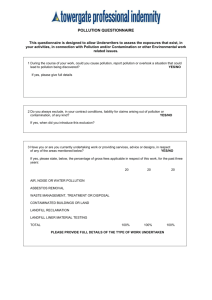

FMENV019 Pollution Prevention

advertisement

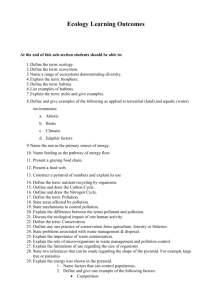

FM ENV 019 Pollution Prevention - Environmental Management Procedure Safety Health & Environment Section Environmental Management System (EMS) FM/ENV/019 Pollution Prevention Environmental Management Procedure March 2015 Version 3.0 Document review due: March 2016 Please Note – Prior to migration to SharePoint this document was on version 4.0. This is a controlled document, please ensure you are using the most recent version available on the UCLan intranet. Page 1 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Document History Date Author Version Description of modifications 27.07.10 S. Buckland 0.1 Initial draft of document issued for review. 26.08.10 S. Buckland 1.0 Comments included, final draft for authorisation. 23.08.11 S. Buckland 2.0 All sections updated following audit actions and receipt of trade effluent exemptions. 03.08.12 C.Challen 3.0 Section 2.2, Figure 2 – minor amendments regarding link to spill kit locations & competent persons FMENVREC049, Section 2.1 descriptions of incidents changed to better reflect University operations. Minor amendments to 1.1, 1.3, 3.3 04.09.13 S. Buckland 4.0 Updated version following internal audit ENV0313. 26.09.13 S. Buckland 1.0 Migration to SharePoint April 14 S. Buckland 2.0 Minor alterations to incorporate internal audit findings to: 3.1 Adelphi Diesel generators removed, 3.2.3 foul water, trade effluent and compost leachate descriptors adjusted. March 15 C.Challen 3.0 Addition of new sections 3.10 Radioactive Materials and 3.12 Smoke Control Removal of section on Legionella – covered by the Statutory Compliance Manager Minor alterations to incorporate internal audit findings and changes in responsibilities to various sections. References # Title Version File Name [1] Environmental Aspects Register 2.0 FM ENV 004 [2] Environmental Sustainability Policy 1.0 (in FM ENV 002 sharepoint) [3] Newground Legislation Register N/A [4] ISO14001 2004 [5] Sustainable Procurement Environmental Management Procedure 3.0 FMENV014 [6] F- Gas Register N/A File with Building Services Manager [9] Spill Containment – Competent Persons 7.0 (in FMENVREC049 Page 2 of 28 sharepoint) http://product.legislationupdatese rvice.co.uk FM ENV 019 Pollution Prevention - Environmental Management Procedure [12] PPG22 Dealing with Spills Apr 11 www.environment-agency.gov.uk [13] PPG18 Managing fire water & major spillages - www.environment-agency.gov.uk Page 3 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Document Control Authorised: Michael Ahern Chief Operating Officer Date Approved: Paul Morris Director of Facilities Management Date Reviewed: Christine Edwards Safety Health & Environment Manager Date Author: Sarah Buckland Environment & Sustainability Manager PP Clair Challen Environment & Sustainability Manager Date Page 4 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Contents 1 Introduction 1.1 1.2 1.3 1.4 Purpose Scope Responsibilities Continual Improvement 2 Emergency Response 2.1 2.2 Determining the type of response necessary Dealing with spillage and release of Environmentally Hazardous Substances 3 Preventative Operational Controls 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11 3.12 3.13 3.14 3.15 Oil Storage Water Pollution Fertilizer, Plant Protection Products Ozone Depleting Substances/F- Gases Waste Management Contaminated Land Environmental Nuisance Asbestos COSHH Radioactive Materials Polychlorinated Biphenyls (PCBs) Smoke Control Gas Safety / Boiler Emissions Vehicle Emissions Greenhouse Gas Emissions Page 5 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 1 Introduction 1.1 Purpose This procedure describes the approach UCLan will take to manage and mitigate its potential to pollute the environment as a category of significant environmental aspects (FMENV004), within the University’s Environmental Management System (EMS), to ensure the University’s operations remain compliant with relevant parts of its: Environmental Sustainability Policy; Environmental Management Plan 2013-2016; Sustainability Strategy (in Corporate Plan); Register of environmental legal and other requirements (Newground Legal Compliance Service), including; o The Control of Pollution (Oil Storage) (England) Regulations 2001 (SI 2001/2954) o Water Industry Act 1991 as amended by Water Industry Act 1999 o Contaminated Land (England) Regulations 2006 SI 1380 as amended SI 2012/263 o The Environmental Damage (Prevention and Remediation) Regulations 2009 (SI 2009/153) as amended SI 2009/3275, SI 2010/587 o The Environmental Noise (England) Regulations 2006 (SI 2006/2238) as amended SI 2008/375, SI 2009/1610, SI 2010/340 o The Environmental Protection (Disposal of Polychlorinated Biphenyls and other Dangerous Substances) (England and Wales) Regulations 2000 (SI 2000/1043) as amended SI 2000/3359 o The Environmental Protection (Controls on Ozone-Depleting Substances) Regulations 2011 (SI 2011/1543) o The Ozone-Depleting Substances (Qualifications) Regulations 2009 (SI 2009/216) o The Fluorinated Greenhouse Gases Regulations 2009 (SI 2009/261) o Clean Air Act 1993 as amended SI (2014/3318) o The Smoke Control Areas (Authorised Fuels) (England) Regulations 2014 (SI 2014/2366) o Control of Pollution Act (COPA) 1974: Part III as amended by the Environmental Protection Act 1990, Water Resources Act 1991, Water Industry Act 1991, Noise and Statutory Nuisance Act 1993 o Anti-Pollution Works Regulations 1999 (SI 1999/1006) o Control of Pesticides Regulations 1986 (SI 1986/1510) as amended SI 2007/188 o The Plant Protection Products (Sustainable Use) Regulations 2012 (SI 2012/1657) o The Control of Substances Hazardous to Health (COSHH) Regulations 2002 (SI 2002/2677) as amended SI 2003/978, SI 2004/3386 o The Control of Asbestos in the Air Regulations 1990 (SI 1990/556) o Control of Asbestos Regulations 2012 (SI 2012/632) o Radioactive Substances Act 1993 as amended SSI 2011/147, SSI 2011/207, SR 2011/289, SR 2011/290 o The Environmental Permitting (England & Wales) Regulations 2010 (SI 2010/675 Page 6 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure o Gas Safety (Installation and Use) Regulations 1998 UCLan’s Environmental Aspects Register (FMENV004) identifies the University’s use of gases (including refrigerant) and the delivery and storage of hazardous materials as having the most significant impact on the environment. This aspect will therefore be the focus of our mitigation and management within the EMS. However, as a matter of good practice we will also outline operational controls required to ensure pollution prevention in line with related legal requirements. 