Energy labelling and ecodesign requirements for heat pumps

advertisement

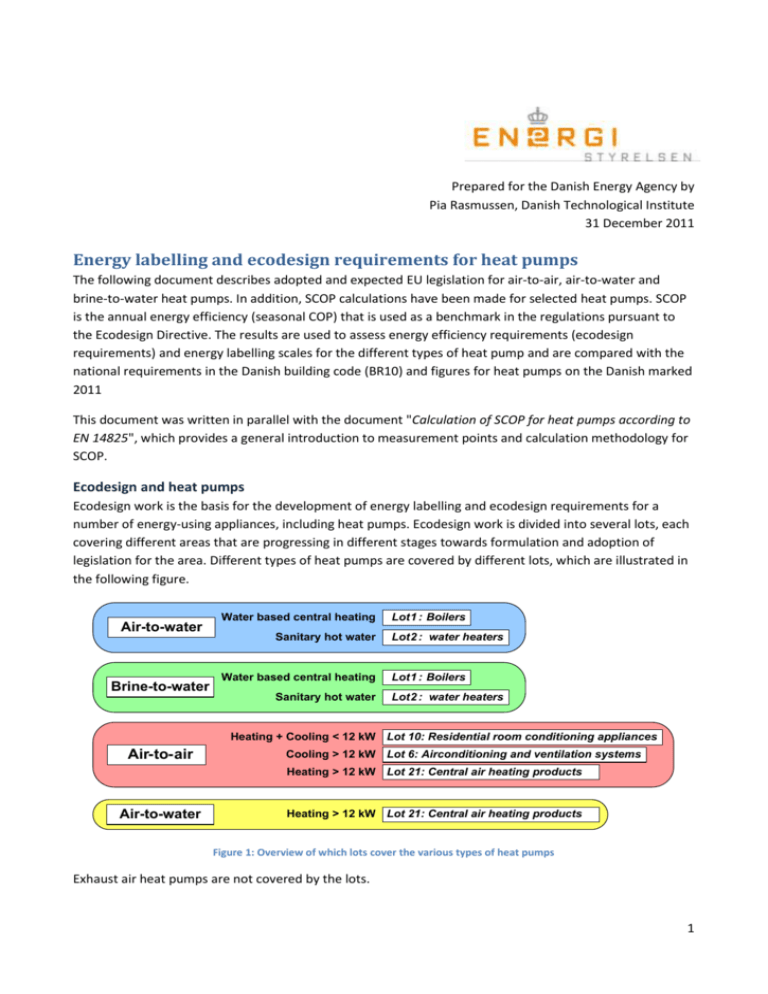

Prepared for the Danish Energy Agency by Pia Rasmussen, Danish Technological Institute 31 December 2011 Energy labelling and ecodesign requirements for heat pumps The following document describes adopted and expected EU legislation for air-to-air, air-to-water and brine-to-water heat pumps. In addition, SCOP calculations have been made for selected heat pumps. SCOP is the annual energy efficiency (seasonal COP) that is used as a benchmark in the regulations pursuant to the Ecodesign Directive. The results are used to assess energy efficiency requirements (ecodesign requirements) and energy labelling scales for the different types of heat pump and are compared with the national requirements in the Danish building code (BR10) and figures for heat pumps on the Danish marked 2011 This document was written in parallel with the document "Calculation of SCOP for heat pumps according to EN 14825", which provides a general introduction to measurement points and calculation methodology for SCOP. Ecodesign and heat pumps Ecodesign work is the basis for the development of energy labelling and ecodesign requirements for a number of energy-using appliances, including heat pumps. Ecodesign work is divided into several lots, each covering different areas that are progressing in different stages towards formulation and adoption of legislation for the area. Different types of heat pumps are covered by different lots, which are illustrated in the following figure. Air-to-water Brine-to-water Water based central heating Sanitary hot water Water based central heating Sanitary hot water Lot 1 : Boilers Lot 2 : water heaters Lot 1 : Boilers Lot 2 : water heaters Heating + Cooling < 12 kW Lot 10: Residential room conditioning appliances Air-to-air Cooling > 12 kW Lot 6: Airconditioning and ventilation systems Heating > 12 kW Lot 21: Central air heating products Air-to-water Heating > 12 kW Lot 21: Central air heating products Figure 1: Overview of which lots cover the various types of heat pumps Exhaust air heat pumps are not covered by the lots. 1 The figure shows that a total of five lots cover heat pumps. The status of these lots are: Area Status Lot 1: Boilers Lot 2: Water heaters Lot 6: Airconditioning & ventilation Lot 10: Residential room conditioning Lot 21: Central hot air heating Expected adoption 2012 Expected adoption 2012 Preliminary study in preparation Adopted and published Preliminary study in preparation Implementation of the step 1 requirements expected in 2014 expected in 2014 ? 1 Jan. 2013 ? Table 1: Overview of status of European legislation on heat pumps Lot 1 on space heaters for water-based central room heating systems and combined room- and water heating, Lot 2 on heating sanitary hot water have been synchronised in the work flow. A data basis for future assessment of legislative options is still under preparation for Lot 6 and Lot 21. The following description focuses on Lot 1 for brine-to-water and air-to-water heat pumps and Lot 10 for air-to-air heat pumps with a rated capacity below 12 kW. Air-to-air heat pumps with a rated capacity below 12 kW Legislation for air-to-air heat pumps with a rated capacity below 12 kW was adopted in spring 2011 and will enter into force on 1 January 2013. The legislation includes both energy efficiency requirements and energy labelling, and covers requirements for heating as well as cooling. As illustrated in the following figure, regulations will be introduced in stages over several years. 