Case Study 2 - Load Lifting Circuit Analysis

advertisement

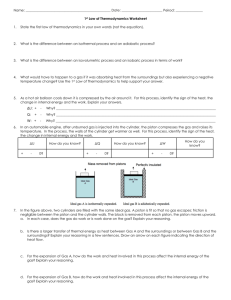

The circuit below is used to control the lifting and lowering of a 5 kN load. The hydraulic cylinder has a blank side area of 1200 mm2 and a rod side area of 700 mm2. The circuit piping is of 25 mm diameter and the equivalent lengths for the segments and fittings at this diameter are given in the table below. The hydraulic fluid used has a density of 900 kg/m3 and a dynamic viscosity of 0.1 Pa.s 1. Assuming laminar flow is maintained up to ReD = 2000, find the maximum load speed, vc at which laminar flow conditions are maintained in the piping. 2. Determine the pump power and the overall efficiency during the lifting, lowering and holding states at a load speed of vc and of 2 vc 3. Suggest an alternative circuit design to improve efficiency during the lowering and the holding stages. Piping Segment / Fitting Equivalent Length (m) A–B 10 B–C 2 D–E 10 F-G 10 H–I 10 I–J 14 Pressure Relief Valve 20 Directional Control Valve 8 1 1. Maximum load speed for laminar flow: The pipe speed, 𝑣𝑝 , which results in 𝑅𝑒𝐷 = 2000 is calculated from the definition of 𝑅𝑒𝐷 as: 𝑅𝑒𝐷 = 𝜌𝑣𝑝 𝐷 𝜇 = 2000, 𝑣𝑝 = 𝜇𝑅𝑒𝐷 𝜌𝐷 0.1×2000 = 900×25×10−3 = 8.89 m/s We need to check that the 𝑅𝑒𝐷 ≤ 2000 in the pipe connected to the blank side of the cylinder and to that connected to the rod side of the cylinder. Note that because the area of the blank side of the cylinder is larger than that of the rod side, the flow speed in the piping connected to the blank side is larger than that connected to the rod side for a given load speed. The load speed 𝑣𝑐 that produces the value of 𝑣𝑝 = 8.89 m/s in the pipe connected to the blank-side of the cylinder is calculated using continuity between the blank side of the cylinder and the piping connected to the blank side, 𝑣𝑝 𝐴𝑝 = 𝑣𝑐 𝐴𝑏 , 𝜋 where 𝐴𝑏 = 1200 mm is the area of the blank side, and 𝐴𝑝 = 4 × 252 = 490.87 mm2 is the area of 2 the pipe. Thus, 𝐴𝑝 𝑣𝑐 = 𝑣𝑝 𝐴 = 8.89 × 𝑏 490.87 1200 = 3.64 m/s. Similarly, the value of 𝑣𝑐 which produce 𝑣𝑝 = 