Hazard Communication Program (WAC 296-800-170)

advertisement

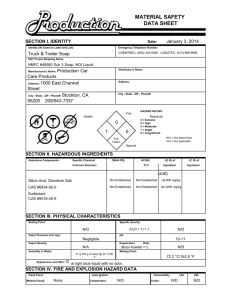

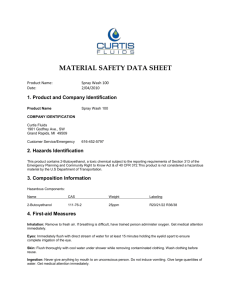

Hazard Communication Program (WAC 296-800-170) The Chemical Hazard Communication standard was developed to ensure employers and employees are informed about chemical hazards in their workplace. Hazard Communication applies to all winery operations that may expose employees to hazardous substances under normal working conditions or during an emergency situation. Workers, including supervisory, clerical, and maintenance personnel, are covered, even if there is a remote possibility of exposure to hazardous substances. Information regarding the hazards associated with non-routine tasks should also be addressed. A Hazard Communication program should inform employees of the requirements of the Hazard Communication Standard, hazardous properties of chemicals used at the winery, safe chemical handling procedures, and the measures employees can employ to protect themselves from chemicals. DOSH defines a hazardous chemical as any chemical that is a physical or health hazard. A health hazard is defined as a chemical, mixture, biological agent, or physical agent that may cause health effects in short- or long-term exposed employees. Health hazards can include cancer, reproductive problems, corrosion, sensitization, liver toxicity, or temperature extremes. Specific DOSH Hazard Communication Program requirements include: Make a list of the hazardous chemicals present in your workplace. Prepare a written Chemical Hazard Communication Program. Inform employees about this rule and the Hazard Communication program. Providing employee training about working in the presence of hazardous chemicals. Get and keep the Material Safety Data Sheets (MSDS) for any hazardous chemicals used. It is helpful to keep all current MSDS in one location, such as a notebook that is labeled ‘Material Safety Data Sheets’ Make sure containers of hazardous chemicals are properly labeled and that labels are easy to read. Products exempt from the Hazard Communication rule include consumer products (when used for the purpose intended by the manufacturer at a frequency experienced by consumers), hazardous waste, and food and alcoholic beverages. Material Safety Data Sheets and the NFPA Diamond Material Safety Data Sheets or MSDS are provided by the chemical manufacturer and are an extensive source of information on the hazards and exposure precautions for dangerous chemicals. Sometimes the MSDS contain a considerable amount of information about worst-case scenarios that can make just about any product seem dangerous. However, they can be a very useful way to learn about for effects of exposure, allowable exposure limits, and first aid information. Learning how to read and interpret the MSDS is the key. A common chemical reference used on many MSDS is the National Fire Protection Association (NFPA) diamond. The NFPA diamond (shown below) is an easy visual reference for health, fire, and reactivity hazard information found on MSDS and on product labels. The diamond is divided into four colored quadrants. Blue represents health hazard. Red represents flammability. Yellow represents reactivity. White provides information about special precautions. The NFPA rating system rates hazardous chemicals from 0 to 4 as follows: 4 – Extreme/Severe 3 – High/Serious 2 – Moderate 1 – Slight 0 – Minimum The ‘Special Hazards’ box can have various codes based on the specific chemical hazard. Hazardous Chemicals often found in Wineries Most products used for wine production have MSDS available from the manufacturer. Wineries use few toxic products, but some wine additives and yeasts fall under the category of “Irritants” as a health hazard. The most hazardous chemicals found at a typical winery are sulfur dioxide, diatomaceous earth, carbon dioxide, and caustic cleaners. Other hazardous chemicals that may be found at a winery include ozone, anhydrous ammonia, copper sulfate, and carbon monoxide. A brief summary of the health hazards, NFPA rating, and recommended personal protective equipment can be found in Table 1 below Table 1 Common Hazardous Chemicals Found in Wineries Chemical Synonyms Health