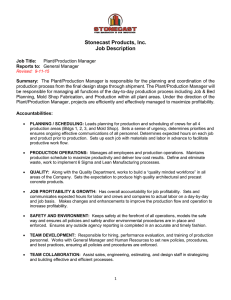

Stonecast Products Production / Quality Manager Job Description

advertisement

Stonecast Products Production / Quality Manager Job Description Updated 3 30 15 Reports to: General Manager SUMMARY: The Production / Quality Manager is responsible for providing leadership and direction to the facility, supporting the vision and values of the company. An ideal manager instills a “Culture of Quality and Safety” for all employees by promoting and modeling an employee driven and hazard controlled environment. Ensures employees are equipped to meet production and delivery schedules, quality expectations, and budgeted cost/efficiency expectations through sound resource planning and plant floor involvement. Holds self and employees accountable for implementation and adherence to all standards, policies & regulations for the safe, and environmentally compliant production of quality precast concrete products. Ensures employees are held accountable for the development and execution of all continuous improvement initiatives. Leads and directs employee training and development initiatives to ensure robust succession planning at all production levels. POSITION RESPONSIBILITIES PERFORMANCE & GROWTH Ensures daily productivity and efficiencies are achieved to result in a low cost operation. Leads the production team (Quality, Safety, Efficiency, and Preventative Maintenance & Housekeeping). Works to build a “quality minded” workforce in all areas of production. Ensures systems and processes exist in the facility to manufacture quality products at industry-leading efficiency levels. Has accountability for job profit and cost reduction in the plant. Sets expected hours for labor and crews and compares to actual labor on a day-by-day and job basis. Makes changes and enhancements to improve the production flow and quality initiatives to increase the profitability of the business. Supervise, onboard, and train new and existing production team members in disciplines that will improve performance and quality; provide leadership and development, succession planning, and learning opportunities. Creates a fun and motivating culture within plants. Exhibits the ability to make changes in staffing when required to ensure that all positions have the right level of talent that will drive the business forward. Leads the performance management goals of the business that includes identifying, communicating, and forward thinking, to establish Key Performance Metrics in the plant. Drive performance improvements in all areas of the plant and makes suggestions to management for improvements in other areas. Establish and monitor performance plans for employees; track key performance metrics and hold employees accountable for results. Manage daily production goals to meet or exceed budgeted cost and hours for each area of the plant, always looking for cost reduction opportunities. MOLD SHOP / PRODUCTION AREAS: Manages all production areas including Mold Shop and Plant. Along with scheduler, maintains production schedule to maximize productivity and deliver low cost results. Define and eliminate waste, implement 6 Sigma and Lean Manufacturing processes that improve productivity and reduce cost. Implements and maintains up-to-date scheduling boards for all areas of the business including mold shop, production, quality control, etching and shipping. Boards will communicate job information that is readily available to employees, including job, start date, end date, shift, daily and weekly goals posted, and actual performance vs. goal. Coordinates all communication with scheduling department, setting priorities for overall scheduling by taking into consideration, customer demands, change orders, design, mold shop, production capacity and profitability. Focuses on improvements in processes and procedures to enhance the daily operations. Holds daily meetings with crews to communicate expectations and hold employees accountable to do their job. QUALITY Oversees Quality Department, using experience and sound judgment to ensure production of high quality architectural and structural precast concrete products, including inspection, sampling, and testing. Builds and initiates a robust quality process, creating a “quality minded” approach to all production activity, and focuses to continually grow and improve the quality process on an ongoing basis. Ensures that all aspects of quality are in accordance with PCI Standards and revolve around superior quality standards. Prepares company for Precast Concrete Institute Audit every 6 months. Meets regularly with employees to discuss quality improvements and communicate quality expectations. Holds all employees accountable for knowing and understanding the quality process and implementing it into all production activity. Proactively coordinates objectives with production and quality procedures in cooperation with other departments to maximize reliability and minimize costs. Directs quality control inspections and testing activities to ensure continuous control over materials, facilities, and products. Conducts research and development as needed. SAFETY AND ENVIRONMENT Creates and sustains a safe working environment for the entire facility. Keeps safety, environment, and housekeeping as #1 priority for the workplace and all employees. Along with Safety Coordinator, creates, implements, and manages safety principles and practices as a core component of the workplace. Holds weekly tool box talks with all crews with signed document of completion. Ensures all employees understand that organization and neatness is a way of life. “A place for everything and everything in its place”. Safety and housekeeping must be “visual” within the operation and office environment at all times. “Tour ready” is the term to use every day. Holds monthly safety meetings with crews and staff, highlighting performance and new safety techniques. TEAM DEVELOPMENT Interviews and makes hiring decisions for production employees. Maintains training and job performance reviews on a regular basis (90 days, annually). Maintains documentation of all employee discussions and reviews in employee personnel files. Provides guidance and discipline of employees when needed. Leads employees with a developmental and team building mindset, optimizing talent and skill sets so crews work in a cross-discipline fashion in all production areas. In addition, ensure that all training and developmental activity is documented in employee personnel files. Expectations of crew and employees are established in job descriptions and explained to all individuals, holding all employees accountable for set expectations. Ensure employees understand quality requirements and that quality is built into product manufacturing. In addition, ensure that all necessary paperwork is complete. COMPETENCIES NECESSARY FOR SUCCESS Analytical Thinking: Ability to read architectural and commercial blueprints. Ability to do mental math quickly and calculate new formulas for improved performance. Knows computer languages and e-mail proficiently. Understands how to work within a business management system. Expertise in manufacturing computer systems and all components including design, costing, accounting, customer service, etc. Leadership: Able to motivate others to take personal responsibility; mobilize people to face, define, and solve problems; develop capacity of others to adapt to change; lead past status quo to achieve new levels of excellence or change. Respect: Create a strong leadership style that earns the respect of all employees; one that initiates a ‘buy in’ mentality into the values and goals of each department within the Company. Motivation: Able to present information or new ideas in such a way that others get excited; use a positive approach to motivate others at any level of the organization. Strategic Perspective: Able to develop long-term, big picture strategies to enhance competitiveness; recognize broad implications of issues; balance and integrate strategic vision with day-to-day activities. Develop Others: Able to mentor and help others learn from their mistakes; define and provide appropriate learning experiences to develop others; help others develop and achieve short and long-term goals; challenge others to think things through for themselves. Decisiveness: Able to use available information to draw a timely conclusion and take quick and timely action; make quick and timely decisions in stressful situations and when otherwise necessary. Team Building: Able to develop team effort; confront negative attitudes to build commitment and morale; get parties with competing perspectives to learn from one another; integrate efforts and talents of team members. Commitment / Diligence: Able to persevere in accomplishing tasks or objectives; commit to long hours of work; do everything possible to reach goals; have a sense of urgency about getting results. Prioritizing: Able to quickly focus on what is important; establish a sequence of tasks and completion dates; set priorities and allocate time and resources when faced with competing demands. Communication: Able to effectively deliver a message to employees, customers, vendors, or management team in a group or individual setting, so that it is received and understood. Being a good listener is the start of being a good communicator. Profitability: The ability to execute these leadership qualities is an instrumental part of increasing the profitability of the company. TREAT THE BUSINESS AS IF IT WERE YOUR OWN! ALL DECISIONS SHOULD BE BASED ON THIS STATEMENT