Supplemental Material-APL-final

advertisement

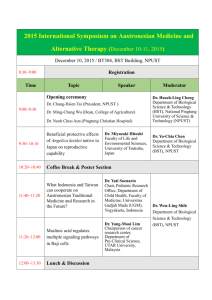

Growth of ferroelectric Ba0.8Sr0.2TiO3 epitaxial films by UV pulsed laser irradiation of chemical solution derived precursor layers A. Queraltó1, A. Pérez del Pino*,1, M. de la Mata1, J. Arbiol1,2, M. Tristany1, A. Gómez1, X. Obradors1, T. Puig1 1 Institut de Ciència de Materials de Barcelona, Consejo Superior de Investigaciones Científicas (ICMAB-CSIC), Campus UAB, 08193 Bellaterra, Catalonia, Spain. 2 Institució Catalana de Recerca i Estudis Avançats (ICREA), Passeig Lluís Companys, 23, 08010 Barcelona, Catalonia, Spain SUPPLEMENTAL MATERIAL 1. Photothermal simulation As a first approximation, the model considers photothermal and not photochemical mechanisms as the main ones acting on the irradiated materials. The calculations are performed by numerically solving the heat equation (S1) in combination to the finite element method (FEM). A two-dimensional BST/LNO/LAO architecture is considered with thicknesses of BST, LNO and LAO systems of 40 nm, 25 nm and 1 m, respectively. t T F 4 Ln ( 2) C p k thT e t 2 1 R e z (S1) In heat equation, T is the temperature, t the time, ρ is the material density, kth the thermal conductivity, Cp the specific heat capacity, F is the incident laser fluence which is assumed to be uniform in the simulation, is the laser pulse duration (Gaussian evolution with ~3 ns FWHM), R is the reflectance of the material in normal incidence to its surface, and is the optical absorption coefficient at = 266 nm wavelength. The values of optical and thermophysical magnitudes for BST, LNO and LAO materials are presented in Table S1. It should be noted that, due to the lack of experimental data, the variation of thermophysical properties with temperature is not considered. Moreover, it is also assumed that all the accumulated laser pulses have the same effect in the irradiated material. Then, the “incubation effect” is neglected for the sake of simplicity. FEM method is applied dividing the geometry in small triangle domains (mesh), with maximum size for each unit of one order of magnitude lower than the optical penetration depth in each layer. We assumed symmetry along the XY plane, and negligible convection and radiation losses. Example of the BST/LNO/LAO meshed geometry used in numerical simulations. 2. Materials parameters used in photothermal simulation. Melting kth Cp point Kg/m3 W/m K J/kg K m-1 R % K BST 5900 [†] 4.1 [†] 472 [†] 1898 [†] 20.9×106 [+] 7 [+] LNO 7200 10.0 400 1953 [*] 21.2×106 15 LAO 6500 11.7 448 2373 2.0×104 1 [+] Measured by spectrophotometry of an amorphous BST film. [*] Melting point of La2NiO4 [†] Data of crystalline BST. Table S1. Optical and thermal properties of the studied materials used for the numerical simulations. 3. Optical properties of amorphous BST. Fig. S1. Reflectance, transmittance, refractive (n) and extinction (k) coefficients, absorption coefficient () and optical penetration depth (1/) of amorphous BST layers as a function of the incident wavelength. 4. Additional PFM measurements Fig. S2. Additional PFM amplitude-electric field butterfly and phase-electric field hysteresis loops taken at different places of the samples obtained by laser irradiation with 40 mJ cm-2 and 10000 accumulated pulses per site, and by thermal annealing at 900ºC during 14400 s.