Journal of Materials Chemistry_21_2_2011 - Spiral

advertisement

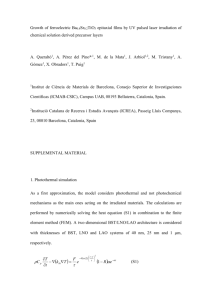

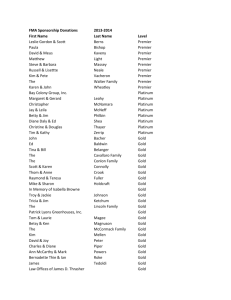

Evidence for the Catalytic Oxidation of La2NiO4+δ R. Sayers, S. J. Skinner* 1 Imperial College London, Exhibition Road, London, SW7 2AZ, UK *s.skinner@imperial.ac.uk, UK Telephone: +44 (0)20 7594 6782, Fax: +44 (0)20 7594 6757 Abstract The redox behaviour of lanthanum nickelate La2NiO4+δ (LNO) has been studied by insitu high temperature x-ray diffraction. Higher order Ruddlesden-Popper phases, La3Ni2O7-δ and La4Ni3O10-δ, rapidly form on heating LNO in contact with platinum. These oxidation products were not formed when an alumina barrier layer was placed between LNO and platinum over the same heating regime. Platinum catalysis of the oxidation of LNO occurs at 800°C and above, with significant formation of the higher order Ruddlesden-Popper phases at temperatures greater than 800°C. It is proposed that the mechanism of formation of the higher oxidation state phases occurs by reduction of molecular oxygen in the gas phase catalysed by platinum to form O2ions, which are then incorporated into bulk LNO. The incorporation of these additional O2- ions is compensated for by an increase in the nickel oxidation state, leading to formation of the higher order Ruddlesden-Popper phases. Keywords Lanthanum nickelate; Mixed conducting oxides; SOFCs, HT-XRD 1.0 Introduction Intermediate temperature solid oxide fuel cells (IT-SOFC) are of interest as a sustainable energy source due to their high energy conversion efficiencies and good fuel flexibility. SOFCs produce energy as a result of an electrochemical reaction 1 (Eqns 1 to 3) with the major byproduct being water/ steam, assuming a hydrogen fuel is used. Cathode reaction: O2(g) + 4e- → 2O2- Equation 1 Anode reaction: 2H2(g) + 2O2- → 2H2O(g) + 4e- Equation 2 Overall reaction: O2(g) + 2H2(g) → 2H2O(g) Equation 3 In SOFCs, the oxygen reduction reaction occurs at the cathode (Equation 1), which is subject to a large activation polarisation due to the relatively slow reduction of oxygen on its surface, producing a high overpotential; a significant amount of research has focussed on improving cathode performance to reduce this overpotential, including development if novel new materials.. Lanthanum nickelate, La2NiO4+δ (LNO), is a potential cathode material for IT-SOFCs with an operating temperature in the region of 500°C to 700°C. LNO displays excellent oxygen ion transport properties in this temperature range 1, 2 and layered cathode structures have shown promising performance with the IT-SOFC electrolyte Ce0.9Gd0.1O2-δ 3, indicating that it is a suitable candidate for IT-SOFC cathodes. The stoichiometric compound has a network of unoccupied interstitial sites that, upon oxidation of the material, allow for the accommodation of excess oxygen 4 . La2NiO4+δ, has shown relatively high solubility for oxygen excess, with values of δ as high as 0.3 being reported 5. Computational modelling indicates that the oxygen excess is compensated for by nickel holes 6, 7 whereby the oxygen interstitial concentration is accommodated due to the mixed valency of nickel and the presence of Ni2+/Ni3+. The structure of La2NiO4+δ consists of perovskite layers of LaNiO3 separated by rocksalt-type layers of LaO 8. La2NiO4+δ, is a Ruddlesden-Popper material with 2 general formula An+1BnO3n+1 where n = 1 and n refers to the number of perovskite blocks in a formula unit. An increase in the number of perovskite blocks with increasing n leads to formation of the higher order Ruddlesden-Popper phases La3Ni2O7-δ and La4Ni3O10-δ 9-12. Platinum is a well known oxygen reduction catalyst13, 14; the reaction mechanism has been intensively studied and there is extensive literature available on the topic. Pt is also commonly used as an electrode material and/or current collector in fuel cell technology. However, as Adler 15 points out in his detailed and comprehensive review of oxygen reduction in SOFCs, much