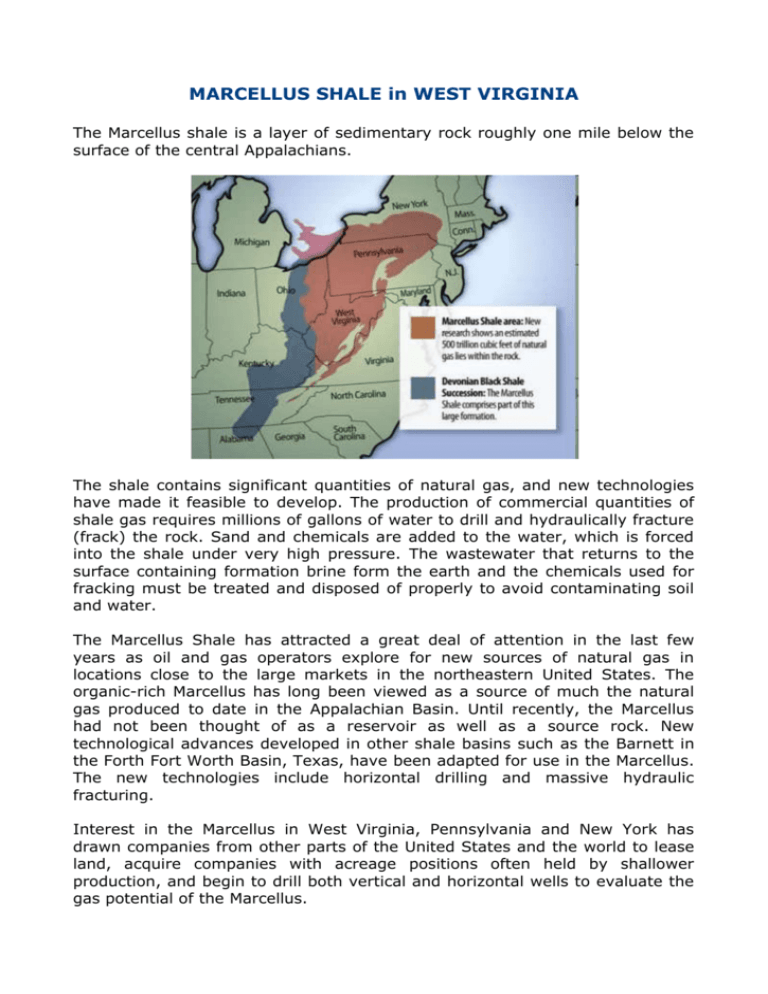

MARCELLUS SHALE in WEST VIRGINIA

The Marcellus shale is a layer of sedimentary rock roughly one mile below the

surface of the central Appalachians.

The shale contains significant quantities of natural gas, and new technologies

have made it feasible to develop. The production of commercial quantities of

shale gas requires millions of gallons of water to drill and hydraulically fracture

(frack) the rock. Sand and chemicals are added to the water, which is forced

into the shale under very high pressure. The wastewater that returns to the

surface containing formation brine form the earth and the chemicals used for

fracking must be treated and disposed of properly to avoid contaminating soil

and water.

The Marcellus Shale has attracted a great deal of attention in the last few

years as oil and gas operators explore for new sources of natural gas in

locations close to the large markets in the northeastern United States. The

organic-rich Marcellus has long been viewed as a source of much the natural

gas produced to date in the Appalachian Basin. Until recently, the Marcellus

had not been thought of as a reservoir as well as a source rock. New

technological advances developed in other shale basins such as the Barnett in

the Forth Fort Worth Basin, Texas, have been adapted for use in the Marcellus.

The new technologies include horizontal drilling and massive hydraulic

fracturing.

Interest in the Marcellus in West Virginia, Pennsylvania and New York has

drawn companies from other parts of the United States and the world to lease

land, acquire companies with acreage positions often held by shallower

production, and begin to drill both vertical and horizontal wells to evaluate the

gas potential of the Marcellus.

Here is a map showing the Marcellus wells in West Virginia:

As you can see from the above shown map, the wells are endless in numbers

and therefore there is a great need of companies who can service this industry.

There are several companies already investing in fractionators and crackers.

For an industry perspective, see the Marcellus Shale Coalition at

http://marcelluscoalition.org/?iframe=true&width=85%&height=85%.

Below there are articles related to the companies who announced projects in

West Virginia (Gastar Exploration & Fluids Management of AES Drilling Fluids

LLC) and expansion (Caiman Energy) due to the Marcellus Shale.

