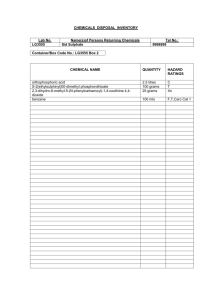

Chemical Safety Booklet - Dan, Ali, Chelsea, Maninder

advertisement

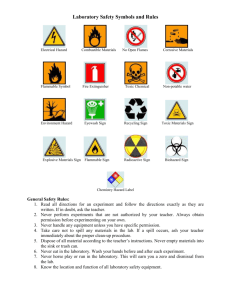

1 Workplace Hazardous Materials Information System (WHMIS) Introduction to WHMIS WHMIS stands for Workplace Hazardous Materials Information System. Its purpose is to provide information about many hazardous materials used in the workplace. WHMIS has a classification system of six hazard classes. These classes are depicted by eight hazard symbols that identify the specific hazards of controlled products. Note: A controlled product is one that falls into one or more of the hazard classes described below. Classification Class A: Compressed gas This class includes compressed gases, dissolved gases, and gases liquefied by compression or refrigeration. Class B: Flammable and Combustible material This class includes solids, liquids, and gases capable of catching fire in the presence of a spark or open flame under normal working conditions. Class C: Oxidizing material These materials increase the risk of fire if they come in contact with flammable or combustible materials. Class D: Poisonous and infectious material Division 1: Materials Causing Immediate and Serious Toxic Effects These materials can cause death or immediate injury when a person is exposed to small amounts. Examples: sodium cyanide and hydrogen sulphide. Class D: Poisonous and Infectious material Division 2: Materials Causing Other Toxic Effects These materials can cause life-threatening and serious long-term health problems. Less severe but immediate problems may also occur to a person who is repeatedly exposed to small amounts. 2 Class D: Poisonous and Infectious material Division 3: Biohazardous Infectious Material These materials contain harmful micro-organisms that have been classified into Risk Groups 2, 3, and 4 as determined by the World Health Organization (WHO) or the Medical Research Council of Canada. Class E: Corrosive material This class includes caustic and acid materials that can destroy the skin or eat through metals. Examples: sodium hydroxide, hydrochloric acid, and nitric acid. Class F: Dangerously reactive material These products may self-react dangerously (they may explode) upon standing or when exposed to physical shock or to increased pressure or temperature. Furthermore, they may emit toxic gases when exposed to water. Material Safety Data Sheets (MSDS) Material safety data sheets (MSDS) are technical documents intended to provide important information about controlled substances, including most chemicals used in high school labs. MSDS is the second part of WHMIS giving additional information to the symbols. What is included in MSDS? All MSDS must have the following nine categories with the included pertinent information: 1) Hazardous Ingredients Chemical names and concentrations of hazardous ingredients LD50 and LC50 – short term toxic potential CAS number – useful if product is known by multiple names 2) Preparation Information Name, address, and phone number of who prepared the MSDS Date MSDS was prepared 3 3) Product Information Identifies substance by name on supplier label Chemical name, family, formula, and molecular weight Product identifiers, manufacturer and supplier names, addresses, and emergency phone numbers 4) Physical Data Substance state (solid, liquid, gas) Odour Appearance Specific gravity, vapour density, evaporation rate, boiling point, and freezing point Vapour pressure (higher concentration means higher possible air concentration) Odour threshold – lowest airborne concentration that can be perceived by smell pH – reflects the corrosive or irritant nature of the substance 5) Fire and Explosion Hazard Temperature and conditions that will cause the substance to catch fire or explode o UEL (upper explosion limit) or UFL (upper flammable limit) indicates highest concentration of a substance in the air that will produce a fire or explosion when there is a source of ignition (heat, spark or flame) o LEL (lower explosion limit) or LFL (lower flammable limit) indicates lowest concentration of a substance in the air that will produce a fire or explosion when there is a source of ignition o From the LEL to the UEL, the mixture is explosive. Below the UEL the mixture is too lean to burn; above the LEL the mixture is too rich to burn, but is still very dangerous as lowering the concentration by introducing fresh air will cause it to enter the explosive range Means of extinguishing the fire, including type of extinguisher and personal protective equipment Some storage requirements – see reactivity data section for full storage details 6) Reactivity Data Chemical stability and reactions to light, heat, moisture, shock, and incompatible materials Storage requirements based on reactivity and instability Incompatible products – must not be mixed or stored together Needs for disposal before substance becomes extremely reactive 4 7) Toxicology Properties Harmful effects of exposure How product is likely to enter and effect the body and organs Short-term (acute) and long-term (chronic) effects