of the focus on platinum electrodes has been with liquid electrolytes. Of course with SOFCs the electrolyte is a solid ceramic and it is likely that the electrode behaviour will differ significantly with solid state electrolytes. Previous studies 3, 16 of the effect of platinum on the electrochemical performance of cells with LNO electrodes have determined that platinum enhances the overall performance of the LNO cathode, however the mechanism by which this occurs is unclear. In general, the oxygen reduction reaction at SOFC cathodes is composed of the following steps: i. Oxygen surface adsorption and dissociation by breaking the covalent bond of O2 molecules ii. Reduction of O species into oxide ions, O2- iii. Oxide ion, O2-, transfer within the bulk cathode iv. Oxide ion transport across the cathode/electrolyte interface 3 The oxygen ions are introduced into the bulk of the electrode via a surface exchange process, which is composed of mass transport and charge transfer processes. The general steps involved in the surface exchange of oxygen are outlined in Equations 47 17, however, there still exists much debate about the order that these steps occur in and which of them are rate limiting 15. Surface adsorption of oxygen on electrode (mass transport) Dissociation of oxygen Charge transfer at electrode incorporation Equation 4 O2 ad 2Oad Equation 5 '' Oad Oad 2h Equation 6 at electrode (mass transport) Oxygen O2 ( g ) O2 ad at '' Oad VO OOx Equation 7 electrode/electrolyte interface The electrode performance of La2NiO4+δ (n = 1), La3Ni2O7-δ (n = 2) and La4Ni3O10-δ (n = 3) as symmetrical cells on the doped lanthanum gallate electrolyte, La0.9Sr0.1Ga0.8Mg0.2O3-δ has been studied by Amow et al. 9. The authors observe that the lowest Area Specific Resistance (ASR) for the electrode was obtained for the highest value of n, with ASR values increasing in the order La4Ni3O10-δ < La3Ni2O7-δ < La2NiO4+δ, however the activation energies increase slightly with increasing n, with 1.24 eV reported for the n = 1 system, 1.27 eV for n = 2 and 1.36 eV for n =3. The authors suggest that ASR decreases with increasing electronic conductivity, however in the oxygen deficient phases (n = 2 and 3) the observed trend may also be related to 4 the systematic oxygen deficiency, which may facilitate improved oxide-ion conduction through the provision of vacant oxygen sites in the perovskite layers. The long term stability of LNO is an important consideration for operation in an ITSOFC. Odier et al. 18 find the A2BO4 structure of LNO to be stable in air up to 1200°C and Skinner 19 found LNO to be stable up to 800°C in vacuum. Long term ageing of La2NiO4.15 was performed by Amow et al. 9, 10 who found that after heating in air for 2 weeks at 900°C, a mixed valent (Ni2+/Ni3+) impurity phase formed, indicating that the higher order phases are more stable at elevated temperatures. The formation of higher order Ruddlesden-Popper phases from ageing of LNO is an important consideration for the use of LNO in SOFC devices. For this reason the redox behaviour of LNO is a key consideration for understanding cathode performance and in this study the oxidation behaviour of LNO in contact with platinum has been investigated by in-situ high temperature x-ray diffraction. 2.0 Experimental La2NiO4+δ powder (CerPoTech) was calcined at 1400°C for 5 hours and ballmilled with zirconia mixing balls for 48 hours in ethanol. The cation stoichiometry was verified by inductively coupled plasma atomic emission spectroscopy (ICP-AES) using a Thermo Scientific iCAP 6000 series instrument. The room temperature oxygen stoichiometry was determined using iodometric titration by dissolving the powder in HCl, adding KI and titrating against a 0.02N solution of sodium thiosulphate, in a nitrogen atmosphere using starch solution as an indicator. Phase purity of the LNO powder at room temperature was determined by powder x-ray diffraction (XRD) using a Philips PW1700 series diffractometer with Cu Kα radiation (λ = 1.5418 Å) and a graphite secondary crystal monochromator. 