NonlinearFree Vibration Response of Functionally

advertisement

International Journal on Mechanical Engineering and Robotics (IJMER)

_______________________________________________________________________________________________

NonlinearFree Vibration Response of Functionally Graded Materials

Cylindrical Shell in Thermal Environment.

1

P. D. Khaire, 2N. H. Ambhore, 3K. R. Jagtap

1,2

Department of Mechanical Engineering,Vishwakarma Institute of Information Technology, Kondhwa, Pune-48

3

Department of Mechanical Engineering,Sinhgad Institute of Technology and Science, Narhe, Pune -41

E mail:1Pradeep.khaire08@gmail.com, 2nitin.ambhore@gmail.com, 3krjagtap_sits@sinhgad.edu

Abstract- In this paper the nonlinear free vibration

response of functionally graded materials (FGMs)

cylindrical shell is investigated. The cylindrical shell is

subjected to uniform temperature distribution with

temperature independent (TID) material properties. The

basic formulation is based on higher order shear

deformation theory (HSDT) with Von-Karman nonlinear

strain kinematics using modified C0 continuity. A direct

iterative based nonlinear finite element method

(DIFEM)developed by last two authors for the

Functionally Graded Materials plate is extended for

cylindrical shell. The present outlined approach has been

validated with those available in literature.

Keywords:

FGM, cylindrical shell, nonlinear free

vibration, HSDT.

I. INTRODUCTION

cutouts in thermal environment by using higher order

shear deformation theory with C 0 continuity. K. R.

Jagtap et al. [2]presented stochastic nonlinear free

vibration analysis of functionally graded material plate

resting on elastic foundation in thermal environment by

using higher order shear deformation theory with von

Karman nonlinear strain kinematics with modified C 0

continuity. Achchhe Lal et al. [3] investigated nonlinear

bending response of laminated composite spherical shell

panel with system randomness subjected to hygrothermo-mechanical loading. A direct iterative based C 0

nonlinear finite element method combined with mean

centered first-order perturbation technique (FOPT) for

the plate is extended for the spherical shell panel

subjected to hygro-thermo-mechanical loading. Singh

B.N. et al. [4] investigated composite laminate plate

using finite element method. The formulation is based

on higher order shear deformation theory. Randomness

in the system properties are computed by using first

order perturbation technique. Hiroyuki Matsunaga

[5]studiedfree vibration and stability of functionally

graded shallow shells according to a 2D higher-order

deformation theory. Hui-Shen Shen and Hai

Wang[6]investigated the large amplitude vibration

behavior of a shear deformable FGM cylindrical panel

resting on elastic foundations in thermal environments.

The formulation is based on a higher order shear

deformation shell theory which includes shell panelfoundation interaction and the thermal effects. The

material properties of FGMs are assumed to be

temperature-dependent. The equations of motion are

solved by a two-step perturbation technique to determine

the nonlinear frequencies of the FGM cylindrical panel.

Functionally Graded Material (FGM) is a composite,

consisting of two or more phases, which is fabricated

such that its composition varies in some spatial direction

by changing the volume fraction index of constituent

materials. This design is intended to take advantage of

certain desirable features of each of the constituent

materials. For example, if the FGM is to be used to

separate regions of high and low temperature, thenat the

hotter end it may consist of pure ceramic as the ceramic

is having better resistance to higher temperatures. In

contrast, the cooler end may be pure metal because of its

better mechanical and heat transfer properties.Rapid

advances in the manufacturing techniques of bulk FGMs

have created exiting new possibilities of their

applications in large scale structural system such as

rocket heat shields, wear resistant lining in mineral

processing industry, thermoelectric generators, plasma

facing for nuclear reactors and electrically insulating

II. FORMULATION

metal/ceramic joints,thermoelectric generators, dental

implantation, andbone replacement and electrically

Consider schematic diagram a FGMs cylindrical shell

insulating metal/ceramic joints. A large number of

which consist of ceramic and metal at top and bottom

literatures have been reportedon linear and nonlinear

layer of length a, width b, and total thickness h.

free vibration of plates. K. R. Jagtapet al. [1]investigated

effect of random material properties on free vibration

response of functionally graded materials plate with

_______________________________________________________________________________________________

ISSN (Print) : 2321-5747, Volume-2, Issue-2,2014

37

International Journal on Mechanical Engineering and Robotics (IJMER)

_______________________________________________________________________________________________

the mid surface with respect to x and y axes, x and y

are the slopes along x and y directions, θx =

θy =

dw

dy

dw

dx

and

.