1.jan 2013 1.jan 2014 Energy efficiency requirements 1 Energy efficiency requirements 2 Energy label 1 1.jan 2015 1.jan 2017 1.jan 2019 Energy label 2 Energy label 3 Energy label 4 Figure 2: Timetable for introduction of energy efficiency requirements and energy labels for air-to-air heat pumps Energy efficiency requirements for the first and second round are shown in the following figure. As the figure shows, the reduced energy efficiency requirement can be met, if heat pumps use particularly environmentally friendly refrigerants. 1.jan. 2013 SCOP SEER GWP>150 3,40 3,60 GWP≤150 3,06 3,24 SCOP SEER GWP>150 3,80 4,60 GWP≤150 3,42 4,14 1.jan 2014 <6 kW 6-12 GWP>150 kW GWP≤150 SCOP SEER 3,80 4,30 3,42 3,87 Figure 3: 1. and 2. Minimum requirements for energy efficiency of air-to-air heat pumps 2 For most heat pumps, this means that they must observe a SCOP of 3.40 in 2013 and 3.80 in 2014. Similarly, a number of energy classes based on SCOP values will be introduced. These will be: A+++ SCOP ≥ 5,10 SEER ≥ 8,50 A++ 4,60 ≤ SCOP < 5,10 6,10 ≤ SEER < 8,50 A+ 4,00 ≤ SCOP < 4,60 5,60 ≤ SEER < 6,10 A 3,40 ≤ SCOP < 4,00 5,10 ≤ SEER < 5,60 B 3,10 ≤ SCOP < 3,40 4,60 ≤ SEER < 5,10 C 2,80 ≤ SCOP < 3,10 4,10 ≤ SEER < 4,60 D 2,50 ≤ SCOP < 2,80 3,60 ≤ SEER < 4,10 E 2,20 ≤ SCOP < 2,50 3,10 ≤ SEER < 3,60 F 1,90 ≤ SCOP < 2,20 2,60 ≤ SEER < 3,10 G SCOP < 1,90 SEER < 2,60 Figure 4: Scale for energy labelling of air-to-air heat pumps Until the above labelling enters into force, the current European energy labelling will apply which is based on efficiency at a single operating point. To achieve an A label under the "old" scale, COP must be more than 3.6 at operating point 7˚C/20˚C. In Denmark, new air-to-air heat pumps for installation must have an A label. Calculated SCOP values for air-to-air heat pumps In order to assess the magnitude of the energy efficiency classes, as well as the energy efficiency requirements, SCOP values have been calculated for a number of heat pumps that comply with requirements included in the list of air-to-air heat pumps prepared by Danish Energy Saving Trust1. At present, no calculated annual efficiency performance is used for air-to-air heat pumps. Instead, requirements included in the requirements for the Danish Energy Saving Trust list have been determined at specific operating points, as illustrated below. Where the temperature refer to the air temperature at the cold side (outdoor temperature), while the temperature at the warm side (indoor temperature) is constant and 20˚C Temperature -7 ˚C 2 ˚C 7 ˚C COP minimum requirements 2,5 2,8 3,6 Table 2: Energy efficiency requirements at various temperatures for inclusion on the Danish Energy Saving Trust list of energyefficient air-to-air heat pumps SCOP has been calculated for five heat pumps, for which data has been available for four full load test points (-15˚C, -7˚C, 2˚C and 7˚C) and two part load test points (2˚C and 7˚C) measured at approx. 50% capacity. Values from these test points have been interpolated and extrapolated to the values required by 1 The Danish Energy Saving Trust is an independent, public-sector organisation, promoting energy efficiency in households, the public sector and the business community. 3 the SCOP calculation. The heat pumps are all with variable speed compressors and SCOP is calculated on the basis of interpolated part load efficiency based on the stated part load points. For calculation purposes, it is assumed that all of the air-to-air heat pumps are reversible, which makes energy consumption for various standby consumptions in the SCOP calculation minimal, as the number of hours in the different operating conditions is significantly less. The following has been assumed: a crankcase heater consumption of 10W, a thermostat off consumption of 2W and an off consumption of 1W for all sizes of heat pump, which means a maximum of 0.2% for the SCOP value. The results of the calculations are shown in the following table, in which both the SCOP value and the corresponding energy label are indicated. As mentioned previously, the energy efficiency requirement for SCOP