5 In-situ high temperature x-ray diffraction (HT-XRD) data were collected using a Panalytical X’Pert diffractometer with a Bühler HDK 2.4 temperature stage and a platinum-rhodium heating strip, in static air. Cu-Kα radiation and a graphite secondary crystal monochromator were used for scans of 10 to 60 °2θ with a step size of 0.04 °2θ, a dwell time of 10 seconds/step and a heating and cooling rate of 60°C/min. Diffraction patterns were collected at room temperature and then every 100°C between 600°C and 1000°C on heating with a dwell time of 1 minute prior to data collection on reaching the measurement temperature. LNO powder was deposited on a platinum foil substrate for heating, which was placed on the Pt-Rh heating strip. In a second set of experiments, to determine any reactivity between LNO and the Pt strip a thin barrier layer of commercial alumina powder was deposited between the LNO and platinum foil by sieving. The temperature of the sample stage was calibrated using thermochromic paints. All data refinements were performed using GSAS20 and EXPGUI21 and in all cases the background was fitted using a Shifted Chebyschev function with six terms. Thermogravimetric analysis (TGA) was performed using a Netzsch STA 449C Jupiter combined TGA-DTA/DSC instrument in flowing air, ~40 mg of LNO was heated from 25°C to 1000°C at a heating and cooling rate of 10°C/minute. 3.0 Results and Discussion Room temperature XRD confirmed the starting powder was single phase. The cation ratio and oxygen stoichiometry of LNO at room temperature prior to commencing the HT-XRD study are shown in Table 1. There is good agreement between the measured values and the expected composition of cation stoichiometric oxygen excess La2NiO4+δ. Based on these values the mean room temperature oxidation state of nickel 6 is calculated to be +2.3. The room temperature lattice parameters were determined using the orthorhombic Fmmm space group reported at room temperature by Skinner19 and were found to be a = 5.460(1) Å, b = 5.474(1) Å and c = 12.688(3) Å. High temperature x-ray diffraction patterns recorded from LNO directly deposited on a platinum substrate indicate the formation of a new phase at temperatures of 800°C and above. Previously a reaction between LNO and Pt had been observed after heating to 900°C for 72 hours22; here the phase formation occurs rapidly (less than one hour) at 800°C. XRD patterns obtained in the 2θ range 29° to 34° are shown in Figure 1; the growth of a major new peak is clearly visible at 31.8 °2θ. Figure 2 shows the room temperature x-ray diffraction pattern for the same sample of LNO deposited on platinum at 35°C before and after heating to 970°C; arrows indicate the Pt-Rh heating strip including impurity peaks on the heating strip, (which are not in contact with LNO), and the platinum substrate (which is in contact with LNO). The irreversible nature of the new phase formation can clearly be seen in diffraction pattern (b) in Figure 2 after heating LNO to 970°C, from the presence of additional diffraction peaks belonging to the new phase at approximately 25, 32, 38 and 57 °2θ. Identification of the new phases was made by considering the XRD patterns for LNO and the higher order Ruddlesden-Popper phases, La3Ni2O7-δ (3-2-7) and La4Ni3O10-δ (4-3-10), shown in Figure 2. The major new diffraction peak at 32 °2θ is a good match to the major peaks of both the 3-2-7 and 4-3-10 phases and the peaks at 25, 38 and 57 °2θ provide a good match with the 4-3-10 phase. This indicates that La2NiO4+δ in contact with platinum undergoes a rapid oxidation process on heating to form the higher order Ruddlesden-Popper phases La3Ni2O7-δ and La4Ni3O10-δ. Due to the structural similarity between these RP phases, unambiguous phase attribution from 7 powder XRD data is challenging and hence it is currently not possible to state categorically which of the higher order phases is the decomposition product. To achieve this