STD/1134

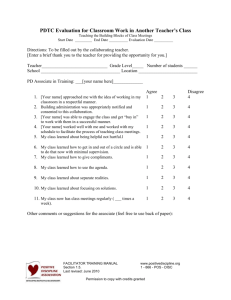

advertisement