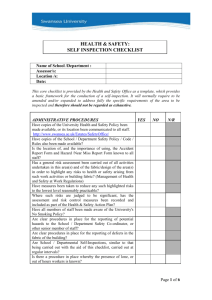

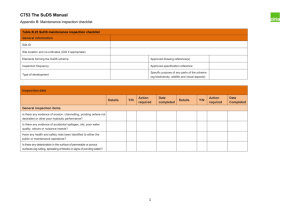

Laboratory Inspection Checklist (Workplace

advertisement

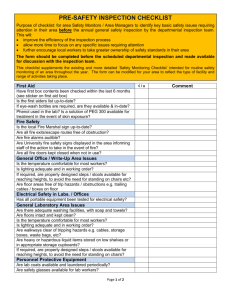

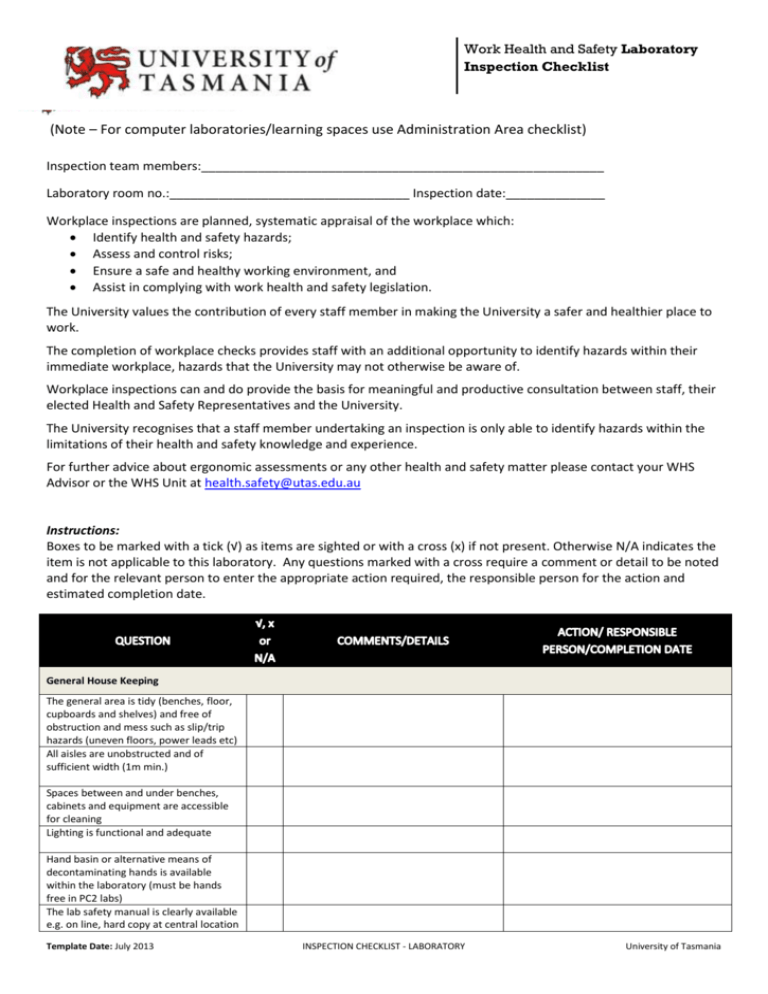

Work Health and Safety Laboratory Inspection Checklist (Note – For computer laboratories/learning spaces use Administration Area checklist) Inspection team members:_________________________________________________________ Laboratory room no.:__________________________________ Inspection date:______________ Workplace inspections are planned, systematic appraisal of the workplace which: Identify health and safety hazards; Assess and control risks; Ensure a safe and healthy working environment, and Assist in complying with work health and safety legislation. The University values the contribution of every staff member in making the University a safer and healthier place to work. The completion of workplace checks provides staff with an additional opportunity to identify hazards within their immediate workplace, hazards that the University may not otherwise be aware of. Workplace inspections can and do provide the basis for meaningful and productive consultation between staff, their elected Health and Safety Representatives and the University. The University recognises that a staff member undertaking an inspection is only able to identify hazards within the limitations of their health and safety knowledge and experience. For further advice about ergonomic assessments or any other health and safety matter please contact your WHS Advisor or the WHS Unit at health.safety@utas.edu.au Instructions: Boxes to be marked with a tick (√) as items are sighted or with a cross (x) if not present. Otherwise N/A indicates the item is not applicable to this laboratory. Any questions marked with a cross require a comment or detail to be noted and for the relevant person to enter the appropriate action required, the responsible person for the action and estimated completion date. General House Keeping The general area is tidy (benches, floor, cupboards and shelves) and free of obstruction and mess such as slip/trip hazards (uneven floors, power leads etc) All aisles are unobstructed and of sufficient width (1m min.) Spaces between and under benches, cabinets and equipment are accessible for cleaning Lighting is functional and adequate Hand basin or alternative means of decontaminating hands is available within the laboratory (must be hands free in PC2 labs) The lab safety manual is clearly available e.g. on line, hard copy at central location Template Date: July 2013 INSPECTION CHECKLIST - LABORATORY University of Tasmania Work Health and Safety Laboratory Inspection Checklist Facilities for the storage of outer garments and personal items are available outside of the laboratory There is a procedure for waste disposal and sufficient and appropriate segregated waste disposal containers There are appropriate sharps disposal containers available Exposure to noise is prevented General ventilation, temperature and humidity is sufficient Signage Requirements Entrance signage indicates Authorised access only No food or drink allowed Warning signs are posted ie for chemical, biological, radiation Any other information ie PPE required First aid signage is visible and contains details of first aid officers for the area Fire wardens with current contact numbers signage is visible Emergency exits are clearly marked with exit doors being clearly visible, egress clear and closed but not locked from the inside Emergency exit plans in prominent positions Safe work procedures are available, ideally displayed next to equipment Emergency Requirements A first aid kit is available in the near vicinity and adequate for type of work undertaken Fire equipment is appropriate, accessible and free of obstruction Fire extinguishers have been