8.89 in the rod side piping is calculated using continuity between the rod side of the cylinder and the piping connected to the rod: 𝑣𝑝 𝐴𝑝 = 𝑣𝑐 𝐴𝑟 , 𝐴 𝑣𝑐 = 𝑣𝑐 𝐴𝑝 = 8.89 × 𝑟 490.87 700 = 6.23 m/s 𝑣𝑐 = min(3.64 ,6.23) = 3.64 m/s A lower limit on 𝑣𝑐 is necessary in order maintain laminar flow in the pipe connected to the blank side. When the piston moves at a speed 𝑣𝑐 = 3.64 m/s, The speed of flow in the pipe connected to the blank side is 𝑣𝑝−𝑏 = 8.89 m/s as calculated above. The speed of flow in the pipe connected to the rod side, 𝑣𝑝−𝑟 is calculated from continuity based 𝑣𝑐 = 3.64 as: 𝐴 700 𝑣𝑝−𝑟 = 𝑣𝑐 𝐴𝑟 = 3.64 × 490.87 = 5.19 m/s 𝑝 2.a Pump power and circuit efficiency during load lifting: Note that during lifting the pump flow is that of the rod-side of the cylinder. Pump power may be calculated from the product of the head and flow rate as: 𝑃𝑝𝑢𝑚𝑝 = 𝑄𝑝𝑢𝑚𝑝 ∆𝑝 𝑄𝑝𝑢𝑚𝑝 = 𝑣𝑐 𝐴𝑟 = 3.64 × 700 × 10−6 = 2.55 × 10−3 m3/s ∆𝑝 = 𝑝𝑜𝑢𝑡 − 𝑝𝑖𝑛 , 𝑝𝑖𝑛 = 𝑝𝑎𝑡𝑚 = 0, 𝑝𝑜𝑢𝑡 = 𝑝𝑟 + 𝑝𝑙𝑜𝑠𝑠−𝑟 𝑝𝑙𝑜𝑠𝑠−𝑟 = 32𝜇𝐿𝑒𝑞−𝑟 𝑣𝑝−𝑟 𝐷𝑝2 where 𝑝𝑟 is the pressure in the rod side of the cylinder, 𝑝𝑙𝑜𝑠𝑠−𝑟 is the pressure loss in the pipe connected to the rod side, and 𝐿𝑒𝑞−𝑟 is the equivalent length of the this pipe, 𝐿𝑒𝑞−𝑟 = 10 + 2 + 8 + 10 = 30 m 2 𝑝𝑙𝑜𝑠𝑠−𝑟 = 32×0.1×30×5.19 (25×10−3 )2 = 796.4 kPa The value of 𝑝𝑟 , may be calculated from a force balance on the piston. Assuming that the piston is moving with a constant speed upwards, we have ∑ 𝐹 = 0, 𝑝𝑟 𝐴𝑟 − 𝑝𝑏 𝐴𝑏 − 𝑊 = 0, 𝑝𝑟 = 𝑝𝑏 𝐴𝑏 +𝑊 𝐴𝑟 where 𝑝𝑏 is the pressure in the blank side of the piston, calculated as 𝑝𝑏 = 𝑝𝑎𝑡𝑚 + 𝑝𝑙𝑜𝑠𝑠−𝑏 where 𝑝𝑙𝑜𝑠𝑠−𝑏 is the pressure loss in the pipe connected to the blank side of the piston. Considering gauge pressures, 𝑝𝑎𝑡𝑚 = 0, and calculating the equivalent length, 𝐿𝑒𝑞−𝑏 , of the blank side pipe: 𝐿𝑒𝑞−𝑏 = 10 + 8 + 10 + 14 = 42 m 𝑝𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 = 𝑝𝑟 = 𝑝𝑏 𝐴𝑏 +𝑊 𝐴𝑟 = 32𝜇𝐿𝑒𝑞−𝑏 𝑣𝑝−𝑏 𝐷𝑝2 = 32×0.1×42×8.89 (25×10−3 )2 1911.47 ×103 ×1200×10−6 +5×103 700×10−6 = 1911.5 kPa = 10418.9 kPa The outlet pressure of the pump can then be calculated as 𝑝𝑜𝑢𝑡 = 𝑝𝑟 + 𝑝𝑙𝑜𝑠𝑠−𝑟 = 10418.9 + 796.4 = 