L 07 Pulse loading of resistors

advertisement

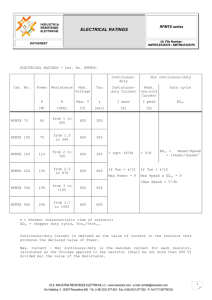

Passive Electronic Components Lecture 7 Page 1 of 11 01-May-2015 Pulse loading of resistors 1. Resistive element temperature estimation. 2. Physical phenomena related to pulse loading. 3. Pulse-proof chip resistors. Pulse loading of a resistor refers to short-time (commonly less than 1 second) voltage application to the resistor terminals. Safe limit of instantaneous power dissipated by the resistor for a short time may significantly exceed the rated steady state power dissipation. For example, steady-state power rating of a standard 1.6mm 0.8mm (RR 1608M) thick-film chip resistor at a temperature below 70C is 0.1W. The same resistor may safely survive single pulses with power of 1W, 3W, 10W and respectively 10ms, 1ms, 10s pulse duration. Excessive power applied to a resistor may cause one or more of the following phenomena in resistive element material: thermal decomposition, oxidation, electrical break-down, mechanical cracking. 1. Resistive element temperature estimation. Let us split the span of possible pulse durations as the following: Long-time pulses (from several milliseconds to several seconds). Significant part of generated heat escapes from the resistor to ambiance during pulse application. Maximum temperature in the resistor will depend mainly on heat transfer process from resistor to ambiance. Short-time pulses (from several nanoseconds to several microseconds). During pulse application almost all generated heat remains in the resistive element because pulse duration time is non-sufficient for significant amount of heat to escape out of resistive element. By other words, resistive element may be approximately regarded as thermally isolated (adiabatic process). Medium-time pulses (several milliseconds). Heat transfer inside the resistor (for example from film resistive element to ceramic substrate) cannot be ignored while insignificant heat flow out of the resistor (to PCB) may be ignored. 1.1. Long-time pulses (from several milliseconds to several seconds). Lumped resistor model will be used for its temperature estimation. Suppose that resistor is a uniform solid body. Resistor itself and its relationship with the ambiance are characterized by the following parameters: c – specific heat capacity of its material [J/(kgK)], m – mass of the resistor [kg], Rt – thermal resistance between the resistor and the ambiance [K/W], P – electrical power dissipated inside the resistor starting from the moment of time t = 0 [W], T T t –temperature rise in the resistor [K]. It is the difference between resistor temperature and ambient temperature and depends on time t. Passive Electronic Components Lecture 7 Page 2 of 11 Thermal energy dissipated inside the resistor during short time dt is P dt . According to the definition of thermal resistance Rt T P1 , where P1 is the power of heat escape outside the resistor. Therefore, P1 T Rt . Thermal energy that escaped from the resistor during time dt will be P1 dt T Rt dt . The balance of thermal energy ensures temperature change dT in the resistor. Differential equation that represents the energy balance in the resistor will be: cm dT P dt 1 T dt Rt or cm dT 1 TP dt Rt with initial condition T 0 0 . The solution of the above differential equation is t T t P Rt 1 exp cmRt It is valid for all types of resistors: both having 2-dimensional resistive element (thick-film, thin-film, foil) and resistors with 3-dimensional resistive element made of bulk material (wirewound, metal strip, carbon composition). When t the above solution transforms into T t P Rt , i.e. into expression for temperature rise in the case of steady-state power dissipation in the resistor (see plot below). T t P Rt t T t P Rt 1 exp cmR t 1.2. Short-time pulses (from several nanoseconds to several microseconds). Let us consider the case of very short pulse duration time t. In this case almost all generated heat remains inside the resistive element (adiabatic process). For small t values the above solution of differential equation may be linearized: T t T 0 t P t mc Passive Electronic Components Lecture 7 Page 3 of 11 The temperature rise in resistive element is linear function of pulse duration t. The slope of liner function is expressed through pulse power P, resistive element mass m, specific heat capacity c of resistive element material. The above equation is valid for all types of resistors: both having 2-dimensional resistive element (thick-film, thin-film, foil) and resistors with 3-dimensional resistive element made of bulk material (wirewound, metal strip, carbon composition). 