1.2 Scope This document applies to operations conducted from the University’s Preston campuses. Normal Condition Management of Asbestos Register Management of F-Gas Register Storage and use of compressed and liquid gases Operation of air conditioning systems Small volumes of environmentally hazardous substances are used and disposed of Normal deliveries of diesel and heating oil Fat and silt traps in operation Production of dust and ceramic fumes, lab fume cupboards. Abnormal Condition Identification of a leak of refrigerant gas Leak of compressed gas or liquid Larger quantities of oil are disposed of from workshops in Wharf Larger volumes of environmentally hazardous substances are used and disposed of Oil spill during delivery or disposal Noise from construction projects, evening sports games at the University Sports Arena or race car preparation in motorsport workshops Emergency Condition Large fuel leak during delivery or collection Major chemical spill, e.g. during transport to hazardous waste stores Fire in hazardous waste stores 1.3 Responsibilities This document applies to staff within the University who are involved in; ordering, delivery, storage, use and/or disposal of environmentally hazardous materials. These general responsibilities are summarized in the table below. Further details of specific role responsibilities can be accessed in FMENV003 EMS Manual, section 4.1.4 responsibility, roles, resources and authority. Legal or other requirement Responsibility Operational control The Control of Pollution (Oil Storage) (England) Regulations 2001 Building Services Manager Grounds Maintenance Manager Building Surveyors (including Principals) Catering Manager FM ENV 019 UCLan Emergency Plan Page 7 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Water Industry Act 1991 Water Industry Act Amendment Regulations (England and Wales) 2009 SI3104 Building Surveyors LIS Technicians Academic staff labs Post graduate researchers (labs) Grounds Staff Maintenance Engineers FM ENV 019 UCLan Emergency Plan (Section 2.2.3) Control of Pesticides Regulations 1986 (as amended) (COPR) Grounds Maintenance Manager FM ENV 019 Building Services Manager FM ENV 012 (Regarding inspections of efficiency of systems) FMENV019 (Regarding leaks and competency) UCLan F-Gas Register Waste (See section 1.3 if FMENV016 Waste Management) Numerous, see FMENV016 for details. FM ENV 016 Contaminated Land (England) Regulations 2006 SI 1380 Building Surveyors Estates Manager FM ENV 015 FM ENV 019 Environmental Noise (England) (Amendment) Regulations 2009 (SI2009/1610) SHE Section – monitoring Building Surveyors - projects Student Union and University Sports Arena Management Events FM ENV 019 Gas Safety (Installation and Use) Regulations 1998 and subsequent amendments. Building Services Manager FM ENV 012 (Section 6.4.8 – details of legal requirements) FMENV 019 - Description & responsibilities. Clean Air Act 1993 as amended SI (2014/3318) The Smoke Control Areas (Authorised Fuels) (England) Regulations 2014 (SI 2014/2366) Building Services Manager FMENVREC 113 Control of Asbestos Regulations 2006, SI 2739 Asbestos Guidance HSG246 Statutory Compliance Manager Building Surveyors UCLan Asbestos Register A1370 Policy & Procedure for the Control of Legionella Bacteria in Water Systems Statutory Compliance Manager A1370 Policy & Procedure for Control of Legionella Bacteria in Water Systems. COSHH, Control of Substances Hazardous to Health Regulations 2002/ 2003/ 2004 SHE Section - Procedure Users FM SHE 005 The Plant Protection Products (Sustainable Use) Regulations 2012 (SI 2012/1657) Ozone Depleting Substances: Environmental Protection (Controls on Ozone-Depleting Substances) Regulations 2002 Fluorinated Greenhouse Gases Regulations (F-Gas Regulations) 2008 (SI 41) Ozone depleting substances (Qualification) Regulations 2009 (See Section 6.4.3 of FMENV012 Use of Natural Resources) Page 8 of 28 FM SHE 021 Guidance on Compliance with the Noise Activity at Work Regulations 2005 FM ENV 019 Pollution Prevention - Environmental Management Procedure Radioactive Substances Act 1993 The Environmental permitting (England & Wales) Regulations 2010 Authorisation to accumulate & dispose of radioactive waste no. AV0266 Safety, Health & Environment Manager (Radiation Proctection Officer) Radiation Protection Supervisors FM SHE 022 Local Rules for unsealed radioactive sources. FM SHE 023 Local Rules for sealed radioactive sources Environmental Protection (Disposal of Polychlorinated Biphenyls (PCBs) and other Dangerous Substances) (England and Wales) Regulations SI 2000/1043 Building Services Manager FM ENV REC 008 Record of PCB Levels in UCLan Transformers The Environmental Damage Regulations 2009 Anti-Pollution Works Regs 1999 Building Surveyors FM ENV 0015 MOT Vehicle Emissions Test Business Services Manager Fleet Vehicle Servicing Schedule FMENV017 Travel / Transport – Environmental Management Procedure Greenhouse Gas Emissions (See section 1.3 if FMENV012 Use of Natural Resources) Numerous, see FMENV012 for details. FMENV012 Clean Neighborhoods and Environment Act 2005 Buildings Operations Manager FMENV019 1.3.1 Role Competence Within FM ENV 018 EMS Training Needs Analysis the training and development required by the roles listed in section 1.3 are outlined to ensure adequate experience and competence. 1.4 Continual Improvement The University will monitor the implementation of the operational controls identified within this procedure using a combination of internal audits and targets. These targets will be part of a programme of improvement under an overall continual improvement objective for land development and buildings within FM ENV 020 Environmental Management Plan. Page 9 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 2 Emergency Response This section describes the steps to be taken to prevent pollution occurring in the event of an incident. Figure 2, summarises emergency response order of action to be taken. Environmental Environmental incident incident is is witnessed/found witnessed/found en en Notification of incident Ext 333 Staff/student/visitor/public external source e.g. Environment Agency, United Utilities Y Y emergency plan? * Security Supervisor N N Initiate Emergency Plan Follow relevant plan in section 2 of Emergency Plan file Initial Responder, could be: Security Buildings Staff Local Manager Use section2.1 below to determine the scale of the incident. If atominor or major Use section2.1 below determine the incident of the following people can scale of one the incident. If a minor or major decide putof the Emergency Plan into incidenttoone the following people can action: decide to put the Emergency Plan into *action: Directorate ** FM Emergency Management Team Directorate ** Security Supervisor FM Emergency Management Team Does the Does the incident warrant incident use of the warrant use of emergency the plan? Determine Incident Level Figure 2 Emergency Response – Order of Action 1. 2. 3. 4. 5. 6. Contact a member Contact: of either: Relevant operational wasteor & recycling or team S,H,E.g. E section grounds Spill containment trained staff (see FMENVREC049 for list of competent persons Spill containment trained staff and spill kit locations) Order of Action: Put on appropriate PPE Plug source of spill/ leak Contain environmentally hazardous material Clean Up spillage Dispose of contaminated clean up materials Request restock of spill kit used (FMENVREC030 or follow local procedures) Site drainage plans indicating key containment points for higher risk buildings available from Building Managers, Security & on S Drive/FM Office/Env & Sustainability/Drainage Plans. Witness/ reporter/ clean up team member to complete an Environmental Incident/ Near Miss/ Nonconformity Form (FMENVREC040). Security will use ‘Campus Security Reports’ instead. Submit form to SHE Section (shesection@uclan.ac.uk) Key Start of process End of process Connector to separate process Reference Environmental Control Page 10 of 28 Environment & Sustainability Manager to investigate conditions of the incident and manage preventative action as necessary, in line with the University Incident Investigation Procedure (FMSHE056) and as identified in section 4.7.3 & 5.3 of this manual. FM ENV 019 Pollution Prevention - Environmental Management Procedure The EMS Manual (FMENV003) Section 4.7 details the procedure for notification and reporting of an environmental incident. 