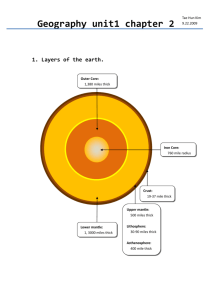

Frame Works Structure - DR. YSR Horticultural University

advertisement

Dr. Y. S. R. HORTICULTURAL UNIVERSITY VENKATARAMANNAGUDEM – 534 101 BID DOCUMENT FOR SUPPLY, ERECTION AND MAINTENANCE OF CENTRE FOR EXCELLENCE ON PROTECTED CULTIVATION OF VEGETABLES AND FLOWERS INCLUDING AUTOMATED PLUG TYPE SEEDLING PRODUCTION UNDER CENTRE FOR RESEARCH AND DEVELOPMENT AT VENKATARAMANNAGUDEM, WEST GODAVARI DISTRICT AT Dr. Y. S. R. HORTICULTURAL UNIVERSITY CAMPUS ADMINISTRATIVE OFFICE VENKATARAMANNAGUDEM – 534 101 Dr. Y. S. R. HORTICULTURAL UNIVERSITY VENKATARAMANNAGUDEM – 534 101 WEST GODAVARI DISTRICT ANDHRA PRADSEH Dr. Y S R HORTICULTURAL UNIVERSITY ADMIN. OFFICE - V R GUDEM, West Godavari Dist. Tender Notice No : NIT. No: 1/ Dr YSRHU/ 2015-16 Date of Commencement of DOWN LOADING OF THE BID DOCUMENT : 30.11.2015 AT 3.00 PM Last date for receipt of bids. : 21.12.2015 AT 10.00 AM at Principal Investigator & UL, O/o Director of Reserach, Administrative Office, Dr YSRHU, Venkataramannagudem TIME AND DATE OF Presentation of Detailed Project Report and opening of Technical bid at : 21.12.2015 AT 11.00AM The Principal Investigator & UL O/o Director of Research Administrative Office Dr Y S R Horticultural University Venkataramannagudem-534101 West Godavari District ADDRESS FOR COMMUNICATION: THE PRINCIPAL INVESTIGATOR & UL, O/o DIRECTOR OF RESEARCH ADMINISTRATIVE OFFICE VENKATARAMANNAGUDEM - 534 101 WEST GODAVARI DISTRICT, ANDHRA PRADESH Mobile No: 7382633655 email: universitylibrarian@drysrhu.edu.in The tender document containing terms and conditions for the execution of this project along with specifications and EMD to be paid are appended. 2 SCOPE OF WORK The university is establishing a Centre for Research and Development at Venkataramannagudem West Godavari District including Automated plug type seedling production, Installation site – Dr.YSR Horticultural University Campus, Venkataramannagudem, W G Dist. This Facility is for an annual production capacity of 100 lakhs Vegetable Seedlings. This facility is integrated with state-of-the-art production unit comprising of synchronized automation with Hi-tech control Greenhouse, Hardening Chamber, to be operated with minimum human interface and demonstration plot of protected cultivation of vegetables & Flowers. This tender is inviting for suitable proposal along with all necessary details and an estimated cost for the setting up of such a unit with one year running-growing module. The interested specialized organizations/Firms who are involved and having experience of designing, executing, running and maintenance of such projects, only may participate with their best attractive proposals with us. 3 TERMS AND CONDITIONS I) The location of the plant is at DrYSRHU campus, Venkataramannagudem, West Godavari District of Andhra Pradesh. II) The required land, buildings, water and power connection will be provided by the DrYSRHU and the bidder has to carry out all the works from supply and erection of Structure, electrical/Irrigation equipment installations as per the approved tender schedule. Successful trial run and maintaining the units supplied for 12 months including all maintenance and running cost, duly rectifying all defects during the above period, at the cost of bidder. III) The bidders are also required to furnish their experience certificate along with details of previously erected structures of similar kind with that of similar specifications. IV) The erection of structure must be carried out as per the standard specifications under the supervision of concerned authority of DrYSRHU and has to be got certified by him, duly handing over all warranty certificates for the structure and electrical/irrigating equipments. 1. Supply, erection of all structures is on Turn Key basis. The total project is to be set-up on Turn-key Basis including inter-connecting pipeline / irrigation sections. Bids will be evaluated on Turn-key basis. All bidders must quote section wise, otherwise bid will be summarily rejected. 