1.3. Medium-time pulses (several milliseconds). In many cases heat capacity of 3-dimensional resistive element (wirewound, metal strip, carbon composition) is the major part of heat capacity of the entire resistor. At that, heat transfer inside the resistor may be neglected. Or by other words temperature rise in resistive element may be estimated using the equation for short-time pulses. Thermal capacity of 2-dimensional resistive element is negligible when compared to heat capacity of the entire resistor. When pulse duration is in milliseconds range or longer there is significant internal heat transfer between resistive element that generates the heat and substrate that absorbs the heat. Therefore, the equation for short-time pulses that is based on adiabatic heating of resistive element is not applicable. Let us consider temperature rise distribution in flat resistor with 2-dimensional resistive element loaded by medium duration pulse. Suppose that a flat resistor has a uniform (non-trimmed) resistive film layer on the surface of its substrate. The substrate is commonly much thicker than the resistive film. Assume that the resistor dissipates a square-wave (constant voltage) pulse. Assume also that the pulse parameters (duration, power/energy) and thermo-mechanical properties of the resistor substrate (thermal conductivity, heat capacity and density) are known. The temperature rise distribution in the resistor is to be found as a function of coordinates and time. Proposed mathematical model is a substrate with essentially infinite outline dimensions and thickness (half-space substrate). It is topped by resistive film of thickness d that has uniform heat generation capability over its volume (Fig.1). The uniformity of the heat source results in constant temperature in each plane parallel to the surface of the infinite substrate. It means that the substrate temperature rise may be represented as a function of two independent variables: time t and spatial coordinate z: T T( z, t ) . Axis Oz has its origin on external surface of the resistive layer, and is normal to it. Assume that T( z,0) 0 (the initial temperature rise in each point of the substrate is zero) and that heat generation starts at the time t 0 with constant rate. Temperature rise distribution T( z , t ) has to be determined. Heat source layer d 0 Substrate z Fig.1 It may be shown that in the case of transient heat conduction process [1, p.10] Passive Electronic Components Lecture 7 Page 4 of 11 1 T A 2T , a t K (1) where: t - time [s], A - heat source power per unit volume [W/m3] (in general case it is a function of coordinates and time), a K - thermal diffusivity [m2/s], c K - thermal conductivity [W/(mK)], - density [kg/m3], c - specific heat capacity [J/(kgK)]. The solution T( z, t ) of equation (1) that corresponds to the described condition is given in [1, p.80]. In the substrate volume (z > d) : T( z, t ) 2aAt z d f K 2 at zd f 2 at . where: T( z , t ) – temperature rise, K; K – thermal conductivity of the substrate material, W/(mK); c – specific heat capacity of the substrate material, J/(kgK); – density of the substrate material, kg/m3; d – thickness of the heat source layer, m; A(t) – volumetric density of heat power production in the heat source layer, W/m3; A(t ) A, t ; A(t ) 0, t . a – thermal diffusivity of the substrate material, m2/s: The function f( x) is the following: f( x) 1 2 1 2 x 2 erfc( x) x exp( x 2 ). 4 where: x –dimensionless real variable. erfc( x) – complementary error function: erfc( x) exp d 2 2 x (2) Passive Electronic Components Lecture 7 Page 5 of 11 Assume that the thickness of the heat source layer is infinitesimal, so that d0. Then the solution (2) can be simplified: T( z , t ) 2 at w z 2 z z exp erfc K 4at 2 at 2 at . (3) Here w – surface density of heat power generation in the two-dimensional heat source layer, W/m2. Equation (3) may be presented in the following form: T( z , t ) 2 w at Θ(θ), K (4) Θ(θ) exp θ 2 θ erfc θ , θ( z , t ) z 2 at (5) . Suppose that z 0 . Then 0 , erfc 0 1 , 0 1 and the equation (4) will transform into expression for the surface (resistive film) temperature as a function of time: T( 