2.1 Determining the type of response necessary If the incident involves incident level 1 or 2 a member of either Directorate or the Facilities Management (FM) Management Team must decide if the University Emergency Management Plan should be initiated: Incident Level 1 Leakage or spillage of oil, other hazardous substances or waste that escapes from the site (e.g. A brook, canal, river, air or uncovered ground). 2 An exemption limit has been breached. A list of exemptions that the University has for our operations (water and waste) can be found on the staff intranet. If the incident involves incident level 3 or 4 use the steps outlined in section 2.2 to mitigate the environmental impact and clean up: Incident Level 3 A leakage or spillage of an environmentally hazardous substance that is contained on site but may require significant clean up. 4 A leakage or spillage of an environmentally hazardous substance that is contained within the local area, has not caused contamination and requires a relatively minor clean up. All other incidents for example a complaint about noise should be reported using the procedure laid out in the EMS Manual (FMENV003), Section 4.7. These will then be investigated and corrective / preventative action taken as required. 2.2 Dealing with spillage and release of Environmentally Hazardous Substances Releases and spillages of environmentally hazardous substances (e.g. any substance that if released into the environment would cause damage, including; oils, chemicals, inks, dairy products) need to be dealt with safely and effectively in order to reduce the risk of injury to people, damage to University premises and the environment. During an incident the safeguarding of life and health is paramount and should not be compromised in order to protect equipment, buildings or the environment. Before purchasing hazardous substances information regarding risks associated with that substance is required to be obtained. Spillage procedures are part of that information. Page 11 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Initial Action In the event of a release or spillage of a hazardous substance take the following action: Move away from the site of the spill or release; Seal off the area and alert others in the vicinity; Try to identify what you saw; Raise the alarm o If you feel any spillage is too large or dangerous for you to control, obtain help, call the Fire Brigade immediately by dialling 333 on any University phone; or, o For large spillages/releases of flammable liquids/gases (>5 litres) sound the fire alarm to initiate full evacuation of the building and call out the emergency services; or, o If there are local spill containment trained staff call them to the scene, if not call security by dialling 2068 who will then contact the most relevant person from the list of competent persons FMENVREC049. Locate the relevant COSHH Assessment or Material Safety Data Sheet (MSDS). Attend to people who may be contaminated with the spilled material. Remove contaminated clothing immediately and wash the skin with water for up to 15 minutes. If a shower or hose is needed to aid this process these can be found in MB248, DB028 and the Stewart Building. Contact a First Aid Officer and/or the emergency services. Cleaning up spillages The relevant competent person will decide if the spillage clean-up is within the capabilities of the locally trained spill containment trained staff, if not a member of Directorate or the FM Management Team must be contacted to activate the Emergency Plan. Location of spill kits and staff responsible for ensuring kits are restocked can be found in FMENVREC049 located on the staff intranet within the FM Resource Centre. Each spill kit is also labelled with details of the person responsible for restocking and they must be informed of items used to enable them to maintain stock levels. The Environment and Sustainability Manager(s) conduct checks on the oil selective ‘grab and go’ spill kits and the hazardous waste store kit as part of the internal audits on pollution prevention. The Principal Technician (Labs) is responsible for restocking the chemical ‘grab and go’ spill kits and for checking contents. Prior to starting a clean-up, the hazardous substance(s) must be identified so that appropriate personal protective equipment and/or respiratory protective equipment can be chosen for the task. This information will be found on the COSHH Assessment. Do: Wear suitable personal or respiratory protective equipment at all times; Use the absorbent material in the spill kits to soak up any liquid spills; Protect potential drainage points with spill booms or absorbent pads; Work from the outside, circling to the inside for final pick up of the spilled material; Ventilate the area by opening windows; Pack the contaminated absorbent material and any contaminated equipment, other substances (e.g. contaminated soil) in a sealable container (if using bags ensure at least 2 are used) of a compatible material and dispose of as you would of the material that has been cleaned up. So if the material would have been a hazardous waste, the absorbent materials must be disposed of as such; Page 12 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Fully label all containers of contaminated material with the name of the spilled substance, associated hazards and type of contents contaminated (e.g. absorbent pads); Ensure the area affected, adjacent areas and equipment are fully decontaminated (Check floors directly above/below as appropriate); Ensure all spill equipment is decontaminated before it is returned to the spill kit (brushes, mops, PPE etc); Complete a FMENVREC028a Hazardous waste transfer note; Report all spillages/releases to the SHE Section on an Environmental Incident/ Near Miss/ Nonconformity Reporting Form (FMENVREC040) Ensure the spill kit is replenished, by contacting the relevant responsible person detailed in the table above. Do not: Rush into an area where the hazards have not been fully identified; Attempt to clean up a spill while you are alone; Walk through any spilt material. Try to reduce contamination of a wider area; Allow staff and student to re-enter an area until it has been fully decontaminated; General Health and Safety Precautions The main risks to the health and safety of personnel involved in the spillage/pollution operation are: Fire/explosion & Inhalation of toxic fumes Contamination of skin/body surface Asphyxiation due to oxygen starvation All members of University staff who are trained to deal with spillages, should be aware of the risks, and should consider the following guidelines when dealing with a spillage: Approach the spillage from an upwind direction Wear the appropriate protective clothing Remove the contaminated clothing as soon as possible Seek medical advice if ill effects are experienced Do not smoke Do not operate electrical or battery powered equipment, unless told it is safe to do so. Do not eat or drink with contaminated hands or whilst wearing contaminated clothing Page 13 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 