higher resolution data such as that provided by the latest generation synchrotron sources would be required. In addition, small broad diffraction peaks are visible in diffraction pattern (b) in Figure 2 at 46 and 50 °2θ, which the higher order Ruddlesden-Popper phases do not provide a match for. Attempts to identify this phase where unsuccessful; the peaks did not match the perovskite LaNiO3 phase or La2O3, Ni and NiO phases. Rietveld refinements were performed to determine the lattice parameters of the reaction phases formed from LNO in contact with platinum; the phases were identified as La2NiO4 (with the orthorhombic Fmmm space group at room temperature and tetragonal I4/mmm at 600°C and above) and to La4Ni3O10 (orthorhombic Fmmm), as these phases result in the best fit to the observed diffraction patterns. An example of the resulting fit for LNO deposited on Pt heated at 1000°C is shown in the Supplementary Information (S1). The calculated cell volume and obtained lattice parameters are plotted in Figure 3 with the tetragonal a and b lattice parameters converted to the orthorhombic setting via the √2a relationship. The linear increase with temperature for the a and c lattice parameters in La2NiO4+δ are in good agreement with the trends reported by Nakamura et al.23. The values of a and c are slightly larger than those reported by Nakamura et al., however as these authors conclude in their study, the lattice parameters of LNO are sensitive to both oxygen stoichiometry and oxygen partial pressure. There is no apparent deviation from the linear increase in a and c above 800°C despite the growth of higher order Ruddlesden-Popper phases. The refined phase fractions are shown in Figure 4. At 8 800°C and 900°C there is approximately 10% of the higher order La4Ni3O10 phase present, however on heating to 1000°C there is a significant increase to 40%. This indicates that there is a temperature regime above 900°C where the higher order phase formation is more thermodynamically favourable and below this temperature the phase formation is limited. To further investigate the source of this phase decomposition and determine if the presence of the reduction catalyst Pt was affecting this materials a thin layer of powdered alumina was placed between the LNO and platinum support. It is clear from comparing the diffraction patterns in Figure 5 that the absence of diffraction peaks at 32 and 57 °2θ confirms that there is no higher order Ruddlesden-Popper phase formation when alumina is used as a barrier layer between LNO and Pt. Previous authors have observed the formation of the La3Ni2O7-δ and La4Ni3O10-δ after thermally ageing single crystals of La2NiO4+δ 24 and La2NiO4+δ powder 9, 10 , however the minimum thermal treatment in these studies was performed over 6 days. In this investigation we observe rapid formation (after less than one hour) of the higher order Ruddlesden-Popper phases, on heating single phase LNO above 800°C in static air. The mechanism for the formation of the higher order Ruddlesden-Popper phases from single phase stoichiometric LNO is not comprehensively discussed in the literature, however it is believed that it is associated with an oxidation process, as the oxidation state of nickel increases in the order 2-1-4 < 3-2-7 < 4-3-10. Based on oxygen stoichiometry contents of the higher order Ruddlesden-Popper phases reported by Amow et al. the nickel oxidation states are calculated to be La2Ni(2.28+)O4.14, La3Ni(2.45+)2O6.95 and La4Ni(2.47+)3O9.78. As the lanthanum to nickel cation ratio 9 decreases with increasing nickel oxidation state, it is reasonable to assume that the formation of the higher order phases is associated with either lanthanum deficiency or nickel enrichment; possible proposed reactions for the formation of these phases by oxidation of LNO are outlined below. 