Thermal Analysis of Fire Resistive Joint Design for

Architectural Expansion Joints

by

Jason A. Shaw

An Abstract of a Thesis Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING

Major Subject: Heat Transfer

The original of the complete thesis is on file

In the Rensselaer Polytechnic Institute Library

Approved:

____________________________________________________

Professor Ernesto Gutierrez-Miravete, Thesis Adviser

Rensselaer Polytechnic Institute

Troy, New York

Month, Year

(For Graduation August 2013)

© Copyright 2013

by

Jason A. Shaw

All Rights Reserved

i

CONTENTS

LIST OF TABLES ............................................................................................................ iii

LIST OF FIGURES .......................................................................................................... iv

ACKNOWLEDGMENT ................................................................................................... v

ABSTRACT ...................................................................................................................... 1

INTRODUCTION/BACKGROUND ................................................................................ 2

LITERATURE REVIEW .................................................................................................. 5

THEORY/METHODOLOGY ........................................................................................... 6

ii

LIST OF TABLES

iii

LIST OF FIGURES

Figure 1: Example of an Architectural Expansion Joint .................................................... 2

Figure 2: Illustration of Fire Barrier Design ...................................................................... 4

iv

ACKNOWLEDGMENT

Type the text of your acknowledgment here.

v

ABSTRACT

Type the text of your abstract here.

1

INTRODUCTION/BACKGROUND

Architectural expansion joints are openings or gaps that are designed into the

structure of a building to permit movement between the concrete slabs or other structural

members. Building movement can occur for several reasons, including thermal loading

(i.e., change of weather season), wind loading, or seismic activity. These openings can

vary anywhere between 0.5 inches up to and exceeding 32 inches. Typically, a metal

cover plate is installed over the expansion joint to conceal the joint and to permit

pedestrian traffic across the joint. An example of an architectural expansion joint can be

seen in Figure 1.

Figure 1: Example of an Architectural Expansion Joint

2

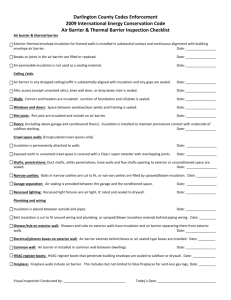

Building codes often require that these expansion joints include a fire resistive

system, or fire barrier, to prevent the spread of smoke, heat, and flames in the event of a

fire.

American Society for Testing and Materials (ASTM) E1966, "Standard Test

Method for Fire-Resistive Joint Systems", Reference (a), is the standard test method

used to evaluate the performance of a fire barrier system. The acceptance criteria for the

standard is that the transmission of heat through the fire barrier must not raise the

average temperature of the unexposed side more than 250⁰F. The barrier is then rated as

having satisfied the acceptance criteria for a stated period of time (0.5 hours, 1 hour, or 2

hours).

Additionally, since these expansion joints are designed to permit building

movement, the fire barriers themselves must be capable of moving with the joint while

maintaining the fire barriers integrity. ASTM E1399, "Standard Test Method for Cyclic

Movement and Measuring the Minimum and Maximum Joint Widths of Architectural

Joint Systems", Reference (b), is the standard test method used to verify the movement

capability of a fire barrier system.

Underwriters Laboratories (UL) 2079, "Standard for Tests for Resistance of

Building Joint Systems", Reference (c), combines the requirements of both ASTM

E1966 and ASTM E1399, as well as other standards, to test a complete architectural

expansion joint system (cover plate and fire barrier). This is the standard test used in

industry today to qualify cover plate and fire barrier designs.

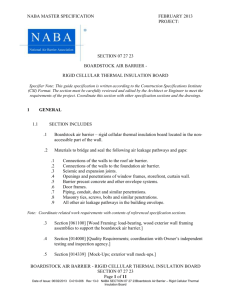

The fire barrier design of interest is illustrated in Figure 2. The fire barrier consists

of the following basic components (working from the unexposed boundary to the

exposed boundary):

Two galvanized steel "L" brackets - Used to attach the fire barrier the

concrete floor slabs and to provide some axial rigidity.

Ceramic fiber blanket - Used as the main insulation material. Number of

layers and the thickness varies based on fire barrier rating.

Stainless steel foil - Used as an insulation material (radatiave shield), to

prevent the transmission of hot gasses, and to provide some rigidity to the

fire barrier assembly.

3

High temperature cloth - Used to provide structural support for the fire

barrier and as an insulation material.

Figure 2: Illustration of Fire Barrier Design

The goal of this project is to validate the fire barrier design based on the

requirements set forth in UL 2079 for a 2 hour rating. If the proposed configuration does

not satisfy the UL 2079 requirement, recommendations will be made.

4

LITERATURE REVIEW

Several investigators have published documents on thermal analysis of fire barriers

used for architectural expansion joints. Of particular interest is the American Society of

Mechanical Engineers (ASME) paper titled "Transient Heat Transfer for Layered

Ceramic Insulation and Stainless Foil Fire Barriers", Reference (d). This paper develops

a course numerical one dimensional model for a fire barrier in a standard test situation

that is tested to ASTM E119, "Standard Methods of Fire Tests of Building Construction

and Materials".

The Reference (d) paper first conducts a test in accordance with ASTM E119, which

has the same acceptance criteria as ASTM E1399 (unexposed side temperature rise less

than 250⁰F). Reference (d) then develops and applies a numerical model, which is a

course finite difference/finite volume formulation of the standard transient conduction

energy equation with radiative heat flux and the radiative heat transfer equation. While

the numerical model was able to predict the thermal performance of the test system, the

test setup and subsequent analysis is for a geometrically different fire barrier design and

application.

In addition to the Reference (d) paper, the ASME paper titled "Simulations of

Thermal Performance for One- and Two- Dimensional Insulation and Aluminum Foil

Fire Barriers", Reference (e), discusses thermal models of fire barriers. This paper

focuses on the thermal interactions of 2-D architectural expansion joint corners (i.e., a

90⁰ directional change), and if "hot spots" form or any degradation in thermal

performance occurs at these corners. In order to quantify this, a numerical simulation of

the fire barrier is accomplished. The analysis suggested that a fire barrier at a 2-D

architectural expansion joint corner is thermally less robust than a standard 1-D straight

architectural expansion joint.

While the numerical simulation was successful in

matching the thermal performance of previously tested system, the analysis is for a fire

barrier design at a corner is

5

THEORY/METHODOLOGY

6

REFERENCES

(a) Standard Test Method for Fire-Resistive Joint Systems, ASTM E1966

(b) Standard Test Method for Cyclic Movement and Measuring the Minimum and

Maximum Joint Widths of Architectural Joint Systems, ASTM E1399

(c) Standard for Tests for Resistance of Building Joint Systems, UL 2079

(d) Transient Heat Transfer for Layered Ceramic Insulation and Stainless Foil Fire

Barriers, ASME Paper

(e) Simulations of Thermal Performance for One- and Two- Dimensional Insulation

and Aluminum Foil Fire Barriers, ASME Paper

7