11215.3 kPa Pump power is then: 𝑃𝑝𝑢𝑚𝑝 = 𝑄𝑝𝑢𝑚𝑝 ∆𝑝 = 2.55 × 10−3 × 11215.3 × 103 = 28.6 kW Circuit efficiency during lifting is therefore, 𝜂= 𝑃𝑜𝑢𝑡 𝑃𝑖𝑛 𝑊×𝑣 =𝑃 𝑝𝑢𝑚𝑝 = 5000×3.64 28599 = 63.57% Alternative method to calculate pump power: 𝑃𝑝𝑢𝑚𝑝 = 𝑃𝑜𝑢𝑡 + 𝑃𝑙𝑜𝑠𝑠−𝑏 + 𝑃𝑙𝑜𝑠𝑠−𝑟 Where 𝑃𝑙𝑜𝑠𝑠−𝑏 and 𝑃𝑙𝑜𝑠𝑠−𝑟 are the power losses in the piping connected to the blank-side and rodside of the cylinder, respectively, calculated as: 𝑃𝑙𝑜𝑠𝑠−𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 × 𝑄𝑏 = 1911.5 × 103 × 4.36 × 10−3 = 8.34 kW 𝑃𝑙𝑜𝑠𝑠−𝑟 = 𝑝𝑙𝑜𝑠𝑠−𝑟 × 𝑄𝑟 = 796.4 × 103 × 2.55 × 10−3 = 2.03 kW 𝑃𝑜𝑢𝑡 = 5000 × 3.64 = 18.2 kW 𝑃𝑝𝑢𝑚𝑝 = 18.2 + 8.34 + 2.0 = 28.6 kW 𝜂= 𝑃𝑜𝑢𝑡 𝑃𝑖𝑛 𝑊×𝑣 =𝑃 𝑝𝑢𝑚𝑝 = 5000×3.64 28599 = 63.57% The same approach may be used to calculate the efficiency for load speed 𝑣𝑙 = 2𝑣𝑐 = 2 × 3.64 = 7.28 m/s. The outlet power in this case is 𝑃𝑜𝑢𝑡 = 𝐹. 𝑣 = 5000 × 7.28 = 36.4 kW 3 To calculate the power loss in the piping, the speed of flow in the blank-side and the rod-side piping 𝑣𝑝−𝑏 and 𝑣𝑝−𝑟 can be calculated from continuity as: 𝑣𝑙 𝐴𝑏 = 𝑣𝑝−𝑏 𝐴𝑝 , 𝐴 1200 𝑣𝑝−𝑏 = 𝑣𝑙 𝐴𝑏 = 7.28 × 490.87 = 17.8 m/s 𝑝 and 𝑣𝑙 𝐴𝑟 = 𝑣𝑝−𝑟 𝐴𝑝 , 𝑣𝑝−𝑟 = 𝐴 𝑣𝑙 𝑟 𝐴𝑝 = 7.28 × 700 490.87 = 10.38 m/s Reynolds numbers in the rod-side and the blank-side piping are calculated as: 𝑅𝑒𝐷−𝑏 = 𝜌𝑣𝑝−𝑏 𝐷 900 × 17.8 × 25 × 10−3 = = 4000 𝜇 0.1 and 𝑅𝑒𝐷−𝑟 = 𝜌𝑣𝑝−𝑟 𝐷 900 × 10.38 × 25 × 10−3 = = 2336 𝜇 0.1 Both 𝑅𝑒𝐷−𝑏 and 𝑅𝑒𝐷−𝑟 are above the critical value for laminar flow and the flow is turbulent in both pipes. Assuming a relative roughness of 0.01, the friction factors in the blank-side and the rod-side pipes are calculated using Haaland’s formula: −2 1.11 6.9 𝜀 ⁄𝐷 𝑓 = (−1.8 log ( +( ) 𝑅𝑒 3.7 )) From which we obtain: 𝑓𝑏 = 0.05, 𝑓𝑟 = 0.06 The frictional losses in the blank-side and rod-side pipes are therefore: 𝑝𝑙𝑜𝑠𝑠−𝑏 = 𝑓𝑏 𝑝𝑙𝑜𝑠𝑠−𝑟 = 𝑓𝑟 2 𝐿𝑒𝑞−𝑏 𝜌𝑣𝑝−𝑏 𝐷𝑝 ( 2 2 𝐿𝑒𝑞−𝑟 𝜌𝑣𝑝−𝑟 𝐷𝑝 ( 2 ) = 0.05 × 42 900×17.82 ( ) −3 25×10 2 30 = 11977 kPa 900×10.382 ) 2 ) = 0.06 × 25×10−3 ( = 3491 kPa The power loss in the blank side and rod-side piping is calculated as: 𝑃𝑙𝑜𝑠𝑠−𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 