Hardy Lab

advertisement

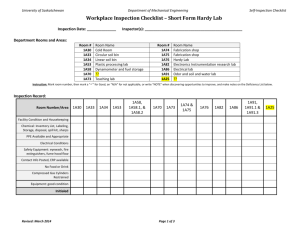

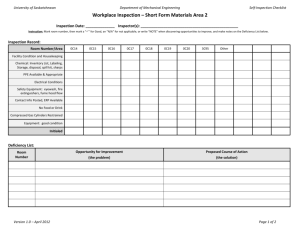

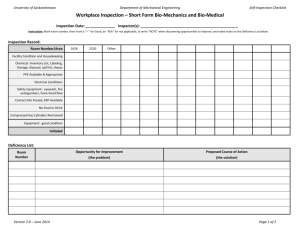

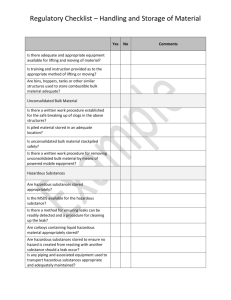

M.E. Workplace Inspection Checklist Version #: 1.0 Department of Mechanical Engineering Workplace Inspection Checklist: Hardy Lab Inspection Date: ______________ Department Rooms and Areas: Inspector(s): _______________________________________________ Type: Monthly Term External: _______ Room # 1A30 1A33 1A34 1A53 1A58 1A73 Room Name Cold Room Circular soil bin Linear soil bin Plastic processing lab Dynamometer and fuel storage Teaching lab Room # 1A91 1A74 1A75 1A76 1A82 1A86 Room Name Odor and soil and water lab Fabrication shop Fabrication shop Hardy Lab Electronics Instrumentation research lab Electrical lab Instruction: Mark room number, then mark a “” for Good, an “N/A” for not applicable, or write “NOTE” when discovering opportunities to improve, and make notes on the Deficiency List below; for Term inspections attach any documentation of inventory inspections and other details; refer to previous inspection Deficiency List(s) to help ensure hazards have been effectively controlled Inspection Record: Room Number/Area 1A30, 1A33, 1A34, & 1A53 1A58, 1A58.1, & 1A58.2 1A73 1A74 Facility Condition and Housekeeping Personnel Have Appropriate Training Personal Protective Equipment Ergonomics and Lifting Activities Electrical Conditions Equipment, Instruments and Tools Chemicals and Hazardous Products Emergency Preparedness and Fire Safety Initialed Revised: March 2014 Page 1 of 3 1A75 & 1A76 1A82 1A86 1A91, 1A91.1 & 1A91.3 M.E. Workplace Inspection Checklist Version #: 1.0 Deficiency List: Room Number Opportunity for Improvement (the problem) Revised: March 2014 Proposed Course of Action (the solution) Responsible Party Page 2 of 3 Refer to Local Safety Committee Target Completion Date Completed & Initialed M.E. Workplace Inspection Checklist Version #: 1.0 WSEP Inspection Guidelines and Reference Notes for Electrical and Computer Engineering Laboratories and Spaces: 1.0 Inspections 1.1 Previous inspection records are available 1.2 Previous inspection findings and issues have been addressed 2.0 Facility Condition 2.1 “No Food or drink in laboratories” is being honoured 2.2 Lab and storage areas uncluttered (i.e. aisles and exits free from obstructions 2.3 Adequate work space is provided for personnel 2.4 Adequate lighting, ventilation and temperature control in work area 2.5 Floors are clean and free of debris 2.6 Floors are in good condition (tile flooring, linoleum, carpet, etc.) 2.7 Work benches and work surfaces are in good condition 2.8 There are no observed water leaks or damage to ceiling, walls or floors 2.9 No mould odors or mould growth is present 2.10 No visible potential airborne hazards observed (dust, mists, vapors, gases) 2.11 Racking, shelves are secured to walls 2.12 Work spaces, storage areas, access points stairwells are uncluttered 2.13 Exits are clearly marked and equipped with emergency lighting 2.14 Door locks are functional 2.15 Fire extinguishers are available and tested annually 2.16 Fire extinguishers are free from obstruction 2.17 Electrical cords are secured down when exposed to foot traffic 2.18 Breaker panels are free from obstruction 2.19 First aid supplies and register (log book) are readily available and clearly visible 2.20 AED inspected 3.0 Training 3.1 Standard Operating Procedures (SOP’s) for Research labs are kept and reviewed regularly. 3.2 Standard Operating Procedures (SOP’s) for equipment used in Research labs, are kept and reviewed regularly. 3.3 Staff who work in Research labs have WHIMIS training and required WSEP. List is kept and refresher courses are taken in a timely manner. 3.4 Grad students working in research labs have taken appropriate WSEP courses and listing in Tech Office 2C94 is up to date. 3.5 All grad students have taken “Safety Orientation for Employees” and listing is kept in Tech Office. 