ggge2305-sup-0002-txts01

advertisement

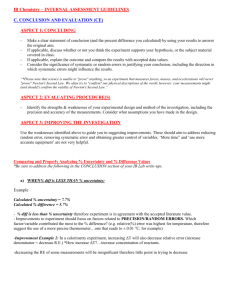

Text S1: Ti-in-quartz methods S1. Methods Samples were chosen to ensure a complete spread across both the carapace and core structural zones of Goodenough, Mailolo, Morima, and northwest Normanby dome. The quartz grains analyzed by this study were >75 μm in diameter, which is the resolution of the LA-ICP-MS. Analytical spots were scattered as far apart as possible in the mount, in an attempt to obtain a spatially-averaged mean Ti concentration for the sample as a whole. In 54% of the samples, less than the full suite of eight spot analyses was included in the mean Ti concentrations. On average, seven spots were analyzed per sample. Wherever possible, spot analyses were taken from both the rim and core of up to four different quartz grains to yield eight spot analyses. This was successfully undertaken on 22% of the samples analyzed here. On average six quartz grains were analyzed per sample (Table 1). The high number of quartz grains that do not include separate core and rim spot analyses resulted from several analytical limitations: (1) rejection of contaminated signal (~42%), (2) fracturing during ablation destroying the rim or core of the grain analyzed (~32%), and (3) small grain size (<125 μm) allowing only one ablation pit per grain (~26%). The LA-ICP-MS was tuned before every analytical run to ensure a high stability and sensitivity of the NIST 612 standard. Each analytical run was arranged using standard-sample bracketing; four unknown analyses were bracketed by two NIST 612 standard analyses. Consistency of 47Ti/29Si and 43Ca/29Si were monitored during data processing as variations in these ratios suggest ablation of an undesirable mineral phase. The New Wave 193 μm solid-state Nd-YAG laser at VUW causes trace element-poor and Si-rich material to fracture during interaction of the laser with the target. Ideally, this interaction should create a round crater. This fracturing results in the creation of mineral shards in the first few seconds of laser ablation that are subsequently blown away by the gas flow, and may result in unwanted mineral phases being incorporated into the signal and the destruction of the area immediate to the shot. Laser settings (such as optional gas flow, extract voltage, and torch position) were tuned during ablation of the NIST 612 standard to ensure that: (1) the quartz ablated as well as possible, and (2) the ICP-MS was at optimum sensitivity and low internal errors (Table S1). The switch between pulse (P; <1 x 106 counts per second; 43Ca, 47Ti, 49Ti, 27 Al) and analog (A; >1 x 106 counts per second; 29 Si) counting modes was carried out by the ICP-MS. The P/A factor was measured on all analyzed elements during tuning to ensure the switch between high and low signal was performed correctly. Elemental oxide production was maintained below 1.5% by tuning the conditions of the plasma torch, and was monitored by ThO+/Th+. Table S1. Analytical conditions of the LA-ICP-MS ICP-MS System Agilent 7500CS Acquisition mode Peak-hopping pulse (43Ca, 47Ti, 48Ti, 27Al) and analogue Detection mode (29Si) Laser ablation New Wave 193 nm (deep UV) solid state System laser Laser power 65% for NIST 612, ~85% for quartz grains Ablation mode Static spot analysis Repetition rate 10 Hz Standards Bracketing/Calibration standards NIST 612 Analysis method Standard/sample acquisition 60 seconds Wash out/background acquisition 90 seconds Measured isotopes and integrations 29 times Si, 43Ca, 47Ti, 49Ti, 27Al; all 0.01 seconds Tuning Tuning standards NIST 612 29 Monitored isotopes during tuning Si, 43Ca, 47Ti, 49Ti, 27Al Ablation mode 50 μm diameter spots Monitored isotopes during ablation 29Si, 43Ca, 47Ti, 49Ti, 27Al 47 Background Ti <400 counts per second* Oxides <1.5% (checked during tuning) Carrier gas (Ni) 0.75 -0.85 L min-1 Optional gas (He) 75 - 85% RF Power 1500 W RF matching 1.96 V Sample depth 3 – 4 mm *Counts per second or signal measure by the LA-ICP-MS Ti concentration was internally corrected during data reduction with respect to Si. The equations used for this correction can be written as: [ Si] Smpl = [ Si] Std ´ and CPSSmpl CPSStd [Ti] Smpl = [Ti] Std ´ CPSSmpl CPSStd where [i]Smpl is the concentration of the element of interest in the