GROUP 5 Prelab 1 Solvent Extraction (RK JT AD DQ).

advertisement

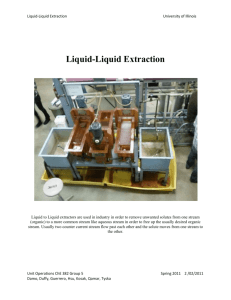

Liquid-Liquid Extraction University of Illinois Liquid-Liquid Extraction Liquid to Liquid extractors are used in industry in order to remove unwanted solutes from one stream (organic) to a more common stream like aqueous stream in order to free up the usually desired organic stream. Usually two counter current stream flow past each other and the solute moves from one stream to the other. 1 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois Lab Prep Report Unit Operations II Lab 1 January 23, 2011 Group 5 Andrew Duffy Daniyal Qamar Jeff Tyska Bernard Hsu Ryan Kosak Tomi Damo Alex Guerrero 2 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois 1. Introduction Often times in chemical industry the components of liquid solutions must be separated. Liquid extraction, also known as solvent extraction, is a viable means of physically separating constituent elements of these chemical solutions. This process is based on the principle of relative solubility of the compounds. In liquid extraction processes two immiscible solvents are combined. Because of the physical properties of these solvents a given solute will dissolve in one of the solvents more readily than the other. For instance a polar solute will dissolve into an aqueous solution more readily than into a non-polar solvent. In this liquid extraction process the solute requiring separation will be Acetic Acid, and both water and Chevron Superla White Oil will be the immiscible solvents. The liquids will be mixed and then settled in a cascade of three stages. Each stage will have both a mixing and settling portion. Once the liquids are allowed to settle the denser aqueous layer (density of 1.00g/mL) will settle on the bottom and the lighter oil layer (density of 0.853g/mL) will form on the top. (MatWeb) The Acetic Acid solute has a higher affinity towards dissolving in the aqueous solvent and will therefore be found in much higher concentrations in the bottom layer of the settling tanks. In many cases a single mixing/settling tank will not provide the required separation of solute from the original solvent. To achieve a higher separation multiple cascading stages will be used with counter-current flowing feed streams. Initially the Acetic Acid will be mixed with the white oil and this stream will be referred to as the feed. The Acetic Acid-Water solution found in the 3 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois settling tanks is the extract, and the white oil solution that the Acetic Acid has been removed from is the raffinate. 2. Literature Review/Theory Liquid-Liquid extraction works because of differences in the solubility of the solute in the extract and raffinate. In general, polar compounds have a higher affinity for other polar compounds than non-polar compounds, and vice versa. This means that a polar compound in a non-polar solvent will transfer easily to a polar solvent, and vice versa. For example, in this lab a non-polar raffinate, white oil, and a polar solvent, water are being used. Acetic acid is polar, and will therefore dissolve easier in water than oil, and thus will transfer from the raffinate to the extract. One way of expressing a solute’s affinity for two phases is with a K-value, which is the ratio of the amount of solute that can be dissolved in the extract to the amount of solute that can be dissolved in the raffinate at equilibrium. Another way of expressing the composition of the extract and raffinate is a triangle plot (show picture from handout), which also takes into account the fact that the extract and raffinate may be slightly miscible. 4 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois Figure 1: Triangle Equilibrium Plot shows liquid equilibrium among three component mixing A single stage Liquid-Liquid extraction is the simplest process in which the feed that contains component to be extracted comes into contact with the extracting solvent. If the phase equilibrium is linear, then the equilibrium can be expressed as 𝑦 = 𝐾𝑥 (1) Where: y = product concentration in extraction solvent x = product concentration in the feed solvent K = equilibrium constant (Wankat 299). When equation (1) is combined with a mass balance of a single stage, then the graphical solution to the equilibrium concentrations of x and y is as shown in Figure 1. 