3.6 All personnel are familiar with applicable Job Safety Analyses. 4.0 Personal Protective Equipment (PPE) 4.1 Personnel are wearing appropriate clothing and PPE for the type of work being conducted (e.g. eye protection in machine shop, at solder stations, gloves, lab coats, coveralls.) 4.2 PPE is in good condition, is properly maintained and stored; and is readily available 4.3 Personnel are observed wearing proper footwear 5.1 5.0 Hygiene 8.9 Revised: March 2014 5.2 5.3 6.0 6.1 6.2 6.3 7.0 7.1 7.2 7.3 8.0 8.1 8.2 8.3 8.4 8.5 8.6 8.0 8.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 Methods are in place to remind personnel about good hand hygiene (i.e. hand washing signs posted in washrooms, entrances, etc.) Food or drinks are not present in laboratories or areas where eating and drinking is prohibited Food and drinks are not stored in laboratory refrigerators or freezers Other Respiratory Equipment Respiratory protection equipment is stored properly Personnel using respiratory protect have been fittested Personnel are wearing respiratory equipment as required Noise High noise areas are identified and posted with warning signs. (2C75 Machines lab or 2C95 Machine Shop) Ear plugs are kept in Tech Shop 2C94 and readily available Personnel working in areas with elevated noise levels are aware of the hazards and understand rules regarding hearing protection. Ergonomics “ECE Department Safety Manual” has information and links in regard to understanding ergonomic hazards and how to protect from musculoskeletal injuries. There is no indication from personnel of musculoskeletal type injuries as a result of work activities Equipment and tools are in good working condition and properly maintained Work stations, surfaces and equipment are at an appropriate height for the type of work being performed Chairs are appropriate for the task and in good condition Heavy objects are confined on shelves that are at approximately waist height, Materials stored above shoulder height are secured so that they do not fall, etc. Hazardous Materials Safety Personnel are aware of the hazardous substances they are working with and their proper handling and storage Appropriate hazard warning signs are posted (e.g. WHIMIS, biosafety, radiation safety, noise, etc.) Emergency response plans are available and reviewed by all personnel (i.e. fire, power outage, spill, etc.) Emergency contact information is posted and update-to-date There are a minimum of two evacuation routes from work areas Hazardous materials inventory is kept and up to date. (chemical, biological and radiological) Material Safety Data Sheets (MSDS): Link to web document “How to find MSDS on-line” is operational. Personnel know the nearest location of emergency shower and eyewash stations, and fire extinguishers Laboratories and storage areas are locked and secure when not in use 8.10 Warning signs are posted on laboratories, storage areas (e.g. refrigerators) and equipment consistent with hazards located within 8.11 All hazardous substance containers are labeled in accordance with Workplace Hazardous Material Information System (WHMIS) labelling requirements or with the appropriate hazardous waste label 8.12 Hazardous processes producing volatile or obnoxious fumes are performed in a fume hood 8.13 Flammable liquids are stored and used away from ignition sources 8.14 Incompatible substances are appropriately segregated 8.15 Unstable substances such as ethers and peroxide forming chemicals are tested routinely (recorded with test date and result) 8.16 All hazardous substances are stored below eye level 8.17 Hazardous substances are not stored under sinks 8.18 Procedures for emergency response and spill response and clean-up are available and understood by personnel 9.0 Laser/X-Ray Safety 9.1 There are operating procedures for the use of laser and X-ray equipment 9.2 X-ray equipment registered with WSEP 9.3 X-ray equipment is in good operating condition and properly maintained 9.4 Laser equipment registered with WSEP 9.5 Laser equipment is in good operating condition and properly maintained Other 10.0 Electrical Safety 10.1 Red emergency power shut-off buttons (3C63 and 3C73) are checked annually and records are kept in the Tech Office 2C94. 