2. All taxes and duties to be paid to the government needs to be included in the price quoted. V) The bids should be submitted with in time specified at the office of Principal Investigator & UL,office of the Director of Research, Admin. Office, Venkataramannagudem along with EMD as specified here under against each item. EMD Amount to be paid Sl.No Work/Equipment (in Rupees) A Works/ Structures 1 Constructing of naturally vented polyhouses, 15,00,000-00 fan and pad system and automated seedling production unit and other units (items from 1 to 18 as given in the tender document) Bidders must pay the EMD amount specified as above against the item in the form of crossed D.D. drawn in favor of The Comptroller, Dr YSRHU, Venkataramannagudem, Tadepalligudem payable at Andhra Bank/ any nationalized bank, Tadepalligudem. Tender documents without earnest money deposit will be rejected and processing fee of Rs.5,000/- (Rupees Five thousand only) through DD in favor of The Comptroller, Dr YSRHU, Venkataramannagudem, Tadepalligudem payable at Andhra Bank/ any nationalized bank, Tadepalligudem which is nonrefundable. VI) Specifications given are indicative and the tender is to give a detailed description and specifications on each section. The same would be given weightage in finalizing the tender. VII) The structure to be supplied by the tenderers should be branded and meet the quality standard and as per the existing norms. Period of warranty shall be 1 year from the date of supply. 4 VIII) The specifications and other conditions prescribed in Annexure – III of this Tender shall also be treated as part of these tender documents for all purposes. TERMS OF PAYMENT: 1) Against the delivery of complete material. 2) After completion of 75% of total work 3) After completion of entire project construction work. 4) At the time of project handover from firm/ company to department IX) X) 50% of the project cost. 20% of the project cost. 20% of the project cost. 10% of the project cost. At the time of awarding the contract the University reserves the right to insist Performance guarantee security for a warranty period of one year at the rate of 10% by way of Bank guarantee on the total order value, and the same will be released after warranty/agreement period of one year expires and in case the performance is bad or the equipment is not working to the satisfactory level, the company will forfeit the performance guarantee deposit. The company should have strong technical manpower to take up such work. The company approved as an R & D company by DSIR Government of India will be preferred. ELIGIBILITY CRITERIA (1) (2) (3) (4) (5) The preference would be given to manufacturer with experience of having under taken complete project on Turn-key Basis and having executed similar projects in reputed Agricultural Universities / State department of Horticulture / ICAR institutes/private organizations. Certificate from the project client for award of contract and stage of satisfactory project completion (in terms of value) in original or its notarized copy for each project claimed to be submitted. The company bidding should be in the industry for at least 10 years in the same field. Tenderers should have authorized dealer certificate of a reputed company (Please attach certificate). Tenderers should have total turnover of at least Rs.20 crores for constructing of naturally vented polyhouses, fan and pad system and automated seedling production unit. Audited financial statements duly certified by chartered accountant for the last three financial years ending March, 31st, 2015 should be submitted. The buyer reserves the right to evaluate the tender on Technical Presentation/ capabilities and is not bound to accept lowest tender / quotations. 5 Evaluation of Bid: 1) The Technical Bid Documents will be opened first and evaluated by the Tender Committee. Financial Bid Documents of only those bidders will be opened who have qualified in Technical Bid. 2) The Competent Authority reserves the right to accept or reject any tender without any reason thereof. 3) Prices to be quoted on FOR basis including all taxes including VAT/freight/ installation/commissioning/trial/training charges etc in Indian rupees. 