5 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois Figure 2 However, in the case of this laboratory, there is not only 1 stage, but 3 and equilibrium data is for the 3 components of Acetic Acid, Water and Oil. The equilibrium chart for these components is as shown (triangle plot). Since there are 3 stages and the purpose of this experiment is to determine the effect of the speed of mixing on the efficiency of extraction of the unit. The Murphree efficiency of the extract phase in stage S is a useful measure of the efficiency of extraction during that step. It is defined as 𝐸𝑀𝐸 = 𝑌𝑆+1 −𝑌𝑆 ∗ +𝑌 𝑌𝑆+1 𝑆 (2) ∗ 𝑌𝑆+1 = composition of extract phase equilibrium with raffinate phase leaving the (S+1)th stage. ∗ 𝑌𝑆+1 Ys = real composition of the extract phase leaving the (S)th stage ∗ 𝑌𝑆+1 Y(s+1) = real composition of the extract phase leaving the (S+1)th stage 6 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois Eq (3) defines the Murphree efficiency of the raffinate phase: 𝐸𝑀𝑅 = ∗ 𝑋𝑆+1 𝑋𝑆 −𝑋𝑆+1 ∗ 𝑋𝑆 −𝑋𝑆+1 (3) = composition of the raffinate phase in equilibrium with extract phase leaving the (s+1)th phase. ∗ 𝑋𝑆+1 Xs = real composition of the raffinate leaving the (S)th stage ∗ 𝑋𝑆+1 x (s+1) = real composition of the raffinate leaving the (s+1)th stage And the overall efficiency, Eo is 𝐸𝑜 = 𝑛𝑇 𝑛𝑇 (4) 𝑛𝑎𝑐𝑡 = theoretical number of stages required 𝑛𝑎𝑐𝑡 = actual number of stages used All of these efficiencies assume that the equilibrium values of the system or K for the system is known. If equilibrium values are not known, the efficiency of the system is not easily found. The efficacy of the system, however, can still be deduced from the data, by noting the percent removal of the solute from the feed or from a stage. The percent removal of the solute in the overall system can be defined as %Removal = (x(in) – x(out))*100/(x(in)) (5) and the percent removal of the solute in a stage can be defined as %Removal in nth stage = (x(n)-x(n+1))*100/(x(n)) 7 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 (6) Liquid-Liquid Extraction University of Illinois With these two quantities the amount of solute that is transferred to the extract can be found, and the overall efficacy of the system can be found. 3. Experimental 3.1 Apparatus Figure 3: Liquid-Liquid Extraction Apparatus 8 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois Figure 4: Feed Pump and Stage Drainage The above apparatus shows the two holding tanks, oil and acetic acid on the right and oil raffinate on the left, located on the sides of the three mixing stages. The flow of each stream will be described with reference to direction given by the above picture. The feed (oil and acid) will start from the feed tank and be pumped up to the top of the right most stage (Stage 1). The feed will flow to the bottom of stage 1 and then to the mixing section (bottom) of stage 2. From there it will continue upwards to the top of stage 2 where it will transfer over to the top of stage 3. From there it will separate on top and enter the overflow region in the bottom of stage 3 which leads into the oil holding tank. The water will start at the opposite end and flow a path counter to that of the oil. 9 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction # Equipment 1 Mixer-Settler Tanks 2 Mixing Section/Agitator Tank 3 Settling Section 4 Separation Section 5 Agitator Motor 6 Agitator Ball/Disc Variable Speed Transmission 7 Feed Pump 8 9 Pump Power Switch Oil-Acid Mix Feed Tank 10 Oil Capture Tank 11 Water Rotameter 12 Oil-Acid Rotameter 13 Feed Recycle Valve 14 Safety Switch 15 Holding Tank Lids 16 Mixer-Settler Covers 17 Green Recycle Valves 18 Vacuum Drain Valves University of Illinois Description 3 tanks in which the oil, acid, and water mix Where the mixing occurs Where the components settle out from one another Where the separation occurs 3 motors, one for each tank. ¼ HP with a max RPM of 1725 Speed variance for the agitators Feeds the oil-acid mix into the system. 1/3 HP with a max RPM of 3450 Turns pump on and off Holding tank Collects the oil that has gone through the system Controls the flow rate of the water entering the system. 0-100% with a 1.12 GPM max Controls the flow rate of the oil-acid feed from its holding tank to the system. 0-100% with a 1.12 GPM max Allows flow back into the oil-acid mix feed tank Controls power to the three agitators. 30 Amp, 3 phases, 240 V.A.C. Covers holding tanks Covers the mixing-settling tanks so the acetic acid does not evaporate off and to protect from splashing Allows recycle in the mixer-settler tanks Allows all of the tanks and compartments to drain Manufacturer Denver Equipment Company Denver Equipment Company Denver Equipment Company Denver Equipment Company Mac Graham Dayton N/A N/A N/A F & P Co. F & P Co. Speedaire Square D Company N/A Denver Equipment Company Grinnel Saunders N/A Table 1: This table shows the necessary equipment on the apparatus. 