The function f1 (z) and f2 (z) can be written as,

f1 z = C1 z - C2 z ;

and f 2 z = -C4 z With

3

C1 = 1, C2 = C4 =

The properties of the FGMs shell are assumed to be

varying through the thickness. The effective mechanical

and thermal properties of the FGMs shell at an arbitrary

point within the shell domain are expressed as[2],

(1)

Where, t and b represents the ceramic and metal

constituents, E,α,ρ and k are the effective young

modulus, thermal expansion coefficient, density and

thermal conductivity, VC is the volume fraction index,

function of coordinate in the thickness direction (z),

z

Vc z 0.5 ,

h

0n

v w y x y x ]T (4)

2.2 Strain Displacement Relations

l nl t (5)

k z k b [k t k b ]Vc z

n

[u

The strain vector consisting of strains in terms of midplane deformation, rotations of normal and higher order

terms associated with displacement for isotropic layer is,

E z E b E t E b Vc z

ρ z ρ b ρ t ρ b Vc z

4h2

.

3

The displacement vector for the modified model can be

written as,

Fig.1 Geometry of cylindrical shell

α z α b α t α b Vc z

3

h

h

z ,

2

2

Where l , nl and t are the linear and nonlinear

strain vectors (Von-Karman sense), thermal strain vector

respectively. The nonlinear strain vector can be written

as,

1

2

nl [ Anl ] (6)

Where

(2)

Where, n is volume fraction index and is always

positive. For n=0, the shell is fully metal and when n=1,

the composition of metal and ceramic is linear. The

Poisson’s ratio depends weakly on temperature

change and is assumed tobe a constant.

w, x 0

0 w

,y

w, x

1

Anl w, x w, y and

2

w, y

0 0

0 0

2.1 Displacement field model

The thermal strain vector t is represented as,

0

Higher order shear deformation theory with C

continuity has been used to find displacement field

model. Displacement field is given as [4]

u u f1 ( z)x f 2 ( z) x ,

v v(1

z

) f1 ( z ) y f 2 ( z ) y ,(3)

R

ww,

Where (u, v, w) denote the displacement of a point

along the (x, y, z) coordinates axe, (u, v, w) are

corresponding displacements of a point on the mid

plane, x and y are the rotations at z=0 of normal to

t

x

1

y

2

xy T 12 (7)

0

yz

0

zx

Where 1 , 2 and 12 are the coefficient of thermal

expansion in the x, y and z directions respectively which

can be obtained from the thermal coefficient in the

longitudinal 1 and transverse 2 directions of the

ceramic and metal using the transformation matrix and

T is the uniform and nonuniform temperature change.

_______________________________________________________________________________________________

ISSN (Print) : 2321-5747, Volume-2, Issue-2,2014

38

International Journal on Mechanical Engineering and Robotics (IJMER)

_______________________________________________________________________________________________

The temperature field for nonuniform temperature

change is expressed as,

U

T = T z T0 (8)

Where T z is expressed as,

1

2

1

[ D] dA 2 [ D ] A dA

1

T

2

1

2

A

l

l

[ D ] A

T

A

l

T

4

T

5

T

Where [ D] , [ D3 ] , [ D4 ] and

Where T z is the temperature distribution along z

matrices and

surface, and parameter z is defined as,

1

z

k

z

ktb2

z

0.5

h

(2n 1) kb2

2 n 1

z

0.5

h

4 n 1

4

tb

k

(2n 1) kb4

shell

stiffness

is the linear mid-plane vector. The

l

strain energy function calculated for each element above

can be summed to get the total strain energy.

e 1

n 1

{q}T [ Kl K nl (q)]q (13)

3 n 1

z

0.5

h

5 n 1

k

(2n 1) kb5

[ D5 ] are

NE

ktb3

z

0.5

h

(3n 1) kb3

5

tb

(12)

U U e

tb

( z ) 0.5

0.5

c

h (n 1)kb

h

3

dA

T z Tb Tt Tb z

direction, Tt and Tb , are temperature of top and bottom

l

dA

A [ D ] A

A

T

A

Where [ Kl ], [ Knl ] and {q} are defined as global linear,

nonlinear stiffness matrix and displacement vector

respectively.

