TEP

5.4.50

-01

Quantitative X-ray fluorescence analysis

of alloyed materials

Related topics

Bremsstrahlung, characteristic X-radiation, energy levels, fluorescent yield, Auger effect, coherent and

incoherent photon scattering, absorption of X-rays, edge absorption, matrix effects, semiconductor energy detectors and multi-channel analysers.

Principle

Various alloyed materials are subjected to polychromatic X-rays. The energy of the resulting fluorescence radiation is analysed with the aid of a semiconductor detector and a multichannel analyser. The

energy of the corresponding characteristic X-ray fluorescence lines is determined.

In order to determine the concentration of the alloy constituents, the intensity of their respective fluorescence signals is compared to that of the pure elements.

Equipment

1

1

1

1

1

1

1

1

XR 4.0 expert unit 35kV

XR 4.0 Goniometer for X-ray unit, 35 kV

XR 4.0 Plug-in module with W X-ray tube

Diaphragm tube d = 1 mm

Diaphragm tube d = 2 mm

XR 4.0 XRED cable 50 cm

Screened cable, BNC, l = 750 mm

Multi-channel analyser

09057-99

09057-10

09057-80

09057-01

09057-02

09058-32

07542-11

13727-99

1 X-ray energy detector

1 Universal crystal holder for the X-ray unit

Set of samples for the quantitative

1 X-ray fluorescence analysis, set of 4

Set of metal samples for the X-ray

1 fluorescence analysis, set of 7

1 Software for the multi-channel analyser

PC, Windows® XP or higher

09058-30

09058-02

09058-34

09058-31

14452-61

This experiment is included in the upgrade package: XRM 4.0 X-ray material analysis.

