Bachelor/Master project

advertisement

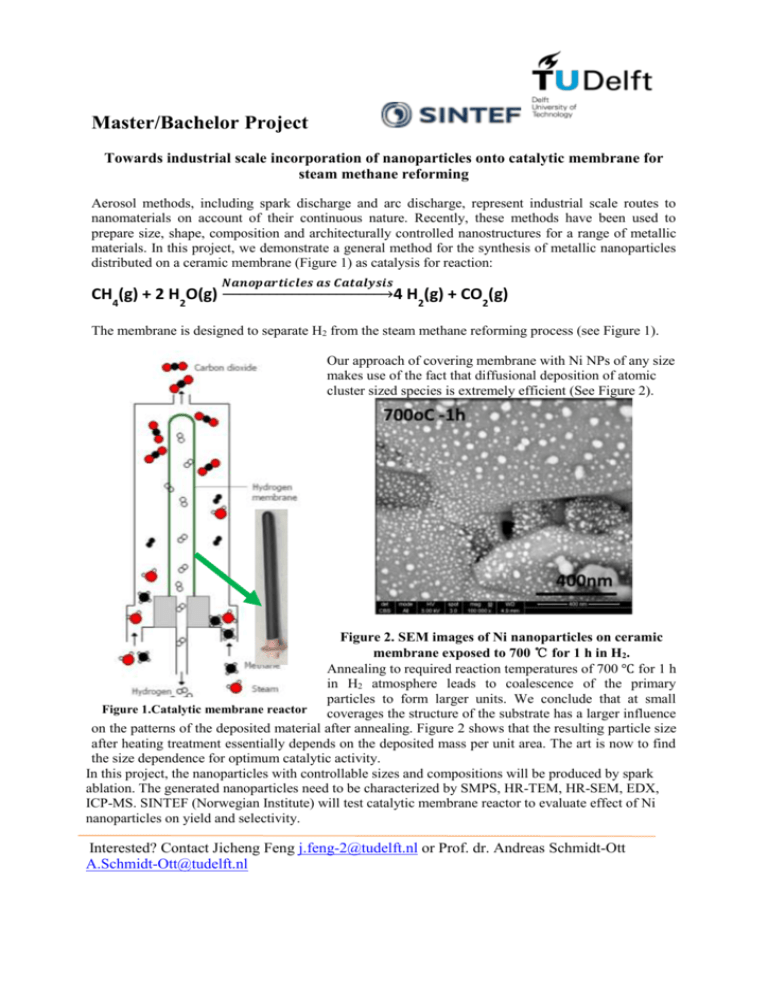

Master/Bachelor Project Towards industrial scale incorporation of nanoparticles onto catalytic membrane for steam methane reforming Aerosol methods, including spark discharge and arc discharge, represent industrial scale routes to nanomaterials on account of their continuous nature. Recently, these methods have been used to prepare size, shape, composition and architecturally controlled nanostructures for a range of metallic materials. In this project, we demonstrate a general method for the synthesis of metallic nanoparticles distributed on a ceramic membrane (Figure 1) as catalysis for reaction: 𝑵𝒂𝒏𝒐𝒑𝒂𝒓𝒕𝒊𝒄𝒍𝒆𝒔 𝒂𝒔 𝑪𝒂𝒕𝒂𝒍𝒚𝒔𝒊𝒔 CH4(g) + 2 H2O(g) → 4 H2(g) + CO2(g) The membrane is designed to separate H2 from the steam methane reforming process (see Figure 1). Our approach of covering membrane with Ni NPs of any size makes use of the fact that diffusional deposition of atomic cluster sized species is extremely efficient (See Figure 2). Figure 2. SEM images of Ni nanoparticles on ceramic membrane exposed to 700 ℃ for 1 h in H2. Annealing to required reaction temperatures of 700 ℃ for 1 h in H2 atmosphere leads to coalescence of the primary particles to form larger units. We conclude that at small Figure 1.Catalytic membrane reactor coverages the structure of the substrate has a larger influence on the patterns of the deposited material after annealing. Figure 2 shows that the resulting particle size after heating treatment essentially depends on the deposited mass per unit area. The art is now to find the size dependence for optimum catalytic activity. In this project, the nanoparticles with controllable sizes and compositions will be produced by spark ablation. The generated nanoparticles need to be characterized by SMPS, HR-TEM, HR-SEM, EDX, ICP-MS. SINTEF (Norwegian Institute) will test catalytic membrane reactor to evaluate effect of Ni nanoparticles on yield and selectivity. Interested? Contact Jicheng Feng j.feng-2@tudelft.nl or Prof. dr. Andreas Schmidt-Ott A.Schmidt-Ott@tudelft.nl