of exposure Exposure limits – indicate maximum concentration of hazardous substance in air that most people can be repeatedly exposed without adverse effects o TWA – time weighted average; maximum average concentration people can be safely exposed to for a normal 8hour workday or 48-hour workweek o STEL – short-term exposure limit; maximum concentration people can be safely exposed to for a 15 minute period; STEL is higher than TWA; may not exceed more than four exposures per day o C – ceiling; concentration that may NOT be safely exceeded at ANY time; C is higher than STEL o Exposure limits for gases and vapours expressed in ppm, for dusts, fumes and mists as mg/m3 Personal protective equipment MUST be used if limits are to be exceeded Information used to assess health issues of those exposed to or working with the substance and if substance is responsible 8) Preventative Measures Safe use, handling, and storage of substance Personal protective equipment or safety devices needed Spill clean-up procedures Waste disposal requirements 9) First Aid Measures First aid measures, in correct sequence, for acute effects of substance exposure Emergency planning assistance information Trade Secret Exemptions: Some information of any given product may be withheld to protect industries’ rights to protect confidential business. Product industries may withhold any name, concentration, or relevant names of studies of any ingredient. Product labels must state the date the exemption was filed and exemption claim registration number. The corresponding MSDS must state: an exemption has been granted, the date granted, registry number, and product hazards. 5 Who is responsible for MSDS? Suppliers Creating/ obtaining MSDS for all controlled substances imported/ sold for use in a workplace Ensure MSDS has information current at time of sale/ importation of substance Ensure MSDS was signed and dated no more than three years before date of sale or importation Make MSDS available in both official languages Ensure purchaser of substance has current MSDS at time of or prior to receiving product Make any information deemed confidential available to any physician or nurse when requested Employer – School, Principal, and/or teacher(s) Obtain current MSDS from supplier – be sure it is dated within three years of current date Update MSDS every three years OR within 90 days of new hazard information being made available Make all MSDS readily and easily available to all staff, students, and health and safety representatives as either hard-copy (most common) or electronic Instruct all staff and students are instructed in the information required on the MSDS and its importance Print additional MSDS and/or alter format to suit particular needs as long as all original information is included Worker – School, Principal, teachers, and students Follows training of principal, school board, or teacher(s) Follows safe and preventative measures as instructed Aware of MSDS location and how to find important information in a timely manner All information gathered from the University of Regina 6 Cleaning LABWARE/GLASSWARE SAFETY Labware should be washed immediately after use, when possible. Labware should be cleaned immediately to avoid having irremovable residue left behind. If cleaning immediately after use if not possible, labware should be soaked in water. Brushes may be used to help remove residue, because they will not scratch or abrade the glass. When washing soap, or cleaning powder should be used to help lift chemical residue. The wash water should be hot to help lift left behind residue. Cleaning powders will be mildly abrasive to help lift residue, but will not be abrasive enough to abrade the glassware. Brushes should vary in size, and not be worn down to the spine, so they can be fit into labware of various sizes such as pipettes, burets, test tubes, funnels, graduates, flasks and bottles. Scratched glassware should not be used, because it is prone to breaking when used with experiments involving heat. Rinsing After cleaning, and prior to use, rinse labware with running tap water. Allow the water to run into and over the labware for a period of time. The labware should then be filled to one half with water, and be shaken a few times to remove any left behind cleaning agents. If tap water is hard, deionized water should be used as a rinse prior to use. Finally, rinse the labware in a large bath of distilled water to remove any left behind residue. Removing Grease Grease can be removed by soaking the labware in a mild solution of sodium carbonate, acetone, or other fat solvents. After this, labware should be soaked in acetone or fuming sulfuric acid for 30 minutes. All labware should then be rinsed accordingly to removing cleaning agents. Contaminated Labware Glassware, which is contaminated with blood clots, such as serology tubes, culture media, petri dishes, etc., must be sterilized before cleaning. It can best be processed in the laboratory by placing it in a large bucket or boiler filled with water, to which1-2% soft soap or detergent has been added, and