310715184743abstractSusChemE2015

advertisement

SusChemE 2015

International Conference on Sustainable Chemistry & Engineering

October 8-9, 2015, Hotel Lalit, Mumbai

MODELING AND SIMULATION OF PLATE HEAT EXCHANGERS WITH

GENERALIZED CONFIGURATION

Faizan Ahmad1, Sadaf Zaidi1

1

Department of Chemical Engineering, Z.H.C.E.T, Aligarh Muslim University, Aligarh- 202002, India

E-mail: f4faizahmad1989@gmail.com, sadaf63in@yahoo.com.

1. Introduction

The aim of this work is to develop a plate heat exchanger (PHE) modeling framework that is suitable for any configuration.

The purpose of such a model is to study the influence of the configuration on the exchanger performance. The model

equations are solved by a numerical simulation program in MATLAB 7.0.1 based on the R-K 4 numerical approach. The

program act’s as an ‘experimental’ tool to examine the combined effect of most of the geometrical parameters on the

operation of PHE, particularly the momentum and heat transfer rates. The results are compared with those obtained by Gut

and Pinto [1], who used second order centered finite difference method adopted for sugar solution system.

2. Material and Methods:

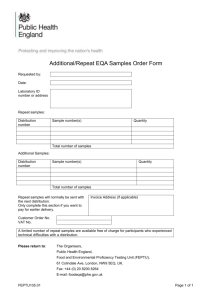

In this work, a configuration characterization of the PHE is presented by using the six simple parameters, which are used to

define the geometry of the PHE. The model equations based on some simplified assumptions are derived with the use of the

energy balance equations, which yield a set of ordinary differential equations (ODEs). The fluid inside a channel exchanges

heat with the fluid in the neighbouring channels through the thin metal plates, as shown in Fig.1.

On applying the energy balance on the differential element “control volume” as shown in Fig.1 in the direction of flow of

fluid, the following equations are obtained:

𝑑𝜃1

𝑑𝜂

= 𝑠1 𝛼 𝐼 (𝜃2 − 𝜃1 ) for first channel

(1)

𝑑𝜃𝑖

= 𝑠𝑖 𝛼 𝑠𝑖𝑑𝑒(𝑖) (𝜃𝑖−1 − 2𝜃𝑖 + 𝜃𝑖+1 )channel𝑖: (1 < 𝑖 < 𝑁𝑐 ), 𝑠𝑖𝑑𝑒(𝑖) = {𝐼, 𝐼𝐼} n

𝑑𝜂

(2)

𝑑𝜃𝑁𝑐

= 𝑠𝑁𝑐 𝛼 𝑠𝑖𝑑𝑒(𝑁𝑐) (𝜃𝑁𝑐 −1 − 𝜃𝑁𝑐 )𝑙𝑎𝑠𝑡𝑐ℎ𝑎𝑛𝑛𝑒𝑙, 𝑠𝑖𝑑𝑒(𝑁𝑐 ) = {𝐼, 𝐼𝐼}

𝑑𝜂

(3)

The equations 1, 2 and 3 are linear ODE(s) which can be solved analytically or by any numerical method. In this study RK4 order numerical method is used.

3. Results and Discussion:

The results obtained by the simulation program (Fig.2) for the general model of the PHE for the given inputs are compared

with those obtained by Gut and Pinto [1] (Fig. 3), who used a second order centred finite difference method adopted for

sugar solution system. The results of this work are close to that obtained by Gut and Pinto [1]. The variation of the

temperature with respect to the height of the plate shows almost the same trends as obtained by Gut and Pinto [1]. To

understand the trend of temperature profiles, the program in this work has been run for 7 channels. Here the configuration

has been taken in which hot fluid is flowing in side (I) and cold fluid in side (II).

1

SusChemE 2015

International Conference on Sustainable Chemistry & Engineering

October 8-9, 2015, Hotel Lalit, Mumbai

The small deviation from the results of Gut and Pinto [1] may be attributed to the fact that the present model has used 7

channels whereas in [1] 36 channels have been used. Moreover, the numerical methods used for solving the two models are

also different.

Figure 1: Control volume for derivation of energy balance in an upward flow channel.

35

side I, 1st pass

30

theta 1

theta 2

thata 3

theta 4

theta 5

theta 6

theta 7

T(oC)

25

side I, 2nd pass

20

15

10

side II, 2st pass

5

side II, 1st pass

0

0

0.2

0.4 η

0.6

0.8

1

Figure 2: Simulated results for PHE by RK-4 numerical approach

2

SusChemE 2015

International Conference on Sustainable Chemistry & Engineering

October 8-9, 2015, Hotel Lalit, Mumbai

Figure 3: simulated results by Gut and Pinto

4. Conclusions:

In the present a model has been developed to study the performance of PHE. The simulation results have been compared

with those obtained by Gut and Pinto [1]. The program developed in this study is an important tool for studying the

influence of the configuration on the exchanger performance. Further, an optimization method can be developed for a

rigorous configuration selection for PHE.

References:

[1] Gut, J.A.W., Pinto, J.M, “International Journal of Heat and Mass Transfer”, 46 (2003) 2571–2585.

3