Ethical Dilemma: Is Flow Worth the Risk?

advertisement

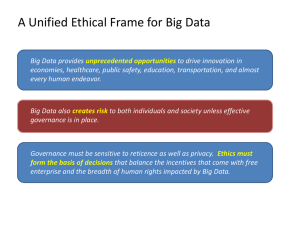

Vidic 2:00 R04 ETHICAL DILEMMA: IS FLOW WORTH THE RISK? Elena Ream (emr79@pitt.edu) SCENARIO I am working on research for a chemical manufacturing company. The company wants to reduce their output of toxic waste, but has limited economic resources to go about researching new ways to make their products. One of their products can only be made using a trichloroethylene, a toxic and carcinogenic solvent [1]. Because so much solvent is needed in batch chemical production, this solvent creates a lot of toxic waste that must be treated. Some of it is inevitably released into the environment, which is harmful to public health [2]. The company I work for heavily values green chemistry, which is a set of ideas for making chemical processes more environmentally sustainable [2]. The advancements of green chemistry have always been of interest to me as a chemical engineer, which is one of the aspects that drew me to this company. It has been my assignment to research a method in which the material could be synthesized while minimalizing solvent use. My Role in the Company I have been researching a method to synthesize this product through flow chemistry for the past two years. Flow chemistry is a fairly new development in chemistry. In flow reactors, a constant flow of reactants is sent through very thin tubes, called microtubes, in which chemical reactions take place. This differs from traditional, or batch reactors, in which all of the reactants are mixed together in a large reaction vessel and the products are isolated after the reaction [2]. I have been very interested in researching flow processes since my first year of college because of their implications for greener chemical processes. One of the main benefits of flow reactors over batch reactors is that flow reactors use significantly less solvent because of smaller reaction surface area, which is why I have been researching how flow chemistry might help with my company’s environmental impact in this situation [2]. Through my research, I have developed a method to synthesize our product through flow reactors on a small scale. My work so far has shown that flow reactors could decrease solvent use by 72%, which is fantastic news for my company. However, one problem with the flow reactors is that in 12% of trials, the tubes will become clogged. This implies that large-scale flow reactors could require much more maintenance than the traditional reactors, which would use up resources and could delay production. University of Pittsburgh, Swanson School of Engineering 1 2014-10-28 FIGURE 1 [3]. An example of a larger scale flow reactor to demonstrate what is being developed. The light in this reactor fuels the reaction. My task is to make the decision for our company to either start researching and building large scale flow reactors for this synthesis or to continue using batch reactors. I can only base the decision on whether or not to move forward on my small-scale research because of the investment largescale research would require. The flow reactors will cost a significant amount of money to develop, and might not work as efficiently as the old reactors. However, if successful flow reactors could be built, it would significantly decrease my company’s toxic waste output. My own personal interest in flow chemistry and investments in my research lead me to believe that flow reactors would be the best thing for my company, but if I don’t use our resources wisely, I could be putting the company at a great deal of risk. CODES OF ETHICS When I encounter difficult decisions in my engineering career, it is always vital to consult the relevant codes of ethics of my profession. Especially working in chemical industry, which is the largest producer of toxic chemical waste in the USA, I have a great responsibility to the environment [4]. This responsibility is relevant in the codes of both the National Society of Professional Engineers and Elena Ream “engineers shall be objective and truthful in professional reports... They shall include all relevant and pertinent information in such reports…” [6]. I cannot ethically follow this code if I do not properly inform the supervisors in my company of the possible problems with that could arise from using flow reactors, or provide a truthful report on how the development of such reactors would affect the company financially. I need to inform them of the times our trials with the small-scale flow reactors failed due to clogging, and that it is a possibility that the large scale reactors would require frequent maintenance. A final and important canon of the NSPE that I must consider in this dilemma is their fourth canon of ethics, stating “engineers shall act for each employer or client as faithful agents or trustees” [6]. I must remain faithful to my company and act in their best interest. Environmental concerns are important, but cannot come at the cost of harming my company. Part of following this canon, as described in the NSPE’s code of ethics, is that “engineers shall disclose all known or potential conflicts of interest that could influence or appear to influence their judgment or the quality of their services” [6]. Seeing as I have been working on this flow chemistry project for the past two years with this company, I am heavily biased toward implementing flow reactors. I would like to see what I have been researching become a reality in how this product is manufactured, and should inform those ranking above me in the company of my own personal interests. I can offer a great deal of sound advice due to my specialty in the subject and the research I have conducted, but perhaps the responsibility of making the final decision for the company should be left up to somebody with a more objective point of view in order to eliminate bias. the American Institute of Chemical Engineers, as well as within the Principles of Green Chemistry. Responsibility to the Environment Earlier, I mentioned Green Chemistry, an important concept to my company and all professionals working with chemistry. Among the Twelve Principles of Green