RELECTROPH.SW - Faculty of Medicine

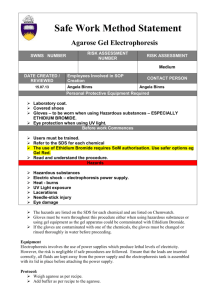

advertisement

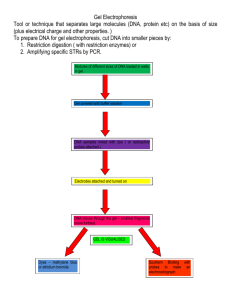

OHS026 Safe Work Procedure Faculty/Division Medicine Document number RELECTROPH.SW School/ Divisional Unit nephrology Initial Issue date Current version 13-03-2009 1.0 Current Version Issue date 20-04-2010 Next review date 20-04-2013 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Set up Electrophoresis Description: Use to electrophoresis to run gels with DNA, RNA and protein Associated risk assessment title and location: RA agarose electrophoresis for DNA and RNA, RA waste management and RA working with electrical equipments Describe the activity or process Place gel into the gel tank of the electrophoresis, take the comb out and add appropriate amount of running buffer solution to cover the gel. DNA and protein gels can be carried out on the bench top. RNA gels must be carried out the fume-hood as they contain formaldehyde. Load sample into the lanes. Put the lid on the gel tank. Always remember that sample lanes close to negative (BLACK) when doing DNA and RNA gel. Make red connect to red and black connect to black when doing protein gel and for transfer membrane. Switch on machine, select voltage, current and time required. Press start to run the gel. Press stop and then take the gel out off the tank when the gel run has finished. Switch off the machine when the work done. Clean up the tank with detergent and then water when finished. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Lab gown, safety glasses, disposable gloves, closed shoes Samples, buffer, marker, loading dye, agarose Pipettes, tips, tank, comb Ethidium bromide for DNA and RNA gel, formaldehyde for RNA gels Electrophoresis List potential hazards and risk controls including specific precautions required Potential chemical hazardous – for chemicals, check MSDS, Always wear suitable PPE, clean up all spills of chemicals immediately. Always wear double and change gloves immediately after finished when handling ethidium bromide. Use fume cupboard to handle formaldehyde and to run RNA gel Potential electrical hazard – do annual inspection of electrical equipment and ensure inspection tag is current Sample can be contaminated or infectious – training is required if handling human sample and all human samples treated as infectious. Wipe out all contaminations with 70% alcohol. Dispose all wastes in biological and chemical waste. ___________________________________________________________________________________________________________ ___________ Page 1 of 2 Safe Work Procedure Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010 List emergency shutdown instructions Electrophoresis has “OFF” switch that can be used in emergency. Shut all electrical equipment off at power point in case of emergency. List clean up and waste disposal requirements Wipe down all spills with 70% alcohol or detergent and then water Dispose all chemical waste in chemical waste bin Dispose all tubes, tip gloves in biological waste List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects Australian Standard AS2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. Australian Standard AS2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance Safe Work Procedure Form (OHS026) UNSW Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: P PEAKE Signature: Plant custodian: Signature List competency required – qualifications, certificates, licensing, training - e.g. course or instruction: SWP review date: 20-04- 2013 Responsibility for SWP review: ___________________________________________________________________________________________________________ ___________ Page 2 of 2 Safe Work Procedure Date Effective: 15.5.2010 Uncontrolled document when printed Current Version: 15.5.2010

![Student Objectives [PA Standards]](http://s3.studylib.net/store/data/006630549_1-750e3ff6182968404793bd7a6bb8de86-300x300.png)