boiled for 30 minutes. The glassware can then be rinsed in tap water, scrubbed with detergent, rinsed again (Aldrich, 2013). You may autoclave glassware or sterilize it in large steam ovens or similar apparatus. If viruses or spore-bearing bacteria are present, autoclaving is absolutely necessary (Aldrich, 2013). Handling and Storage When washing and handling near a sink, be careful not to let tips hit the sink, or water facet. Dry test tubes and other labware by hanging on pegs, and placing in baskets downwards. Dry cylinders and other labware by placing them on a folded piece of paper towel to allow excess water to drain out. To protect labware from 7 dust a cotton stopper may be placed in the mouths of glassware to prevent dust from collecting. Glassware must them be placed in a dust-free cabinet for storage. Store glassware in specially designed racks. Avoid breakage by keeping pieces separated (Aldrich, 2013). Handling Broken Labware/Procedure Bio-hazardous: Broken glass and pipette tips that are infected must be cleansed prior to disposal. An autoclave is most effective on broken labware that has been contaminated. In some cases, chemical disinfection can be used, but it is less effective than autoclaving, and must be done with extra care. Broken glass and sharps should be placed in a puncture proof container (sharps box) that can withstand high autoclave temperatures, and has a sterilization indicator. Once the waste has been disinfected it can be collected by biohazard control. Chemically contaminated: Broken chemically contaminated labware must be segregated from other broken labware by using a hazardous materials/waste tag. It must also be placed in a puncture proof container for disposal. Mercury Thermometers: All labware with mercury or mercury containing compounds must be segregated and disposed of separate from other labware because disposal extremely hazardous and expensive. The broken labware containing mercury, or mercury containing compounds must also be placed in a puncture proof container. Non-Chemically contaminated: Broken glass, and pipette tips that are clean, or have been used with non-hazardous materials and do not contain liquids can be placed in a regular garbage can. However, the pieces of broken glass must first be placed in a puncture proof container, or in a container marked broken glass to ensure the trash is safe for custodians to handle. Heating and Boiling Solutions Heating and boiling solutions, though seemingly simple, can quickly become cause for injury in the classroom when enough care and attention are not observed. A safe procedure for heating and boiling solutions can be found below. Checklist: Always check the MSDS for conditions that may cause fire or explosion Place the heating apparatus – hot-plate or Bunsen burner – on a flat, stable surface (lab bench) away from the edge and clear of all other materials, flammable or not o If using a Bunsen burner, secure a ring-stand and mesh or tube clamp above the burner If the solution is to be boiled, add a boiling chip before heating If the solution is to be heated to a specific temperature, add a thermometer to the container 8 When heating a large amount of solution or dissolving solutes, use a stirring rod to stir periodically or add a magnetic stirrer before adding heat Keep hot-mitts and tongs on hand for removal of the solution container Place the container to be heated in the center of the hot-plate or above the Bunsen burner a reasonable distance above the flame Gradually heat the solution – do not immediately turn the heat to full Gradually increase speed of magnetic stirrer if being used NEVER leave a heating or boiling solution unattended Turn off and unplug the hot-plate or turn off the Bunsen burner and gas when finished Use hot-mitts and/or tongs to remove the heated container for further use Chemical Storage, Handling, and Disposal Storage: Chemicals should be properly stored in a laboratory to avoid accidents. Checklist for storing chemicals: Make an inventory list of chemicals with MSDS. Regularly update the list. Chemical containers should have purchase and expiry dates. Secure storage areas against unauthorized removal of chemicals by students or others. Use of a WHMIS-approved labeling system that segregates all chemicals into classes to make it easy to access and replace them in their proper storage. Maintain clear access to and from the storage areas. Protect the school environment by restricting emissions from stored reagent chemicals. Vents should be ducted to the outside. Where possible, storage areas should have two separate exits. Use an appropriate "Acid Cabinet" for any acid solutions of 6 M concentration or higher. Nitric acid should be isolated. Metals: All metals, except mercury can be stored together. Metals should be stored separate from all oxidizers, halogens, organic compounds, and moisture. Oxidizers (except ammonium nitrate). Oxidizers include such chemicals as: nitrates, nitrites, permanganates, chromates, dichromates, chlorates, perchlorates, and peroxides. They should be separated from metals, acids, organic materials, and ammonium nitrate. They should be separated from flammable liquids by a one-hour firewall or a distance of 8 meters. Ammonium nitrate: Ammonium nitrate should be stored in isolation from all other chemicals. Bases: All strong bases, such as sodium hydroxide, potassium hydroxide, or ammonium hydroxide should be stored in a dedicated corrosive chemicals cabinet that is coated with corrosion-resistant material. Acids: All inorganic acids (except nitric acid), and all regulated organic acids should be stored in a cabinet constructed of corrosion resistant material. Acids may be stored with bases, but fumes from acids and bases may produce an annoying coating of salt crystals on the outside of reagent containers. 