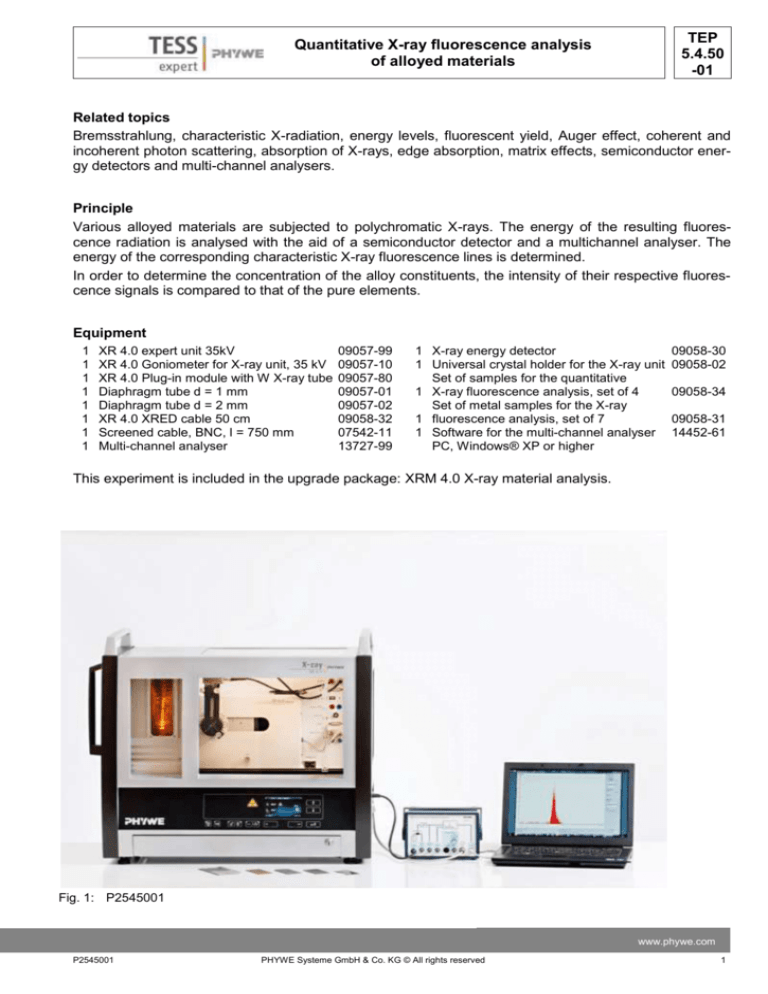

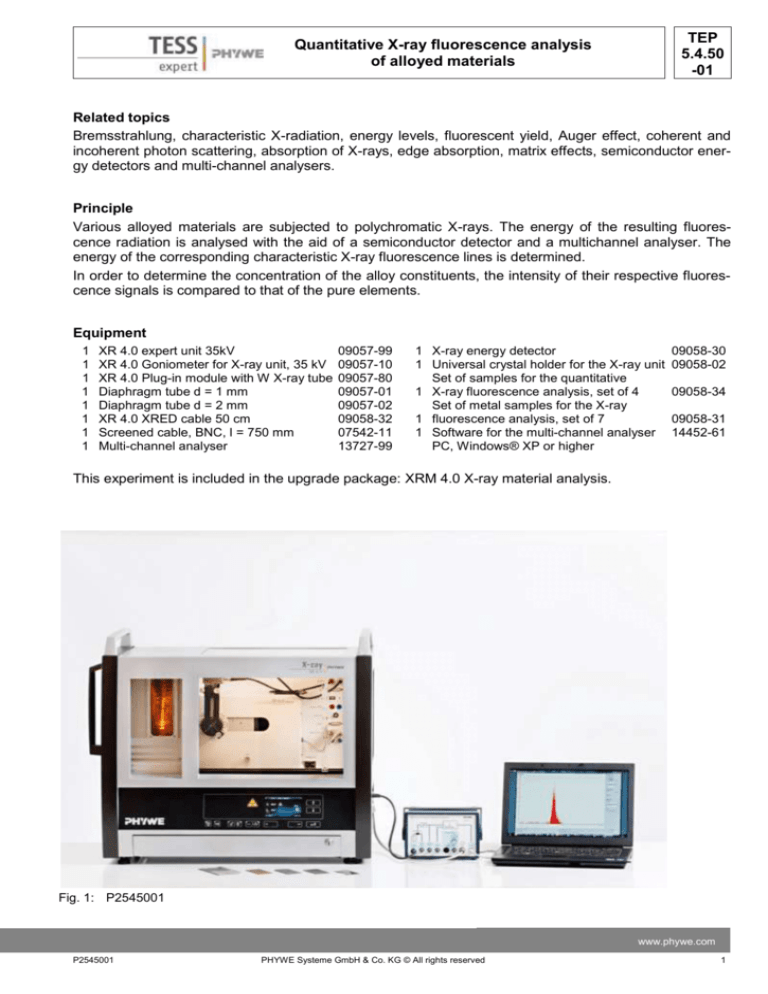

Fig. 1: P2545001

www.phywe.com

P2545001

PHYWE Systeme GmbH & Co. KG © All rights reserved

1

TEP

5.4.50

-01

Quantitative X-ray fluorescence analysis

of alloyed materials

Tasks

1. Calibrate the semiconductor energy detector

with the aid of the characteristic radiation of the

tungsten X-ray tube

2. Recording of the fluorescence spectra that are

produced by the alloyed samples.

3. Recording of the fluorescence spectra that are

produced by the pure metals.

4. Determination of the energy values of the corresponding fluorescence lines.

5. Calculation of the concentration levels of the alloy constituents.

Set-up and procedure

Set-up (Fig. 1)

Screw the adapter ring onto the inlet tube of the

Fig. 2: Connections in the experimentation area

energy detector.

Connect the signal and supply cables to the

corresponding ports of the detector with the aid

of the right-angle plugs.

Connect the signal and supply cables from the

MCA to the appropriate connections in the experiment chamber of the X-ray unit (signal cable: red, supply cable: green (see Fig. 2)).

Connect the external ports for the X RED of the

Fig. 3: Connection at the external panel of the XR 4.0 Xx-ray unit (signal cable red, supply cable green,

ray expert unit to the MCA

see Fig. 3) to the multi-channel analyse (MCA).