Chemistry, as listed by the American Chemical Society, is “it is better to prevent waste than to treat or clean up waste after it has been created,” and “wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment” [5]. In regards to this particular synthesis, using less of the required toxic solvent could decrease both waste production and the release of trichloroethylene into the environment, which would decrease public exposure to carcinogens. Flow reactors allow the company to use less solvent, and based on these principles, seem to be the ethically correct thing for our company to invest in. Even so, there is much more to consider. The first canon of the NSPE code of ethics states that “Engineers shall hold paramount the safety, health, and welfare of the public” [6]. This canon is very important to my decision. I know that flow chemistry can help improve public safety by decreasing pollution. This principle is similarly stated under the professional obligations of the NSPE. It states that “Engineers shall at all times strive to serve the public interest,” which also includes that “Engineers are encouraged to adhere to the principles of sustainable development in order to protect the environment for future generations” [6]. Certainly, it is not only in my company’s best interest protect the environment we live in, it is our personal responsibility to others in our community and in our world. In using such a hazardous solvent, the company should keep public health in mind. Likewise, the AIChE code of ethics states that chemical engineers must “[use] their knowledge and skill for the enhancement of human welfare” [7]. This is very applicable to my current situation. After researching flow reactors, I know that this application of engineering can be used to improve my company’s impact on the environment. From these codes of ethics, it seems obvious that I should urge my company to move forward with the development of large-scale flow reactors. CONSIDERING THE FACTS Though the company’s final decision on whether or not to implement flow reactors in this synthesis may not ultimately be in my hands, it is still my responsibility to offer the best advice. To do this, I need to look more closely at the possible benefits and detriments of this new manufacturing method. If we introduced techniques of flow chemistry in this particular large-scale synthesis, it would put the company ahead of other chemical manufacturers in environmental compatibility. Not only would this bring my company, and my own research, prestige, but could lead to other companies adopting similar techniques to decrease toxic waste emissions. Success with flow chemistry could lead to a lasting, positive environmental effect from chemical manufacturers. It is important to consider the future of chemical processes when we decide what to work on today, pertaining to green chemistry [8]. Also, due to the fact flow reactors require much less energy than batch reactors and that less waste will need to be Responsibility to the Employer Still, with limited funding, I need to consider how much my company’s current approach to synthesis is adversely affecting the environment. If the company is not violating any regulations its waste output, is it still the company’s responsibility to invest in making processes even more sustainable? And what about the economic and production risks associated? The NSPE also states, 2 Elena Ream treated, successful flow reactors could save the company a great deal on energy. If the company decided to research the large-scale reactors, I could make a clear estimate on how long it would take for money saved with the new reactors to make up for their cost. However, if we decide to develop these flow reactors and they do not work as well as we had hoped, it would set the company back greatly. It would have a very negative impact on the company’s reputation. The company would be investing a significant amount of money in this risk, and while there is a high chance for it to bring great success, much could go wrong. I know that our company does not have very much money to spare at the moment, and the possibility of harming the company is something that must be considered. I do not think it is ethical to advice my company to do something that could hurt its reputation and ability to invest in other new innovations. Is the opportunity to be slightly greener in one of its syntheses worth this potential setback? I believe that it would be best to consult those responsible for the company’s finances and human resources in order to provide the best advice for my company. community, I sought out a documentary piece on chemical waste. In an episode of Earth Focus from Link TV, I learned about toxic pollution in the town of Toms River, New Jersey. The town was home to a dye manufacturing plant. The plant dumped a great deal of waste into the river in ways that were entirely legal at the time. This contaminated river was a main source of drinking water for the town, unknown to the citizens. Today, the citizens feel there is reason to believe that this pollution is the cause for many cases of childhood cancer and other health issues. One of the toxic culprits in this situation was trichloroethylene, my company’s solvent [10]. Looking at Examples I know that I will need to discuss the risks of further research with the responsible parties, but now it is up to me to think about the worth of the company’s environmental impact. One resource I will go to is a case study in engineering and its environmental impact. In the case to which I am referring, an environmental engineer working for a manufacturing company has noticed that pollution in a nearby lake is over the legal limit. However, the process of fixing this issue would cost somewhere over $200,000, which the engineer’s company cannot easily afford. His manager suggests that he adjusts the report so that the company appears fall within its regulations, because the costs of fixing the problem would hurt the company’s reputation and would cause many employees to lose their jobs [9]. This differs from my situation in that my company is not violating any pollution regulations