2.5 Work done

With ktb kt kb and k is defined as thermal

conductivity. The uniform temperature change Eq. can

be written as,

Where, T0 is initial temperature.

Because of uniform and nonuniform temperature

change, pre-buckling stresses in FGM shell are

generated the in-plane pre-buckling stress resultant per

unit length are reason for buckling. The work done (W)

by in-plane stress resultants in producing out of plane

displacements ‘w’ can be expressed as,

2.3 Stress strain relation

W

T ( z) T0 (Tt Tb ) (9)

The stress strain relation accounting thermal effect can

be written as,

1

[ N x ( w, x ) 2 N y ( w, y ) 2

2 A

2 N xy ( w, x ) 2 ( w, y ) 2 ]dA

T

x

y

Q or xy (10)

yz

xz

1 w, x N x

2 A w, y N xy

Q11 Q12

Q 21 Q 22

0

0

0

0

0

0

0

0

0

0

Q 66

0

0

Q 44

0

0

N xy w, x

dA

N y w, y

Where N x , N y and N xy are thermal in plane,

thermal compressive stress resultant per unit length.

Using finite element method and summing over the

entire element above equation can be written as,

0

0

0 l nl t

0

Q 55

Where Q ij , and are the transformed stiffness

matrix, stress and strain vectors for isotropic shell

respectively.

2.4 Strain energy of the shell

The strain energy of the FGM shell is given by,

U

(14)

T

1

dv (11)

v

2

NE

NE

e 1

e 1

W W ( e ) {(e ) }T T [ K g(e ) ]{(e ) } T {q}T [ K g ]{q} (15)

Where T and [ K g ] are defined as critical thermal

buckling temperature and global geometric stiffness

matrix.

2.6 Kinetic energy of FGM shell

The kinetic energy (T) of the vibrating FGM shell can

be expressed as

(k )

T {uˆ}T {uˆ}dV (16)

V

Where and {uˆ} { u v w } are the density and

velocity vector of the shell respectively, above equation

can be expressed as,

Above equation can be expanded as,

_______________________________________________________________________________________________

ISSN (Print) : 2321-5747, Volume-2, Issue-2,2014

39

International Journal on Mechanical Engineering and Robotics (IJMER)

_______________________________________________________________________________________________

NE

NE

v w y y 0, at x 0, a;

e 1

e 1

u w x x 0 at y 0, b

T T ( e ) {}T [m]{} (17)

{q}[ M ]{q}

4.1 Validation of fundamental frequency and parametric

study

Where, [M] is the global mass matrix.

III. EQUATION OF MOTION AND ITS

SOLUTION

The governing equation for thermally induced nonlinear

free vibration of the shell analysis can be derived using

Lagrange’s equation of motion.

t2

(U W T )dT 0 (18)

t1

Substituting the values and obtaining in the form of

nonlinear generalized eigenvalue problem as,

[ K ]{q} [M ]{q} 0 (19)

Where, [ K ] {[ Kl ] [ K nl (q)] T [ K g ]}

The above equation is nonlinear free vibration equation

which can be solved as a linear eigenvalue problem

assuming that the shell is vibrating in its principal made

in each iteration, the above equation can be expressed as

generalized eigenvalue problem as,

[[ K ] [M ]]{q} 0 (20)

Where 2 with is natural frequency of the shell.

The nonlinear eigenvalue problem is solved by

employing a direct iterative based C 0 nonlinear finite

element method in conjunction with perturbation

technique.

IV. RESULT AND DISCUSSION

A nine noded Lagrange isoparametric element with 63

DOFs per element for the present HSDT model has been

used for discretizing, (4 × 4) mesh has been used for the

study.The results are compared with those in literatures.

The dimensionless nonlinear fundamental frequencyof

the FGMs cylindrical shell is,

b2 / h

m / Em , (21)

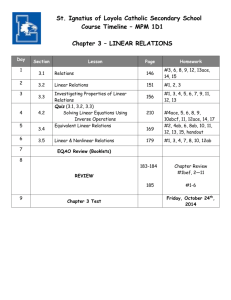

Table 2 shows the dimensionlessnonlinear fundamental

frequency of FGM(Si3N4/SUS304)simply supported

cylindrical shell in thermal environments with

temperature independent material properties and

a/b=b/R=1, a/h=20. Clearly, it is observed that the

present results using C0 DIFEM are in good agreement

with the available semi analytical method published

results[6].