will be 3.4 in 2013 and 3.8 from 2014 under the new European scheme. Navn SCOP Energy label VP1 4,12 A+ VP2 4,13 A+ VP3 4,05 A+ VP4 3,92 A VP5 3,99 A Table 3: Calculated SCOP values for five heat pumps from the Danish Energy Saving Trust list of energy-efficient air-to-air heat pumps Trends in energy efficiency requirements and energy labelling of air-to-air heat pumps The five selected heat pumps all have SCOP values of around 4.0, and the future European requirements will be 3.4 in 2013 and 3.8 from 2014. This means that all of these heat pumps will comply with both the first as well as the second set of ecodesign requirements. The requirements in the Danish Energy Saving Trust list are therefore more stringent than future Ecodesign requirements. Furthermore, the results show that these heat pumps will be at the top of the A energy efficiency class or at the bottom of the A+ energy efficiency class. The five selected heat pumps in this analysis represent the best heat pumps currently available on the Danish market. More of these heat pumps are within the A+ class and there is therefore room to reward further development in the energy efficiency of air-to-air heat pumps with even better energy labels. However, the A+ label will not become available before 2015 and A++ label before 2017. This means that there is no incentive to improve energy efficiency of the currently best heat pumps before 2017, at which time such an improvement can be reflected in the energy label. Design of energy label for air-to-air heat pumps As illustrated in figure 2, the energy label will be introduced in four versions. The design of the four labels will be similar, with the exception that the labelling scale will be adjusted every other two year. 4 The first label is shown in figure 5. The scale on the first energy label will be A to G. The label shows the energy efficiency of heating in the three different climate zones (different climate conditions) as well as cooling. Energy label information is optional for cooling, and for Warmer and Colder climate conditions. The label also indicates noise levels form the inside part as well as outside part. Moreover, the label shows the design capacity in kW, calculated SCOP and annual energy consumption for the three climate zones, and for cooling. Design capacity is the heating demand at the design temperature and it is the same as is used in the SCOP calculation (Average = -10 ˚C, Colder = -22 ˚C and Warmer = 2 ˚C). This means that an energy label is not only a tool to assess the energy efficiency of heat pumps; consumers can use energy labels to choose the size of heat pump to suit their needs, which could prove to be crucial for the efficiency actually experienced by the consumer in practice. Figure 5: European energy label for air-to-air heat pumps from 1 Jan. 2013 Shown in figure 6 is the design for the next three energy labels to be introduced on 1 January 2015, 2017 and 2019, respectively. The best heat pumps on the Danish marked today, which are currently eligible for the A+ label, will therefore only be able to obtain an A label until 2015. Similarly, from 2015 to 2017 these pumps will only be able to obtain an A+ label, and from 2017 to 2019 only an A++. 5 Figure 6: Energy labels for air-to-air heat pumps from 1 Jan. 2015, 2017 and 2019 Air-to-water heat pumps and brine-to-water heat pumps So far, no common European regulation has been adopted for the area covered by Lot 1 "Space heaters and combination heaters", which includes air-to-water and brine-to-water heat pumps. However, specific proposals have been drafted and updated documents were released on 2 February, on which the following is based. The regulation is expected to be adopted in 2012. Furthermore, the requirements will most likely become applicable two years after the adoption. Expected implementation is shown in the following figure. 