9 Nitric acid should be stored separately from acetic acid, either in an isolated portion of the acid cabinet, or in the Styrofoam container in which it was shipped. Fuming nitric acid should never be used. Organize chemicals into their compatible chemical families. The actual sequence of compatible families on the shelves is not critical. What is important is to keep the compatible families separate and to keep the organic and inorganic families as far apart as possible. Label storage areas with a general hazard symbol to identify hazardous chemicals and indicate correct firefighting procedures. Store all chemicals at eye level and below. The preferred shelving material is wood treated with polyurethane or a similar impervious material. Store chemical reagents prepared in the laboratory in plastic bottles (if possible and appropriate to the chemical) to minimize the risk of breakage. When newly received reagent chemicals are opened, immediately read the warning labels to be aware of any special storage precautions such as refrigeration or inert atmosphere storage. Check chemical containers periodically for rust, corrosion, and leakage. Store bottles of especially hazardous and moisture-absorbing chemicals in chemical-safe bags. Keep storage areas clean and orderly at all times. Have spill cleanup supplies (absorbents, neutralizers) in any room where chemicals are stored or used. Storage of Flammable and Combustible Liquids: When possible, store flammable and combustible liquids in their original containers or safety cans. A safety can is an approved container of not more than 5 gallons (18.9 L) capacity. The container should have a spring-closed spout cover and an integral flame-arrester and be designed to relieve internal pressure safely when exposed to fire. Storage of Compressed Gases: o Use small bottle-type gas cylinders only. Store all gas cylinders in an upright position and away from corrosive and flammable substances. o Store empty gas cylinders separately from full gas cylinders. o Store flammable or toxic gases at or above ground level - not in basements. o Use cylinders of toxic, flammable, or reactive gases in fume hoods only. Labeling of Stored Chemicals: Proper labeling is fundamental to a safe and effective laboratory operation. Reagents created in the laboratory also require labeling. All purchased reagent chemicals should be labeled with: Chemical name Date received Date of initial opening 10 Shelf-life Hazard warnings Storage classification location Name and address of manufacturer Solutions: All reagents created in the laboratory should be labeled with: Chemical name and formula Concentration Date prepared Name of person who prepared the reagent Storage classification Hazard warning label Reference to original source of chemical Handling Chemicals Dispensing Reagent Chemicals: One should always consult an MSDS before a chemical is used. Use the smallest amount of the chemical possible in any experiment. Consider distributing the amount of chemical for an experiment into vials for each student. This minimizes waste and can save time during the class period. Use proper containers for dispensing solids and liquids. Solids should be contained in wide-mouthed bottles and liquids in containers that have dripproof lips. Label all containers properly. Never return dispensed chemicals to stock bottle, as it inevitably results in contamination despite your best precautions. Dispensing Flammable Liquids: When a liquid flows from one container to another, static electricity can build up in one of the containers. If this charge becomes large enough, a spark will be produced between the containers, and a flammable liquid may be ignited. This is particularly a danger when the liquid is stored in a large container and distributed to smaller containers. Containers containing flammable liquid should be bonded and grounded. Bonding refers to providing an electrical connection between the two containers. Commonly this is accomplished by attaching a wire, fastening one end each to the two containers. Grounding refers to connecting one of the containers (usually the stationary one) to a grounding source such as a metallic water pipe. Note: Alcohols are one of the many chemicals that require special handling in classrooms. As science teachers, we must teach students how to minimize risks 11 