The website of Just Beneath The Surface (www.justbeneaththesurfacewv.com)

gives you the facts about the natural gas industry in West Virginia, containing

the latest in natural gas news and providing factual information and two-way

communication on the subjects of economic benefits, environmental standards

and regulations, safety and the future of energy in West Virginia.

C om p a ny P l an n i ng t o S p e n d $20 0 M i l l i o n i n

M ar sh al l C o un t y

November 30, 2011

By CASEY JUNKINS - Staff Writer , The Intelligencer / Wheeling News-Register

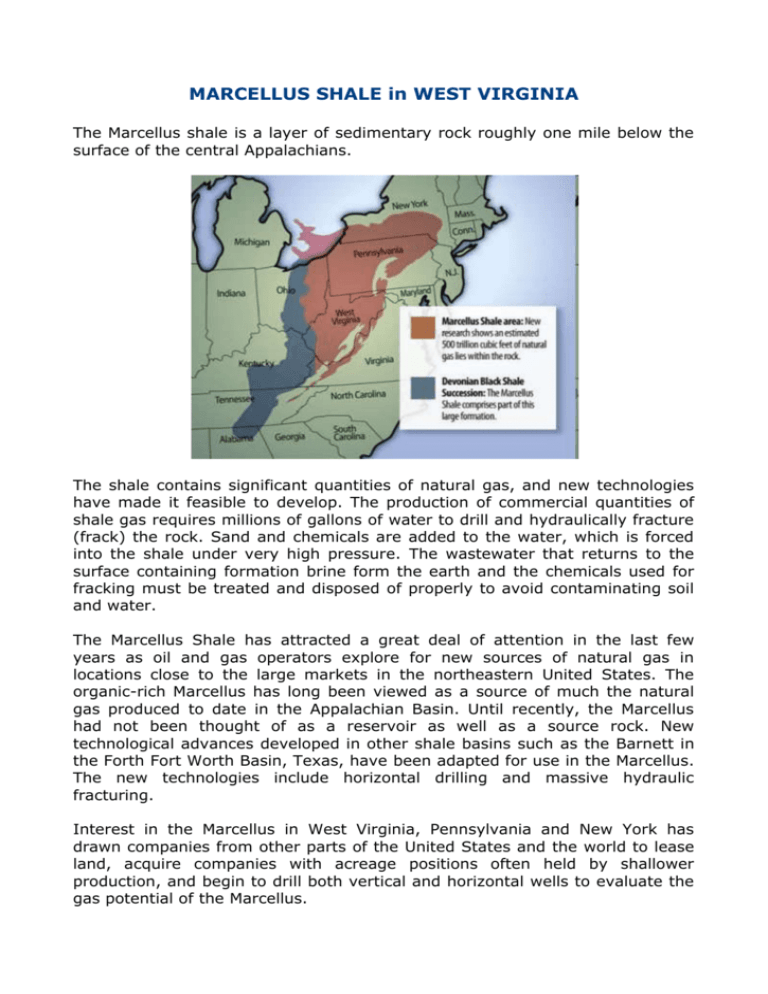

GRAYSVILLE - Gastar Exploration plans to invest about $200 million in West

Virginia's Marcellus Shale field in 2012, with virtually all of the money directed

to Marshall County.

With five producing natural gas wells in the area - and plans for more over the

next several years - officials with the Houston, Texas-based driller are working

to establish good public relations with Marshall County leaders and residents.

This includes spending about $2.5 million to repave Rines Ridge and Burch

Ridge, both of which suffered damage from heavy equipment traveling to

Gastar drilling sites.

"We want people to know who we are, and we want to hear their concerns,"

Gastar Vice President-Northeast Michael McCown said during a break at the

company's Tuesday open house event at the Graysville Community Center.

Photo by Casey Junkins

Gastar Exploration Vice President-Northeast Michael McCown, right, shows Marshall County

Commissioner Brian Schambach a piece of Marcellus Shale during an open house in

Graysville.

About 100 interested residents, state and local officials and gas industry

employees participated in the open house.

In addition to repairing Rines Ridge and Burch Ridge, McCown said Gastar is

going to spend an additional $2.5 million to refurbish an old state road that is

not currently in use. This road, which he said would be exclusively for drilling

truck traffic, would connect W.Va. 2 to Waynes Ridge, relieving much of the

truck traffic from the other two roads.

"The terrain is a significant challenge for drilling here in West Virginia,"

McCown admitted. "We need to take advantage of as much flat ground as

possible."

