Under Instrumentation spec, the following Automation spec needs to

advertisement

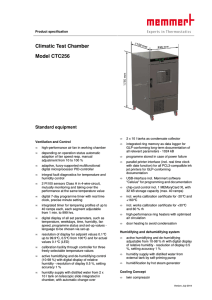

1. Under Instrumentation spec, the following Automation spec needs to be added. EQUIPMENT SPECIFICATION: Automation CLIENT: REV/BY/DATE SPEC. NO: 1213/C1/ES/A4/02 REVISION COMMENT PROJECT: ASTM D5338 SETUP PROCESS REV/BY/DATE: 0/NRK/22-Dec2013 REV : 1 TAG NO. 2 REFERENCE DRAWING 3 PROCESS DATA OPERATING TEMPERATURE FUNCTION Type of control TK-001 : : : 58±2°C : To swich gas flow from different chambers as per predefined sequence : : PLC control with programmed logic Logic control connected with computer to record data of perticular chamber Connectivity 4 QUANTITY : 2 No. 5 Make : PLC: Siemence / ABB 2. Under Equipment specifications – instead carbon steel pipe , the following changes in the respective spec number. EQUIPMENT SPECIFICATION: Stainless Steel Tube CLIENT: PROJECT: ASTM D5338 SETUP PROCESS REV/BY/DATE: 0/NRK/12-Dec-2012 REV 1 GENERAL ITEM Size MOC SERVICE PRESSURE (NOR/MAX) TEMPERATURE (NOR/DESIGN) MATERIAL TEST CERTIFICATE 2 LENGTH, m REV/BY/DATE : Seamless SS Tube : ½” OD : SS304 : Dry Air : 0.6/0.8 bar : 15-70ºC : Required : 40 SPEC. NO: 1213/C1/ES/A4/04 REVISION COMMENT 3. Specifications for environmental chamber instead of water bath EQUIPMENT SPECIFICATION: ENVIRONMENTAL CHAMBER CLIENT: REV/BY/DATE SPEC. NO: 1213/C1/ES/A4/02 REVISION COMMENT PROJECT: ASTM D5338 SETUP PROCESS REV/BY/DATE: 0/NRK/22-Dec2013 RE V : 1 TAG NO. 2 REFERENCE DRAWING 3 PROCESS DATA OPERATING TEMPERATURE FUNCTION Temperature Range Temperature Control Temperature Uniformity Temperature Sensor : : : : Work Space & dimensions # of Shelves Shelf Construction Electrical 58±2°C To keep 16 vessels of 2L volume spaciously to do biodegradability experiments : 5°C to 70°C : ±0.1°C : ±0.3°C : : Humidity Range Humidity Control Humidity Sensor Interior Construction Exterior Construction TK-001 : : : 3-wire RTD 20 to 98% RH controlled humidity vapour on need basis without wasting energy ±2% RH Capacitive Type 304, 2B Finish, Solid Stainless Steel : Cold Rolled Steel, Powder Coated : : : GLASS DOOR : Air flow system : sufficient to keep the vessels and remove whenever necessary, also should facilitate air circulation 4 Standard; 25 Maximum Type 304, Perforated Stainless Steel, Electropolished 208/230V, 60 Hz, 8A Heated, triple pane, and argon filled which minimizes condensation for a clear view of the products inside Horizontal air flow which generates evenly distributed airflow across all shelf locations.Temperature uniformity, even under heavy loads required. VOLATILE MEMORY : During power failure, non volatile memory should set the chamber temperature back to its original set point. ALARM : DUAL DISPLAY : INTERIOR & SHELVES : Set point deviation alarm with audible alerts, also convenient option to silence the audible alarm to be provided Dual display of temperature and humidity to visualize set points and operating conditions, set points to be adjusted by pressing the keys. Corrosion resistant Stainless steel interior & shelves that are adjustable, perforted 5 MAKE : LICOR OR EQUIVALENT 6 QUANTITY : 2 No.