4) It is necessary to submit all the relevant documents like Pan Card, ISO Certification, VAT/Sales Tax Registration, Authorized dealer of a reputed company, Certificate of Incorporation / Partnership Deed. 5) Tenderer should submit the copies of Purchase Orders in support of their genuineness in supplying of the goods in reputed Universities / Colleges / Departments/institutes/private organizations. The tenderer should submit users list for the last 5 years including for term key basis projects involving construction of naturally vented polyhouses, fan and pad system and automated seedling production unit. EVALUATION SCORING MATRIX The technical bid will be evaluated on a scale of 100 and the weightage for each criterion would be as follows: S. No. 1 2 3 Main Criteria Experience: The firm must have prior experience of establishment and running of minimum 3 to 4 such Plug Type Nursery Seedling Production Unit Projects and expertise in growing different vegetable and flower crops in polyhouses in respect of Designing, Planning, Execution, Running and Maintenance with its actual successful performance in Public funded /universities/private institutions for more than 2 years. Each project worth should not be less than 4.50 Crores. The Work Orders with Performance Certificate for such installations to be enclosed with the offer. Financial Strength (Turnover of company over each of last three years) a). Bidder will get 10 marks for turnover of more than Rs.20 Crore. The Bidder will have to submit audited Balance sheets for past three years, along with Certificate from the Auditor to show that the turnover is from Construction business of Greenhouses/Vegetable Seedling Production Unit/Protected Cultivation, if the Company is engaged in other businesses also. 10 Marks b). Bidder is required to have Solvency Certificate of value up to 10 crore for execution of the project. Copy of this certificate from their bankers should be enclosed with the bid. 05 Marks Technical competency for running of the said project The bidder will get 10 Marks for having an adequate number of in-house technical staff of crop scientists in different disciplines like: 1) Horticulturist 2) Vegetable Expert, 3) Plants Protection Expert. Details/CV of them should be attached with the offer. Marks 35 Marks 15 Marks 10 Marks 6 4 5 6 7 8 9 Methodology and work plan proposed Scaled Design/Drawing with CAD (Computer Aided Design) The Bidder will get 05 Marks for providing work plan with detailed specification of materials/equipment used for implementing the Project. Scaled high level technical drawings for entire project including greenhouses, automation unit to be submitted. Registration of R&D Centre by DSIR, Govt. of India The Firm should be approved as R&D center/advanced facility by Government of India/State Govt., and having their own running R&D/Technology Development Centre for the similar activities under protected cultivation at different levels in India. The proof of the same to be appended with the proposal. a. The firm should have NSIC registration. b. Satisfied user list with their endorsements, addresses and contact numbers The bidder should have the following ISO Certifications: ISO 9001:2008, ISO 14001:2004, & ISO OHSAS 18001:2007 The firm should have acquired with minimum SE-1B CRISIL Rating. Technical Presentation on Entire Project Plan The bidder has to give a detailed technical presentation in front of purchase committee or higher officials as desired while technical bid is opened. Total Technical Score 10 Marks 10 Marks 05 Marks 03 Marks 02 Marks 10 Marks 100 Marks For being technically qualified in the tender, the bidder must have secured minimum 75 points out of 100 points to open commercial BID. DISQUALIFICATION: The EOI may, at its own sole discretion, at any time during the EOI process, disqualify any Interested party from the EOI process if: (a) If the response to the tender is submitted after the dead line for submission. (b) If the Interested Entity has made misleading or false representation in the forms, statements, attachments submitted in proof of eligibility. (c) If the tender is not accompanied by required documentation. (d) If the Interested Entity failed to provide clarifications related thereto, when sought. 7 Annexure – I (Part I) TECHNICAL BID: filling up of Proforma The technical bid shall accompany with the enclosures for components as per Performa prescribed and is attached with the document and details is as under: S. Intervention/Component No. 1 Company Profile 2 Past Experience of the firm with certificates/ work order/ completion etc 3 No. of years of experience in this field 4 Past experience in carrying out work in related field 5 Experience of Engineers, horticulturist and Technician 6 Financial Strength of the Firm 7 Office details 8 Sales Tax, Income Tax, CST registration 9 Any others as specified in the general bid document Annexure (With page nos.) The Dr YSRHU reserves the right to verify the claims made by the Bidder and to carry out the capacity assessment of the bidder and the Dr YSRHU decision shall be final in this regard. 