0, t ) 2 w at . K (6) It is evident from comparing (4) and (6), that function Θθ Tz, t T0, t represents the relative temperatures in the substrate with respect to the surface (resistive film) temperature T0, t . As shown in Fig.2, Θθ is a descending function. Thus, at every instant of time maximum temperature in the substrate is reached in its surface z 0. () 1 0.5 0 0 1 Fig. 2 2 Passive Electronic Components Lecture 7 Page 6 of 11 Fig. 2 demonstrates that almost all of the heat energy absorbed by the substrate is related to 0 θ 1 range. Replacement of the variable with the variables z and t using (5), results in: 0 z 2 at . (7) The significance of the last result is that at any instant of time vast majority of the heat energy absorbed by the substrate is contained in a substrate layer defined by (7). The remaining portion of the infinitely thick substrate, 2 at z has negligible influence on the temperature distribution in the layer (7). In other words, the relatively simple infinite model of the resistor is applicable to the temperature analysis of film resistor loaded by pulse when substrate thickness h and pulse duration satisfy the following condition: h 2 a , (8) Assume, now, that a square-wave pulse of power P or energy E and duration time is applied to a real resistor with finite area S of its resistive element. Assume also that the resistor thickness satisfies (8). The power density w of two-dimensional heat source in the model (4) can be calculated as the following: w P E . S S (9) Suppose that heat transfer on direction parallel to resistor’s surface plane is negligible. Then the resistor may be regarded as a portion of infinite “resistor” that dissipates the same pulse power per unit of surface area. Substitution of (9) into (4) yields an expression for the distribution of the temperature rise in the substrate in terms of the given parameters: T( z, ) P a 2 E Θ(θ) Θ(θ). KS cS a 2 (10) Substitution of (9) into (6) yields an expression for the distribution of the temperature rise in the resistive film (z = 0) in terms of the given parameters: T( 0, ) 2P 2E . S Kc S Kc (11) Passive Electronic Components Lecture 7 Page 7 of 11 All the discussed models are systemized in the following table. Type of resistor load 2-dimensional resistive element 3-dimensional resistive element Pt T t mc Short-time pulse Medium-time pulse Long-time pulse Steady state T( 0, ) 2P S Kc T t t T t P Rt 1 exp cmRt T t P Rt Pt mc Comments Heat remains inside resistive element (no heat transfer to ambiance) Heat remains inside resistor (no heat transfer to ambiance) Heat transfer to ambiance is significant For comparison 2. Physical phenomena related to pulse loading. 2.1. Burnout of resistive film. Suppose that chip resistor with bare and uniform (non-trimmed) thick-film resistive element (Fig. 3) is loaded by square-wave pulse. h Fig.3 Suppose that resistor substrate is made of 96% alumina (typical substrate for thick-film resistor), and, therefore, K = 24 W/(mK), c = 8.8102 J/(kgK), = 3.72103 kg/m3, a = 7.310-6 m2/s. Suppose too that duration of applied pulse satisfies (8) where h is resistor substrate thickness. Some example values of and respective minimum values of h calculated per (8) are presented in the table below: Minimum alumina substrate thickness when solution (11) for infinite model is applicable h, mm , ms 1 3 10 It follows from (11) that 0.17 0.30 0.54 Passive Electronic Components Lecture 7 Page 8 of 11 P T( 0, ) S Kc . 2 (12) Functions P or E are common characteristics of resistor’s withstandability to pulse load. They may be found in resistor datasheets and standards. Suppose that T(0,) = 250C, S = 1.7 mm2 (1206 size of chip resistor). The results of calculations per (12) are presented in Fig.4. Experimental verification of relationship (12) was performed using 1206 non-trimmed chip resistors. The resistors were loaded by 10,000 square-wave pulses characterized by selected pair of P, values at +70C ambient temperature. Period of pulses was selected to keep average power much lower than rated power of the resistor. The plotted in Fig.4 experimental data represents maximum pulse power at the given pulse duration that results in resistance shift less than 1%. Resistance shift in this case results from thermal destruction (burnout) of resistive film. Basing on disclosed theory maximum temperature of resistive film in the described experiment may be