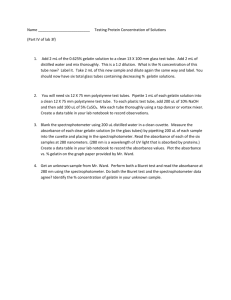

The yield of the extraction of gelatin from the residue of the tilapia

advertisement

Influence of hydrolysis timings on the characteristics of the gelatin from the Tilapia: A Preliminary evaluation of its use as a biopolymer source. Morsyleide F. Rosa2, Mª Mozarina B. de Almeida1, Men de Sá M. S. Filho2, Mabel R. da Cruz1, Edla F. de Melo2, Mª do L. L. Rodrigues*1 1 Universidade Federal do Ceará, Av. Humberto Monte, S/N 2 EMBRAPA – Agroindústria Tropical, Rua Sara Mesquita, Summary: The objective was to make the extraction of gelatin from the CMS waste of the Tilapia (Oreochromis niloticus), using different hydrolysis timings, aiming to evaluate its influence on the characteristics of the obtained gelatin. To make the extraction, the residue remained in the acetic acid 0,2Mol.L-1/1,5h. After that, it was submitted to two hydrolysis: NaOH 0,2Mol.L-1 and H2SO4 0,1Mol.L-1 at room temperature. The material was then immersed in water at 45ºC/ 2h to the hydrolysis timings of 60, 120, 180, 240 and 300 minutes. The liquid was deodorized, vacuum filtered, rot evaporated, lyophilized and grinded. For the characterization of the material obtained, the color Hunter was determined as well as the Gel’s strength, pH, Humidity, Zeta potential, Water activity and Infrared Spectroscopy. The gelatins obtained presented good proprieties, which means they can be used to the development of new materials, as a source of biocomposites. Key-words: residue of tilapia, biopolymers, gelatin, tilapia, hydrolysis INTRODUCTION The industries that benefit from pescado generate large amounts of waste, mainly due to the lack of acknowledgement of this resource as a feedstock and source to other products. In Brazil, the use of such waste is still at a small scale. Approximately 50% of the biomass in Brazil is discarded during the process of canning or in other lines of production, as filleting. In the process of searching for viable alternatives to reuse waste from pescado, a lot of products can be obtained, for instance, the production of hydrolyzed protein and the extraction of collagen and gelatin, increasing the income of the companies and reducing the environmental problem. The collagen is a protein which has as a main characteristic the formation of insoluble fibers with a high elastic endurance, being the gelatin the product obtained by partial hydrolysis of derived collagen from the skin, from the white tissue and from the animal’s bones, which also can be used in the manufacture of capsules or casings to pills. The gelatin is a biopolymer, which can be used in food applications, pharmaceutical products, cosmetics and photography, due to its particular functional and technological proprieties. In the food industry, the gelatin is used in pastry products. In the medical and pharmaceutical field the gelatin is used as a source to implants, liberation of injectable drugs, microspheres and in intravenous infusions. MORPHOLOGY The processes used in the pre-treatment were done at room temperature. The residue was impregnated in acetic acid 0,2 Mol.L-1 , at the ratio sample/solution of 1:3 for 90 minutes. Then it was neutralized with a basic solution, the residue was added NaOH 0,2 Mol.L-1 , at a ratio of 1:3 of sample/solution, starting the basic hydrolysis, the residue remained at NaOH 0,2 Mol.L-1 , under constant agitation, through different hydrolysis timings(60, 120, 180, 240, 300 minutes). When the basic hydrolysis time was over, the sample was neutralized and then preceded to the acid hydrolysis adding H2SO4 0,1 Mol.L-1 at a ratio 1:3 of the sample/solution under constant agitation also for different hydrolysis timings (60, 120, 180, 240, 300 minutes). After this, the sample was again neutralized with a basic solution. The pre-treated residue was used to make the extraction of the gelatin. The extraction was made using the residue obtained after the pre-treatment. Then distilled water was added at the temperature of 60ºC, under constant agitation, with a relation of sample/solution 1:3 for two hours. The mix was vacuum filtered with filter paper. The gelatin was deodorized with charcoal to eliminate the odor of the fish. The charcoal was then mixed to the solution right after the vacuum filtering, using 2% of charcoal