4 La2NiO4.15 + ½ O2 ↔ 2 La3Ni2O6.95 + La2O3 + 0.35 O2 3 La2NiO4.15 + ½ O2 ↔ La4Ni3O9.78 + La2O3 + 0.34 O2 7 La2NiO4.15 + O2 ↔ 2 La3Ni2O6.95 + La4Ni3O9.78 + 2 La2O3 + 0.69 O2 From the XRD patterns in Figure 2, it is clear that the reaction observed here does not proceed fully as there is still a significant proportion of La2NiO4+δ present. In addition, in Figure 2 there is no evidence for the presence of La2O3 after heating of La2NiO4+δ. This is in agreement with the XRD patterns obtained by Amow et al. where there is no evidence of La2O3 as a by-product from the formation of higher order Ruddlesden-Popper phases on heating LNO. Gauquelin et al. 24 comment that the formation of these phases is associated with either nickel enrichment or lanthanum depletion and may be due to diffusional segregation of the cations from the surface or the evaporation of a volatile lanthanum species. In the latter case the lanthanum species would therefore not be detectable by powder XRD and is a possible explanation for the absence of diffraction peaks belonging to a lanthanum oxide phase in Figure 2. It is also possible that La2O3 is present as an amorphous phase, which againwould not be observable by powder XRD. The TGA trace in Figure 6 shows an increase in the total mass between 25˚C and 400˚C, which corresponds to an increase in the oxygen stoichiometry of 0.01, assuming δ = 0.15 at 25˚C as determined by iodometric titration. There is a gradual loss in mass between 400˚C and 1000˚C which corresponds to a change in oxygen 10 stoichiometry from 4.15 at 25˚C to 4.09 at 1000˚C. These observations are in excellent agreement with those of Boehm et al.25 who observed a slight increase in oxygen non-stoichiometry, from δ = 0.16 to δ = 0.17 between 25°C and 400°C, followed by a linear decrease up to 1000°C to δ = 0.11. This indicates that the mass loss is associated with changes in the oxygen stoichiometry and within the measurable limits of the TGA there is no detectable change in weight which would be associated with the loss of a volatile lanthanum species. The formation of the higher order Ruddlesden-Popper phases is thermally initiated in an air environment and appears to be catalysed by platinum; the same sample of LNO does not undergo any new phase formation when a barrier layer of alumina is present between LNO and platinum. This is an important observation as platinum is often used in SOFC cathode testing, for example as a current collector. It is clear from this study that the presence of platinum in contact with LNO has a detrimental effect on the LNO structure and in turn an effect on the cathode properties and behaviour. The formation of higher order Ruddlesden-Popper phases occurs by the oxidation of LNO, which is catalysed by platinum, however platinum is an oxygen reduction catalyst. This apparent anomaly can be explained by consideration of the oxygen reduction reaction mechanism. The reduction of gaseous oxygen is a key step at the cathode and results in O2- ions which are then incorporated into the bulk electrode material and transported to the electrolyte. It is proposed that platinum catalyses the reduction of oxygen in the gas phase, which is then incorporated on to the surface of LNO as O2- ions. A schematic of the proposed process is shown in Figure 4, indicating the surface exchange process of oxygen adsorption, incorporation and 11 charge transfer (outlined in equations 4 to 7) as well as the incorporation of O2- ions created by the platinum catalysed reduction of gaseous oxygen. LNO is known to display fast oxygen diffusion kinetics 1, 26 , and it is proposed that the catalysed reduction of gaseous oxygen results in an abundance of O2- ions in the LNO bulk, which are compensated for by an increase in the nickel oxidation state and results in the formation of higher order Ruddlesden-Popper phases. This indicates that platinum is enhancing the surface exchange processes of LNO, which is likely to contribute to the improvement in LNO electrode performance observed with symmetrical cells of LNO and a platinum current collector 3, 16. 