Flex-A-Clay Installation

advertisement

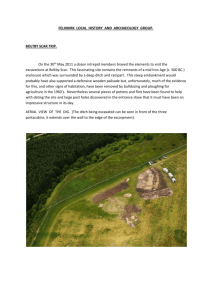

True Pitch, INC 620 8th ST SW Altoona, Iowa 50009 1-800-647-3539 How to install FLEX-A-CLAY ® Congratulations on choosing to use Flex-A-Clay® as a surface for your infield, home plate area, and the pitching mound. The correct installation and maintenance of Flex-A-Clay® will enhance the consistent performance of your baseball or softball fields and will significantly reduce your upkeep time. Whether you are applying to a new field or remodeling a ball field, Flex-A-Clay® will bind nicely to native soils and is east to install – following these directions. If at any time you have a question, please call the office. Questions? Call 1-800-647-3539 or (515) 967-2303 Reconstructing a Baseball Pitcher’s Mound using Flex-A-Clay®. Mound specifications for high school fields through the major leagues call for a mound circle that is 18 feet in diameter and the top of the pitcher’s rubber 10 inches higher than home plate. For youth leagues, consult the rule book of the governing organization. Refer to diagram for pitching mound layout. Check to make sure the rubber measures 60’ 6” from the back of home plate to the front edge of the rubber and is 10 inches above home plate. With the rubber properly located now you need to measure an 18 foot pitcher’s circle. Measure 18 inches directly out in front of the pitcher’s rubber and drive a spike. REMEMBER, ON A 90’ FIELD, THE CENTER OF THE MOUND IS 18” IN FRONT OF THE RUBBER. With a string or a tape, measure out exactly 9 feet from the spike and circle the entire mound marking the outline. This will give you an 18’ diameter circle Dig out 4 inches of material in the pitching lane. Remove 2 inches of material from the rest of the mound to provide for a 2” cap of Flex-A-Clay®. Most fields I apply 4 inches of clay but on college fields I will use 6 inches of clay. After the proper depths have been excavated and all the pitching mound measurements are exact, you are now ready for the application of Flex-A-Clay®. I usually begin by building the pitching platform. When building this platform, care must be taken not to disturb the location of the pitcher’s rubber. I mark the table area with either steaks or you can assemble a wooden frame. See picture below and notice the steaks. REMEMBER TO MOISTEN AREA PRIOR TO APPLYING FLEX-A-CLAY® TO THE MOUND. When applying Flex-A-Clay®, you must mix the clay with water either in a wheelbarrow or a mixer. You can also pour the dry clay right from the bag onto your surface and add water and mix with a rake until it is thoroughly mixed. EACH BAG NEEDS APPROXIMATELY ½ GALLON OF WATER FOR THE RIGHT RATIO. With the clay thoroughly mixed, place it on the table and spread evenly and tamp into place. Tamp the clay in 2 inch layers and moisten. (Covering your tamp with heavy-duty black construction bags prevents the clay from sticking to the tamp) After the table is built, I start applying the clay in the pitcher’s lane. Moisten the excavated area, place the mixed clay in the lane, spread around and tamp. Repeat this procedure until you get 4 inches of clay throughout the entire pitching lane. CAPPING THE REST OF THE MOUND Moisten the rest of the mound. Apply a 2 inch layer of Flex-A-Clay® and tamp. This final clay application should bring the profile of the mound to official dimensions. An adequate amount of drying time is needed before using the mound. The amount of time varies but generally a period of 24 up to 72 hours is needed. During this “curing process” the mound will look like this…. After the clay has hardened, water generously and lightly scratch (chicken scratch) the clay with a garden rake and then tarp. You are ready to “PLAY BALL!” After each game or practice, lightly water the mound and rake the area. Rake the displaced Flex-A-Clay® back into its original position and tamp then lightly moisten and cover with a tarp. Remove the tarp an hour prior to game time the next day and you are ready to pitch. PROPER SLOPE FOR PITCHING MOUND A key element in mound construction is a proper slope for the front of the mound. The slope drops 1 inch for every 1 foot down the front of the mound to the grass. The slope begins 6 inches in front of the rubber. From that point, the mound drops 1 inch per foot to the grass line. A slope gauge is crucial in this measurement. REMEMBER TO KEEP MOUND TARPED WHEN NOT IN USE!!! HOME PLATE AREA Excavate the batter’s boxes and catcher’s box 4 inches. Mix the clay with water (remember ½ gallon per 50lb bag) and tamp into boxes in 2 inch layers. Then cover area with your infield surface. Flex-AClay® makes an ideal playing surface when played directly on the surface without the use of topdressing. Apply 4 inches in the batter’s and catcher’s area and then apply a 2 inch cap of clay on the rest of the home plate area. Use the same application guidelines for the mound. SOFTBALL FIELD APPLICATION The installation of Flex-A-Clay® on the softball pitching mound will enhance the consistent playing performance of the pitching area and significantly reduce your maintenance requirements. For maximum performance, apply 4 inches (6inches on college fields) in the pitcher’s lane and behind the rubber. I usually create a 4’ x 8’ pitching lane in front of the rubber. The same application guidelines used in constructing baseball mounds also apply to softball mounds. FLEX-A-CLAY® MOUND REPAIR AFTER GAMES *sweep out loose product from holes with broom *lightly water entire mound surface *lightly scratch mound and pull clay into the holes and tamp *for a professional look, use a cocoa mat or a broom and circular drag from outside perimeter to top of mound *moisten mound and tarp – remove tarp the next day 1 hour prior to game and “PLAY BALL!” *use heavy duty trash bags to cover tamp to eliminate clay from sticking to tamp *getting the right water consistency will get easier with practice – if mound is too wet, then rake in dry Flex-A-Clay® to dry out *never use “kitty litter” or other drying agents – just add more Flex-A-Clay®