Table 2 validation of mean dimensionless fundamental

frequency of cylindrical shell subjected uniform

temperature distributionwith Wmax/h=1, a/h=20.

T (K)

n

Present

Shen H S [6]

Tc=400K

Tm=400K

1

14.8713

15.9915

5

11.9025

12.8445

Table 3 showsthe effect of temperature change (∆T),

thickness ratio, volume fraction index (n), amplitude

ratio(Wmax/h)and uniform temperature distribution on

the dimensionless nonlinear fundamental frequency of

SSSS supported FGM(ZrO2/ Ti-6Al-4V) cylindrical

shell with R/a=10, ∆T=30K.

Table 3The effect of temperature change (∆T), thickness

ratio, volume fraction index (n), amplitude ratio(W max/h)

and uniform temperature distribution on the

dimensionless nonlinear fundamental frequency of SSSS

supported FGM (ZrO2/ Ti-6Al-4V) cylindrical shell

with R/a=10, ∆T=30K.

a/h

0

10

Table 1The following temperature independent material

properties are used

Types

of

material

E

(N/m2)

ZrO2

151e+9

Ti-6Al4V

α

(1/C)

n

K

(W/mK)

( Kg / m3 )

204

2707

18.591e-6

1

0

70e+9

6.941e-6

Boundary Condition:

All edges simply supported (SSSS):

2.09

3000

20

1

Wmax/h

0.3

0.6

0.9

1

l

0.3

0.6

0.9

1

l

0.3

0.6

0.9

1

l

0.3

0.6

0.9

nl

6.8151

8.1318

9.8770

10.4496

6.2423

5.5676

6.6761

8.1393

8.6132

5.0831

6.8300

8.2435

10.0708

10.7317

6.1694

5.5736

6.7692

8.3069

_______________________________________________________________________________________________

ISSN (Print) : 2321-5747, Volume-2, Issue-2,2014

40

International Journal on Mechanical Engineering and Robotics (IJMER)

_______________________________________________________________________________________________

1

l

8.8617

5.0113

[2]

Jagtap K. R., Achchhe Lal, Singh B. N.,

stochastic nonlinear free vibration analysis of

elastically supported functionally graded

materials plate with system randomness in

thermal environment , composite structures

2011;93:3185-3199.

[3]

Achchhe Lal, Singh B. N., Soham Anand,

Nonlinear bending response of laminated

composite spherical shell panel with system

randomness

subjected

to

hygro-thermomechanical loading, International Journal of

Mechanical sciences 2011;53:855-866.

[4]

Singh B. N., Yadav D., Iyengar N.G.R., A C 0

element for free vibrationof composite plates

withuncertain material properties, advanced

composite material 2003;11:331-350.

[5]

Hiroyuki Matsunaga, free vibration and stability

of functionally graded shallow shells according

to a 2D higher-order deformation theory,

composite structures 2008; 84:132-146.

[6]

Hui-Shen Shen, Hai Wang, Nonlinear vibration

of shear deformable FGM cylindrical panels

restingon elastic foundations in thermal

environments, Composites 2014; 60:167–177.

V. CONCLUSION

A C0 nonlinear finite element method based on direct

iterative procedure [DIFEM] is used to compute the

nonlinear fundamental frequency simply supported

FGM cylindrical shell in thermal environment. Higher

order shear deformation theory with von-Karman

nonlinearity with modified C0 continuity is used for

basic formulation. The nonlinear fundamental frequency

of vibration increases with increase in the amplitude

ratio. It is also observed that for same thickness ratio and

the amplitude ratio, the fundamental frequency of

vibration increases. It is also observed that for same

thickness ratio and amplitude ratio, the nonlinear natural

frequency decreases with increase in volume fraction

index because of decrease in the stiffness.

REFERENCES

[1]

Jagtap K. R., Achchhe Lal,Effect of random

material properties on free vibration response of

functionally graded materials plate with cutouts

in thermal environment. International Conference

on Modern Trends in Industrial Engineering,

2011.

_______________________________________________________________________________________________

ISSN (Print) : 2321-5747, Volume-2, Issue-2,2014

41