2014 2016 Energy efficiency requirements 1 Energy efficiency requirements 2 Energy label 1 Energy label 2 Figure 7: Expected timetable for implementation of energy efficiency requirements and energy labels for air-to-water and brineto-water heat pumps Air-to-water and brine-to-water heat pumps will be compared across heating technologies and will therefore be assessed according to the same energy labelling scale as, for example, oil-fired boilers and gasfired boilers. However, a special energy labelling scale has been made for heat pumps for low-temperature systems, such as underfloor heating. This is due to the fact that the output temperature plays a significant role for the energy efficiency of the heat pumps. The requirements have been determined for underfloor heating with a design flow 6 temperature of 35 ˚C, corresponding to "low temperature" in the EN14825 standard. The comprehensive energy label is designed for radiator systems with design temperatures of 55 ˚C. Conversely, different ecodesign requirements are set for gas and oil boilers, electrical boilers and heat pumps for different output temperatures. The following analysis focuses solely on space heating and not heating of sanitary hot water. The proposal for the EU regulations provides for labelling of combined sanitary hot water and space heating. In order to compare energy input across different technologies, an energy efficiency factor for space heating is applied known as "Seasonal space heating energy efficiency" as a benchmark (referred to as ηs in the figures). The factor describes the heat output compared to the energy input. For electricity, a conversion factor of 2.5 is used as input, known as the primary energy factor (PEF), where the calculated SCOP value is divided by the PEF value on the assumption that it takes 2.5 energy units of primary fuel to produce 1 energy unit of electricity. The Ecodesign requirements are shown in figure 8. 55 ˚C 2014 SCOP 2,25 2016 SCOP 2,50 35 ˚C ηs SCOP ηs 90 % 2,88 115 % ηs SCOP ηs 100 % 3,13 125 % Figure 8: 1. and 2. Minimum requirements for energy efficiency of air-to-water and brine-to-water heat pumps Similarly, a number of energy classes based on SCOP values will be introduced. Energy efficiency classes for radiator heating are shown to the left and underfloor heating (low temperature) to the right. A+++ SCOP > 3,75 A++ 3,13 ≤ SCOP < 3,75 A+ 2,45 ≤ SCOP < 3,13 A 2,25 ≤ SCOP < 2,45 B 2,05 ≤ SCOP < 2,25 C 1,88 ≤ SCOP < 2,05 D 0,93 ≤ SCOP < 1,88 E 0,85 ≤ SCOP < 0,93 F 0,75 ≤ SCOP < 0,85 G SCOP < 0,75 ηs > 150 % 125 % ≤ ηs < 150 % 98 % ≤ ηs < 125 % 90 % ≤ ηs < 98 % 82 % ≤ ηs < 90 % 75 % ≤ ηs < 82 % 37 % ≤ ηs < 75 % 34 % ≤ ηs < 37 % 30 % ≤ ηs < 34 % ηs < 30% A+++ SCOP > 4,38 ηs > 175 % A++ 3,75 ≤ SCOP < 3,88 139 % ≤ ηs < 175 % A+ 3,08 ≤ SCOP < 3,75 123 % ≤ ηs < 150 % A 2,88 ≤ SCOP < 3,08 115 % ≤ ηs < 123 % B 2,68 ≤ SCOP < 2,88 107 % ≤ ηs < 115 % C 2,50 ≤ SCOP < 2,68 100 % ≤ ηs < 107 % D 1,55 ≤ SCOP < 2,50 62 % ≤ ηs < 100 % E 1,48 ≤ SCOP < 1,55 59 % ≤ ηs < 62 % F 1,38 ≤ SCOP < 1,48 55 % ≤ ηs < 59 % G SCOP < 1,38 ηs < 55 % Figure 9: Scales for energy labelling of air-to-water and brine-to-water heat pumps for 55 ˚ C (left) and 35 ˚C (right) In addition, there are two correction factors that influence the calculation of ηs in relation to SCOP. Due to temperature regulation, 3% is deducted for heat pumps. Due to energy consumption for geothermal 7 heating, a further 5% is deducted for brine-to-water heat pumps alone. Therefore, the calculation of ηs is as follows: Air-to-water heat pumps: 𝜂𝑠 = Brine-to-water heat pumps: 𝜂𝑠 = 𝑆𝐶𝑂𝑃 𝑃𝐸𝐹 𝑆𝐶𝑂𝑃 𝑃𝐸𝐹 − 3% − 3% − 5% Correction factors have not been included in SCOP in figure 9. To find the exact corresponding SCOP, the shown SCOP should be added 0,075 for air- to – water heat pumps and the SCOP value for brine-to –water