5.0 Conclusions Single phase La2NiO4+δ has been shown to undergo an oxidation process on heating that results in the formation of higher order Ruddlesden-Popper phases, La3Ni2O7-δ and La4Ni3O10-δ. This reaction is catalysed by platinum, which acts as a reducing agent for gaseous oxygen, forming O2- ions that are incorporated into bulk LNO and result in an increase in the nickel oxidation state and the formation of these new phases. The reaction is prevented by the addition of an alumina barrier layer between LNO and platinum. This is an important consideration for SOFC testing of LNO and related cathode materials, in which platinum is frequently used as a current collection layer. Further elucidation of the reaction mechanism by which higher order Ruddlesden-Popper phases catalytically form from heating La2NiO4+δ is required to fully understand the reaction kinetics. 12 Acknowledgements The authors would like to thank EPSRC Supergen Fuel Cells for funding of a studentship (RS). Thanks to Esther Valliant (Imperial College London) for assistance with ICP-AES measurements. 13 References 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. R. Sayers, R. A. De Souza, J. A. Kilner and S. J. Skinner, Solid State Ionics, 2010, 181, 386 - 391. A. Chroneos, D. Parfitt, J. A. Kilner and R. W. Grimes, Journal of Materials Chemistry, 2009, 20, 266-270. R. Sayers, M. Rieu, P. Lenormand, F. Ansart, J. A. Kilner and S. J. Skinner, Solid State Ionics, 2010, In Press, Corrected Proof. J. Jorgensen, B. Dabrowski, S. Pei, D. Richards and D. Hinks, Physical Review B, 1989, 40, 2187-2199. A. Aguadero, J. A. Alonso, M. J. Martínez-Lope, M. T. Fernández-Díaz, M. J. Escudero and L. Dazaad, Journal of Materials Chemistry, 2006, 16, 34023408. A. R. Cleave, J. A. Kilner, S. J. Skinner, S. T. Murphy and R. W. Grimes, Solid State Ionics, 2008, 179, 823-826. L. Minervini, R. W. Grimes, J. A. Kilner and K. E. Sickafus, Journal of Materials Chemistry, 2000, 10, 2349-2354. A. Mehta and P. J. Heaney, Physical Review B, 1994, 49, 401-571. G. Amow, I. J. Davidson and S. J. Skinner, Solid State Ionics, 2006, 177, 1205-1210. G. Amow and S. J. Skinner, Journal of Solid State Electrochemistry, 2006, 10, 538-546. M. D. Carvalho, M. M. Cruz, A. Wattiaux, J. M. Bassat, F. M. A. Costa and M. Godinho, Journal of Applied Physics, 2000, 88, 544-549. M. Greenblatt, Current Opinion in Solid State and Materials Science, 1997, 2, 174-183. S. Srinivasan, Fuel Cells: From Fundamentals to Applications, Springer, New York, 2006. R. E. White, ed., Modern Aspects of Electrochemistry 40, Springer, New York, 2007. S. B. Adler, Chemical Reviews, 2004, 104, 4791-4844. M. Rieu, R. Sayers, M. A. Laguna-Bercero, S. J. Skinner, P. Lenormand and F. Ansart, Journal of The Electrochemical Society, 2010, 157, B477-B480. P. S. Manning, J. D. Sirman and J. A. Kilner, Solid State Ionics, 1996, 93, 125-132. P. Odier, Y. Nigara, J. Coutures and M. Sayer, Journal of Solid State Chemistry, 1985, 56, 32-40. S. J. Skinner, Solid State Sciences, 2003, 5, 419-426. A. C. Larson and R. B. Von Dreele, Los Alamos National Laboratory Report LAUR 86-748, 1994. B. H. Toby, Journal of Applied Crystallography, 2001, 34, 210-213. A. Montenegro Hernandez, L. Mogni and A. Caneiro, International Journal of Hydrogen Energy, 2010, 35, 6031 - 6036. T. Nakamura, K. Yashiro, K. Sato and J. Mizusaki, Solid State Ionics, 2010, 181, 292 - 299. N. Gauquelin, T. E. Weirich, M. Ceretti, W. Paulus and M. Schroeder, Montash Chem, 2009, 140, 1095–1102. E. Boehm, J. M. Bassat, P. Dordor, F. Mauvy, J. C. Grenier and P. Stevens, Solid State Ionics, 2005, 176, 2717-2725. 14 26. S. J. Skinner and J. A. Kilner, Solid State Ionics, 2000, 135, 709-712. 