estimated as 250C + 70C = 320C (Temperature rise plus ambient temperature). Pulse power, W Single Pulse Load of 1206 Non-Trimmed Chip Resistor Calculated (T=250K) Experimental 1.E-07 1.E-05 1.E-03 1.E-01 Pulse duration, s Fig.4 3.2. Substrate cracking. Failure analysis of the resistors failed after application of single pulse reveals burnt resistor film in all the cases (Fig.5a). But sometimes substrate cracking is observed too (Fig. 5b). The theory of substrate cracking phenomenon was developed in [2]. Passive Electronic Components Lecture 7 Page 9 of 11 Fringe area a) b) Fig.5 In qualitative level it may be explained as the following. A short time of pulse load is insufficient for appreciable heating up of substrate fringes – areas not covered by resistive film (see Fig.5). Nevertheless, the fringes are forced to follow the thermally induced expansion of the central part of the resistor. This situation produces significant tensile stresses in the fringes that may result in substrate cracking. It was shown both theoretically and experimentally in [2] that cracking takes place when pulse duration is about 1ms and longer. 3.3. Fatigue cracking of soldering joints. There are many applications where chip resistors are subjected to a series of pulses. There is specific effect related to multiple pulses impact - fatigue cracking of soldering joints. Fig.6 It commonly happens when pulse duration is close to time of heat propagation all way through the substrate. In this case as it follows from (8) h 2 a , h2 . 4a (13) In this case mechanical “actuation” of the substrate is more efficient compared to longer or shorter pulses: temperature gradient is high all way through substrate thickness as shown in Fig.2. Thermal expansion of substrate material results in about spherical shape of its top and bottom surfaces (see Fig.6). At that, PCB remains flat therefore high level of mechanical stress is induced in solder joints Passive Electronic Components Lecture 7 Page 10 of 11 of the resistor. A solder is known to be plastic material susceptible to fatigue fracture when mechanical stress is applied repeatedly hundreds and thousands times. Fatigue cracking of solder joins that results from ambient temperature changes and TCE mismatch between chip component and PCB may develop for months and years because common duration of ambient temperature cycle is several hours. In the case of pulse loading of resistor temperature cycle duration may be seconds or less. That is why crack development in this case may happen after several hours. 3. Pulse-proof chip resistors. Pulse-proof chip resistor may withstand significantly higher electrical pulse load when compared to standard chip resistor of the same size. It is achieved by the following. 3.1.Non-trimmed resistors. Resistive element without laser trimming has no current concentrators (hot spots). Chip with laser trim Chip without laser trim (Red lines – direction of electrical current) Fig.7 3.2.Cylindrical chips (MELF. It follows from (12) that pulse power rating of film resistor is proportional to surface area of its fusing element. Cylindrical chip (Fig.8a) has times more resistive element element area than flat chip resistor (Fig.8b) that has the same projection. a) MELF chip resistor b) Flat chip resistor Fig.8 3.3.Symmetrical chip with 2 resistive elements. Chip resistor shown in Fig.9 has twice more fusing element area than flat chip resistor having the same projection and respectively has twice higher pulse power rating. Symmetrical construction prevents thermally induced bending of chip (see Fig.6) and significantly increases withstandability of solder joints to fatigue cracking. Passive Electronic Components Lecture 7 Page 11 of 11 Resistive element 1 Substrate Resistive element 2 Fig.9 Literature 1. Carslaw H.S., Jaeger J. C., Conduction of heat in solids. Oxford at the Clarendon Press, 1959. 2. Belman M., Fillion P., Safe pulse loading of thick-film chip resistors. CARTS 2002 (22nd Capacitor and Resistor Technology Symposium) Proc., pp. 43-51. 3. Belman M., Kadim Y., and Akhtman L., Reliable Operation of Thick-Film Chip Resistors under Pulsed Conditions. CARTS 2003 (23rd Capacitor and Resistor Technology Symposium) Proc., pp. 117-123. 4. Belman M., Kadim Y., and Akhtman L., Surpassing Design of Surge Current Chip Resistor. CARTS- EUROPE 2004 (18th European Passive Components Conference) Proc., pp. 182187.