heat pumps should be added 0,075 + 0,125. The magnitude of these requirements and energy efficiency classes is assessed by calculating SCOP values for selected heat pumps that comply with the requirements of the Danish building regulation 2010. The requirements of Building regulation 2010 are based on a nominal energy efficiency which is calculated on the basis of four or five full load test points. In the following, calculations and results are reviewed for air-to-water and brine-to-water heat pumps, respectively, as well as for, radiators and underfloor heating. Since the nominal energy efficiency is based on other test points than SCOP, the values for the calculations have been interpolated and extrapolated. The following has been assumed: a crankcase heater consumption of 15W, a thermostat off consumption of 2W and an off consumption of 1W for all sizes of heat pumps. This means that these consumptions are more significant for smaller heat pumps than large heat pumps. For instance, this means a reduction in SCOP of approx. 1.3% for a heat pump with a nominal capacity of 6kW, compared with a reduction in SCOP of approx. 0.5% for a heat pump with a capacity of 13kW. Furthermore, calculations are based on full load data in accordance with the calculation method. SCOP values will be slightly higher if part load tests are conducted for frequency controlled heat pumps. For further information about the SCOP calculation method, please see "Calculation of SCOP for heat pumps according to EN 14825". Air-to-water heat pumps SCOP calculation results The test points for calculating the nominal energy efficiency and the SCOP values for radiator heating and underfloor heating are shown in the following table. See annex 1 of "Calculation of SCOP for heat pumps according to EN 14825" for a general overview of test points, which also includes the climate profiles Warmer and Colder. Test points nominal energy efficiency Test points SCOP 55˚C reference (radiator) 7/45 ˚C 2/45 ˚C 7/35 ˚C 2/55 ˚C -7/55 ˚C -7/52 ˚C 2/42 ˚C 7/36 ˚C 12/30 ˚C Test points SCOP 35˚C reference (underfloor heating) -7/34 ˚C 2/30 ˚C 7/27 ˚C 12/24 ˚C 8 Table 4: Test points for the calculation of nominal energy efficiency and SCOP values for air-to-water heat pumps Results air-to-water 55˚C Radiator heating Nine heat pumps have been selected from the Danish Energy Agency's list of heat pumps (dated December 2011, at that time almost 170 A/W were at the list). All nine pumps are immediately above or below the requirements for energy efficiency stipulated in the building regulations. Building regulation 2010 stipulates a nominal energy efficiency of more than 2.7 from 1 January 2012. The table below shows the nominal energy efficiency and calculated SCOP values for the heat pumps. Seasonal space heating energy efficiency (ηs) is also shown in the table because EU regulation for this type of heat pump is based on energy efficiency. Name VP1 VP2 VP3 VP4 VP5 VP6 VP7 VP8 VP9 Capacity 7/45 [kW] Optimum Pdesignh [kW] Nominal energy efficiency (NEF) Calculated SCOP Energy efficiency (ηs) SCOP/NEF Expected energy efficiency class 4.00 5.45 5.94 6.25 6.35 7.60 13.15 14.60 15.10 4.2 6.1 6.7 6.7 7.0 7.8 15.6 15.7 16.0 2.74 2.75 2.66 2.72 2.67 2.61 2.79 2.74 2.89 2.68 2.65 2.73 2.67 2.69 2.51 2.80 2.75 2.97 107% 106% 109% 107% 108% 100% 112% 110% 119% 98% 97% 103% 98% 101% 96% 101% 100% 103% A+ A+ A+ A+ A+ A+ A+ A+ A+ Table 5: SCOP calculation results for air-to-water heat pumps with a 55˚C design flow temperature; radiator heating The SCOP value is calculated from ηs and the correction factor on 3% is included. The results above have relatively little uncertainty, as test values of the nominal energy efficiency fall within the same temperature range as the values that are used in the SCOP calculation. Only the point 12/30˚C falls outside the available