UoB-CLN-LAB-QCD-009 Analytical assay failure v1.0

advertisement

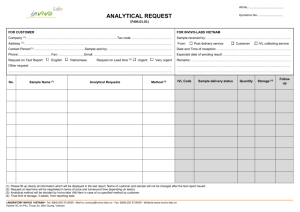

Analytical assay failure Guideline Purpose and use of this guideline document On occasion an analytical run of clinical trial samples may fail. This may be due to equipment failure or because a calibration curve or control sample(s) falls outside of the specified acceptance limits determined during the assay validation procedure. Analytical assay failures should always be recorded, reviewed and acted upon. This document provides guidelines as to how to handle analytical failures during the analysis of clinical trial samples and can be used for the development and implementation of trial-specific written procedures. Scope of this guideline document This guideline document does NOT cover the repeat analysis of patient samples which may give an anomalous result/alert value when the analytical assay has proceeded to completion without issue. Guidelines for this are available (see UOB-CLN-LAB-QCD-018 Repeat analysis). Record keeping You are strongly advised to develop a means of documenting analytical failures and the corrective and preventative action(s) undertaken as a result. An example form for this is available (see UoB-CLN-LAB-QCD-028 Analytical failure report). Note that if an analytical run fails due to equipment failure, additional procedures and actions may be necessary (see UoB-CLN-LAB-QCD-010 Impact assessment of equipment failure or equipment calibration failure, UoB-CLN-LAB-QCD-016 Adverse events in the analytical laboratory, UoB-CLN-LAB-QCD-021 Equipment maintenance record, UoB-CLN-LAB-QCD029 Impact assessment of equipment failure or equipment calibration failure report and UoBCLN-LAB-QCD-032 Adverse Event report). All records must be stored safely and securely throughout the trial and archived with the other trial documents when the trial closes. Developing written procedures You are advised to include the following: The name or job title of the person(s) responsible for reviewing analytical failures, reporting the failure and to whom (if appropriate) and deciding upon corrective and preventative action(s). The name or job title of the person(s) responsible for documenting the analytical failure and corrective and preventative action(s). Procedures developed from the guidelines below. Guidelines Correct equipment malfunctions immediately wherever possible so that the analysis may continue. If this is not possible consider using the guideline documents and example forms UoB-CLN-LAB-QCD-010 Impact assessment of equipment failure or equipment calibration failure, UoB-CLN-LAB-QCD-016 Adverse events in the analytical laboratory, UoB-CLN-LABQCD-021 Equipment maintenance record, UoB-CLN-LAB-QCD-029 Impact assessment of equipment failure or equipment calibration failure report and UoB-CLN-LAB-QCD-032 Adverse Event report for additional procedures and actions. If analytical failure is because the calibration curve or control samples fall outside of the specified acceptance limits, prepare fresh standards and control and run the analysis again (this may depend upon the availability and stability of the samples concerned). Document the analytical failure and the corrective and preventative action(s) undertaken as a result (see UoB-CLN-LAB-QCD-029 Impact assessment of equipment failure or equipment calibration failure report). Consider having the report reviewed and signed off appropriately. UoB-CLN-LAB-QCD-009 Analytical assay failure v1.0 (EAv1.0) Page 1 of 2 Analytical assay failure Guideline Related documents UoB-CLN-LAB-SOP-001 Procedures for GCP compliance in the laboratory UoB-CLN-LAB-QCD-010 Impact assessment of equipment failure or equipment calibration failure UoB-CLN-LAB-QCD-016 Adverse events in the analytical laboratory UoB-CLN-LAB-QCD-018 Repeat analysis UoB-CLN-LAB-QCD-021 Equipment maintenance record UoB-CLN-LAB-QCD-028 Analytical failure report UoB-CLN-LAB-QCD-029 Impact assessment of equipment failure or equipment calibration failure report UoB-CLN-LAB-QCD-032 Adverse event report UoB-CLN-LAB-QCD-009 Analytical assay failure v1.0 (EAv1.0) Page 2 of 2