision consequences. – C Doran, Anglo American Control Applied Timeframe Site Requirements Before equipment arrives on-site, machine specifications, mine design years Separation Controls Before equipment enters working areas months Operating Procedures While people are operating or working near equipment weeks Authority to Operate Before people are permitted to enter site or a specific work area or operate equipment days Fitness to Operate At the start and during a shift while people are operating or working around equipment shift Pre-start Checks Before people commence operation of equipment hours Visibility Assistance Before takeoff or while equipment is being moved / operated minutes Advisory Controls When operating near other equipment, plant, people, obstacles and voids seconds Intervention Controls When operator has failed to take appropriate action to prevent a hazardous interaction ms Impact Protection To minimize the potential for harm if all other controls have failed On impact Illustration of the control system with four in red box as focus for EMESRT to influence upstream design 6. Exercise 1 – Objectives for operator & machine augmentation – attendees will be divided into teams and asked to determine the Objectives for two operator augmentation control types (visibility assistance and advisory controls) and two machine augmentation control types (intervention controls and impact protection) 7. Deriving Performance Requirements from Objectives – a presentation on the approach to further developing control Objectives into more detailed control Performance Requirements – B Lucke, Glencore 8. Exercise 2 – Performance Requirements for operator & machine augmentation – attendees will be divide into teams to derive Control Performance Requirements to further detail the Objectives identified in Exercise 1. DAY 2 – Wednesday June 11 - 8 am to 5 pm (Sir James Foots Building (SMI), Uni of QLD – Brisbane) 9. Review of Day One Outcomes – J Joy 10. Interaction Control Failure Modes – the equipment – small panel discussion about the nature of EIM control failures related control equipment design (ex. Equipment communication issues, etc.) – I Curran, B Lucke and possibly Mark Dunn from CSIRO 11. Interaction Control Failure Modes – the human factor - presentation about the nature of EIM control failures due to human factors (ex. People / systems interface issues, etc.) – R Burgess-Limerick 12. Finalisation of Interaction Management workshop outputs – overview of the outputs to this point that may fit the EMESRT approach to selected OEMs. - J Joy 13. Discussion about an EMESRT position on Interaction Management – including consideration of information such as the following. – T Egan Current related Anglo and Glencore information Risk assessment / SIL component (AS 61508) MDG 2007 Automation ISO Standard CIM GMSG work in Canada ANCAP 5 Close of workshop NOTE THAT AN EMEREST WORK PLANNING MEETING WILL IMMEDIATELY FOLLOW THE WORKSHOP – THE EMESRT ADVISORY GROUP MEMBERS WILL BE REVIEWING WORK PLANS FOR 2014-2015. INTERESTED OBSERVERS ARE WELCOME.