Case Study - Volunteer State Community College

advertisement

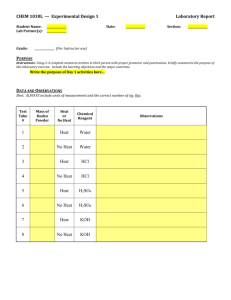

CHEM 1030L - Fundamentals of Chemistry Laboratory Case Study for Biofuels Fuel for Thought On Friday, September, 19th 2008, Zach headed to the local gas station to get gas before going to his morning class at Volunteer State. Gas prices had slightly moved upwards for a week. However, that morning gas was $4.69 per gallon and the cars were lined up out into the street. His father and grandfather had told him of similar stories of gas lines during 1973 and 1979 gas embargoes. One week earlier Hurricane Ike made its final landfall near Galveston, Texas as a strong Category 2 hurricane. At that time, Hurricane Ike became the third-costliest hurricane ever to make landfall in the United States, and the costliest hurricane in Texas history. It forced the shutdown of several oil refineries and crippled some for months. These refineries serve the Southeastern United States. Zach had $10.00 in his pocket and thought he could buy at least 4 gallons of gas. However, that morning his money barely bought 2 gallons of gas. Several years later Zach graduated with his Bachelor of Science degree in geology from the University of Tennessee and started his professional career as petroleum geologist and energy consultant. Zack reads the following letter that is published in The Tennessean: "Corn should be used as food, not fuel" The Tennessean Gerry Calhoun, Dec 1, 2012 Six million children died of starvation last year, while almost 100 million people went hungry. The cost of animal feed has sent meat and poultry prices spiraling. Yet, we burned 40 percent of America’s corn crop in our cars to the detriment of the poor throughout the world. Now, the federal government has recommended an increase from 10 percent to 15 or 20 percent of ethanol in every gas tank. Besides all the carbon dioxide created by converting corn to sugar to ethanol, the decreased mileage of this diluted gasoline makes drivers buy more fuel, thus canceling any net reduction of carbon emissions. So, why do national policies foster rising food prices and global hunger without really decreasing atmospheric pollution? It seems that Cargill and Arthur Daniels Midland built too many distilleries. Rather than write off such a mistake, they send legions of lobbyists to Congress to avoid losses by demanding we use more ethanol. Big Grain exceeds Big Oil in its lack of shame in pursuing obscene profits. Making matters worse, the summer drought eliminated as much as a tenth of this year’s corn harvest, pushing prices above $7 a bushel. At that level, it simply becomes too expensive for the world’s poor. U.S. taxpayers unwittingly fostered malnutrition and even starvation by allocating $6 billion for corn subsidies in 2011. Adapted from the Boyce Thompson Institute, CDW and Genecor Parris Powers, Douglas Williams, and Thomas Ekman, Volunteer State Community College, Gallatin, TN 3.29.2015 Another potential global disaster is the palm oil stampede. In Indonesia, areas the size of Maine long covered by rain forests are being burned. About 30,000 more square miles are poised to join the inferno because lucrative sales of palm oil have trumped biodiversity. Furthermore, burning the trees and then draining the bare peat soil releases immense quantities of greenhouse gases — about 558 million metric tons by 2020. Like alternatives to palm oil, alternatives to corn-based ethanol also exist. In Brazil, sugar cane already powers flex-fuel automobiles, and here in the U.S., sugar beets can produce twice as much ethanol per acre as corn. Such sources offer greater efficiency because neither involves the extra expense and CO2 generation of an initial conversion to sugar before their conversion to ethanol. The U.S. has already lowered its carbon footprint more than any other developed country. Reducing coal for power plants from over 50 percent to 39 percent, and increasing natural gas from 20 percent to 31 percent, has radically cut emissions because gas releases only half as much CO2 as coal. Also, the cheaper price of gas, thanks to abundant supplies generated by fracking and horizontal drilling, has pared the cost of producing electricity. We do not need to starve children or burn rain forests or subsidize Big Grain to reduce CO 2 emissions. Such draconian measures actually harm rather than protect the world. Now if someone would just figure out how to turn kudzu and switchgrass into food or fuel. As a partner with the National Science Foundation initiative – Collaborative Research: Community College Undergraduate Research (CCURI), students at Volunteer State have begun such investigations looking at switchgrass and kudzu as potential renewable biofuels to replace the use of corn. In past semesters, CHEM 1030 lab students investigated methods that could be used to produce biofuel from switchgrass. This semester, CHEM 1030 students will apply those same methods to kudzu, to see if this common invasive plant is a better potential source of biofuel. Adapted from the Boyce Thompson Institute, CDW and Genecor Parris Powers, Douglas Williams, and Thomas