8 Annexure– I (Part–II) “DECLARATIONOF THE BIDDER” 1) That I/We am/are the authorized nominee (s) of the firm here by submit tender to Dr. Y S R Horticultural University, West Godavari District for Centre for Research and Development at Dr. Y. S. R. Horticultural University, Venkatramannagudem - 534101, West Godavari District. The copy of the power of Attorney is attached here with. 2) I am to state that the information provided in the tender form is true and correct 3) I/We may be punished as per law for any wrong information, misleading facts provided in the tender form besides rejection of my/our tender. 4) In case of any dispute, the Jurisdiction will be W G DIST only. 5) I/We have carefully read all the general and specific terms and conditions of the tender and I solemnly declare that the same are acceptable to me/us and binding on me/us. Place: Signature of Bidder: Date: Name of Bidder : Capacity in which signed : Full address of the Bidder : (Attach Identity card Xerox) Mobile No. : With seal & stamp Phone No. : : 9 Annexure - II (Part I) TECHNICAL SPECIFICATIONS Commercial Bid Proforma (This should be enclosed in envelope No.2) S. No. Product Number 1 2 Automated machine assembly for plug seedling production Hi-tech climate controlled polycarbonate seedling greenhouse 1075 sq. m Seedling Hardening Poly-shade house facility, 2112sq.m Protected cultivation of Tomato Capsicum and Cucumber, Naturally Ventilated Polyhouse (NVPH), area 580 sq. m each unit Protected cultivation of Vegetable and Flowers Fan & Pad Polyhouse(FPPH),area580 sq. m each unit Protected cultivation of Carnation, Roses and Gerbera, NVPH, Area 580 sq. m Protected cultivation of Chrysanthemum, (Fan & Pad), Area 580 sq. m Open field sprinkler irrigation system for 1000 sq. mt Open field drip irrigation system for 1000 sq. mt Insect proof net house 1008 Sq.mt. Automation Fertigation and irrigation system Common facility for all units Over head covered water tank: capacity: 25000 ltr with complete plumbing work etc. Made by RCC as per standard civil work, guide line. Complete Main Electrical and Plumbing works: Electrification work /cabling / plumbing/sanitation/surface drainage for entire facility. Security & protection: by chain link fencing with 2’’x 2’’X6mm angle iron pole , fencing height up to 5’, pole to pole distance 7.5’, proper RCC grouting and one main gate for all complete unit Power back-up unit: qty.01 Generator operating capacity 63 KVA make kirlosker or equivalent make with Automatic on/off panel. Shelter with platform for Generator Housing for generator unit (12’X15’) Pack house (20’ x 40’) Production of Seedlings and Vegetable/flowers cultivation module Supervision and operational charges for plug type seedlings unit as well as protected cultivation of vegetables and flowers for one year (Includes skilled and unskilled manpower and supervision by horticulture expert.) 1 No 1 No 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 (In. Rs) Quoted Price 1 No 3 No’s 2 No’s 3 No’s 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 No 1 year 10 Annexure – II (Part –II) (ThisshouldbeenclosedinenvelopeNo.2) Specifications of tender cost for Supply, Erection and Maintenance of Centre for Research and Development at Venkataramannagudem, West Godavari District Plug type Seedlings Production Unit: 1. Automated machine assembly for plug seedling production All synchronized & automation units will be equipped with series of machines and transportation system for the production of Plug type vegetable seedlings all around the year. S. No. Technical Details of Project 1 Automation System For Plug Type Seedling Production Diffuser & Mixer: Diffuse growing medium bricks and other material by means of built in electrical driven pivot system equipped with fluffing mechanism to homogenous substrates. Units Complete set 1 unit Size: 2438 x 1219 x 1828mm (LxWxH) ( size may differ by 5 to 10 % depending on the bay width and number of bays) Capacity: 1.4 cubic meters (brick size capacity) Diffuser time: 4 to 5 minutes Level Control Mechanism: It is fixed between mixer and auto seeder, control level of material to filled in so that material should not over flow permit only homogenous even material for tray filling. 