Connect the signal cable via a screened BNCcable to the “Input” port of the MCA and the

X-ray energy

supply cable to the “X-Ray Energy Det.” port of

detector

the MCA.

Secure the energy detector in the holder of the

swivel arm of the goniometer (Fig 4). Lay the

two cables with sufficient length so that the goniometer can be swivelled freely over the entire

swivelling range.

Connect the multi-channel analyser and computer with the aid of the USB cable.

Insert the tube with the 2-mm-aperture.

Left position of the

Bring the goniometer block and the detector to

goniometer

Universal crystal

their respective end positions on the left. Bring

holder with metal

the detector to the 90° position in the 2:1 cousample

pling mode (Fig. 4).

Calibration of the multi-channel analyser

(if there is no other already existing calibration that

can be used)

- Bring the goniometer block and the detector

Fig. 4: Set-up at the goniometer

2

PHYWE Systeme GmbH & Co. KG © All rights reserved

P2545001

Quantitative X-ray fluorescence analysis

of alloyed materials

-

-

-

-

-

TEP

5.4.50

-01

to their respective end positions on the

right.

Insert the tube with the 1-mm-aperture into

the exit tube of the X-ray tube.

With the X-ray unit switched on and the

door locked, bring the detector to the 0° position. Then, shift the detector by some

tenths degree out of the zero position in order to reduce the total rate.

Operating data of the tungsten X-ray tube:

Select an anode voltage UA = 25 kV and an

anode current IA = 0.02 mA and confirm Fig. 5: calibration of the multi-channel analyser

these values by pressing the “Enter” button.

Switch on the X-radiation

In the MEASURE program, select “Multi channel analyser” under “Gauge”. Then, select “Settings

and calibration”. After the “Calibrate” button has been clicked, a spectrum can be measured. The

counting rate should be < 300 c/s. Energy calibration settings: - 2-point calibration, - Unit = keV,

Gain = 2 – Set the offset so that low-energy noise signals will be suppressed (usually a few per

cent are sufficient), See Fig 5.

Measuring time: 5 minutes. Use the timer of the X-ray unit.

Make the two coloured calibration lines congruent with the line centres of the two characteristic

X-ray lines. The corresponding energy values (see e.g. P2544701) E(L3M5/L3M4) = 8,41 keV and

E(L2N4) = 9,69 keV are entered into the corresponding fields, depending on the colour. (Note:

Since a separation of the lines L3M5 and L3M4 Lines is not possible, the mean value of both lines

is entered as the energy of the line).

Name and save the calibration.

Spectrum recording

- Insert the tube with the 2mm-aperture.

- Bring the goniometer block and the detector to their respective end positions on the left. Bring the detector to the 90° position in the 2:1 coupling mode.

- Insert the sample with the universal crystal holder (sample at 45°).

- Operating data of the molybdenum X-ray tube: Adjust an anode voltage Ua = 35 kV and an anode

current so that the counting rate is ≤ 200 c/s.

- Measuring time: 10 minutes (use the timer of the X-ray unit).

Evaluation of the measurement curves

- In order to determine the line energy, switch from the bar display to the curve display. To do so,

click “Display options” and then “Interpolation and straight lines”.

- Extend the relevant line section with the aid of the zoom function

.

-

Then, select the curve section with

. Open the window “Function fitting”

“Scaled normal distribution” and confirm.

-

Find the line centroid of the normal distribution with “Peak analysis”

function “Survey”

(see Fig. 7).

. Then, select

or determine it with the

www.phywe.com

P2545001

PHYWE Systeme GmbH & Co. KG © All rights reserved

3

TEP

5.4.50

-01

Quantitative X-ray fluorescence analysis

of alloyed materials

Theory

In order to determine the concentration of the elements in a sample with the aid of X-ray fluorescence

analysis, a qualitative analysis must first be performed. During the assignment of the fluorescence lines,

it must be taken into consideration that the relaxations that follow the primary ionisation process can only

take place if they fulfil the quantum-mechanical selection rules Δj = 0, ±1 and Δl = ±1 (j = total angular

momentum, l = orbital angular momentum). In addition, it should be noted that every element has groups

of X-ray lines that have a certain intensity relation.