Fact Box

Gastar Exploration

- In 2010, had total revenue of $42.76 million.

- A Canadian company incorporated in Alberta in 1987.

- Gastar is publicly traded on the NYSE Amex under the ticker symbol GST.

McCown said the Marcellus Shale play in northern West Virginia is one of the

more exciting ventures of his 35-year career.

"The liquids-rich Marcellus is here," he said in reference to gas that contains

ethane, propane, butane and pentane, in addition to the methane natural gas.

"That makes the operations here more valuable."

With about 79,000 acres leased in West Virginia, McCown said the company

will drill about 20 Marcellus wells on the acreage this year. As leasing deals

continue - including some that are made from the company's local leasing

office on Warden Run Road near Oglebay Park - Gastar plans to drill about 25

wells in the area next year.

Eighty percent of the company's capital investments next year, McCown said,

will come in West Virginia, with almost all of this in Marshall County.

"All of our gas goes to Caiman" Energy, McCown said of the company that

operates the ever-expanding processing plant along U.S. 250 near Cameron.

Once the gas goes to Caiman, the natural gas liquids - ethane, propane,

butane and pentane - are separated from the methane natural gas, so that

the products can be sent to market.

Marshall County Commission President Jason "Jake" Padlow is excited about

the investments from Gastar, Caiman and other natural gas companies especially when the companies repair the roads they damage.

"It is good to have them at an event like this, taking a proactive approach

with the community," he said of the driller. "They are working to repair the

roads they are damaging."

In speaking of all gas companies working in Marshall County in general,

Padlow added, "They are here, so let's work together."

McCown said any residents with questions or concerns about Gastar's

operations should call the Clarksburg, W.Va. office at 304-622-4796.

© Copyright 2012 The Intelligencer / Wheeling News-Register. All rights reserved. This

material may not be published, broadcast, rewritten or redistributed.

D ri l l i ng F l ui d P l a nt C om i ng t o Be nw o od

November 30, 2011

By SCOTT McCLOSKEY - Staff Writer , The Intelligencer / Wheeling News-Register

BENWOOD - A new, $2 million "drilling mud" facility has located in Benwood,

bringing further hope of an economic rebirth to the small city.

The Intelligencer has learned that Fluids Management, a Division of AES

Drilling Fluids LLC of Houston, Texas, plans to open the multi-million-dollar

plant in Benwood's Industrial Park before February. More than a dozen large

steel containers that will hold the drilling fluids currently are located on a

concrete pad several feet thick as construction of the plant continues.

Fluids Management will serve as a drilling fluid vendor for the region's

burgeoning natural gas drilling industry. Drilling fluid, also called drilling mud,

is used to aid in the drilling of boreholes into the Marcellus and Utica shales.

Photo by Scott McCloskey

Fluids Management, a Division of AES Drilling Fluids LLC of Houston, Texas, which serves as a

vendor for the region’s growing gas drilling industry, is set to open a new facility at the

Benwood Industrial Park by February.

The new facility, which is initially expected to create between 12 to15 full-time

jobs for local residents, makes a synthetic oil-based drilling fluid called ABS-40

that is used in the drilling process, said Russell Marks, operations manager for

Fluids Management.

"We basically rent the fluid to the customer ... whether it's Chevron,

Chesapeake or whomever, and they use it to drill the well," Marks said. After

the hole is bored, Marks said the drilling fluid is returned to the plant, where it

will be "reconditioned" and used again.

"The drilling fluid helps you removes the cuttings from the well ... and (it also

helps) run casings and complete the well," Marks said.

He did point out that Fluids Management has nothing to do with the hydraulic

fracturing process used to extract the natural gas.

The new facility, located along the Ohio River, sits on a 180 foot by 120 foot

concrete pad and is located just south of Automatic Recycling.

When complete, it will hold about 20 large tanks that provide nearly 9,000

barrels of drilling fluid storage.

Marks said the company also will have several tanks to store calcium chloride

water.

Locating in Benwood made sense for the company, he added.

"We can service our southwestern Pennsylvania customers, our West Virginia

customers and southeast Ohio customers ... the logistics (were) good for us,"

he said.

Fluids Management has a regional office in Canonsburg, Pa.

The five-year deal with Fluids Management also will work out well for

Benwood. City Economic Development Committee Co-Chair and Police Chief

Frank Longwell said he is hopeful the project, which was a joint venture

between the development committee and Mull Industries, is another step

toward what he called the "rebirth" of the city and also the CSX rail yard.

