Polywhatylene

advertisement

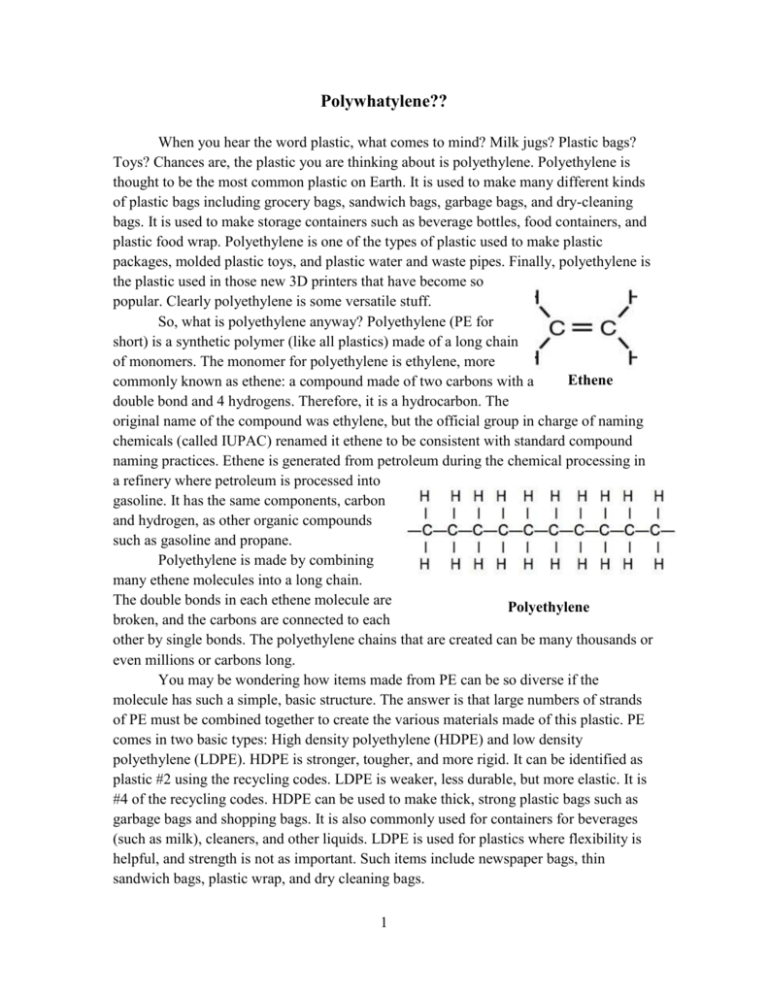

Polywhatylene?? When you hear the word plastic, what comes to mind? Milk jugs? Plastic bags? Toys? Chances are, the plastic you are thinking about is polyethylene. Polyethylene is thought to be the most common plastic on Earth. It is used to make many different kinds of plastic bags including grocery bags, sandwich bags, garbage bags, and dry-cleaning bags. It is used to make storage containers such as beverage bottles, food containers, and plastic food wrap. Polyethylene is one of the types of plastic used to make plastic packages, molded plastic toys, and plastic water and waste pipes. Finally, polyethylene is the plastic used in those new 3D printers that have become so popular. Clearly polyethylene is some versatile stuff. So, what is polyethylene anyway? Polyethylene (PE for short) is a synthetic polymer (like all plastics) made of a long chain of monomers. The monomer for polyethylene is ethylene, more Ethene commonly known as ethene: a compound made of two carbons with a double bond and 4 hydrogens. Therefore, it is a hydrocarbon. The original name of the compound was ethylene, but the official group in charge of naming chemicals (called IUPAC) renamed it ethene to be consistent with standard compound naming practices. Ethene is generated from petroleum during the chemical processing in a refinery where petroleum is processed into gasoline. It has the same components, carbon and hydrogen, as other organic compounds such as gasoline and propane. Polyethylene is made by combining many ethene molecules into a long chain. The double bonds in each ethene molecule are Polyethylene broken, and the carbons are connected to each other by single bonds. The polyethylene chains that are created can be many thousands or even millions or carbons long. You may be wondering how items made from PE can be so diverse if the molecule has such a simple, basic structure. The answer is that large numbers of strands of PE must be combined together to create the various materials made of this plastic. PE comes in two basic types: High density polyethylene (HDPE) and low density polyethylene (LDPE). HDPE is stronger, tougher, and more rigid. It can be identified as plastic #2 using the recycling codes. LDPE is weaker, less durable, but more elastic. It is #4 of the recycling codes. HDPE can be used to make thick, strong plastic bags such as garbage bags and shopping bags. It is also commonly used for containers for beverages (such as milk), cleaners, and other liquids. LDPE is used for plastics where flexibility is helpful, and strength is not as important. Such items include newspaper bags, thin sandwich bags, plastic wrap, and dry cleaning bags. 1 To make HDPE, the PE strands are combined under very high heat and pressure which enables them to bond tightly and densely together. Because the strands are densely packed, they are stronger and resistant to tearing. In addition, other chemicals are added, called organometallics, which enable this dense bonding pattern to occur. To visualize the bond pattern, think of a strong rope made of many individual fibers. This type of reaction is so important to plastics today, that a chemist won a Nobel Prize for developing these organometallic compounds. A different process is used to create LDPE plastics. When these polymers are created, the polymers are allowed to form branched structures. The branching interferes with the combining of the polymers, so instead of being densely packed, they are loosely packed (low density). LDPE can be imagined as masses of spaghetti that remain weak and flexible even when they are thick. Polyethylene (HPDE and LDPE) as well as other