10 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois 3.2 Materials and Supplies # Material/Supply Description Manufacturer Highly refined, Chevron Superla White 19 colorless, odorless, and Chevron Oil tasteless 20 Acetic Acid Glacial, A38C-212 Fisher Scientific 21 Sodium Hydroxide pH 8.6 Fisher Scientific Used for taking 22 Graduated Cylinder N/A samples Used for titrating 23 Various Beakers N/A samples Used for titrating 24 Burett N/A sodium hydroxide Table 2: The above table lists the required materials and fluids required to perform the extraction. 3.3 Experimental Procedure 1. Adjust the Water Rotameter (11) to allow pure water to flow through the system. Ensure that all valves and pipes are clear of obstructions. 2. Scrub walls of Holding Tanks (9 & 10) and remove all paint chips that may cause clogging. 3. Prepare a 0.5 weight percent mixture of acetic acid mixed with Chevron Superla White Oil. This is done by adding 1mL of Acetic Acid for every 244.5mL of Oil assuming the Acid and Oil have densities of 1.049g/mL and 0.853g/mL respectively. (MatWeb) 11 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois 4. Pour appropriate amounts of acetic acid and white oil into the Oil Acid Mix Feed Tank (9). 5. Turn on the Feed Pump (7) and allow the mixture to flow through a closed circuit by closing the valve feeding the mixture to the settling tanks. This will allow the Oil/Acid solution to completely mix. 6. Using a small beaker take a sample of the Oil/Acid mixture to be titrated later. 7. Keeping the Oil/Acid feed valve closed turn on the water flow to the feed tanks. Allow mixing-settling tanks to fill with water and then adjust the water feed using the Water Rotamer (11) so that steady levels are obtained. 8. Turn on all three agitators and adjust the Agitator Motors (5) to 50% of their maximum power. 9. Open the Oil/Acid feed valve and adjust the feed using the Oil-Acid Rotameter (12) so that it is 50% of the water feed. 10. Adjust booth feeds so that steady levels are established but be sure that the water feed is always two times greater than the Oil/Acid feed. 11. Allow steady state to be reached. 12. Obtain samples of both oil and water phases from all three of the mixing-settling tanks. 13. Produce a 0.01M solution of NaOH by mixing concentrated NaOH and distilled water. Use the equation 𝑀1 𝑉1 = 𝑀2 𝑉2 to make the solution. 14. Titrate the samples from all three tanks along with the sample obtained in step 6 using the NaOH solution and phenolphthalein indicator to determine the concentration of Acetic Acid. 15. Repeat steps 11 through 14 using agitator speed of 25%, 75%, and 90%. 12 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois 16. Shut off off pumps and mixers. 17. Open drain valves to drain the liquids from the mixing/settling tanks. If draining is slow the liquids can be removed via siphoning. 4. Anticipated Results This experiment was setup to remove a solute (Acetic Acid) from white oil with solvent (water) extraction using a three-stage mixer/settler system. This was done to investigate the effect of the speed of mixing on the extraction efficiency. In the mixer/settler system each stage includes a mixer – where the feed and the solvent are mixed using an agitator – and a settler where the mixed liquids are allowed to separate, allowing the lighter fluid to stay on top while the heavier liquid remains at the bottom. As stated earlier, liquid-liquid extraction is possible through a difference in solubility between two liquids. It is based on the principle that polar compounds have a greater affinity towards other polar compounds than to non-polar compounds, and vice versa. So the liquid-liquid extraction method begins with the addition of a solvent to two immiscible phases that are mixed together to allow the molecules to partition (dissolve) into the preferred solvent. Once the different phases are separated they can then be extracted. It can be assumed that the better the mixing of the liquids the better the molecules are able to partition. In this lab experiment white oil is non-polar and both water and Acetic Acid are polar. This means that since Acetic Acid is polar it will dissolve easier in water than oil and the more mixed the liquids are, the more Acetic Acid will be transferred from the white oil to the water. For these reasons it is anticipated that by increasing the agitation speed (and therefore increasing the mixing efficiency) the volume of extracted acetic acid will increase due to the increase of acetic 13 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois acid contact with water. In effect the concentration of Acetic Acid in the water should increase as the agitation speed is increased. The concentration of the Acetic Acid extracted is measured by titration volume in ml at three different agitation speeds (slow, medium, and high) at three separate times. So in terms of magnitude the concentration of Acetic Acid extracted should be lowest with the slowest agitation speed, highest with the fastest agitation speed, and in between these values for a medium agitation speed. 