𝑄𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 (𝑣𝑝−𝑏 𝐴𝑝 ) = 11977 × 103 × (17.8 × 490.87 × 10−6 ) = 104.65 kW 𝑃𝑙𝑜𝑠𝑠−𝑟 = 𝑝𝑙𝑜𝑠𝑠−𝑟 𝑄𝑟 = 𝑝𝑙𝑜𝑠𝑠−𝑟 (𝑣𝑝−𝑟 𝐴𝑝 ) = 3491 × 103 × (10.38 × 490.87 × 10−6 ) = 17.79 kW 𝑃𝑝𝑢𝑚𝑝 = 𝑃𝑜𝑢𝑡 + 𝑃𝑙𝑜𝑠𝑠−𝑏 + 𝑃𝑙𝑜𝑠𝑠−𝑟 𝑃𝑝𝑢𝑚𝑝 = 36.4 + 104.65 + 17.79 = 158.8 kW 𝜂= 𝑃𝑜𝑢𝑡 𝑃𝑖𝑛 36.4 = 158.8 = 5000×3.64 28599 = 22.9 % 4 2.b Pump power and circuit efficiency during load lowering: Using the expression above for the power produced by the pump, 𝑃𝑝𝑢𝑚𝑝 = 𝑄𝑝𝑢𝑚𝑝 ∆𝑝, and observing that during the lowering of the load, pump flow is directed to the blank-side of the cylinder, 𝑄𝑝𝑢𝑚𝑝 and ∆𝑝 are calculated as: 𝑄𝑝𝑢𝑚𝑝 = 𝑣𝑐 𝐴𝑏 = 3.64 × 1200 × 10−6 = 4.37 × 10−3 m3/s ∆𝑝 = 𝑝𝑜𝑢𝑡 − 𝑝𝑖𝑛 , 𝑝𝑖𝑛 = 𝑝𝑎𝑡𝑚 = 0, 𝑝𝑜𝑢𝑡 = 𝑝𝑏 + 𝑝𝑙𝑜𝑠𝑠−𝑏 𝑝𝑙𝑜𝑠𝑠−𝑏 = 32𝜇𝐿𝑒𝑞−𝑏 𝑣𝑝−𝑏 𝐷𝑝2 where 𝑝𝑏 is the pressure in the blank side of the cylinder, 𝑝𝑙𝑜𝑠𝑠−𝑏 is the pressure loss in the pipe connected to the rod side, and 𝐿𝑒𝑞−𝑏 is the equivalent length of the pipe connected to the blank side, calculated as 𝐿𝑒𝑞−𝑏 = 10 + 2 + 8 + 10 = 30 m. 𝑝𝑙𝑜𝑠𝑠−𝑏 = 32×0.1×30×8.89 (25×10−3 )2 = 1365.5 kPa The value of 𝑝𝑏 may be calculated using a force balance on the piston as above. Assuming that the piston is moving with a constant speed downward, we have ∑ 𝐹 = 0, 𝑝𝑟 𝐴𝑟 − 𝑝𝑏 𝐴𝑏 − 𝑊 = 0, 𝑝𝑏 = 𝑝𝑟 𝐴𝑟 −𝑊 𝐴𝑏 where 𝑝𝑟 is the pressure in the rod side of the piston, calculated as 𝑝𝑟 = 𝑝𝑎𝑡𝑚 + 𝑝𝑙𝑜𝑠𝑠−𝑟 = 0 + 32𝜇𝐿𝑒𝑞−𝑟 𝑣𝑝−𝑟 𝐷𝑝2 Considering gauge pressures, 𝑝𝑎𝑡𝑚 = 0, as above. The value of 𝐿𝑒𝑞−𝑟 , is: 𝐿𝑒𝑞−𝑟 = 𝐹𝐺 + 𝐺𝐻 + 𝐻𝐼 + 𝐼𝐽 = 10 + 8 + 10 + 14 = 42 m. Thus, 𝑝𝑟 = 𝑝𝑏 = 𝑝𝑟 𝐴𝑟 −𝑊 𝐴𝑏 = 32×0.1×42×5.19 (25×10−3 )2 = 1116.1 kPa 1116.1×103 ×700×10−6 −5000 1200×10−6 = −3515.6 kPa 𝑝𝑜𝑢𝑡 = 𝑝𝑏 + 𝑝𝑙𝑜𝑠𝑠−𝑏 = −3515.6 + 1365.5 = −2150.1 kPa 𝑃𝑝𝑢𝑚𝑝 = 𝑄𝑝𝑢𝑚𝑝 (𝑝𝑜𝑢𝑡 − 𝑝𝑖𝑛 ) = 4.37 × 10−3 × (−2150.1 × 103 − 0) = −9.4 kW The ‘power output’ at the load side is: 𝑃𝑜𝑢𝑡 = 𝐹. 𝑣 = −5000 × 3.64 = −18.2 kW The minus sign in the equation above indicates that the direction of the force is opposite to the load speed. Note that since both signs are negative, the output power of the system is at the pump side, and the input power is at the load. The efficiency therefore is: 𝜂= 𝑃𝑜𝑢𝑡 𝑃𝑖𝑛 9.4 = 18.2 = 51.6 % 5 Calculations of the pump power and circuit efficiency when the load speed 𝑣𝑙 = 2𝑣𝑐 = 7.28 m/s may proceed by considering the input power (at the load) to be: 𝑃𝑙𝑜𝑎𝑑 = 𝐹. 