test points from the nominal energy efficiency test. However, as heating demand decreases with increasing temperatures, it is assumed that this point only has a peripheral impact on the SCOP value. The results show a strong correlation between the calculated value for nominal energy efficiency and the calculated SCOP value. This is also illustrated in the last column in which the calculated SCOP value has been divided by the nominal energy efficiency (NEF). The SCOP/NEF ratio indicates that the European SCOP calculation method represents heat pump operation under Danish conditions just as well as the existing Danish nominal energy efficiency. If the current requirements of the Danish Building regulation 2010 for energy efficiency are converted, they correspond to a requirement of 108%. This requirement will be tightened no later than 2015, with the 9 adoption of new building regulations. EU ecodesign requirements for both 2013 (90%) and 2015 (100%) are less than the Danish requirements. Moreover, the results show that all the nine heat pumps will all obtain the A+ energy label. Results of air-to-water 35 ˚C underfloor heating Building regulation 2010 stipulates a nominal energy efficiency of 3.2 for underfloor heating. SCOP values for the same nine air-to-water heat pumps have been calculated. All the selected heat pumps have a nominal energy efficiency above the requirement of Building regulation 2010. The results are shown in the following table. Name VP1 VP2 VP3 VP4 VP5 VP6 VP7 VP8 VP9 Capacity 7/45 [kW] Optimum Pdesign [kW] Nominal energy efficiency NEF 4.00 5.45 5.94 6.25 6.35 7.60 13.15 14.60 15.1 5.00 7.0 7.5 7.7 8.2 9.2 16.8 17.3 19.1 3.54 3.26 3.39 3.20 3.40 3.08 3.37 3.40 3.62 Calculated SCOP Energy efficiency ((ηs)) SCOP/NEF 3.82 3.14 3.47 3.50 3.53 3.38 3.54 3.53 3.88 153% 125% 139% 140% 141% 135% 142% 141% 155% 108% 96% 102% 109% 104% 110% 105% 104% 107% Expected energy efficiency class A++ A+ A+ A+ A+ A+ A+ A+ A++ Table 6: SCOP calculation results for air-to-water heat pumps with 35˚C design flow temperature; underfloor heating The SCOP value is calculated from ηs and the correction factor on 3% is included. The results for air-to-water underfloor heating are associated with a greater degree of uncertainty as the test values for nominal energy efficiency have been monitored at higher temperatures than most of the values used in the SCOP calculation. This means that a certain amount of extrapolation has been applied, which results in greater uncertainty. The test points at the cold and warm side vary, which necessitate inter and extrapolation on both values. For 35˚C, SCOP values are approx. 5% higher than nominal energy efficiency (also at 35˚C), however, the two calculations are still well aligned. The difference between the two calculations could be due to differences in calculation methods for underfloor heating and radiator heating, respectively, as well as uncertainty from extrapolation. If the current requirements of the Danish Building regulation 2010 for energy efficiency are converted, they correspond to a requirement of 128%. This requirement will also be tightened no later than 2015. The EU ecodesign requirements for 2014 (115%) are less than the Danish requirements, while the requirements for 2016 (125%) match the requirements of Building regulation 2010. 