associated with hazardous chemicals (such as methanol). Before doing a laboratory or demonstration, ask: “What would a reasonable and prudent person do?” Procedure for Safe Handling of Alcohol: Always practice a laboratory or demonstration before using in the classroom. Wear indirectly vented chemical splash goggles, chemical resistant aprons or lab coats, and chemical resistant gloves. Methanol and other alcohols are toxic as well as flammable. Avoid inhalation and skin absorption. Handle alcohols in a chemical fume hood or in a well-ventilated (6–10 room exchanges per hour) laboratory. (NFPA 45) Know the location of the A-B-C fire extinguisher, fire blanket, eyewash, and shower. These safety items should be in a location where they can be accessed within 10 seconds. Teachers should receive training in the use of all of these items. Know where spill cleanup materials are located in the event of a spill. Do not work alone in the laboratory. Ensure that all ignition sources are removed from the area near the alcohol. The primary reagent alcohol container should be kept in the chemical storeroom. Only the minimum quantity of alcohol needed for the experiment should be available to students. Remember the vapors of methanol and other alcohols are flammable and denser than air. Know the chemical and physical properties of all chemicals that are used in the laboratory or demonstrations. Refer to the Material Safety Data Sheets (MSDSs) and share the relevant information with students. Conventional alcohol lamps are unsafe and should not be used by students. When using any flammable chemicals in a demonstration, be sure there is a shield between the teacher and the students. The shield only protects students; the teacher is behind the shield - giving a "false sense of security." Keep students away from the demonstration table. Tie back hair, tuck inside a collar/shirt and do not wear loose clothing (baggy sleeves, etc.) Chemical Waste Disposal The disposal of waste chemicals and potentially hazardous materials is very common occurrence in school science laboratories. If the chemical waste is not disposed of properly it could risk harm to people and environment. Disposal of these materials is subject to a number of federal, provincial and municipal regulations. 12 The following are some general guidelines for the handling and disposal of chemical waste: Place each chemical container (jar, tin, etc.) in a heavy clear plastic bag or in freezer bags work well. Seal the bag and label the contents. Pack the bag in vermiculite, Styrofoam chips, or similar material in a box. If the collection of disposables is large, pack chemicals from different hazard groupings in separate boxes (i.e., keep acids and reducing agents separate). Do not pack explosive or highly reactive substances in this way. Resources: Broken Glass Resource: http://www.colorado.edu/ehs/pdf/sharps_disp.pdf This website provides information about disposal of broken glassware, pipette tips and sharps. It discusses how to dispose of glassware contaminated with both radioactive and biological hazards. Additionally, it explains how to dispose of glassware that has traces of chemical residue, as well as uncontaminated glassware. It discusses how to package the glass shards, and pipette tips and sharps for easy clean up, without having to worry about puncturing a garbage bag. It even has a handy chart as to how to evaluate what type of contamination you are dealing with. Lab Safety Educational Video: www.vimeo.com/71782930 I liked this video resource as it can be used with the students on the first day of the school for making the lab safety rules for the lab work. With this video, students can be involved in making the rules as it is fun to watch and students will not be bored half way. There are the rules listed in the video and then students can add to the list and then those lab expectations will be posted in the lab and so students will know that if they don’t follow these rules that will have some consequences. Science Safety Resource: http://www.nsta.org/safety/ The NSTA has put together a large and varied collection of resources for science teachers to reference when needed or simply out of curiosity. This neatly organized collection makes it easy for teachers to find information regarding classroom and laboratory safety across a wide variety of topics from a range of sources. Resources are grouped under elementary and middle/ secondary school categories and arranged alphabetically for ease of access. Workplace Hazardous Materials Information System (WHMIS) Resource: http://www2.worksafebc.com/Topics/WHMIS/Introduction.asp This website provides a comprehensive explanation and resource package concerning WHMIS. It includes an introduction to WHMIS and a succinct, but detailed walk-through of the six classifications including the symbols for each classification. Also, Material Safety Data Sheets are available for download as well as a detailed outline of who is responsible for WHMIS and its importance in chemical safety. Use the tabs on the left to navigate to the desired section.