𝑣𝑙 = 5000 × 7.28 = 36.4 kW Power loss in the piping is calculated as above using 𝑣𝑝−𝑏 = 17.8 m/s and 𝑣𝑝−𝑟 = 10.38 m/s which give 𝑅𝑒𝐷−𝑏 = 4000 𝑅𝑒𝐷−𝑟 = 2336, 𝑓𝑏 = 0.05, and 𝑓𝑟 = 0.06. The frictional losses in the blank-side and rod-side pipes are therefore: 𝑝𝑙𝑜𝑠𝑠−𝑏 = 𝑓𝑏 𝑝𝑙𝑜𝑠𝑠−𝑟 = 𝑓𝑏 2 𝐿𝑒𝑞−𝑏 𝜌𝑣𝑝−𝑏 𝐷𝑝 ( 2 2 𝐿𝑒𝑞−𝑟 𝜌𝑣𝑝−𝑟 𝐷𝑝 ( 2 900×17.82 ) 2 = 8554.7 kPa 900×10.382 ) 2 = 4887.3 kPa 30 ) = 0.05 × 25×10−3 ( 42 ) = 0.06 × 25×10−3 ( The power loss in the blank side and rod-side piping is calculated as: 𝑃𝑙𝑜𝑠𝑠−𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 𝑄𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 (𝑣𝑝−𝑏 𝐴𝑝 ) = 8554.7 × 103 × (17.8 × 490.87 × 10−6 ) = 74.75 kW 𝑃𝑙𝑜𝑠𝑠−𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 𝑄𝑏 = 𝑝𝑙𝑜𝑠𝑠−𝑏 (𝑣𝑝−𝑏 𝐴𝑝 ) = 4887.3 × 103 × (10.38 × 490.87 × 10−6 ) = 24.9 kW The power at the pump side is now the output power and is calculated as 𝑃𝑝𝑢𝑚𝑝 = 𝑃𝑙𝑜𝑎𝑑 − 𝑃𝑙𝑜𝑠𝑠−𝑏 − 𝑃𝑙𝑜𝑠𝑠−𝑟 𝑃𝑝𝑢𝑚𝑝 = 36.4 − 74.75 − 24.9 = −63.25 kW 𝜂= 𝑃𝑜𝑢𝑡 𝑃𝑖𝑛 = −63.25 36.4 = 5000×3.64 28599 = −174 % The negative sign indicates that power is delivered to the system at both the load side and the pump side during the lowering state. This power is lost in the piping due to turbulent friction. 2.c Pump power and circuit efficiency during load holding: The power at the load side in this case is zero and so is the efficiency. The power consumed by the pump is calculated using 𝑃𝑝𝑢𝑚𝑝 = 𝑄𝑝𝑢𝑚𝑝 ∆𝑝 = 𝑄𝑝𝑢𝑚𝑝 (𝑝𝑜𝑢𝑡 − 𝑝𝑖𝑛 ) where 𝑝𝑖𝑛 = 𝑝𝑎𝑡𝑚 = 0 and 𝑝𝑜𝑢𝑡 is estimated by assuming that pressure relief valve opens when the pressure at its inlet reached a certain margin above the maximum pump value calculated during the lifting of the load. This margin is called the shutoff margin for the pressure relief valve and we will assume it to be 110%. Assuming that the system is set to operate at a maximum load speed 𝑣𝑙 = 2𝑣𝑐 and recalling that the rod