10.2 Ground fault systems in 3C63 and 3C73 are checked annually and in good working condition and records are kept in the Tech Office 2C94. 10.3 Lock-out procedures are utilized prior to any work on electrically energized systems or equipment. 10.4 Technicians know the location of electrical panels and shut-off switches. List is kept in Tech Office 2C94? 10.5 There is at least one meter clearance around electrical panels 10.6 Electrical equipment and power cords are in good condition and properly maintained 10.7 There are sufficient electrical outlets (outlets are not overloaded with electrical cords) 10.8 Insulated electrical tools are in good condition and used when conducting electrical work 10.9 Power hand tools are checked and maintained annually and records are kept. 10.10 Hand tools are double Insulated or have class “A” ground fault interrupters 10.11 Electrical cords are CSA approved and in good condition 10.12 Electrical cord plugs are installed in an approved manner and have grounding conductor 10.13 Extension cords are not used as permanent wiring (not from one room to another, not through ceiling spaces, through walls or doorways) 10.14 Electrical extension cords are not run under equipment Page 3 of 3 10.15 Power strips and electrical cords are not daisy chained (connected in series) 10.16 Electrical cords and/or electrical equipment are not in contact with water (unless design for accordingly) 10.17 Electrical cords are not in contact with hot surfaces Other 11.0 Fire Safety 11.1 The web link to the Engineering Evacuation Plan is operational and information is readily available. 11.2 Floor Warden and Door Guard list kept in Tech Office 2C94 (for 3rd floor areas) is up to date and checked bi-annually. All positions are manned adequately. 11.3 Evacuation information in “ECE Department Safety Manual” is current, up to date. 11.3 Emergency fire sprinkler heads are not blocked by materials on shelving or stacked from floor (materials are not stored closer than 18” from ceiling) 11.4 Emergency exits are clearly marked 11.5 Emergency lighting is adequate and regularly tested 11.6 Fire doors are kept closed when not in use 11.7 Fire doors are held open by self-closing device (no wedge or kick stand) 11.8 Fire extinguishers checked annually and free from obstruction 12.0 Compressed Gas Cylinders Personnel are aware of the hazards associated with 12.1 gas cylinders Procedures for handling of compressed gas cylinders 12.2 are available and reviewed by personnel 12.3 MSDS are readily available Gas cylinders are properly marked as to their 12.4 contents Cylinder lines, piping and manifolds are labeled with 12.5 identity of contents Cylinder hoses, tubing and regulators are in good 12.6 working condition Empty gas cylinders are labeled “EMPTY” and moved 12.7 to an approved/designated area Cylinders are properly secured to prevent falling 12.8 (secured with a strap or chain) 12.9 Cylinders are secured on carts during transport Cylinder caps are applied when cylinders not in use 12.10 or in transport Cylinders are kept away from sources of excessive 12.11 heat Cylinders not in use are stored in 12.12 approved/designated area Full and empty cylinders are stored separately in an 12.13 approved/designated area APPENDIX Acronyms Class I Flammable liquids with a flash point less than 37.8C WSEP Workplace Safety and Environmental Protection PPE Personal Protective Equipment RSO Radiation Safety Office SOP Standard Operating Procedure TDG Transportation of Dangerous Goods WHMIS Workplace Hazardous Material Information System WSEP: Call 966-4700 or www.usask.ca/wsep