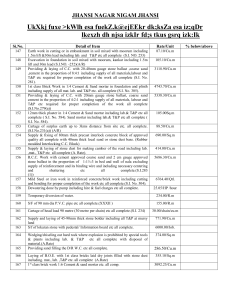

PROJECT DIRECTOR Public Works Department (PIU) MP BHOPAL

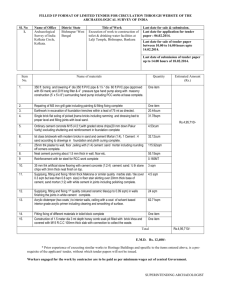

advertisement