1 unit Trays Dispenser Machine: De stacker machine completely electrical & mechanical innovative technique. Dispense automatically as program dispensing of fresh and reused trays. It should handle variety of trays. 1 unit Technical Specifications: Size (L x W x H): 1040mm x 700mm x 1314mm Capacity : 360 trays per hour Operating voltage: 220 volt, 3 Phase. Auto Seeder: Variable seed elevator conveyer vibration system, selection system, control microprocessor touch screen human interface system with software. Roller chain with emergency stop switches. Drum type seeder with vacuum system to pick up the seeds & released in trays. Electronically control pick & release system on conveyer. Control with infra-red beam/alternative mechanism. Machine should be capable to handle different size of seeds tomato to pumpkin. Capacity : approximately 70,000 seed/hour Topping Machine: It is used when tray released by auto seeder it will do topping on the seed and also level. Watering Station: It is used in the line for as auto-watering to the seed tray with control microprocessor. 1 unit 1 unit 1 unit 11 Stacking unit with Roller Conveyer:for lifting and collection of trays and unloading trays on roller conveyer. 1 unit Conveyer Belt Conveyer for transportation of pro trays these specially designed conveyer will be used between machine to machine greenhouse to hardening chamber. These conveyer are very used full to increase the production and these conveyer sizes :( LxWxH) 5mx0.5m x 0.76m( for seedlings trays transportation , seeding machine to Greenhouse , Greenhouse to Hardening chamber and Hardening Chamber to Packing shade ) 19 units Operation : Operating on 220 volts, AC single phase, 50 Hz. +/-8% H- Support Conveyer: This conveyer is used with special electro mechanism which used to shift lane automatically. 2 units Housing Facility for the auto machine equipment (pre-fabricated Structure): Size : L x W x Hc:s 30’x 20’X 15’: 10’ Structure made by: 80mmX50mm, 50mm x 50mm &38mmx38 mm hot dip galvanized pipe.Complete Pre-machined Structure flange based and cladding with puff panel 63mm with inner/outer pre quoted GI sheet 0.5 mm thick. Window: made by aluminum frame with Polycarbonate sheet 6mm thick multiwall and accessories, window size : 4’x4’ Qty. 04 Door:sliding doormade by aluminum frame with Polycarbonate sheet 6mm thick multiwall and accessories, door size 7’x7’ qty. 02 nos. Floor : tiles flooring This project require all inputs to make successful nursery production. University will not give any material or inputs to raise nursery. For all polyhouses also, company/agency will have to bear all inputs to make successful production for one year from the date functioning. 12 2. Hi-Tech Climate Controlled Polycarbonate Seedling Greenhouse: S. No. Technical Details of Project 2 A) Polycarbonate structure Total Area: 1075 sq. m. ( size may differ by 5 to 10 % depending on the bay width and number of bays) Type: Flange based technology. Bay width: 9.6 m. No. of bays: 4nos. G.H. width: 38.4m. G.H. length: 28m. Gutter height: 3.5m to 4 m Ridge height: 5.5 m to 6 m Grid size : 9.6m x4 m Shape: Gothic Gutter slope : 1-2 % provided in civil work Double Door Room: 3m x 3m.x2.43m. (LxWxH) Seedlings production capacity: approximately 4,70,000 seedlings/cycle Units 1 unit Main features: a) Complete Pre-machined Structure and cladding with Polycarbonate sheet 6 mm thick multiwall UV stabilized material: All Structures, Rafters, Perlins, Trusses are hot dip galvanized And designed to take a wind load up to 120 km/hr. Frame Works Structure: Its assembly style without any welding point. All main parts are hot galvanized with zinc cover 275g/m2. a) Columns: Is Hot Dip Galvanized Rectangular Profile, tubular Structures. b) Corner Columns: Double Column, Hot Dip Galvanized Rectangular Profiles c) Gutters: Hot Dip Galvanized Steel d) Arches: Hot Dip Galvanized Steel Pipes e) Arch Column Clamp: Galvanized Steel Sheet f) Crop Bar: Galvanized Pipe g) Cross and Reinforcements: i) Corner Reinforcement: Hot Dip Galvanized Rectangular Profile ii) Column-Arch Reinforcement: Galvanized Pipes iii) Column- Column Galvanized Pipes iv) H –Reinforcement Galvanized Rectangular Profile v) X-Reinforcement Galvanized Pipes vi) Crop Bar-Arch Reinforcement Galvanized Pipes Pipe sections to be used for different Structural Member or equivalent will be as below, given structure size in OD: Pillar: 