Ekman, Volunteer State Community College, Gallatin, TN 3.29.2015 Kudzu: From Biomass to Biofuel Student Pre-Lab Assignment The Big Picture: Think about how much energy you and your family use in a day. Between heating and using electricity in homes and schools and using gas to drive around, most of us use quite a bit of energy on a daily basis. Much of this energy comes from oil and other non-renewable sources. However, due to the high costs of these energy sources, and the negative impacts they have on the environment, biofuels (fuels that are produced from living or recently living plants, rather than from fossil fuels) are being investigated as renewable fuel alternative. In the Tennessee Valley region, where the climate is moist and humid, plants grow easily and produce lots of biomass. If we can meet some of our regional energy needs with locally produced plant materials, which are renewable resources, then we can better protect our environment. Before we can meet our regional energy needs with plant materials, we need to figure out the most efficient way to release glucose (sugar) from plant cell walls and use that glucose to produce biofuels for our transportation needs in the Southeast Region. Many people in Tennessee and neighboring states are figuring out how to use kudzu and other indigenous plants to make gas and other products. You can get involved, too. The Problem: Plant cell walls are strong, rigid, and difficult to break apart. If you have ever been in a forest and seen fallen trees and decaying plant material, you know it takes a very long time for plant material to break down. This material, known as cellulose, is made up of long chains of tightly bound glucose molecules. In order to make biofuels from cellulose, the long cellulose chains need to be broken down into individual glucose molecules. The glucose is fermented by microbes to produce CO2 gas and ethanol, which can be used as a fuel for vehicles. The Investigation: In this lab student researchers will try to find the best way to break down cellulose into glucose using a promising biofuel plant called kudzu. This is still a new science because no one has figured out a cheap and quick way to do this on a large scale. Pre-lab Questions Enter the response to each question in the Question and Analysis section of the Lab Report form. 1. How do you think cellulose is broken down in nature? (Think of the steps involved in a tree decaying in the forest) 2. List at least three environmental factors that might speed up the process of breaking down cellulose in nature. Adapted from the Boyce Thompson Institute, CDW and Genecor Parris Powers, Douglas Williams, and Thomas Ekman, Volunteer State Community College, Gallatin, TN 3.29.2015 Experimental Design Overview Because the process of converting plant materials to glucose requires several steps and is slow, three laboratory periods will be dedicated to this process and to evaluating the results, as briefly described below. Week 1 – Pretreatment of Kudzu: Student researchers will began by using several different methods of pretreating kudzu, with the ultimate goal of determining which pretreatments are best at breaking down the very tough plant cell walls. Pretreatment methods will include grinding, heating, and use of several chemical reagents (H2SO4, HCl or KOH). The goal of Week 1 is to breakdown plant cell walls and expose as much of the cellulose as possible for the next step of the process. Students will carefully consider all of the pretreatment options and write hypotheses describing which pretreatments are expected to break down plant cell walls the most and why. Desired Outcome by Week 2: Chemical pretreatment breaks down the plant cell walls and liberates cellulose molecules. Week 2 – Treatment with Enzyme: Students will neutralize the chemical pretreatment agents, adjust the pH of the experimental mixtures, and add an enzyme that will slowly convert the cellulose that has been freed by chemical pretreatment to glucose. Desired Outcome by Week 3: Enzyme added to cellulose breaks it down into glucose molecules. Week 3 – Glucose Measurement and Evaluation of Hypotheses: Students will measure the amount of glucose produced by each experimental mixture to determine which pretreatment was best at breaking down plant cell walls. Students will also compare their hypotheses from Week 1 with their results from Week 3 to determine whether the hypotheses were correct or incorrect. Finally, students will describe additional experiments that could be performed to further investigate new ways of breaking down plant cell walls to enable the production of glucose from kudzu. Desired Outcome of Week 3: Glucose concentrations measured, best pretreatment or pretreatments identified, hypotheses from Week 1 reviewed. At every step along the way, student researchers will carefully record all observations such as color and clarity of mixtures, exothermic or endothermic reactions, and any other observed change. Adapted from the Boyce Thompson Institute, CDW and Genecor Parris Powers, Douglas Williams, and Thomas Ekman, Volunteer State Community College, Gallatin, TN 3.29.2015