inspected/tagged within the last 6 months Safety shower is functional and checked regularly Emergency eyewash station is available and checked regularly Where an experiment is to be left unattended overnight or at weekends, are signs attached to equipment indicating the relevant person to be contacted in the event of a failure Furniture and Equipment Requirements Electrical equipment is inspected, tested, tagged and in date Equipment is in good order Double adapters are not in use Template Date: July 2013 INSPECTION CHECKLIST - LABORATORY University of Tasmania Work Health and Safety Laboratory Inspection Checklist Extension leads are only used for temporary, short-term connection Power boards with RCD protection are used if not enough GPOs (power points) Fume cupboards and biosafety cabinets have been tested and are in date Fume cupboard is free of clutter and not used for storage of chemicals Chairs/stools are of appropriate height eg Have more GPOs installed PPE/Manual Handling PPE is available, in good condition and stored appropriately Frequently used/heavy items area stored between knee and shoulder height Ladders are accessible to access items stored on high shelves if required. Short ladders allowed but must comply with ASNZS 1892 (2000) Manual handling aids are available if required e.g. Winchester containers, trolleys etc Chemical Aspects A register of chemicals and Safety data sheets (SDS) are available eg. On line or central hard copy Documented risk assessments are available for chemical use Appropriate labels are present on containers are used to store hazardous substances. Containers are labelled correctly Chemicals are stored according to compatibility Chemicals not in use are placed in correct storage locations e.g. flammable, corrosive cabinets Flammables and corrosives are stored in approved cabinets. Toxic/S8 are stored in locked cabinet Estimate and record the total volume of flammable liquids stored in this laboratory – assume that all bottles present are full. Are flammables stored in refrigerators? Has fridge been modified or if not has a risk assessment has been completed Refrigerators are suitably labelled (eg no food or drink, biohazard etc) Is this section relevant? [Yes] [No] (if no, go to next section) eg use RA within CMS eg use labelling process with in CMS database Total volume = There are bunding or spill trays for the storage of hazardous liquids Spill kits are available and maintained Template Date: July 2013 INSPECTION CHECKLIST - LABORATORY University of Tasmania Work Health and Safety Laboratory Inspection Checklist Segregated waste disposal containers are available Compressed/Liquified Gas Aspects Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) Compressed gas cylinder contents are appropriately identified and in good general condition Cylinders are secured appropriately by brackets/ chain All cylinders are at least 3m away from ignition sources and combustible material Empty cylinders are separated from full ones and clearly labelled Appropriate resources are available for transporting gas cylinders The pressure regulator is appropriate for the gas being used Gas lines are labelled and free of leaks, kinks or signs or wear and tear. All cylinders in the laboratory are connected to equipment ie no storage in lab All reticulated gas lines are clearly labelled Gas Cylinder Storage Aspects Cylinder storage areas are well ventilated (in open air preferable) Cylinder storage areas protected from heat sources and fire risks Cylinders stored upright and properly secured Cylinders are segregated according to dangerous Goods class Cryogenic Aspects Dewars <25L have handles and loose fitting lids Dewars > 25L have wheels and pressure release valves Cryogen storage areas are appropriately ventilated Policies and procedures for transport and decanting of liquid nitrogen available to all