in relation to the solution. The charcoal was left in the solution for 24 hours and after that, centrifuged at a speed of 13.000 RPM at a temperature of 28ºC for 15 minutes. The charcoal was withdrawn and the solution was vacuum filtered until the complete removal of all the remaining charcoal. The liquid obtained was rot evaporated and right after, lyophilized. The lyophilized gelatin was grinded in an analytical grinder. RESULTS AND DISCUSSION The yield of the extraction of gelatin from the residue of the tilapia was evaluated considering the mass of produced gelatin, based on the mass of the residue (skin and bones) humid (grams of gelatin by 100 grams of humid residue). The gelatin was analyzed as to its humidity, water activity, zeta potential, pH, Gel’s strength, color Hunter – CIELAB – (parameter L* - luminosity) and infrared analysis by Fourrier (FTIR). As shown on chart 1, the gelatin of residue’s percentage of humidity varied from 912% to the different hydrolysis timings, showing that the samples present their values within the standards of humidity of the commercial gelatin which are 9-14%., however, the samples GP 60 and GP 120 presented lower percentages of humidity. The water activity presented values approximate to 0, 4 to all its samples. The humidity and water activity results indicate to all the samples adequate characteristics to the maintenance of its chemical stability and stability to the microbiological deterioration. The pH values showed figures of approximate 5-6. pH values between 5,0-9,0 indicate that the gelatin is negatively charged, thus confirming the analysis for zeta potential which presented negative values, showing that the surface of the gelatin is negatively charged. Seem as this figure is in module amongst 21 to 25, the suspension is considered to be stable. The gel’s strength for the samples varied in the five different hydrolysis timings; however, they are classified as the ones having the highest Bloom value (220-300). The gelatin applications depend on its Bloom values and the gel’s strength depends on the distribution of the molecular weight, which mainly comes from the processing condition and the composition of amino acids (proline and hydroxyproline) which is specific to each species. The hydroxyproline content is very important to the formation of the gel due to its capacity to establish a hydrogen link through its hydroxyl group. The gelatin gels obtained from the tilapia skin present a high Bloom value, average of 263g. It was noticed that the powder gelatin presented good luminosity, with values close to 100, however, the sample GP 60 presented a L* value higher, as for the samples GP 240 and GP 300 came out with a smaller luminosity value, it may have happened in account of the rigid treatment thus degrading the sample and causing it to have less luminosity. Chart 1: Tilapia’s CMS residue gelatin analysis using different hydrolysis timings. Sample Aw Humidity Gel’s Zeta strength potential pH Yield/income (%) Color (L*) GP 60 0,4 9,7 269,6 -21,3 5,04 6,15 91,35 GP 120 0,44 9,4 348,3 -23,42 5,56 6,35 90,46 GP 180 0,52 11,6 318,7 -23,26 5,85 4,16 87,51 GP 240 0,41 10,56 308,6 -23,26 5,42 5,9 84,97 GP 300 0,45 12,51 488,2 -21,8 5,97 2,6 82,5 The FTIR analysis ehxibited a side of approximate 3441 cm-1 referring to the stretch NH, as for the peak about 1659 cm-1 corresponding mainly to the stretching of C=O and 1553 cm-1 corresponds to the bending N-H and to the stretch C-N. The IR spectrum also presented the lack of the group S-H, which corresponds to the strip of 2550-2600 cm-1, present in the collagen, however, absent in the gelatin. That occurs due to its degradation during the extraction. CONCLUSION It was possible to extract the gelatin from de residues of the mechanically separated meat (CMS) of the Tilapia using different hydrolysis timings. However, the 60 minute hydrolysis time proved to be more viable to the achievement of the gelatin, presenting good income, good humidity and water activity, better luminosity compared to the other timings and high gel’s strength, consistent with the existing literature. The method used on this research also showed that it is possible to obtain a good quality gelatin with good potential to its usage as a source to elaboration of biocomposites.