15 Tables Table 1: Cation ratio (determined by ICP-AES) and oxygen stoichiometry (determined by iodometric titration) of La2NiO4+δ Element Ratio present in LNO La 2.000 ± 0.012 Ni 1.005 ± 0.002 O 4.148 ± 0.002 16 Figure Caption List Figure 1: In-situ high temperature XRD of La2NiO4+δ deposited on platinum on heating, showing the formation of a new phase by the growth of a diffraction peak at 31.8 °2θ at 800°C and above Figure 2: In-situ high temperature XRD of La2NiO4+δ deposited on platinum at 35°C (a) before and (b) after heating to 970°C; phase markers for La2NiO4+δ (JCPDS PDF 00-034-0314), La3Ni2O7-δ (JCPDS PDF 00-050-0244) and La4Ni3O10-δ (JCPDS PDF 00-050-0243) are shown, arrows indicate the platinum substrate (in contact with LNO) and the Pt-Rh heating strip (no contact with LNO), impurities on the heating strip are indicated by *. Note that the changes to the platinum peak intensities before and after heating are due to orientation changes in the polycrystalline platinum texture. Figure 3: Refined unit cell volume (a) and lattice parameters (b) for La2NiO4+δ deposited on platinum, from room temperature to 1000°C Figure 4: Refined phase fractions of La2NiO4 and La4Ni3O10 deposited on platinum Figure 5: In-situ high temperature XRD of La2NiO4+δ at 900°C deposited on platinum and LNO deposited on alumina for (a) 2θ = 30 to 34° and for (b) 2θ = 54 to 60°, where the presence of a new phase is clear by comparing the diffraction peaks at 32 and 57 °2θ 17 Figure 6: Oxygen content of La2NiO4+δ obtained from 25˚C to 1000˚C by TGA in flowing air Figure 7: Schematic showing (A) the surface exchange process outlined in equations 4 to 7 and (B) the proposed process whereby platinum catalyses the reduction of gaseous oxygen to form additional O2- ions, which are subsequently incorporated into the cathode Table Caption List Table 1: Cation ratio (determined by ICP-AES) and oxygen stoichiometry (determined by iodometric titration) of La2NiO4+δ 18 Figures 20000 o 970 C o 900 C o 800 C o 700 C o 600 C Relative Intensity (Arb. units) 16000 12000 8000 4000 0 30 32 31 33 34 Degrees 2 Figure 1: In-situ high temperature XRD of La2NiO4+δ deposited on platinum on heating, showing the formation of a new phase by the growth of a diffraction peak at 31.8 °2θ at 800°C and above 19 (a) 18000 Relative Intensity (Arb. units) 16000 14000 12000 10000 8000 6000 4000 2000 * 0 20 25 ** 30 * 35 40 45 50 55 La2NiO4+ 60 Degrees 2 18000 (b) Relative Intensity (Arb. units) 16000 14000 12000 10000 8000 6000 4000 2000 * 0 ** * La2NiO4+ La3Ni2O7- -2000 La4Ni3O10- 20 25 30 35 40 Degrees 2 20 45 50 55 60 Figure 2: In-situ high temperature XRD of La2NiO4+δ deposited on platinum at 35°C (a) before and (b) after heating to 970°C; phase markers for La2NiO4+δ (JCPDS PDF 00-034-0314), La3Ni2O7-δ (JCPDS PDF 00-050-0244) and La4Ni3O10-δ (JCPDS PDF 00-050-0243) are shown, arrows indicate the platinum substrate (in contact with LNO) and the Pt-Rh heating strip (no contact with LNO), impurities on the heating strip are indicated by *. Note that the changes to the platinum peak intensities before and after heating are due to orientation changes in the polycrystalline platinum texture. 21 Figure 3: Refined unit cell volume (a) and lattice parameters (b) for La2NiO4+δ deposited on platinum, from room temperature to 1000°C 22 Figure 4: Refined phase fractions of La2NiO4 and La4Ni3O10 deposited on platinum 23 (a) Relative Intensity (Arb. units) 12000 10000 8000 6000 4000 o LNO on Pt at 900 C 2000 o LNO on Al2O3 at 900 C 0 30 31 32 33 34 Degrees 2 6000 (b) Relative Intensity (Arb. units) 5000 4000 3000 o LNO on Pt at 900 C 2000 1000 o LNO on Al2O3 at 900 C 54 55 56 57 58 59 60 Degrees 2 Figure 5: In-situ high temperature XRD of La2NiO4+δ at 900°C deposited on platinum and LNO deposited on alumina for (a) 2θ = 30 to 34° and for (b) 2θ = 54 to 60°, where the presence of a new phase is clear by comparing the diffraction peaks at 32 and 57 °2θ 24 4.17 Oxygen content (4+) 4.16 4.15 4.14 4.13 4.12 4.11 4.10 4.09 200 400 600 800 1000 o Temperature ( C) Figure 6: Oxygen content of La2NiO4+δ obtained from 25˚C to 1000˚C by TGA in flowing air 25 Figure 7: Schematic showing (A) the surface exchange process outlined in equations 4 to 7 and (B) the proposed process whereby platinum catalyses the reduction of gaseous oxygen to form additional O2- ions, which are subsequently incorporated into La2NiO4+δ bulk 26