and that the jobs of its employees are not on the line, so there is much less at stake. However, this situation does involve an engineer deciding whether or not to put their company at risk for the sake of the environment. If I were placed in this case, I would report that the company had an excess of pollution. Though this would hurt the company, I believe that the manufacturing company has a responsibility to keep the environment safe and clean. With this in mind, should I do the same thing in my case, even with a smaller risk than the engineer in the case study? The answer is not as clear, but my thoughts on this more extreme example lay a good guideline for how to think of my current situation. To gain a better understanding of how chemical waste affects the nearby environment and FIGURE 2 [10]. Michael, a child from Toms River who survived a cancer of the sympathetic nervous system, likely caused by carcinogenic emissions from a nearby dye manufacturing plant. Just because what the manufacturing plant did not do anything illegal does not mean that it did not have a detrimental effect on public health. If there is anything in my power to decrease public exposure to this hazardous chemical, I feel that it is my responsibility to advise the company to do as such. Watching this documentary helped me see how pollution can affect individuals, and reinforce the weight of my responsibility to the public as a chemical engineer. The documentary also led me to think about growing up in my own hometown, where my mother was my biggest resource for all moral dilemmas. It only seemed appropriate to ask her opinion on this issue, and it would be good to have the direct input of somebody who is not involved in chemical manufacturing. Though she offered no definitive solution to whether or not to go forward with research, she agreed that public health should be my greatest concern. As a parent, she found the stories of childhood cancer in Toms River disturbing, and thought that the prevention of such illness was worth the risk. It was good to speak to the person that helped me develop my own personal moral code, and she confirmed my thoughts about the environment [11]. 3 Elena Ream Angewandte Chemie International Edition. (online article). DOI: 10.1002/anie.201007599 [9] National Academy of Engineering. (2006). “Exceeding Pollution Limits.” Online Ethics Center for Engineering. Retrieved from: http://www.onlineethics.org/Resources/Cases/Pollution.aspx [10] “Toxic Futures: Untold Stories of Chemical Pollution.” Earth Focus. Link TV. (2014). (video). https://www.linktv.org/programs/earthfocus/video/2668152589001 [11] N. Miller. (2014, October 28). Phone Interview. FINAL WORD Because of my personal bias after working with research in flow chemistry for so long, I am in no place to make my company’s final decision on whether or not to develop large-scale flow reactors to develop its product. The solvent that my company must use, trichloroethylene, is toxic and carcinogenic, and while flow reactors would decease solvent use, it is a risky venture. The trials on a small scale during research were not always successful, implying that the large scale reactors could require extensive maintenance or not work at all. I will tell the company this information so that they can make an informed decision on whether or not it is worth the financial investment. However, I will also let the company know that taking a risk by pursuing flow chemistry further would make the process much greener, would be much healthier to the public, and would help make the company a leader in green chemical processes. ADITIONAL SOURCES C. A. Marques. (2014, July 1). “Environmental Sustainability: implications and limitations to Green Chemistry.” Foundations of Chemistry. (online article). DOI: 10.1007/s10698-013-9189-x F. Gupton “Going with the Flow: Flow Chemistry and Breaking Barriers to Innovation.” TED Talks. (2013). (video). R. Sanghi, V. Singh. (2012). Green Chemistry for Environmental Remediation. Hoboken: John Wiley & Sons. (ebook). pp.90-94. Standford University. (2014). “Adaptation of a Safe Component.” Ethics case studies in biodesign. Retrieved from: http://biodesign.stanford.edu/bdn/ethicscases/19safecompon ent.jsp Standford University. (2014). “To Release, or Not to Release: An Engineer’s Perspective.” Ethics case studies in biodesign. Retrieved from: http://biodesign.stanford.edu/bdn/ethicscases/21releasequesti on.jsp REFERENCES [1] Agency for Toxic Substances & Disease Registry. (2011, March 3). “Tricholorethylene (TCE).” http://www.atsdr.cdc.gov/substances/toxsubstance.asp?toxid =30 [2] P. Floreancig. (2014). Lecture. UHC Organic Chemistry I. University of Pittsburgh. [3] J. Knowles, L. Elliott, K. Booker-Milburn. (2012, November 21). “Flow photochemistry: Old light through new windows.” Beilstein J. Org. Chem. http://www.beilsteinjournals.org/bjoc/single/articleFullText.htm?publicId=18605397-8-229 [4] Environmental Protection Agency. (2012). 2012 Toxics Release Inventory National Analysis Overview. (online report). http://www2.epa.gov/sites/production/files/201401/documents/complete_2012_tri_na_overview_document.p df [5] American Chemical Society, P. Anastas, J. Warner. (1998). “12 Principles of Green Chemistry.” Green Chemistry: Thoery and Practice. (online publication). http://www.acs.org/content/acs/en/greenchemistry/what-isgreen-chemistry/principles/12-principles-of-greenchemistry.html [6] National Society of Professional Engineers. (2007). “Code of Ethics for Engineers.” (online publication). http://www.nspe.org/sites/default/files/resources/pdfs/Ethics/ CodeofEthics/Code-2007-July.pdf [7] American Institute of Chemical Engineers. (n.d.). “Code of Ethics.” (online publication). http://www.aiche.org/about/code-ethics [8] H. Frank, L. Campanella, F. Dondi, et al. (2011, July 27). “Ethics, Chemistry, and Education for Sustainability**.” ACKNOWLEDGEMENTS I would like to thank Professor Paul Floreancig for introducing me to the topic of flow chemistry as well as toxic solvents. I would like to thank Kausthubha Yaratha for providing advice on research and for on how to go about writing and formatting this paper. 4 Elena Ream 5