Longwell also said he believes the project will lead to more growth for the

industrial park.

"It's revenue and jobs ... that's why Benwood is doing well," Longwell said

while touring the new facility and surrounding property. The Marcellus Shale is

"like a rebirth of our industry here. We feel that we have the real estate and

transportation assets, which is a big thing."

"We're happy that all of this activity is going on ... It's definitely been a boost

to the CSX yard traffic, as two years ago the rail yard was vacant," he said.

Longwell said with new businesses such as Fluids Management transporting

freight and supplies into the industrial park, it's "breathing new life" into the

rail yard.

"We look for a lot of other things to happen," he said.

Mayor Ed Kuca said he is just happy about the creation of more local jobs in

Benwood that will provide good pay and benefits. "It's jobs you can actually

raise a family on ... and we're excited to see them come to Benwood."

© Copyright 2012 The Intelligencer / Wheeling News-Register. All rights reserved. This

material may not be published, broadcast, rewritten or redistributed.

Caiman Energy Expanding Presence in Marshall County

Company to spend $1.3 billion by 2014

January 20, 2012

By CASEY JUNKINS Staff Writer , The Intelligencer / Wheeling News-Register

CAMERON - A sure sign of increased local natural gas production is that

Caiman Energy plans to bring its total investment in Marshall County

processing infrastructure to $1.3 billion by the end of 2014.

In fact, the Dallas, Texas-based natural gas processing company - which

West Virginia Gov. Earl Ray Tomblin acknowledged for investing more than

$250 million in Marshall County during his "State of the State" speech - is

making plans for more gas processing and fractionating in the county.

The Fort Beeler cryogenic plant, near Cameron along U.S. 250 in Marshall

County, now processes about 120 million cubic feet of gas per day. Some of

this gas flows to the site by a pipeline from Trans Energy's nearby drilling

sites, with more gas flowing to the site from Gastar Exploration and other

drilling operations.

By expanding its Fort Beeler cryogenic natural gas processing plant near

Cameron — and building plants at the Fort Wetzel site and former Olin

Chemical site — Caiman Energy is making more investments in Marshall

County.

By March 1, an additional 200 million cubic feet per day of processing

capacity is expected to be online at Fort Beeler. The facility should be able

to process 200 million more cubic feet each day by Aug. 1, bringing the

total capacity to 520 million cubic feet per day.

Basically, a company like Caiman - along with Dominion Resources and

MarkWest Liberty - is known in the industry as a processor, or

"midstreamer." This is because the processing company accepts the "wet"

Marcellus and Utica shale gas that drillers like Trans Energy, Gastar,

Chesapeake Energy or CNX Gas Corp. draw out of the ground. This gas

contains ethane, propane, butane, pentane and other substances, in

addition to the methane natural gas.

At processing plants, midstreamers separate the methane from the other

substances so that the methane can be sold by utility companies, such as

Mountaineer Gas or Columbia Gas. The ethane, propane, butane and

pentane - collectively known as natural gas liquids - are sent from the

processing facility to a fractionation facility, which will separate these

products from one another. The separated natural gas liquids are then

ready for use, with the ethane possibly going to a cracker plant.

As West Virginia and Ohio leaders await construction of at least one local

ethane cracker, Caiman plans to send ethane out of the Ohio Valley, as the

company is committed to send ethane to Canada for use by the Nova

Chemicals company at a cracker located there. Caiman will transport the

ethane to Sarnia, Ontario, via the Mariner West Project pipeline project

developed by Sunoco.

According to Caiman spokeswoman Casey Nikoloric, the company is

building another processing plant about 5 miles west of the Fort Beeler

facility that will be known as the "Fort Wetzel" cryogenic plant. This plant

should be able to process 200 million cubic feet of gas daily by April 1,

2013, with an additional 200 million cubic feet set for processing each day

by Oct. 1, 2013. This will bring Caiman's total processing capabilities in

Marshall County to 920 million cubic feet per day by the end of next year.

At the Caiman fractionation facility - under construction on the former Olin

Chemical site along the Ohio River, south of Moundsville - the company will

be able to separate 12,500 barrels daily by April 1, with total fractionation

capacity at the site expected to reach 42,500 barrels daily by Oct. 1.

"This is one of the most prolific regions in the country and the positive

economic impact continues to increase," Jack Lafield, chief executive officer

for Caiman, said recently regarding his company's Marshall County

operations.

© Copyright 2012 The Intelligencer / Wheeling News-Register. All rights reserved. This

material may not be published, broadcast, rewritten or redistributed.