Investigating the contamination of groundwater by

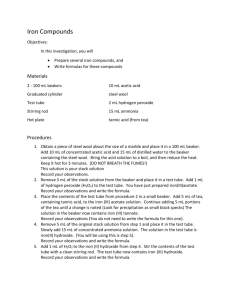

Investigating the Oxidation of Iron

Contamination in water

By: Martin Lai

Iron contamination in water is a common problem for many households and water sources. While ingesting water contaminated with iron has no adverse health effects, it causes the water to develop a bitter, metallic taste. In anaerobic environments (places with no oxygen) such as with groundwater, iron is found in its soluble, bi-valent form (Fe 2+ ), which forms binary compounds such as ferrous bicarbonate. Ferrous iron contamination is difficult to remove effectively when dissolved in water, so common filtration methods involve converting ferrous iron into ferric oxide Fe(OH)

3

, in which iron is tri-valent. The solid precipitate can then be mechanically filtered. In this situation, the process of iron losing an electron to oxygen and becoming more positively charged is known as oxidation. A filtration company or government must know exactly how much oxygen is needed to fully complete the oxidation of ferrous iron, as too much or too little added would cause negative effects, be expensive or would not solve the problem.

In this experiment, students will determine the minimum amount of oxygen required for the complete oxidation of ferrous iron into a solid precipitate of ferric oxide, Fe(OH)

3

by comparing the final mass of the precipitate with the mass of oxygen used to produce it. Two different concentrations of ferrous iron are also used so that the results found using one concentration can be confirmed with the other. Additionally, Stoichiometric calculations will also be used to observe if the experimental results correlated with the theoretical results.

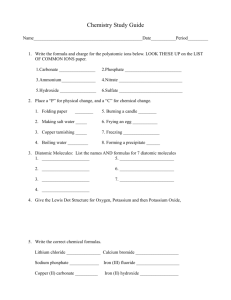

Materials

2 beakers (100mL)

electronic balance

bottle of distilled water

ring clamp

retort stand

50 mL 0.09 M Ferrous iron solution

50 mL 0.12 M Ferrous iron solution

10 test tubes

test tube rack

graduated cylinder (50 mL)

20 Oxygen Tablets (5 g)

50 pieces of filter paper

Lab Precautions

Glassware is used in this experiment, so safety goggles must be worn to protect the eyes.

A Lab apron should be worn, as the iron solution can cause staining of the clothes.

A respirator mask must be worn to enable breathing, as this lab must be performed in an anaerobic lab or chamber.

Procedure:

Note: The solutions of ferrous iron must be kept in a strictly anaerobic environment to prevent them from oxidizing in an uncontrolled manner.

1.

Copy the data collection chart provided. It may expand to include multiple trials.

2.

Obtain two clean 100 mL beakers, and label them by concentration of ferrous iron solution using a grease marker.

3.

Measure 50 mL of 0.09 M ferrous iron solution using a 50 mL graduated cylinder.

Transfer this solution into a 100 mL beaker.

4.

Repeat step 1 with the 0.12 M ferrous iron solution.

5.

Pour the 0.09 M ferrous iron solution into 5 test tubes, with 10 mL in each test tube.

Label the test tubes A

1

to E

1

.

6.

Pour the 0.12 M ferrous iron solution into the other 5 test tubes, with 10 mL in each test tube. Label the test tubes A

2

to E

2.

7.

In test tubes A

1 and A

2

, dispense 1 oxygen tablet.

8.

In test tubes B

1

and B

2

, dispense 2 oxygen tablets.

9.

In test tubes C

1

and C

2

, dispense 3 oxygen tablets.

10.

In test tubes D

1

and D

2

, dispense 4 oxygen tablets.

11.

In test tubes E

1

and E

2

, dispense 5 oxygen tablets.

12.

Agitate the test tubes, and let the solutions sit for 10 minutes. A red-brown coloured precipitate should form in each solution.

13.

Label a piece of filter paper, and record the mass in your data table. Prepare the filtration apparatus shown in step 3 in the diagram.

14.

Swirl test tube A

1

for 1 minute to suspend the precipitate, making sure that none of the solution is spilled. Pour the entire contents, a portion at a time, onto the filter paper.

15.

Rinse the test tube with distilled water and pour the rinse through the filter paper to capture all the precipitate.

16.

When filtrate no longer drops from the funnel over a period of 30 seconds, carefully remove the filter paper and place it in a drying oven overnight.

17.

After the precipitate has dried, measure the mass of the filter paper and precipitate using the electronic balance. Record this mass in your data table.

18.

Repeat steps 11-15 with the rest of the test tubes.

19.

Properly dispose of waste solution in waste beaker.

20.

Repeat steps 1-19 with clean and dry equipment, 4 times, to confirm your results.

21.

For each test tube, take the average mass of the precipitate in the 5 trials performed.

22.

For each concentration, at which test tube did the mass of the precipitate stop increasing and level out even though more oxygen was added?

23.

For each concentration, use the mass of the precipitate produced in that test tube, as well as the minimum mass of oxygen required to form that precipitate, as your final masses.

24.

Convert these masses to moles using the following equation:

Mass/Molar Mass = Number of Moles

25.

Form a molar ratio between moles of oxygen and moles of iron for each concentration.

26.

Compare the ratios found with each concentration. Note any similarities.

27.

