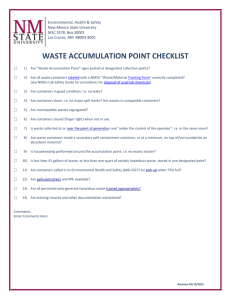

workplace safety checklist

advertisement

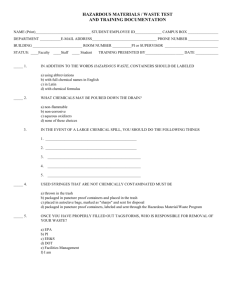

WORKPLACE SAFETY CHECKLIST NAME: LOCATION: DATE: YES __________________________________________________________ __________________________________________________________ __________________________________________________________ NO GENERAL ____ ____ ____ ____ ____ ____ ____ ____ 1. Is the area in order and clean? 2. Are exits accessible and free of obstacles? 3. Are storage areas in a secured place? 4. Are there proper warning signs and tags posted? TRAINING ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Are basic safety trainings provided to new employees? 2. Are job-specific trainings given to employees regularly? 3. Are personnel familiar with MSDS? 4. Are employees familiar with emergency evacuation plan? 5. Are training materials/documents up to date and accessible? SAFE LIFTING ____ ____ ____ ____ ____ ____ ____ 1. Are safe lifting training techniques provided? ____ a. testing load ____ b. Avoiding heavy loads ____ c. Bending knees when lifting ____ d. Firming up abdominals when lifting ____ e. Avoid twisting ERGONOMICS ____ ____ 1. Are workers provided with proper ergonomics, adequate breaks and some activities? FIRE PREVENTION ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Are emergency exit signs well lighted? 2. Are fire extinguishers/alarms located visibly and accessibly? 3. Are manual stairway doors kept closed? 4. Are 18” vertical clearance below sprinkler heads maintained? 5. Are annual inspections of fire extinguishers maintained? 6. Are aisles and stairways clear and free of obstruction? EARTHQUAKE ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Are cabinets, shelves, and storages over four feet tall secured? 2. Does shelve have seismic restraints? 3. Are portable machines secured against movement? 4. Are heavy equipments secured to withstand accelerations? 5. Are storages of heavy & large objects located on lower areas? 6. Are the locations of valuable and sensitive equipments secured (ie. computer disks, glass, instruments)? ____ 7. Are files or equipments in the storage area filed orderly? ____ 8. Are storage cabinets of hazardous materials equipped with latch mechanism? EQUIPMENT AND MACHINERY ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Is it clean and in good condition? ____ 2. Are electrical cords in good condition with proper grounding? ____ 3. Ensure that extension cords are used only as temporary, equipped with circuit breaker and multiple connectors ____ 4. Ensure that combustibles materials are kept away ____ 5. Is there enough ventilation? ____ 6. Are switches and emergency stop mechanism working properly? ____ 7. Are machine guards in place and working properly? ____ 8. Are PPE available to employees whenever necessary? HAZARDOUS MATERIALS ____ ____ ____ ____ ____ ____ ____ ____ 1. Are hazardous containers properly labelled? 2. Are non hazardous containers properly labelled? 3. Are there secondary containers provided for liquid chemicals? 4. Ensure that sinks are clear and away of stored hazardous materials ____ ____ ____ ____ ____ ____ ____ ____ ____ 5. Ensure that there is a proper segregations of solid and chemicals 6. Are chemical containers sealed properly? 7. Ensure that 10 gallons or more of flammable liquids are properly stored 8. Ensure that hazard communication training are completed by your employees ____ 9. Are MSDS and chemical inventory lists accessible? HAZARDOUS WASTE ____ ____ ____ ____ ____ ____ 1. Are waste containers inspected regularly and closed tightly? ____ 2. Are containers labelled properly (ie. date of accumulation, physical state, full chemical names and other hazardous properties)? ____ 3. Ensure that wastes are not to be stored after 9 months ____ 4. Ensure that wastes stored more than 8 months had been reported for waste pick-up ____ 5. No other wastes are to be used for red bags but infectious wastes