No01-ScrubBarOperations

advertisement

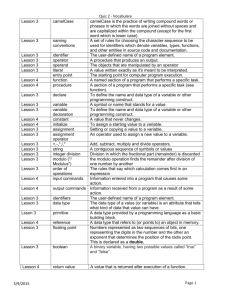

Code of Practice COP-1 Issued Nov 99, Reviewed Oct 2009 No 1 - SCRUBBAR OPERATIONS 1. BACKGROUND TO COP Reason for COP: To prevent personal injury and damage to plant when undertaking scrubbar operations. Scrubbars are used to cut long grass and bush from the sides of drains to maintain the efficiency of the drain. This work is generally conducted where mowers can not reach or the growth is too thick for mowers. Relevant Regulations: Dept of Labour COP for Safety & Health in Tree Work - Part 3 River & Stream Operations. Employee Training/Skills Reqd: Has undertaken a chainsaw/scrubbar operator's course. Purchasing Policy Tools/Plant: Plant purchased must have safety guards fitted. Correct blades will be supplied for the work undertaken. Staff will be provided with ergonomic harnesses, ear defenders and face shields/eye protection. Hard hats to be used when cutting overhead material or material greater than 1.6m high. 2. COP WORK PROCEDURE 1. Ensure supporting harness is adjusted to manufacturers’ instructions and worn when using scrubbar. Ensure emergency release system for the harness is working effectively. Check the weight of the saw is evenly spread and the blade is in the correct position. Ensure the handles are adjusted to give a comfortable working stance. Adjust as necessary. Before commencing operations visually check work area is clear of debris (wire, concrete, bottles etc) and wasp nests. To start - Place machine on level ground with the blade clear of debris. Ensure the blade remains stationary when the motor is in the idle position. If not inform workshop. On a daily basis, grease the blade gear box with manufacturers approved lubricant. Clean the air filter and motor fins of dust and debris weekly. Report any mechanical faults to workshop. Release throttle if blade jams and switch off if jamming persists. Cover or remove blade when the saw is not in use or is being carried to the work place by hand or in a vehicle. Remember carbide tips are expensive - look after them. Report ALL ACCIDENTS OR NEAR MISSES to your supervisor and complete an accident report. 2. 3. 4. 5. 6. 7. 8. 9. 10. Document1 Page 1of 2 Hazard Identification & Analysis Worksheet – HBRC Work Task, Activity or Item of Equipment What can cause harm? How could potential harm situation arise? Significant Hazard Yes/No* Controls that Reduce Harm 01 – Scrub Bar Operations Performing job/ general duties Refuelling and Maintenance Document1 Status Date: Oct 2009 Working outside generic hazards Eye injury from Incorrect or no PPE flying objects Too close to machine operator Using scrub bar too close to ground or debris N M Cuts and abrasions from flying objects Incorrect or no PPE Too close to machine operator Using scrub bar too close to ground or debris N M Limb injury from trip or fall Incorrect PPE Uneven or unsteady ground Underwater snags Y M I Industrial hearing loss Incorrect or no PPE Too close to machine operator Back injury/fatigue – Tiredness. Lasting back damage. Burns Harness incorrectly or not worn Working for excessive periods Poor fitness body condition N M M N M From exhaust From small fire N M Hand or limb, cut from blade changing Burns from fuel ignition Incorrect use of or no PPE Poor mtce of machine N M Haste and splash of fuel on hot exhaust Engine still running Y M Ref COP 00 – Generic Fieldworker Operations Minim PPE – Hard hat, enclosed visor, muffs, chaps, long sleeves and steel cap boots If not operating, maintain clear distance of > 20m Clear site of debris and operator training Minim PPE – Hard hat, enclosed visor, muffs, chaps, long sleeves and steel cap boots. Waders if in water. If not operating, maintain clear distance of > 20m Clear site of debris and operator training Minim PPE – Hard hat, enclosed visor, muffs, chaps, long sleeves and steel cap boots. Waders if in water. Ensure emergency release on harness operational If too wet postpone works. Clear site of debris and operator training Start machine on level ground Minim PPE – Hard hat, enclosed visor, muffs, chaps, long sleeves and steel cap boots If not operating, maintain clear distance of > 20m Ensure correct harness for machine Adjust harness for good fit. No cutting above chest height Ensure regular breaks and stretching Start machine on level ground Maintain safe working distances Work in groups monitoring each others work. Wear gloves Identify defects and regular mtce by workshop Ensure blade is motionless when idling Switch machine off Check/fill oil first to allow scrub bar time to cool Undertake back stretches as part of process to allow scrub bar time to cool In place In place Senior operator monitoring operation In place In place Senior operator monitoring operation In place In place In place Senior operator monitoring operation In place In place In place In place Senior operator monitoring operation In place Senior operator monitoring operation In place In place In place In place In place Page 2of 2