DSEAR - the University of Salford

advertisement

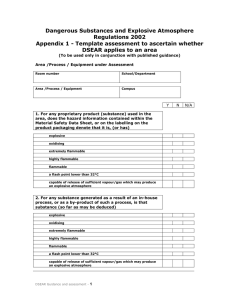

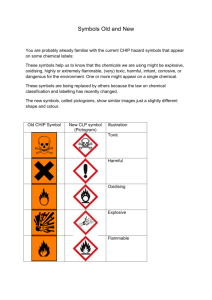

Dangerous Substances and Explosive Atmospheres Code of Practice Effective from 23 March 2011 Version Number: 1.1 Author: Health and Safety Coordinator Health, Safety & Wellbeing te University of Salford DSEAR Code of Practice V1.1 Document Control Information Status and reason for development Status: Revised to update previous version Reason for development: This document was developed to ensure compliance with associated legislation and standards, and University requirements. Revision History Date January 2015 Author Claire Whittaker Summary of changes Document transferred to new template Dave Lamb Document developed March 2011 Version No. V1.1 V1.0 Code of Practice Management and Responsibilities Owner: Associate Director of Health, Safety & Wellbeing Others with responsibilities (please specify): The owner has delegated responsibility for day to day management of the Code to the Safety/Fire Safety Officer All subjects of the Code will be responsible for engaging with and adhering to this policy. Assessment Cross relevant assessments Cross if not applicable Equality Analysis Legal Information Governance Academic Governance Author: Consultation Cross relevant consultations Staff Trades Unions via HR Students via USSU Any relevant external bodies (please specify) N/A ………………………………….. Associate Director of Health, Safety & Wellbeing Authorised by: March 2011 Date authorised: March 2011 Effective from: 2 years from date authorised Review due: Document location: www.salford.ac.uk/hr www.salford.ac.uk/university/governance/policies-and-procedures Document dissemination and communications plan The Safety/Fire Safety Officer will circulate to the Health and Safety Coordinators for the Colleges and Professional Services to enable promotion throughout their area of responsibility. Page 2 of 7 University of Salford 1.0 DSEAR Code of Practice V1.1 Purpose In order to comply with the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) the University must identify substances or processes which may cause fire or explosion and put in place adequate control measures. To do this a risk assessment for each substance / process is required. 2.0 Scope DSEAR applies when there is work being carried out by an employer which involves or is likely to involve a dangerous substance, that is any substance which may explode, cause fire or create an explosive atmosphere. This applies to workplaces where the substances are used, produced or stored. For the University this will apply all occasions / processes where dangerous substances are present. A dangerous substance for the purposes of this legislation is any substance or mixture of substances (known as preparations under DSEAR) which may; 3.0 be classified as explosive, oxidising, extremely flammable, highly flammable or flammable under current CHIP legislation be a dust which when spread in air to form a cloud may explode be a substance or preparation whose properties constitute a risk to safety from fire or explosion (these may not be covered by CHIP). Code of Practice Statements Certain duties are placed upon employers under DSEAR requiring them to assess, eliminate or reduce risks from dangerous substances. Any assessment must take into account the workplace, the activity or process and the harm those work activities could cause to employees, emergency services and members of the public. If there is no or trivial risk identified at this stage no further action is required. If risks are identified then further action must be taken to eliminate or reduce these to a reasonably practicable level. The aim should be to eliminate the risk by either changing the substance for a safer alternative or changing the process to a safer one. If this is not an option then control measures need to be put in place to reduce the risk to an acceptable level. 3.1 Control measures Where risks are identified control measures need to be put in place to control these. These should be chosen in the following order; 3.2 Eliminate This is the preferable control measure when safer substitutes are available. Elimination may not require an alternative substance but may be possible by altering the process for example stopping dusts escaping from the work area. 3.3 Reduce Reduce the quantities of dangerous substances in a process and reducing stock of these substances limiting the potential risk from them. Reducing the frequency of processes is another option to consider. Page 3 of 7 University of Salford DSEAR Code of Practice V1.1 3.4 Isolate Using specifically designed storage away from ignition sources with restricted access reduces the chance of a fire or explosion occurring. 