side pressure loss calculate in section 2.a for this case was 𝑝𝑙𝑜𝑠𝑠−𝑟 = 3491 kPa, 𝑝𝑜𝑢𝑡 is found to be 𝑝𝑜𝑢𝑡 = 1.1 × (𝑝𝑟 + 𝑝𝑙𝑜𝑠𝑠−𝑟 ) = 1.1 × (10418.9 + 3491) = 15301 kPa Using 𝑄𝑝𝑢𝑚𝑝 = 2.55 × 10−3 m3/s as above, the power consumed by the pump in this case is: 𝑃𝑝𝑢𝑚𝑝 = 𝑄𝑝𝑢𝑚𝑝 ∆𝑝 = 2.55 × 10−3 × 15301 × 103 = 39kW We need to check that the pressure generated upstream the pressure relief valve is sufficient to overcome the resistance of the fully open pressure relief valve (equivalent length = 20 m) and segment I-J (equivalent length = 14 m). The pressure upstream the relief valve is 𝑝𝑟𝑣 = 𝑝𝑜𝑢𝑡 − 𝑝𝑙𝑜𝑠𝑠−𝐴𝐵 where 𝑝𝑙𝑜𝑠𝑠−𝐴𝐵 is the pressure loss in segment AB, and is found to be: 6 𝑝𝑙𝑜𝑠𝑠−𝐴𝐵 = 𝑓𝑟 2 𝐿𝑒𝑞−𝐴𝐵 𝜌𝑣𝑝−𝑟 𝐷𝑝 ( 2 ) = 0.06 × 10 900×10.382 ( ) 25×10−3 2 = 1163.7 kPa 𝑝𝑟𝑣 = 𝑝𝑜𝑢𝑡 − 𝑝𝑙𝑜𝑠𝑠−𝐴𝐵 = 15301 − 1163.7 = 14137.3 kPa The friction factor and the fluid speed in the rod-side piping were used above. The pressure loss in the piping segment B-I-J pressure relief valve is calculated using the 𝑝𝑙𝑜𝑠𝑠−𝐵𝐼𝐽 = 𝑓𝑟 2 𝐿𝑒𝑞−𝐵𝐼𝐽 𝜌𝑣𝑝−𝑟 𝐷𝑝 ( 2 20+14 900×10.382 ) 2 ) = 0.06 × 25×10−3 ( = 3956.4 kPa As 𝑝𝑙𝑜𝑠𝑠−𝐵𝐼𝐽 < 𝑝𝑟𝑣 , the pressure loss in the piping B-I-J when the relief valve is fully open is less than the pressure the valve is set to open. The relief valve will thus open partially and is considered somehow oversized for this application. 3. Proposed Methods for Improving Efficiency: The table below lists and compares a number of proposed methods for improving the efficiency of the circuit. 1. 2. 3. 4. 5. Method Decrease the length of the piping Increase the piping area Use an open center directional control valve Use a variable displacement pump Use an unloading valve Notes May not be feasible due to location constraints. Reduces the critical load speed 𝑣𝑐 at which the flow becomes turbulent. Cause an adverse effect if the circuit is designed to operate in the laminar region. Ok. But causes difficulties if more than one lifting station is to be installed on the same pump. Good solution. May increase the initial cost Best solution. Little effect on the initial cost 7