3 Preventative Operational Controls In many cases, pollution incidents can be prevented if appropriate pollution prevention measures are in place or immediately available. It is the duty of all members of the University to ensure that where possible, they do not knowingly contribute to such an incident. Environmental legislation exists to ensure only acceptable quantities of substances are released into the environment. This procedure documents the preventative operational controls taken by the University to ensure legal compliance and prevent pollution. Common Causes of Pollution Pollution incidents tend to result from a combination of causes, which include: 3.1 Inadequate storage tanks, bunds, valves and pipework. Lack of means of containment and appropriately intercepted drainage systems where products and vehicles are stored and handled, and where vehicles are washed down. Unforeseen equipment or installation failures. Inadequate procedures and non-compliance with procedures, including overfilling of tanks and other containers and accidental spillage during delivery/transfer and transport of products. Leaks due to vandalism, sabotage and fire. Lack of awareness or deliberate illegal disposal leading to misuse of surface waters for disposal of chemicals. Lack of briefing and supervision of contractors working on site. Oil Storage Oil accounts for over one quarter of all pollution incidents in the UK. Many drains lead directly to rivers, streams or lakes. If you allow oil to enter these drains, it has the same effect as pouring it directly into the watercourse. Oil is poisonous to fish and other wildlife and it smothers plants. Just two litres of oil could seriously pollute the volume of fresh water needed to fill an Olympic-size swimming pool and make it undrinkable. The University may be prosecuted and fined if oil from its site enters the ground or watercourses and may have to pay substantial clean-up costs. For the purpose of this procedure the term ‘oil’ includes: petrol, diesel, central-heating oil, lubricating oil, mineral oil, vegetable and plant oil. To prevent oil spills and ensure legal compliance; University staff purchasing oil, altering exiting oil storage facilities or creating new ones must ensure the following conditions are met: Deliveries and Collections Deliveries of oil and the collection of waste oil are supervised by a member of UCLan staff trained in spillage containment. A spill containment kit must be located to hand during the delivery or collection to ensure in the event of a spillage it can be contained before oil escapes to the drainage network, open soil or controlled water. This may involve moving the kit to an easily accessible position (potentially outside) prior to commencement of delivery. Page 14 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Before a delivery of oil is made to a bulk tank, a member of UCLan staff must verify to the delivery driver the empty capacity of the oil storage tank. Individuals involved in deliveries and collections must maintain records that demonstrate deliveries have been supervised and capacity checks completed where relevant using form FMENVREC050. Storage Wherever possible oil should be stored using a suitable container situated inside a building. The oil storage equipment must be strong enough to ensure that it is unlikely to burst or leak during ordinary use. Containers must be stored within a drip tray, bund or other suitable secondary containment system (SCS) to ensure any oil that escapes from its container is captured. It is the responsibility of staff purchasing oil or altering/ creating oil storage for use by the University to ensure the oil tanks, intermediate bulk containers and mobile bowsers (including diesel generators) being used, have a secondary containment system that must be able to hold: at least 110% of the volume of any single container in the storage area, or if there is more than one container, at least 110% of the largest container’s storage volume, or at least 25% of their total volume (whichever is greater). For drum storage the drip tray must be able to hold at least 25% of the total storage capacity of the drums. The SCS should be positioned to minimise the risk of damage, e.g. from vehicles. Pipework The University Building Surveyors must ensure the following pipework requirements are met when altering or creating new oil storage facilities: All valves, filters, sight gauges, vent pipes and other equipment, other than fill pipes or draw-off pipes or pumps must be located within the SCS. The base and walls of the bund must not be penetrated by any valve, pipe or opening that is used for draining the system. If any fill pipe or draw-off pipe goes through the base or walls, the junction of the pipe with the base or walls must be sealed to prevent oil escaping from the system. Where a fill pipe is not within the SCS, a drip tray to catch any oil spilled when the container is being filled must be purchased and agreement/ procedure obtained from operational staff responsible for use of the facilities that ensures the drip tray is clean and empty before each delivery. Page 15 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Diesel Generators The University has the following static diesel generators located outside the following buildings: Building Adelphi C&T Media Darwin Darwin Size 500Kva 350 Kva 60 Kva 250 Kva 330 Kva Plant serial number FGWRPES4EPWC0040 FGWRPES200S04948 Musgrave FGWNAV01EFOA08598 D9A2A*7009154353 Tank Capacity 1000 Litres 820 Litres 50 Litres 550 Litres 820 Litres The Oil Storage Regulations rules apply to all of the stand by generators listed above, with the exception of the one at the Media Factory, because it is has a tank capacity of less than 200 litres. The Building Services Manager is responsible for ensuring the maintenance and refuelling of the static generators is compliant with the Oil Storage Regulations. A specialist maintenance contractor is employed to service (up to four times a year) and refuels the generators as required. Refuelling is undertaken by the specialist contractor using a mobile bowser which they bring with them and connect to the oil storage tanks. A member of UCLan Staff supervises all deliveries and is responsible for ensuring a spill containment kit is close by for use in case of a spillage. All of the static generators have integral, double skinned diesel storage tanks. The refuelling points are capped off and locked within the generator. Visual checks of each of the diesel generators are undertaken within the servicing contract. The University also has two mobile unleaded petrol generators which are stored in the Harrington Building Mains Room and the storage container on Vernon Car Park. FM Maintenance Section staff are responsible for the safe use of these generators including refuelling. Fuel is purchased by members of the section from a petrol station as required and transferred from portable containers into the generator. Within the secure compound at the University Sports Arena; oil, petrol and diesel are stored within bunded containers within a locked compound. Periodically oil transformers on site have their oil changed by the energy provider. The Building Services Manager checks that the relevant waste management licences are held by the contractor appointed. Data regarding the consumption of fuel and related greenhouse gas emissions is monitored by the Energy and Carbon Management Officer as described in FMENV012. 