staff and students All cryogenic storage records are current, adequate and accessible Biosafety Aspects There is appropriate Biosafety signage at the laboratory entrance and storage rooms Safety documents including licences and permits are current and available (eg AQIS, GMO) Template Date: July 2013 INSPECTION CHECKLIST - LABORATORY University of Tasmania Work Health and Safety Laboratory Inspection Checklist All cultures or biohazardous materials are correctly labelled A supply of disinfectant for decontamination purposes is available and clearly labelled All keyboards have protective covers Documented risk assessments for use of biological hazards are available Appropriate waste segregation is provided Appropriate waste handling procedures are in place ie autoclaving, disinfecting etc) PC2 Laboratories Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) There is appropriate PC2 signage at laboratory entrance Biohazard stickers are posted on storage units for microorganisms or recombinant or manipulated DNA Protective covers area kept on keyboards which are housed on workbenches Laboratory gowns are stored in a manner that prevents crosscontamination Biological safety cabinets area provided and are in working order A supply of clearly labelled disinfectants for decontamination purposes is available Lasers Documented risk assessments and safe work procedures in place All warning symbols are fixed, legible and clearly visible on equipment Correct warning labels are attached to the equipment according to the class of laser used Guarding on lasers is effective and in good condition ie beam stops and other fail safe devices Ionising Radiation Aspects Access to area/room is limited only to authorised persons Suitable radiation/contamination monitoring equipment available and in working condition Decontamination/emergency procedures clearly displayed Documented risk assessments and safe work procedures available Work surfaces impervious (not wooden benches or tiled surface) Appropriate shielding available Template Date: July 2013 INSPECTION CHECKLIST - LABORATORY University of Tasmania Work Health and Safety Laboratory Inspection Checklist All sources are labelled and stored in secure labelled location Ultraviolet Radiation Aspects Is this section relevant? [Yes] [No] (if no, go to next section) Is this section relevant? [Yes] [No] (if no, go to next section) Appropriate warning labelling in place Appropriate shielding and/or interlocks in place Risk assessment and safe work procedures clearly displayed Machinery Safety Aspects All hazardous parts of machines guarded The guards are adequate to prevent injury The guards are adequate to prevent flying debris causing injury There is easy access to emergency stop buttons Instrument logs up to date Standard operating procedures for machinery and other equipment easily available to users eg rotating parts, pulleys, belts eg cannot be moved while machinery in operation For HSR / Officer-in-Charge to complete: Policies and procedures All projects covered by risk assessments All tasks covered by up to date task risk assessments (TRA) All TRA documentation available and easily locatable Are induction records available for this laboratory, if so, where are they filed? Licences and permits/ Routine monitoring What license or permits cover this workplace/ work area? List and detail specific items covered List all routine monitoring and inspections carried out for this laboratory. Provide file reference and frequency List details of all other health and safety reports for this area carried out over the past 12 months ie manual handling, ergonomic assessment, noise Health and Safety Representative eg poisons - list applicable classes or schedules eg annual fume cupboard inspection Officer Other Comments: Template Date: July 2013 INSPECTION CHECKLIST - LABORATORY University of Tasmania