If, for example, one considers a specific line as the Kα-line of an element, it should be possible to detect

the corresponding Kβ-line in the correct intensity relation, provided that it is not overlaid by a line of another element. When the lines have been assigned to the elements, the line intensity allows for conclusions to be drawn about the concentration of the elements.

In general, matrix effects (see the appendix) make it difficult to determine the concentration directly.

This is why, in practical applications, quantitative analysis is performed via a comparison with the calibration functions that are stored in the computer and that have been created with certified reference samples.

If there are no matrix effects, the concentration ca of an element a of a sample can be determined based

on the relation between the intensity Ia of a line of the element and the intensity Ie of the same line of the

pure element, i.e.:

ca

Ia

Ie

(1)

As a first approximation, the intensity of a fluorescence line can be stated based on its peak value.

Evaluation

Evaluation of the constantan sample

Figure 6 shows the fluorescence spectrum of the constantan sample and the corresponding spectra of

the pure elements. Based on the Kα-lines, Figure 7 shows the method for evaluating these curves. The

corresponding values are shown in Table 1. The pulse numbers that are stated in the table have been

cleared up in terms of the background intensity (approx. 5 pulses).

Ni

Cu

Kα Ni

KαCu

Kα

Kα

Kβ

Kβ

Fig. 6: Fluorescence lines of constantan, copper, and nickel

4

PHYWE Systeme GmbH & Co. KG © All rights reserved

P2545001

TEP

5.4.50

-01

Quantitative X-ray fluorescence analysis

of alloyed materials

Kα Ni

KαCu

Kα Ni

KαCu

Fig. 7: Spectrum evaluation method: Kα-lines of constantan, copper, and nickel with a scaled normal distribution

Table 1: Constantan sample

Sample

Pure element

A

B

Linie

Cu

Ni

Kα

Kα

C

E /keV

D

Ie / Imp.

E

Ia / Imp.

F

ca / %

8,0

183

518

57,8

7,4

172

378

42,2

Column F in the table shown above includes the experimental concentration values of the constantan

sample. According to these values, the sample consists of 57.8% (≈ 55%) of copper and 42.2 (≈ 45%) of

nickel. (Data provided by the manufacturer of the resistance alloy constantan: Cu55Ni45)

Evaluation of a brass sample

Figure 8 shows the fluorescence spectra of a brass sample (CuZn39Pb3) and those of the corresponding pure elements. Again, only the α-lines are used for determining the concentration levels. The corresponding evaluation, with the background intensity being taken into consideration, can be found in Table

2.

Table 2: Brass sample (CuZn39Pb3)

Pure Element

A

Sample

B

Linie

Cu

Zn

Pb

Kα

Kα

Lα

C

E /keV

D

Ie / Imp.

E

Ia / Imp.

F

ca / %

8,0

974

546

56,0

8,6

1037

420

40,5

10,5

235

6

2,6

www.phywe.com

P2545001

PHYWE Systeme GmbH & Co. KG © All rights reserved

5

TEP

5.4.50

-01

Quantitative X-ray fluorescence analysis

of alloyed materials

Cu

Zn

Zn/Pb

Pb

Pb

Lα

Zn

Cu

Kα

Kβ

Lβ

Pb

Kα

Kβ

Fig. 8: Fluorescence lines of brass (CuZn39Pb3), copper, zinc, and lead

Appendix

Normally, the fluorescence intensity of an element A, with the same concentration in alloys with various

alloy constituents, is not identical. This shows that the fluorescence intensity of an element not only depends on the concentration, but also on the combination of elements that form the so-called matrix of the

element that is to be analysed.

If the energy of the fluorescence radiation of an element A is high enough to stimulate the fluorescence

radiation in element B, the radiation coming from B not only depends on the primary intensity, but also

on the concentration of element A. Vice versa, element A can absorb the radiation of element B. These

additional effects are known as matrix effects.

6

PHYWE Systeme GmbH & Co. KG © All rights reserved

P2545001