3.2 Water Pollution Almost any solid, liquid or gaseous substance entering surface waters or groundwater could cause pollution. Substances that are not usually considered harmful can cause serious damage if they are released into the water environment. These substances include: chemicals, salt, metals, wash waters, waste products, sewage effluent , trade effluents , sediments, oils, greases and fuel products, paint and ink, detergents, milk and milk products, fruit juice, hot water or contaminated rainwater. The Page 16 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure University uses and disposes of substances which are unsuitable for discharge to surface waters or groundwater without being treated first. There are different pieces of legislation that affect water, by being aware of the following terms, their meaning and complying with the preventative controls detailed, legislative compliance will be maintained and pollution incidents avoided: 3.2.1 Surface waters Surface waters include; rivers, lakes, reservoirs, ponds, streams, canals, ditches, coastal waters and estuaries. Surface water drains at the University Sports Arena (USA) discharge directly to surface waters. Staff must not allow poisonous, noxious or polluting matter to enter a surface water drains on this site (marked with a blue ‘S’) and reach surface waters or groundwater. On the Preston City Campus, United Utilities have confirmed (see FMENVREC 044 for details) that surface water drains are part of a combined foul/ surface system. All substances entering the surface water drains on this site will therefore pass through a water treatment plant. The surface water drains on this site are therefore not marked with a blue ‘S’. 3.2.2 Ground and Controlled Waters Groundwater is all water below the surface of the ground in the saturation zone, i.e. below the water table. If any of the arrangements described above change, the University must have a permit or authorisation from the Environment Agency before anything other than clean, uncontaminated run-off can be discharged to surface water or groundwater. Controlled waters are all surface waters, coastal waters and ground waters (this is groundwater and all water in the ground above the saturated zone i.e. above the water table). 3.2.3 Foul Water, Trade Effluent Foul waters are effluents that require treatment to improve their quality prior to discharge into the environment. Trade Effluent is any liquid waste (effluent) that is discharged from premises being used for a business, trade or industry. The University must comply with legal restrictions regarding how much trade effluent it discharges because people working in the confined space of a sewer can be at risk from even very small amounts of some chemicals. Trade effluent may consist of waste water contaminated with materials such as: fats, oils, greases, chemicals, detergents, heavy metal rinses, solids, food wastes and vehicle washings. The only liquid wastes which are not classed as trade effluent are: domestic sewage clean, uncontaminated surface water, i.e. clean rainwater which has not been contaminated when running over your site. Page 17 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure The generation of trade effluent is likely to need a consent or agreement from the sewerage undertaker to discharge to their sewers. Trade Effluent on the Preston City Campus: The University does not hold a trade effluent consent, therefore all the materials listed above are disposed in an alternative way, see table below. Material Type University disposal route/ procedure Operational controls Fats and oils Cooking oil is recycled using an external contractor, the Catering Manager is responsible for ensuring the disposal of this waste from refectory kitchens complies with the waste management procedure in FMENV016 as well as the following pollution prevention controls: Oil collection drums to have a capacity of less than 200litres. Drums to be stored in a secured location away from open drains. Collections to be supervised by a member of the catering staff who has received spill containment training and a form FMENVREC050 to be completed. Fat traps at Foster & Harrington Catering kitchens are maintained at least annually by FM Maintenance, the team’s KPI Schedule sets the frequency of inspections at quarterly, emptying at least annually. Associated disposal records to be kept in FM Development, Maintenance and Estates KPI Schedule. FMENV016 Waste Management Environmental Management Procedure FM Planned Preventative Maintenance (PPM) KPi schedule Motorsport/ Engineering oils Waste oils from these areas are disposed of as hazardous waste by LIS Technicians and collected by the external hazardous waste contractor in line with the waste management procedure FMENV016. Technicians take chemicals from across the University classed as any of the following: Explosive, Oxidizing, Flammable, Toxic, Harmful, Irritant, Corrosive, Dangerous to the Environment, or classified as Carcinogenic, Mutagenic, Teratogenic or Ecotoxic to the Hazardous Waste store in the Stewart Building for Hazardous Waste Disposal. School Level Procedure that complies with FMENV016. Chemicals Detergents Solids Page 18 of 28 The SHE Section is responsible for ensuring waste disposal is compliant with FMENV016. Only domestic quantities used i.e. Halls of residence launderette. FMENV016 Not applicable Silt traps have been installed in the following areas FMENV019 of the University: (1) Ceramics workshop, Victoria building FMENV015 FM ENV 019 Pollution Prevention - Environmental Management Procedure Responsibility: Maintenance Manager (Buildings) Sinks are fitted with silt traps, these are checked regularly and the contents emptied into a general waste bin. (2) Concrete Laboratory, Harris Building The disposal grid is fitted with a sump and settlement tank to allow slurry to settle out. It requires a technician to empty it. Responsibility: Maintenance Manager (Buildings) (3) Vehicle wash down area (USA). Responsibility: Grounds Maintenance Manager There is a vehicle wash off area at the University Sports Arena (USA) for ground vehicle use. Up to 2 vehicles may be washed down with water (no detergent) from a hose each day. A silt trap is fitted within the wash down area. The collection chamber is connected to the site foul sewer network. United Utilities have confirmed in writing that this facility is exempt from requiring a trade effluent discharge consent (FMENVREC088). Before each use grounds staff will check whether the silt trap needs emptying. If it does they will arrange for it to be emptied into a general waste bin. FM Planned Preventative Maintenance (KPI) schedule , disposal records stored in Schedule. FMENVREC088 The management of silt in site runoff water during a construction project will be managed by the Facilities Management Development Section in line with FMENV015. Food wastes No food waste is to be disposed of down the drain. FMENV016 An onsite in vessel composting facility has been commissioned to compost kitchen waste. The Catering Manager is responsible for ensuring the disposal of this waste from refectory kitchens complies with the waste management procedure in FMENV016. Vehicle washings Fleet vehicles that are road based are taken to a FMENV019 vehicle washing facility off