3.5 Control Ventilation, containment and segregation are all examples of controls which can be implemented to reduce the likelihood of a fire or explosion happening. Detection and warning systems such as fire alarms and gas monitors may also be used. 3.6 Personal Protective Equipment (PPE) Once all the above options have been examined and implemented then personal protective equipment can be chosen and provided. Where DSEAR is deemed to apply and greater hazards are involved it is insufficient that PPE be used as a primary control measure. 4.0 Code of Practice Monitoring and Performance The application of this code of practice will be monitored as part of the external health and safety management systems audit. 5.0 Related Documentation Not applicable 6.0 Training and Support Support can be obtained from Health, Safety & Wellbeing. 7.0 Appendices DSEAR Assessment form Page 4 of 7 University of Salford DSEAR Code of Practice V1.1 R1 to R19 Explosive Chemicals that explode Explosive, self reactive, organic peroxide Oxidising Chemicals that react exothermically with other chemicals Oxidising gases, oxidising liquids, oxidising solids Extremely flammable Chemicals that have an extremely low flash point and boiling point, and gases that catch fire in contact with air or highly flammable Chemicals that may catch fire in contact with air, only need brief contact with an ignition source, have a very low flash point or evolve highly flammable gases in contact with water Flammable gasses, flammable liquids, flammable solids, flammable aerosols, organic peroxides, self-reactive, pyrophoric, selfheating, contact with water emits flammable gas R1: Explosive when dry R2: Risk of explosion by shock, friction, fire or other sources of ignition R3: Extreme risk of explosion by shock, friction, fire or other sources of ignition R4: Forms very sensitive explosive metallic compounds R5: Heating may cause an explosion R6: Explosive with or without contact with air R7: May cause fire R8: Contact with combustible material may cause fire R9: Explosive when mixed with combustible material R10: Flammable R11: Highly flammable R12: Extremely flammable R14: Reacts violently with water R15: Contact with water liberates extremely flammable gases R16: Explosive when mixed with oxidising substances R17: Spontaneously flammable in air R18: In use, may form flammable/explosive vapour-air mixture R19: May form explosive peroxides R30 Can become highly flammable in use R44 Risk of explosion if heated under confinement R14/15 Reacts violently with water, liberating extremely flammable gases R15/29 Contact with water liberates toxic, extremely flammable gases Page 5 of 7 University of Salford DSEAR Code of Practice V1.1 DSEAR (2002) RISK ASSESSMENT. Substance(s) / Process: Location: (Building and room no) Assessors Name: Supervisors Name (where applicable): Manufacturers Safety Data Sheet(s) available? SDS stored: Does the substance / process match any of the Risk Phrases mentioned above Is the substance: Liquid Gas Solid Powder Flashpoint below 32oc Yes No Electronically Paper copy Yes No Flammable Highly flammable Extremely flammable Explosive Oxidising Yes No If any of the risk phrases / symbols, flammability or flashpoint below 32 oc tick boxes are ticked then please fill in the next section; Approximate quantity to be used? Storage and handling arrangements (including any waste). Measures in place to stop explosive atmosphere forming. Ignition sources. Measures in place to stop ignition of substances / atmospheres. Likelihood of fire or explosion (A). Anticipated scale of accidental fire or explosion after control measures have been implemented (B). Risk level (A x B) (see column A below) (see column B below) If greater than 7, identify additional actions to reduce risk further Additional control measures required. Likelihood and scale after additional controls are in place. (A x B) Page 6 of 7 University of Salford DSEAR Code of Practice V1.1 Completed by; Date: Increasing Consequence Risk Rating: 5 10 15 20 25 4 8 12 16 20 3 6 9 12 15 2 4 6 8 10 1 2 3 4 5 Increasing Likelihood 17-25 Unacceptable – Stop activity and make immediate improvements/seek further advice 10-16 Tolerable – look to improve within specified timescale 5-9 Adequate – Look to improve at next review 1-4 Acceptable - No further action, but ensure controls are maintained Guide to using the risk rating table: Consequences 1 Insignificant – No or very little impact 2 Minor – Business interruption 3 Moderate – Property damage 4 Major – Significant financial loss/ valuable equipment/Minimum number of people at risk 5 Catastrophic – Significant numbers of people at risk/high risk impact e.g. affect on surrounding area Likelihood 1 Very unlikely – 1 in a million chance of it happening 2 Unlikely – 1 in 100,000 chance of it happening 3 Fairly likely – 1 in 10,000 chance of it happening 4 Likely – 1 in 1,000 chance of it happening 5 Very likely – 1 in 100 chance of it happening Page 7 of 7