plastics have major advantages that make them valuable for our daily lives. In addition to being versatile, they are cheap to make, lightweight, durable, and they last a long time. Chemists have been working for 150 years to improve these properties. Now, however, the plastics may last too long. Plastics do not break down naturally, or decompose, the way many other materials do. When placed in a landfill, paper breaks down within weeks or months. Plastic may take hundreds or even thousands of years; no one is really sure because plastics are only about 100 years old. Maybe recycling is the answer because most (but not all) plastics can be recycled. However, when they are recycled, the products that can be made from them are limited. For example, recycled HDPE can be made into things like plastic chairs and plastic “lumber” products, but not into plastic bags or beverage containers. The plastic chairs and lumber then cannot be further recycled because of chemicals added during the first recycling process. This process is sometimes called “downcycling.” This distinguishes the process from true recycling for aluminum and glass which can occur over and over again. When plastics are thrown away in landfills, roadsides, and waterways, they can have damaging effects. Since they do not degrade very much, the land from landfills is likely to never be used again. On land and water, the plastics are easily mistaken for food by animals and can make then sick and die. Worse yet, some plastics actually release materials that may be toxic. One example is bisphenol A (BPA), a molecule which has been in the news often over the past few years. BPA can be released from a type of polycarbonate plastic, recycling #7. The BPA molecule has shown to be toxic at very high doses. Even though human exposures are much lower than the toxic levels, consumers have been concerned. Another method of disposing of plastics is to burn them. Plastics contain a lot of chemical energy which is released as heat when they are burned. The heat can then be 2 used to generate electricity, enough to power approximately 300,000 homes in Connecticut. However, burning plastic is like burning fossil fuels which releases large amounts of carbon dioxide into the atmosphere. This carbon dioxide may be causing global climate change, a phenomenon formerly known as global warming. Plastics are a valuable, versatile material that has come to dominate consumer markets all over the planet. Indeed, you cannot go for long each day without seeing plastics. We walk on them, we wear them, we eat and drink from them, and sometimes we even sleep on them. They can be considered the wonder materials of the second half of the twentieth century. Yet, as you can see, the wonder materials come with a price. As responsible citizens of planet Earth, we must be aware of the consequences of our actions and the drawbacks of the wonder materials. Questions 1. What are the two main ideas presented in this article? Make sure your answer is thorough and accurate. 2. What does versatile (page 1 paragraph 1, and page 2 paragraph 3) mean in the context of this article? 3 3. How do the chemical properties of LDPE correspond to the physical properties of the materials made from them? 4. Based only on reading this article, what is the difference between recycling and downcycling? 5. Do you think burning plastic is a good idea? Support your opinion with information from the article. 6. What does the author mean by the phrase “drawbacks of the wonder materials?” 4 7. What is the author’s conclusion in this article. 8. On a scale of 1-10, how hard was it for you to read this article (10 being hardest). Be honest, there is no right or wrong answer. 5