campus. Campus sweeper wash down at Sizer house FMENVREC112 empties into the foul sewer. United Utilities request that drain grates to be cleaned regularly to remove solids. Responsibility: Recycling Officer Compost leachate At USA the compost facility has a leachate drain, connected to the United Utility Foul Sewer. During wet weather, covers will be used to minimise leachate. The Environment Agency Guidance Note ‘T23 Aerobic Composting and associated prior treatment’ details the limits on the volumes of waste that can be stored at any one time: Page 19 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure You can store or treat up to 80 tonnes of waste at a time if you are: composting waste generated on your farm and you are using the compost on your farmland. You can store or treat up to 60 tonnes of waste at a time if you are: bringing waste from other places onto your farm and composting it; or composting your farm waste and it is going to be used elsewhere. Depending on the circumstances outlined above you can compost either up to 60 or 80 tonnes of waste at a time. To minimise odour and leachate generation within these limits, you can compost up to: 10 tonnes of paper or cardboard 20 tonnes of manure 10 tonnes in total of the wastes listed in Table 2 of T23. Also to reduce the spread of evasive species, leachate and potential odour the compost heaps must be turned every 2 weeks and covered when not in use. FMENVREC111 details confirmation from United FMENVREC111 Utilities that no additional trade effluent consent is required for our composting leachate. 3.3 Fertilizer, Plant Protection Products The FM Grounds Maintenance Section use fertilizers and weedkiller on the pitches at the University Sports Arena. The University is committed to using as little of these products as possible. Where their use is necessary, products with the most negligible environmental impact should be purchased. The Grounds Maintenance Manager is responsible for: Conducting an annual soil analysis to inform the mix of fertilisers required over the following year and ordering products accordingly; Ensuring only approved substances are purchased (further details of the main approval agencies are listed in the Register of Environmental Legal and Other Requirements (Newground Legal Update Service) ); Ensuring the secure storage of the products away from surface water drainage; Ensuring the application by square meter of the products is efficient in relation to need, to prevent the excessive consumption of resources and prevent pollution; Ensuring that team members are trained in the sustainable use of products; Ensuring grounds equipment is brushed down before being hosed off in the vehicle wash down area to minimise the amount of product washed into the foul sewer. Page 20 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure The products used by the University; their format, storage location and likely volumes are listed in the following table: Name of Product Quantity of Product Responsibility and description of product distribution on site. Storage location of product N:P:K (nitrogen, phosphorus, potassium) fertiliser 12 tonnes per year cyclone spreader to all turf areas as required Granules Storage shed at USA trace nutrient supplements 1 tonne per year Cyclone spreader as required Sand based pitches Micro granules Storage shed at USA fish blood and bone 0.5 tonne per year hand applied to flower/shrub beds as required Micro granules Storage shed at USA roundup pro-biactive 50-55 litres per year Storage shed at USA selective herbicide 20 litres in one application biannually granulated calcium 2 tonnes per year pedestrian sprayers all hard surface areas as required Liquid Liquid Bulk spraying of selective herbicide to all pitches and surrounds. Liquid pH correction on sand pitches Granules Bunded container at USA. Storage shed at USA Currently (April 14) herbicides are stored in a locked bunded container within a locked compound (labeled pesticides). The quantity of products stored on site depends upon conditions, needs and may fluctuate annually. Page 21 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 3.4 Ozone Depleting Substances/F- Gases There are two types of refrigeration and air-conditioning units (RAC) at UCLan that use refrigerant gas; Split air conditioners and chillers. Refrigerants in RAC systems may contain: Ozone Depleting Substances (ODS) –e.g. hydrochlorofluorocarbons (HCFCs) Fluorinated Greenhouse Gases (F Gases) –e.g. hydrofluorocarbons (HFCs) Ozone Depleting Substances (ODS) are substances that if allowed to escape would damage the ozone layer in the upper atmosphere. Many ODS are banned (e.g Chlorofluorocarbons (CFCs)) or being phased out and must not be released into the atmosphere; the use of HCFCs in new equipment was banned in 2001 and on 1st January 2015 the use of ‘recycled’ and ‘reclaimed’ HCFCs to top up or service existing equipment was also banned. F gases are powerful greenhouse gases which are often used as a replacement for ODS and are themselves carefully controlled because of their high global warming potential and are also subject to a phase down. The University employs specialist maintenance contractors to service, maintain and repair these refrigeration and air-conditioning equipment. It is the responsibility of the Building Services Manager to keep Records (F-gas Register) and manage these contracts to ensure that contractors have the correct licensing certificates in place and ensure the following: Equipment is tested for leaks All gases are recovered during servicing, maintenance and at the end of the equipment's life; Qualified personnel are employed to service and decommission the equipment (see below); Gas is transported in refillable containers; Containers are labelled as reclaimed with the batch number and the source; Records are kept about the University’s equipment, including service history; Leaks if found are repaired within 14 days; Systems are re-checked for leaks within one month of repair. Service and maintenance personnel working on HFC and HCFC RAC systems at UCLan must hold, or be supervised by someone, who has one of the following minimum qualifications: City & Guilds Level 2 Award F-Gas and ODS Regulations 2079-13 Construction Industry Training Board Safe Handling of Refrigerants Reference J11-14 The level of qualification required depends on the specific task involved. Sulphur hexafluoride is a powerful F-gas used in small quantities in the transmission electron microscope. Under the F-gas Regulations the supplier is required to confirm its legitimate use before future supplies are made. Responsibility: Principal Technician. Page 22 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 3.5 Waste Management The University produces around 1200 tonnes of waste each year and this is consequently identified as one of the University’s significant environmental aspects. A detailed Waste Management Procedure (FMENV016) has been developed as part of the EMS. FMENV016 describes the management steps and responsibilities for ensuring waste is collected, stored and disposed of to ensure legal compliance and the prevention of pollution. NOTE: All refrigeration appliances must be disposed as hazardous waste to a licensed waste contractor or returned to supplier of replacement appliances as WEEE to ensure refrigerants are disposed of correctly. 