Below is the chemical reaction that occurred in this experiment:

𝑭𝒆 + 𝑶

𝟐

+ 𝑯

𝟐

𝑶 → 𝑭𝒆(𝑶𝑯)

𝟑

+ 𝑯

Balance the chemical equation.

28.

Observe the molar ratios in the balanced chemical equation. How well do the ratios found in step 25 correspond with them?

29.

Using the equations Molar Concentration x Liters solution = Moles, and Number of

Moles x Molar Mass = Mass, calculate the mass of iron that is in each concentration.

30.

Using stoichiometric calculations with the balanced chemical equation found in step

27, calculate the mass of oxygen needed to fully react with the ferrous iron in each solution.

31.

Do these results match the minimum mass of oxygen to fully form precipitate, as found in step 23?

Variable IV/DV/CV How it is controlled

Concentration of ferrous iron in solution (mol/L)

Independent

Variable

Specific to 2 significant digits.

Two concentrations of ferrous iron solution would be used in the experiment, one 0.09 M and the other 0.12M. These values were specifically chosen so that the amount of oxygen tablets added would be able to completely oxidize the iron in the solution halfway through the test-tube trials. The 0.09 M samples are completely oxidized starting at test tube C

1,

with 15g of dissolved oxygen. Test tubes

C

1

, D

1

, and E

1

will all produce a precipitate of 100g, so at this point the student will deduce that since the addition of more oxygen will not produce more precipitate, 15g, or 15% of the mass of ferric oxide must be the amount of oxygen needed to completely precipitate the solution.

The concentration of the ferrous iron solution is controlled as the two concentrations used in the experiment are provided; the person performing the experiment does not need to perform their own dilution of the stock solution, so the concentrations used will be controlled.

Total mass of dissolved oxygen in test tube (g)

The measurements of this mass will be specific to 2 significant digits, as that is the precision prescribed by the tablets. The mass of the dissolved oxygen will be manipulated to be

Independent

Variable

The oxygen tablets are prescribed with a specific mass per tablet, therefore the amount of oxygen dissolved into each test tube can be controlled by the number of tablets. The tablets will only dissolve once in the solution, so no spills occur.

different between each test tube of a set (e.g. A

1

– E

1

) but will the same in corresponding letters (A

1

and A

2

). This variable is especially important in reference to the purpose of the experiment, as it would be used in calculations to find the percentage mass of oxygen in reference to iron bicarbonate required to fully oxidize and precipitate all of the iron in the solution.

Volume of solution used in test tubes (mL)

Controlled

Variable

The volume of the solution is specific to 2 significant digits, at

10 mL per test tube, with the zero in this case also being significant as it was measured by a graduated cylinder and not found through rounding. It was maintained at constant values since 10 mL was used for all 10 test tubes.

The volume of the ferrous iron solution would be kept constant throughout the experiment as it was carefully measured by a graduated cylinder at the beginning of the experiment into the test tubes so it would not have to be manipulated during the other stages of the experiment.

Presence of oxygen in lab environment

The lab would be conducted under oxygen-free anaerobic conditions, as to not provoke the uncontrolled oxidation of the ferrous iron solution.

Controlled

Variable

Mass of Filter paper (g)

This precision of the measurement should be that corresponding with the precision of the scale. This variable is measured for the purpose of subtracting its mass from the filter paper and precipitate complex, to determine the mass of only the precipitate.

Controlled

Variable

Mass of filter paper and ferric oxide precipitate (g)

This mass should also be measured to the same number of significant digits provided by the electronic balance. The mass of the precipitate alone can be determined by subtracting the mass of the filter paper

Dependent

Variable

This variable would be effectively controlled during the experiment as the solution would be prevented from coming into contact with oxygen from the lab environment, through the use of an anaerobic apparatus that isolates the solution or in an anaerobic lab.

Therefore, all stages of the lab experiment will be kept in the same anaerobic conditions.

This variable is effectively controlled as only one type of filter paper is used, meaning the mass will be kept uniform throughout all the trials in the experiment.

This variable is effectively controlled by careful measurement of its mass, as well as executing care in making sure that all of the precipitate was captured during the experiment. Contamination can be avoided by proper storage in a dry, clean environment.

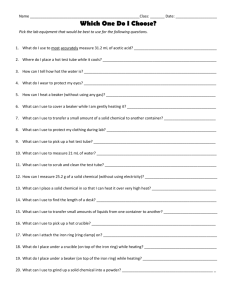

Variable Data Collection Chart:

Concentration of

Ferrous iron solution (mol/L)

Volume of ferrous iron solution

(mL)

10mL

Total mass of dissolved oxygen tablets

(g)

Mass of filter paper

(g)

Mass of ferric oxide precipitate and filter paper

(g)

(5g x number of tablets)

5g

Test

Tube D

1

Test

Tube D

2

Test

Tube E

1

Test

Tube E

2

Test

Tube A

1

Test

Tube A

2

Test

Tube B

1

Test

Tube B

2

Test

Tube C

1

Test

Tube C

2

0.09 M

0.12 M

0.09 M

0.12 M

0.09 M

0.12 M

0.09 M

0.12 M

0.09 M

0.12 M

10mL

10mL

10mL

10mL

10mL

10mL

10mL

10mL

10mL

5g

10g

10g

15g

15g

20g

20g

25g

25g