10 Eight of the nine heat pumps will obtain the energy label A+ for low temperature, while one will obtain A++. Brine-to-water heat pumps SCOP calculation results The test points for calculating the nominal energy efficiency as well as SCOP values for brine-to-water heat pumps for radiator heating and underfloor heating are shown below. A more comprehensive overview is available in Annex 1 of "Calculation of SCOP for heat pumps according to EN 14825". Test points nominal energy efficiency Test points SCOP 55˚C reference (radiator) 0/45 ˚C 0/35 ˚C 0/55 ˚C -5/55 ˚C 0/52 ˚C 0/42 ˚C 0/36 ˚C 0/30 ˚C Test points SCOP 35˚C reference (underfloor heating) 0/34 ˚C 0/30 ˚C 0/27 ˚C 0/24 ˚C Table 7: Test points for use in calculating nominal energy efficiency and SCOP values for brine-to-water heat pumps Results brine-to-water 55˚C radiator heating Similarly, nine brine-to-water heat pumps have been selected from the Danish Energy Agency's heat pump list (December 2011 at that time almost 360 B/W were at the list). All are close to compliance with the energy efficiency requirements of the building regulations which will enter into force 1 January 2012. Building regulation 2010 requires nominal energy efficiency NEF of above 2.8 for brine-to-water heat pumps with a capacity of between 3kW and 6kW, and above 3.0 for heat pumps with a capacity above 6kW. The results are shown in the following table. Name VP1 VP2 VP3 VP4 VP5 VP6 VP7 VP8 VP9 Capacity 0/45 [kW] Optimum Pdesign [kW] 5.30 5.49 7.25 7.40 7.80 8.30 8.59 9.24 9.41 6.7 7.0 9.2 9.4 10.0 10.5 10.7 11.5 11.9 Nominal energy efficiency Calculated SCOP Energy efficiency (ηs) 2.96 2.92 2.99 3.33 3.40 2.98 3.02 3.10 3.03 2.98 2.97 2.99 3.37 3.43 3.03 3.08 3.16 3.17 119 % 119 % 120 % 135 % 137 % 121 % 123 % 126 % 127 % Expected SCOP/Nominal energy energy efficiency efficiency class 101 % 102 % 100 % 101 % 101 % 102 % 102 % 102 % 105 % A+ A+ A+ A++ A++ A+ A+ A++ A++ Table 8: SCOP calculation results for brine-to-water heat pumps with 55˚C design flow temperature; radiator heating The SCOP value is calculated from ηs and the correction factor on 8% is included. 11 The results above have relatively little uncertainty, as test values of the nominal energy efficiency fall within the same temperature range as the values that are used in the SCOP calculation. Furthermore three of the four of the nominal energy efficiency NEF test points have 0 ˚C on the cold side. This means that mainly an amount of interpolation has been applied, which results in lower uncertainty. Only the point 0/30˚C falls outside the nominal energy efficiency test points. However, this point only impacts a very small share of the annual consumption and therefore it only plays a peripheral role. Again there is a strong correlation between SCOP and the nominal energy efficiency, with SCOP approx. 2% better than nominal energy efficiency. The larger efficiency of brine-to-water heat pumps compared to airto-water heat pumps, as indicated by the nominal energy efficiency (NEF) requirements in the national building regulation, is also seen for the calculated SCOP values. Existing Danish building regulation 2010 requirements came into force 1 January 2012 correspond to requirements for energy efficiency (ηs) of respectively 112% and 120%. The EU ecodesign requirements for 2014 (90%) and for 2016 (100%) are less than the Danish requirements which. The national requirements will also be tightened no later than 2015. As brine-to-water heat pumps are slightly more efficient than air-to-water heat pumps, the calculated energy efficiencies for the nine chosen heat pumps (between 119% and 137%) are significantly higher than the EU ecodesign requirements, which are 90% in the first phase and 100% in the second phase. When used for radiator heat four out of nine brine-to-water heat pumps will qualify for A++, while five heat pumps will qualify for A+. Results of brine-to-water 35˚C underfloor heating Building regulation 2010 stipulates nominal energy efficiency NEF of more than 3.6 for brine-to-water heat pumps of between 3kW and 6kW, and 3.7 for heat pumps over 6 kW from 1 January 2012. SCOP values have been calculated for the same nine brine-to-water heat pumps. The results are shown in the following table. Name VP1 VP2 VP3 VP4 VP5 VP6 VP7 VP8 VP9 Nominal Capacity Optimum energy 0/45 Pdesign efficiency [kW] [kW] NEF 5.30 