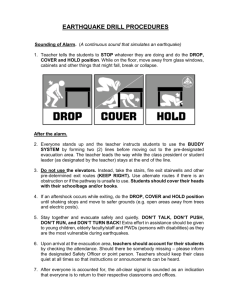

Fire Detection and Alarm

advertisement