14 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois 5. References Hyfoma. Extraction. http://www.hyfoma.com/en/content/processing-technology/separationtechniques/extraction/ "MatWeb - The Online Materials Information Resource." Online Materials Information Resource - MatWeb. Web. 23 Jan. 2011. <http://www.matweb.com/search/datasheet.aspx?matguid=ab1fc45899a5464a8655448211643b1 d&ckck=1> Wankat, P. C., (2007). Separation Process Engineering (2nd ed.). New York: Prentice Hall. 15 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois 6. Appendix I: Job Safety Analysis What is the purpose of this experiment? The purpose of this experiment is to operate the three-stage mixer/settler system to extract Acetic Acid from White Oil using water as a solvent, while we investigate the effect of the speed of mixing on the extraction efficiency. During the procedure, water is first introduced as a solvent into compartments, at a flow rate of about 0.5-1.0GPM, until it reaches a steady stage. Then the speed of the agitator is adjusted to a suitable selected value. After establishing water circulation the feed, composed of a mixture Acetic Acid and White Oil with a 0.5 weight percent ratio of Acetic Acid, will then be fed into the system at a specific flow rate that allows a 2.0 feed/solvent ratio. With these conditions the systems should be allowed to run until it reaches steady state. In addition, all parts of experiment will be conducted at ambient temperature. What are the hazards associated with the experiment? One of the main hazards associated with this experiment is spilling water on the floor. Water spilled on the floor is a potential slip hazard and can cause serious injury. The use of White Oil and Acetic Acid solution also poses a slipping hazard if spilled on the floor. Another potential hazard can be electric shock from touching the power outlet or switch with wet hands. Current can be harmful as it can result in external and internal injuries. Careless contact with the agitating rotating object could potentially injure operating personnel. 16 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois How will the experiment be conducted in a safe manner? Frequent observation of liquid levels in all 3 compartments should be practiced to prevent them from flooding and spilling out due to negligence. Caution will be used to prevent any water spills. The water exiting the system will always be going directly to the drain, but a mop and paper towels will be on hand to clean up any spills. The centrifugal pump should not be run in dry condition as this may damage the instrument. Agitators should not be run at extremely high speeds. As always, close-toed shoes and safety goggles will be worn at all times in the experiment area to decrease the chance of potential hazards. What safety controls are in place? There are covers for each separation compartment that prevent liquid from spilling of this compartment due to turbulence from centrifuge or flooding. This also prevents the loss of Acetic Acid by evaporation. Most importantly, the laboratory area around the experiment will be kept dry using paper towels and a mop to clean any spilled liquid promptly to avoid wet working conditions. The water levels will be monitored to ensure that the water does not overflow and cause a spill in the laboratory. There is also a large bowl underneath the system that prevents any liquid spillage to the floor from the bottom or sides of the compartment stages. Safety goggles will be worn at all times to ensure eye protection. Describe safe and unsafe ranges of operations. The safe range of operation for the feed flow rate (White Oil and Acetic Acid) is from 0.25-0.5 GPM. The safe range of operation of the solvent flow rate (Water) is from 0.50-1.0 GPM. 17 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011 Liquid-Liquid Extraction University of Illinois I have read relevant background material for the Unit Operations Laboratory entitled: “Liquid Liquid Extraction” and understand the hazards associated with conducting this experiment. I have planned out my experimental work in accordance to standards and acceptable safety practices and will conduct all of my experimental work in a careful and safe manner. I will also be aware of my surroundings, my group members, and other lab students, and will look out for their safety as well. Electronic Signatures: Bernard Hsu Daniyal Qamar Jeff Tyska Alex Guerrero Tomi Damo Ryan Kosak Andrew Duffy 18 Unit Operations ChE 382 Group 5 Damo, Duffy, Guerrero, Hsu, Kosak, Qamar, Tyska Fall 2010 1/23/2011