Hazard Health Effects; organ systems NFPA rating DOSH PEL Personal Protective Equipment Anhydrous ammonia Ammonia Irritant, Corrosive skin, eyes, respiratory tract; chemical burns Health - 3 Fire - 1 Reactivity - 0 Respiratory Eye Skin (*) Carbon Dioxide CO2 Asphyxiant Respiratory, nervous system (**) Health - 2 Fire - 4 Reactivity - 0 PEL: 25 PPM STEL: 35 PPM Odor threshold 17PPM PEL:5,000PPM STEL: 30,000PPM Carbon Monoxide CO Asphyxiant Flu-like symptoms; unconsciousness (**) Skin Blood Kidneys Health - 2 Fire - 4 Reactivity - 0 PEL: 35 PPM STEL(5min): 200PPM Health - 3 Fire - 0 Reactivity -0 none PEL: 6mg/m3 (total dust) STEL: 12mg/m3 (total dust) PEL: 0.1 PPM STEL: 0.3PPM Eye Hand Respiratory Copper Sulfate None recommended; proper ventilation None recommended; proper ventilation Eye wash station Cupric sulfate Copper Sulfate Pentahydra te Diatomaceous - silica Earth (DE) (less - Pink DE than 1% silica) - Kieselsol Irritant Carcinogen - Lungs (known carcinogen) - Eyes (irritant) Health - 4 Fire - 0 Reactivity - 3 Ozone - O3 - Ozonated Water Irritant -Eyes -Lungs Health - 4 Fire - 0 Reactivity – 3 Sodium Hydroxide -Caustic Wastewater Treatment -Tank Cleaner -Liquid SO2 -Potassium Metabisulfit e (KMS) Corrosive - Eyes - Skin - Lungs Health - 3 Fire - 0 Reactivity – 1 Ceiling: 2 mg/me Eye Hand Skin Corrosive, Mutagenic, Irritant - Eyes - Skin - Lungs - Nose Health - 3 Fire - 0 Reactivity – 0 PEL: 2 PPM STEL: 5 PPM Eye Hand Respiratory Sulfur Dioxide PEL = Permissible Exposure Limit set by the Division of Occupational Safety and Health; 8-hour time-weighted-average STEL = Short Term Exposure Limit; 15-minute time-weighted-average Ceiling = Concentration not to be exceeded, even instantaneously (*) = See regulations for more specifics on training and personal protective equipment requirements (**) = see below for additional information Eye Hand Skin Carbon Dioxide Carbon Dioxide is a simple asphyxiant, or a gas that displaces air. Effects of oxygen deficiency may include: rapid breathing, diminished mental alertness, impaired muscular coordination, faulty judgment, depression of all sensations, emotional instability, and fatigue. As asphyxiation progresses nausea, vomiting, prostration, and loss of consciousness may result, eventually leading to convulsions, coma, and death. Oxygen deficiency during pregnancy has produced developmental abnormalities in humans and experimental animals. Carbon dioxide, used in winery operations as compressed gas, is usually not considered a hazardous chemical; however, carbon dioxide is also a byproduct of fermentation. Because of its prevalence in wine making and the potential for adverse health effects due to exposure to high concentrations, carbon dioxide should receive special attention in a Hazard Communication program. Carbon dioxide released during fermentation fluctuates throughout crush, but at times can reach dangerous levels or exceed mandated exposure limits. Tank rooms, barrel rooms, cellars, and nearby offices need adequate ventilation to exhaust CO2 and supply fresh air. Entering a tank room during fermentation after the room has been closed must be done with extreme caution. Employees working long shifts in the cellar during crush should be checked for signs of over exposure to CO2. A gas monitor with a carbon dioxide sensor is useful for monitoring cellar CO2 concentrations. Hand held CO2 monitors should also be used whenever an employee enters a wine tank as part of your confined space entry program. Carbon Monoxide Carbon monoxide is product of incomplete combustion and can be found in wineries that use propane-fueled forklifts. Forklifts must be kept well maintained and properly tuned so as reduce carbon monoxide emissions. Converting to electric powered forklift eliminate carbon monoxide emissions, but require charging stations. Other harmful substances used in wine-making include the following: Metabisulphite - which in concentrated solution can be irritating to the skin and the mucous membrane. Tartaric acid - which is considered non-toxic, can be slightly irritating in high concentrations. Disinfectants and detergents for the washing of storage tanks can cause dermatitis and should be used with proper skin protection