3.6 Contaminated Land Many areas of land in the UK are contaminated by previous industrial activities. There is also the potential for University activities to cause land contamination following a spillage or leak of a chemical or fuel. Contaminated land may be hazardous to the environment and human health. Site purchase Before purchasing a new site it is important to conduct due diligence investigations to identify any historical land contamination. These preventative requirements and related responsibilities are detailed in the Land Development and Buildings Environmental Management Procedure (FMENV015). Prevention of land contamination Staff involved in the purchase, storage, use, disposal of chemicals, fuels and solvents as well as the design of the facilities for storage, use and disposal of them should wherever possible adhere to the following best practice to prevent land contamination: Description of Best Practice Responsible Operational Control Person Source the least harmful Staff Recommendation Only - Local controls chemicals and solvents for each purchasing the application. material If no alternatives exist, try to Staff using the Recommendation Only - Local controls reduce the amount that is used, material and only store the amount that you actually need at any time. Regularly inspect and maintain all Staff using the Report any concerns to the FM plant, pipework and other plant, pipework Helpdesk to be progressed using: FM infrastructure, checking for and University Reactive Maintenance damage, leaks and overflows. infrastructure Response Times for Repairs. Keep materials that could harm Staff Relevant sections within this procedure the environment separate from purchasing FMENV019. other materials at all times. This and using the includes: oils, solvents, materials pesticides, chemicals, radioactive substances. Store materials that could Staff Ensure that materials that could Page 23 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure contaminate land in strong, sealed and clearly labelled containers. Store all oil and chemicals in an area where spills can be contained. responsible for storing the materials Staff responsible for storing the materials Supervise deliveries of materials Grounds and fuels to site. Clearly label Maintenance tanks with their contents and Manager storage capacity and provide a method for measuring the amount in the tank. This will reduce the risk of spills from overfilling. contaminate are kept in strong, sealed and clearly labelled containers. Store all oil and chemicals in an area where spills can be contained. This should be within an impermeable bund or secondary containment system (SCS). For further information see section 3.1 on oil storage University Sports Arena – The Grounds Maintenance Manager is responsible for carrying out a monthly dip test within the double skin of the diesel storage tank to check that the secondary containment system (SCS) has not be compromised. Checks will be recorded on the form FMENVREC051. If the second skin is found to be compromised, the tank should be drained and repaired or replaced as a matter of urgency. In both cases maintain records that confirm that deliveries have been supervised using FMENVREC050, see section 3.1. 3.7 Environmental Nuisance The University is committed to ensuring that disturbance and nuisance especially noise arising from our operations is kept to an acceptable level through the following operational controls. Potential sources of nuisance on campus are as follows: Potential source of nuisance Sensitive Receptors Management Controls Responsibility Construction/ Building Work Residential neighbours Contractors required to register with considerate construction scheme, the scheme audits its members: www.ccscheme.org.uk Working hours limited to 07.00 – 21.00. Occasionally work has to be undertaken outside these hours, notification given in advance to neighbours. Main contractor FM Development Project Officer Fire Alarms Residential neighbours Maintenance of alarm systems Activation procedures KPI on false activations FM Security FM Building and Accommodation Staff FM Page 24 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure Commuting Staff/ student parking in residential streets Implementation of the University Travel Plan Director of FM Sustainable Travel Coordinator Grounds Maintenance Equipment Residential neighbours Working hours are limited between 07.30 – 18.00 Grounds Maintenance Manager Biomass Boilerrestocking pellets Halls of Residences Pellet delivery & restocking limited between 10:00 - 15:00 Building Services Manager Students Union – Entertainment Venue Residential neighbours Students Union has been sound proofed to limit nuisance. SU run awareness campaigns about leaving the venue quietly, annually. SU General Manager (outside scope of UCLan’s EMS) Motor Sports Engine Testing Residential neighbours Tests are conducted during the day and indoors to limit nuisance. Motor Sports teaching staff and technicians Sports Arena – during matches, including the use of floodlighting Residential neighbours Operating hours are restricted to 09.00 – 10.00 (Mon – Thurs), 09.00 – 19.30 (Fri), 09.00 – 18.00 (SatSun). USA Development Manager USA Duty Manager Litter Neighbours Provision of litter bins on campus and regular emptying, street cleaning and litter picking services. Building Services Waste and Recycling Service The City Council have a licensing scheme in place to control the free distribution of literature. Procedure FMENV016 on Waste Management details the procedure in the case of illegally dumped waste on campus. Any stakeholder complaints relating to nuisance should be directed to the School or Service responsible for the operations cited in the complaint, see table above. Due to the structure of the University, the majority of activities listed above, identified as potential sources of complaint, are managed by Facilities Management. A copy of the communications should be forwarded to the Facilities Management Information Officer in the Estates Section, in order that central details can be kept on file. Complaints relating to nuisance should be logged on an Environmental Incident/ Near Miss/ Nonconformity Reporting Form (FMENVREC040), the completed form should be sent to the Environment and Sustainability Manager for entering on the EMS Action Tracking System (FM ENV REC 027). The SHE Section are responsible for conducting noise assessments as required to identify if noise complaints are justified, details of the assessment should be forwarded to the Environment and Sustainability Manager who will update the EMS Action Tracking System accordingly. Page 25 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 3.8 Asbestos Asbestos fibres can be very damaging to human health and the environment. Asbestos is toxic and does not break down easily. As a result it remains in the environment for a long time. Asbestos was used extensively in construction and building maintenance during the 1940s1990s for its insulation and fire-proofing properties. The use of asbestos has been banned since 1999. It may be found in any building built or refurbished before 2000, in the floor, wall, ceiling or roofing materials, or in contaminated soils. The University’s Statutory Compliance Manager is responsible for the management of the University’s Asbestos Register, in line with the Control of Asbestos Regulations 2006, SI 2739 and the more recent