EXPERIMENT NO. 5-5

advertisement

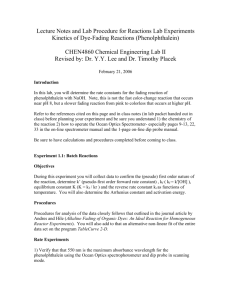

Chemical Engineering Laboratory Manual Reaction EXPERIMENT 461L_2 BATCH and CSTR REACTOR OBJECTIVES: 1. Measure reaction rate constants for a pseudo-first order reversible reaction in an isothermal batch reactor. 2. Use the same reaction to study the start-up (unsteady-state) behavior of a CSTR system. [optional] 3. Compare the observed CSTR start-up behavior with that predicted for an ideal (perfectly mixed) CSTR. [optional] 4. Use the measured rate constants to size a plug flow reactor. [optional] INTRODUCTION: The alkaline hydrolysis of phenolphthalein is an interesting pair of reactions that involve a color change as the reaction takes place. This color change allows the use of a spectrophotometer to indirectly monitor the reaction progress, or rate. The first reaction is the rapid (nearly instantaneous) irreversible conversion of the colorless phenolphthalein to the quinoid form, which has a pink color. The quinoid form (A) then slowly undergoes a rate determining reversible reaction with a hydroxyl ion to form the carbinol form (B) which is colorless. A light absorbance peak is observed for the quinoid form for light with a wave length of 550 nm. Since the light absorbance is linear with concentration, i.e. it follows the BeerLambert Law, then the concentration of the quinoid form is directly proportional to the absorbance. EXPERIMENTAL: This experiment consists of two parts: the batch reaction and the CSTR reaction. a) Batch Reaction Prepare 6 liters of 0.1 N NaOH solution in distilled water, and a solution of 0.4 g phenolphthalein in 100 mL of methyl alcohol. Allow 30 minutes for the spectrophotometer to warm up. Place 0.1 N NaOH in the spectrophotometer sample cell and zero the instrument at 550 nm. At an arbitrary time (called "time zero") add 1 mL of the phenolphthalein solution to 500 mL of the hydroxide solution. Mix thoroughly. Then pour about 3 mL of the mixture (now a bright pink color) into the glass spectrophotometer sample cell and place it in the spectrophotometer set at 550 nm wavelength. Keep all fingerprints off the clear sides of the glass cells. Measure the solution absorbance versus time every 2 minutes (starting at t = 1 minute) until no further change occurs. Ensure the sample cell is not in the beam path (reading location on the carousel) to prevent the light beam from heating the sample above room temperature. Note that at all times the sodium hydroxide level is essentially constant throughout the experiment because it is present in great excess over the phenolphthalein. Your 461L_5 - 1 Chemical Engineering Laboratory Manual Reaction results should verify that the reaction is reversible, pseudo-first order in quinoid form (A) in the forward direction and first order in carbinol form (B) in the reversible direction. b) CSTR Reaction To be added after CSTR is constructed and tested. REPORT: a) Batch Reaction For a reaction: AB (1) in a batch system with an initial A concentration of CAo and a final A concentration (at equilibrium) of CAe, the following equation applies (see below derivation): C A C Ae exp k1 k 2 t C Ao C Ae (2) For CA and CAe we can use absorbance values measured in the spectrophotometer, since the concentrations of A are directly proportional to the absorbances measured. From a plot of ln(CA – CAe) versus time, obtain -(k1 + k2) from the slope and ln(CAo- CAe) and hence CAo from the intercept. The reactor asymptotically approaches equilibrium, so use an extrapolated value for CAe that gives the best straight line fit. Since K = k1/k2 = CBe/CAe = (CAo – CAe)/CAe we can find K (the equilibrium constant). Now that we know K and (k1 + k2) we can find k1 and k2 individually. Obtain CAo, K, k1, and k2 in this way from your data. Also calculate the uncertainty in your experimental k values. b) CSTR Reaction To be added after CSTR is constructed and tested. c) Plug Flow Reactor problem To be added after CSTR is constructed and tested. SAFETY: All must wear safety glasses at a minimum, and safety goggles are recommended. Read appropriate MSDSs for chemicals involved in the reactions. Chemical resistant gloves must be worn when handling MeOH and NaOH solutions. For hot solutions, chemical and heat resistant gloves should be worn. Ensure waste chemicals are disposed of properly. 461L_5 - 2 Chemical Engineering Laboratory Manual Reaction REFERENCES: Fogler, H. S., Elements of Chemical Reaction Engineering, 3rd edition. Prentice-Hall, New Jersey, p. 187-200 (1999). Hill, C. G., An Introduction to Chemical Engineering Kinetics and Reactor Design, John Wiley, New York, p. 388-424 (1977). Levenspiel, O., Chemical Reaction Engineering, 3rd ed. John Wiley, New York, p. 83- 9 (1999). Barnes, M.D. and V.K. LaMer, "Kinetics and Equilibria of the Carbinol Formation of Phenolphthalein," J. Amer. Chem. Soc., 64, 2312 (1942). Chen, D.T.Y. and K.J. Laidler, Can. J. Chem., 37, 599 (1959). ADDITIONAL INFORMATION: 461L_5 - 3 Chemical Engineering Laboratory Manual Reaction 461L_5 - 4