sample or unknown, [i]Std is the concentration of the element of interest in the standard, and CPSi is the counts per second or signal of the sample or standard. SiO2 is by far the major oxide in quartz and therefore has an assumed value of 100% for a pure quartz grain. If the measured Si concentration is less than 100% during analysis, this secondary internal correction for Si increases the Ti concentration of the unknown by a proportional amount. The background-corrected signal for each spot analysis was corrected to the bracketing NIST 612 using GeoReM preferred values. The background for all beams was measured and subtracted from the signal of each spot analysis prior to calculation of the Ti concentration. The mean Ti concentration in quartz for each sample quoted in Table 1 was calculated as the weighted mean of all analyses (up to eight) of the sample (weight equal to std dev-2). The uncertainty of the mean Ti concentration (standard error) was calculated by pooling the weighted residuals. The 95% confidence interval of the mean Ti concentration (quoted as 2σ in Table 1) is given by: ±t × (weighted standard error), where t is the Student’s t statistic for 95% with (n1) degrees of freedom (n is the number of data). S2. Errors and uncertainties calculations The total uncertainty related to the Ti-in-quartz apparent temperature (Table 1) is derived from three sources. First, there is an uncertainty in the slope and intercept of the least-squares regression-analysis carried out during calibration of the thermometer (~5 °C of uncertainty; Thomas et al., 2010). Secondly, there is the analytical uncertainty, which is a 95% confidence interval of the average Ti concentration. Thirdly, there is an assigned uncertainty of ±0.2 in the Ti activity ( aTiO2 ). We suggest that the three sources of uncertainty are independent of each other as they arise from different contributions. Thomas et al., (2010) determined the calibration uncertainty. The analytical uncertainty is calculated from the ICP-MS measurement statistics. The aTiO uncertainty is an assigned value. 2 The combination of the three sources of uncertainties into the single value was determined as a 95% confidence interval of the quotient. The calibration uncertainty (c1 = ±3122, c2 = ±0.04, c3 = ±63), the analytical uncertainty (εj), and the Ti activity uncertainty (α) were all incorporated into the original Thomas et al. (2010) equation: T (°C) = (60952 ± c1 ) + (1741± c3 )P - 273.15 Qtz (1.520 ± c 2 ) - R(ln XTiO ± e ) + R(ln a ± a ) j TiO 2 2 . Expanding the denominator gives ìï æ X Qtz ö æ æ ej ö a öüï TiO2 2 ç ÷ ç ÷ ç 1.520 ± c R ln + ln 1+ ln 1+ í ( ) ï ç a ÷ ç X Qtz ÷ ç a ÷÷ýï . TiO2 ø TiO2 øþ è è î è TiO2 ø Approximating Ln(1+x) by the first term of its power series is valid if x2<<x. If and a <<1, the denominator is approximately aTiO 2 ìï æ X Qtz ö e a üï TiO2 j ç ÷ 1.520 ± c R ln + í ( ) ï ç a ÷ X Qtz a ýï . TiO2 TiO2 þ î è TiO2 ø 2 So the variance of the denominator is se Qtz XTiO 2 ìï æ e ö æ a öüï æ c 2 ö2 j ÷÷ý + ç ÷ = -R ívar çç Qtz ÷÷ + var çç a ïî è XTiO2 ø è TiO2 øïþ è 2 ø , 2 which expands to 2 ü ì 2 a ï æ c2 ö 1 2ï 2 2 =R í se + + ÷ . 2ý ç Qtz 2 2 è ø a ï ( XTiO ï ( ) TiO2 2) î þ ( ) The variance of the numerator is æ c1 ö æ c 3 ö = ç ÷ +ç ÷ è2ø è2ø , 2 2 where we have taken the ranges c1, c2, and α to be 2σ, and c3 to be <<c1. The two variances were then input in the equation for the 95% confidence interval of a quotient: æ Aö 1 A2 varç ÷ = 2 var A + 4 var B, è Bø B B in order to determine the combined uncertainty, with the same requirements as before. S3. One-sided t distribution A one-sided t distribution was used to determine the probability that the slopes for the linear regressions in Figure 11 were negative or zero (Table S2). We assume that the uncertainties or scatter in the data, and hence the slope estimates, are Normal/Gaussian random variables. Table S2. Results of one-sided t distribution Standard No. Slope Deviation of Fault (m) m (sd) dataa Wakonai 0.01157 0.00383 21 Mwadeia 0.00301 0.00213 14 Morima 0.00166 0.00042 5 NW Norm. 0.00071 0.00165 5 SE Norm. 0.00370 0.00126 5 a df = no. of data -2 b Probability slope is negative or zero m/sd 3.01810 1.41544 3.94945 0.42839 2.92843 p0b 0.00353 0.09118 0.01448 0.34863 0.03054 p0 < 1% < 10% < 2% < 35% < 4%