5.49 7.25 7.40 7.80 8.30 8.59 9.24 9.41 7.3 7.3 9.4 9.5 9.8 10.8 11.6 12.0 12.3 3.70 3.71 3.65 4.08 4.23 3.78 3.93 3.85 4.03 Calculated SCOP 3.78 3.82 3.69 4.12 4.32 3.87 4.06 3.95 4.24 Energy efficiency SCOP/NEF (ηs) 151 % 153 % 147 % 165 % 173 % 155 % 163 % 158 % 170 % 102 % 103 % 101 % 101 % 102 % 102 % 103 % 103 % 105 % Expected energy efficiency class A++ A++ A+ A++ A++ A++ A++ A++ A++ Table 9: SCOP calculation results for brine-to-water heat pumps with 55 ˚C design flow temperature; underfloor heating 12 The SCOP value is calculated from ηs and the correction factor on 8% is included. The results for brine-to-water underfloor heating are also associated with a greater degree of uncertainty, than for radiator heating as the test values from the nominal energy efficiency NEF are conducted at higher temperatures than most of the values used in the SCOP calculation. Once again there is good agreement between nominal energy efficiency NEF and the SCOP calculation, where the SCOP value is approx. 2% higher than nominal energy efficiency NEF. The Danish requirements in Building regulation 2010 convert to Energy efficiency (ηs) 144% (3-6kW) and 148%(>6kW). These requirements will also be tightened by no later than 2015. The high level of energy efficiencies (ηs)of the heat pumps is well above the EU energy efficiency requirements for both 2014 (115%) and 2016 (125%). The calculated Energy efficiency (ηs) for the nine pumps from the Danish list are as seen in table 9 from 147% to 170%. Eight of the nineheat pumps will be given energy label A++, while one heat pump will be at the top of the A+ energy class. Expected design of energy labels In the proposal for energilabeling of spaceheaters and combinations send in interservice consultation by the EU commission it is proposed to introduced the energy label for the product in two phases, with the A+++ class being introduced after four years the regulation enter into force. The first energy labels to be introduced two years after the entry into force will range from A++ to G, while the other energy label ranges from A+++ to D. Moreover, there will be two different energy labels for radiator heating and underfloor heating, respectively. These two labels are shown in figure 10 and 11. The energy label shows the energy efficiency class for radiator heating and underfloor heating, respectively. Additionally, heating capacity, including electrical backup at design temperature in the different climate zones, is indicated in the box below. This figure reflects the heating demand used in the calculations at design outdoor temperatures. These values may be a dimensioning parameter, since consumers can look for heat pumps that match their needs at a given temperature. In previous proposal for the design of the energy labelling, energy efficiency should also be indicated; 13 similarly to the label for air to air heat pumps, however, these are not indicated by the label in its current design. The information on the energy efficiency of the heat pump gives the consumer a chance to compare different heat pumps in the same energy class. This is especially important when the energy classes are as big as 25-40% which is the case for heat pumps. The energy label also shows the noise level of the indoor part and outdoor part, respectively. Figure 10: First energy label for air-to-water and brine-to-water heat pumps for radiator heating and underfloor heating If the heat pump can only produce low-temperature heating (underfloor heating), the energy label below should be used.Figure 11: First energy label for air-to-water and brine-towater heat pumps for only low temperature heating (underfloor heating) The energy labels shown below will be introduced two years later. Figure 12: Second energy label for air-to-water and brine-to-water heat pumps and underfloor heating alone 14