Supply Chain - StoneBrewery

advertisement

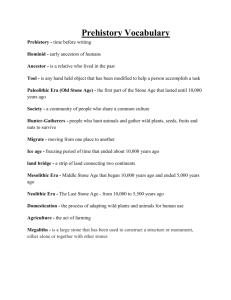

H. Supply Chain Management Stone Brewing uses supply chain management to help establish a system that allows them to distribute there products to 38 different states. The supply chain that Stone uses is illustrated below in figure H.1. The chain works in the following order: Ingredients, such as hops are barley, are acquired from small farmers in Washington State. These small farmers are considered to be tier 3 suppliers who then sell there hops to larger suppliers in larger tiers who then sell directly to Stone. The bottles that Stone uses are purchased from a large bottle manufacture in Portland, OR. This manufacturer is considered to be a tier 1 supply due to the large quantity of bottles they supply. Once the bottles have been purchased they are shipped to a label designer in Los Angeles, CA where the bottles will have the Stone IPA labels baked onto the glass. This process is both costly and time consuming. Once the bottles have been labeled they are shipped the Stone’s brewing facility located in Escondido, CA. The procurement process is very important for Stone to receive quality ingredients and glass but also in a timely manor. After Stone receives all of the necessary supplies then they will brew and bottle the beer at their main location. Once the beer has be bottled and packaged it is then shipped to Stone’s main distribution warehouse which is only a mile away from their brewing facility. From that point it is sent to various distribution centers located throughout the US. These distribution centers will then ship the beer to local stores where it can then be purchased by customers. Stone Brewery’s successes in the market place it dependent on their ability to meet the demand of their customers. It is important that Stone provides value to their customers by ensuring that the freshest beer is available and delivered in a timely fashion. If there is a failure in their supply chain then they are unable to provide a consistent value to their customers. Figure H.1 - Shows the Supply Chain used by Stone Brewing. Supply Chain INGREDIENTS STONE BREWING S3 S2 S1 S3 Washington State LABELING Escondido, CA BOTTLES S1 S1 Portland, OR Los Angeles, CA STONE DISTRIBUTION CUSTOMERS STORE STORE Escondido, CA STORE Key S3 = Tier 3 Supplier S2 = Tier 2 Supplier S1 = Tier 1 Supplier Problems & Uncertainty During the supply chain management stage there can be some uncertainty at times with the supply chain itself and the inventory. Stone maintains as much inventory as their facility can handle but they are dependant on outside supplier to maintain a consistent supply of ingredients and glass bottles. Stone will typically brew up to three different types of beer at a time, this process of brewing has a two week turn around. If a store would like to have a certain type of Stone beer, then they must give Stone a minimum of two weeks notice for their order to be accepted. Since brewing is a timely process, order limitations and time restrictions are necessary to prevent falling behind schedule. Another major part of their inventory is the bottles they have to package the beers in. The main problem with their bottling system that may cause delays in their supply chain and distribution is that unlike many other brewing companies who have blank bottles shipped where they can put any paper label they need depending on the model beer being brewed and shipped, Stone has the labels etched in the bottles through a kiln process before they are shipped to Stone. This can cause a serious problem because Stone will have bottles that already come pre-labeled with the model of beer they are brewing at the moment and if a bullwhip effect takes place they may not have the time nor bottles in stock to brew the demanded beer because they will not have the correct labeled bottles to package the beer and will need to have the suppliers send out the correct labeled bottles which could take a long time. They may also not have enough time to brew a whole new batch of beer because of how long it takes to produce especially during the fermenting stage and it is unfortunate for the beer companies because no matter how much man power you may have at hand to help speed things up, beer fermentation cannot be rushed and needs to fermented and chilled and aged for about 2 weeks. Stone always tries to keep extra inventory around just in case something of that nature may occur, however they may not have enough to produce three brews worth of packaging. They also try to be as accurate as they can on the sales and typically always succeed with deadlines of packaging and distributing.