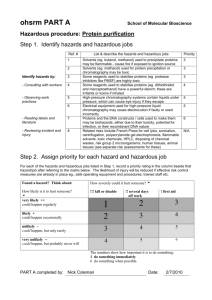

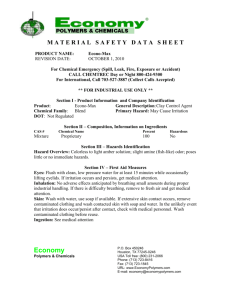

Potential Hazards and Environmental Concerns

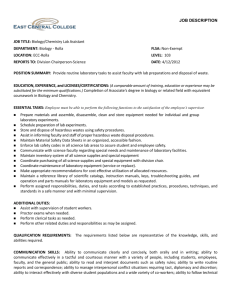

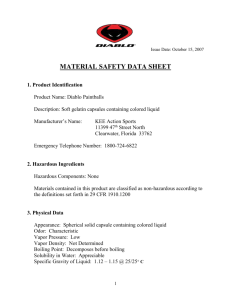

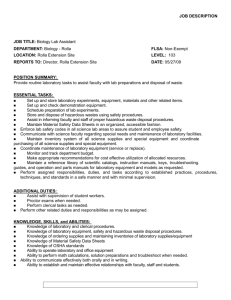

advertisement