Asbestos Guidance HSG246. University Project Officers are required to obtain a Type 3 Asbestos survey prior to ordering intrusive work. 3.9 COSHH Delivery and handling of chemicals on our sites can cause pollution if containers leak for example. Any chemicals received by the University must be supplied with a materials safety data sheet (MSDS). The MSDS contains information about the chemical, including how to store, use and dispose of it safely. The MSDS may also recommend the best methods and materials to use for cleaning up a spill. If a chemical is received without an MSDS, contact the supplier to find out whether or not they have to provide one. Staff who receive deliveries or organise the storage of chemicals on site are responsible for ensuring the following pollution prevention measures are undertaken: 3.10 Deliveries of chemicals and fuels must be supervised by a member of UCLan staff; Label all tanks and containers clearly with their contents and storage capacity. Check levels before deliveries to prevent overfilling and spills; Locate delivery areas to minimise the vehicle movements on site; Drains from delivery areas should connect to the foul sewer; The delivery area should have an impermeable surface; If filling tanks, intermediate bulk containers (IBCs) or mobile bowsers, check that delivery pipes have automatic cut-off valves to prevent overfilling. Radioactive Materials Low level radioactive materials (unsealed and sealed) are used within research and teaching. Under the Radioactive Substances Act 1993 and Environmental Permitting (England & Wales) Regulations 2010 the University has an ‘Authorisation to accumulate & dispose of unsealed radioactive waste no. AV0266’. Local Rules are in place within each area that uses radioactive substances; FM SHE 022 Local Rules for unsealed radioactive sources and FM SHE 023 Local Rules for sealed radioactive sources. The University’s Radiation Protection Officer (SHE Manager) is responsible for compliance with all legislation regarding radioactive substances. Page 26 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure 3.11 Polychlorinated Biphenyls (PCBs) PCBs are a class of organic compounds which were widely used for many applications, especially as dielectric fluids in transformers, capacitors, and coolants. Due to PCB's toxicity and classification as a persistent organic pollutant, PCB production has now been banned. The University has a ‘Control Operation and Maintenance Agreement (Ref Number: 94060)’ with United Utilities Utility Solutions (Industrial) Limited for transformers used by the University. FMENVREC008 documents the transformers maintained by United Utilities and their confirmation that the PCB levels detected in these transformers is well below 50ppm, the recognised limit within the related regulations. 3.12 Smoke Control The University has installed a biomass boiler under the Renewable Heat Incentive (RHI). The campus is within a designated Smoke Control Area as designated by Preston City Council and therefore the boiler make and model must be listed as an exempt appliance by Defra. The biomass installed at Greenbank building is a Herz Firematic 199 which is an exempt appliance when burning wood or wood pellets and therefore permissible under the Smoke Control Areas (Authorised Fuels) (England) Regulations 2014. An RHI emissions certificate FMENVREC113 is confirmation that the boiler meets the RHI air quality requirements of the non-domestic RHI. Compliance under the Clean Air Act 1993 to ensure no dark smoke is emitted is via a service agreement with Rural Energy to service the boiler and to clean the flue and silo twice a year. Rural Energy also check the accuracy of the heat meter for compliance under the RHI. UCLan purchase ENplus standard wood pellets which ensure quality throughout the supply chain from production, delivery through to its use at UCLan. The highest grade quality wood pellets, A1 are also purchased to ensure the highest quality pellets that are available are used. These produce the least amount of ash and ensure that maintenance costs are kept low. The supplier of the wood pellets, Billingtons Bioenergy is an approved supplier of ENplus pellets. Responsibility: Building Services Manager, Energy and Carbon Management Officer 3.13 Gas Safety / Boiler Emissions The University must test the emissions of boilers annually to ensure they are; safe to use, efficiency is maximised and unnecessary emissions to air minimised. The Building Services Manager is responsible for ensuring the necessary checks of boilers in estate buildings including halls of residence are conducted annually and in accordance with the requirements of the relevant legislation. The Building Services Manager contracts out the work to a registered Gas Safe Engineering firm for 3 year contracts, two tenders are sent out one for academic buildings and the other for halls of residence. The Building Services Manager is responsible for ensuring the following steps are taken: installation pipe work, appliances and flues are maintained in a safe condition; an annual safety check is carried out on each appliance and/or flue used; Page 27 of 28 FM ENV 019 Pollution Prevention - Environmental Management Procedure maintenance and annual safety checks are carried out by a Gas Safe registered installer; a record of each safety check is kept by the University for 2 years; in the case of halls of residence, the University must make available (from VE301) a copy of the safety check to each existing tenant within 28 days of a check being completed, and to any new tenant before they move in. This opportunity is communicated to residents as part of the Student Accommodation Code of Practice; all gas equipment (including any appliance left by a previous tenant) is safe or otherwise removed before re-letting; that only Gas Safe registered installers are used to carry out work on gas appliances, fittings and flues provided for tenants use. 3.14 Vehicle Emissions Section 6.1 of the University’s Travel and Transport Environmental Management Procedure (FMENV017) details how the University’s Fleet Vehicle Replacement Strategy gives consideration to the efficiency of replacement vehicles. The same section also describes how the University actively manages the servicing and MOTs of its fleet vehicles to ensure vehicle emissions are minimised. Responsibility: Business Services Manager The remainder of the Travel and Transport Environmental Management Procedure details the steps staff should take to ensure their necessary business travel is as sustainable as possible. In addition, the University’s Travel Plan is the primary tool for reducing solo car commuting by staff and students to the University. Responsibility: Sustainable Travel Coordinator 3.15 Greenhouse Gas Emissions The emission of Greenhouse Gases contributes to climate change and is identified as a significant environmental aspect of the University’s operations in relation to its use of natural resources (energy, fuel, water), travel and transport (business and commuter). As a result two specific environmental management procedures have been developed as part of the EMS to describe the management controls used to reduce the University’s emission of greenhouse gases: Use of Natural Resources Environmental Management Procedure (FMENV012) Travel and Transport Environmental Management Procedure (FMENV017) Page 28 of 28