80mm × 50mm × 3mm thickness hot galvanized rectangular tubes. Distance between pillars to pillars 4m. Arc to Arc spacing: 2m. Arc: 50mm × 50mm × 2mm thickness. Ridge: 50mmx50x2mm thickness. Roof purlins 38mmx38mmx2mm thick, purlin to purlin spacing 1.6m Trusses bottom member: 42mmX2mm 13 Crop bar: 42mmX2mm thickness Trusses tie: 32mm tube structural member fitted with Zn plated nuts and bolt. Gutter: 4m. Long, 248mm wide and 1.5mm thick molding hot galvanized steel plate Roof beam: 40x30x2mm hot galvanized rectangular tubes Bolts and Nuts: DIN Steel Flange Based Technology: Facility should be 100% welding freestructure, so that it can resistance wind load. Fasteners and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). DESIGN LOADS: a) Wind Load Resistance: 120 km/hour b) Accessory Load Resistance: 10 kg/sq. m. b.)Pre Entry Room & Doors: 1) Ante Room/Vestibule: The hardening chamber will have a specific Pre Entry Room of size- 3m. × 3 m. × 2.43m. (L×W×H), made by polycarbonate sheet 6mm and galvanized tubular frame, where all the other spare items can be stored/ dumped out. 2.) Sliding Doors: 1.5 m. wide & 2m. tall single door complete with polycarbonate sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. 3.) Air curtain : auto on/off when door opening/closing. B) Computerized Climate Control System with weather Station, Internet Based : Computerized control system to sense, control and monitoring the following parameters: Light, Temp, R.H., Thermal Screen/Roof screen In sight and over roof and Boomer etc. Computer hardware / software with accessories Climate control software: Climate compartment with multi-day average radiation sum program to achieve an average ambient temperature during one or more 24-hour periods Measuring and controlling of temperature and humidity Control heating system Control of side vent motor based on running time Control program with temperature settings to start the fan system On/off control of exhaust fan step On/off switching air inlet control with input for safety contact to release the exhaust fan step Inside curtain control with shading/energy functions Control of misting pump Control of misting valve for humidification On/off control of air circulation fans C) High luminous flux PAR lamp 400 watt LED light (for horticulture use) each, Special light for plants for providing essential photosynthesis wave length of 400-700nm to the plants for optimum growth & production.24 Nos. 14 D) Forced Cooling System: Axial Flow Fan 48” nos. 08 nos. with louvers auto opening/closing assembly, HD motor fixtures and a 3000 litre water tank to distribute and collect water from pad, cel-pads complete 4” thick 5’ width and lengthwise with Aluminum frame ,fan/pad system . E) Heating system : 2.4 KW with circulation fan qty.12 F) Air circulation fan for inside of chamber. qty 12 G) Complete facility with Pest Monitoring System H) Water Applicator: for irrigating the plants one boomer with 3 ways nozzle, holding span rail/rod in a bay. Water boomer nozzles span is adjustable height-wise. Adjustable range of water applicator span: From Lowest 1.67 m. (up to a normal human eye height) to nearly 4.5m.1 No. I)Internal Screen:- Motorized Internal Screen mechanism using Gear Motor with Inbuilt limit switch for smooth control, Rack & Pinion, Support Aero wheel, Handspike driving shaft, Rolling axes, Pull Rod Clamp, Directing clamp, aluminum pipe for more long life & light in weight. Retraction mechanism supported on polyester wire having with high abrasion strength- which results smooth operation & long durability, aluminum Thermal screen specially design for heat Retention inside the chamber. J) External screen: 50% (Shade net) colour white/black with motorized automatically openable system fixed 1m above polycarbonate roof. K)Side Ventilation: - motorized operated sensor based , driving shaft, Rack Arc & Pinion, Shaft support plate, covered with 40mesh Nylon net with UV stabilized from inside to prevent insect Entry inside the chamber. generally used during power failure. window lift up to 1m wide & length as per chamber’s length. L) Nursery Tray Holding Station: for accommodation of 2384 seedlings trays (size 29’’x18’’) LxW), nursery tray holding station made by GI frame 32x32mm 3mm thick with aluminum frame 72mm x42mm x 2.5 mm thick : complete set M)Foundation wall for chamber WIDE BASED 2' below earth's surface.2' above earth's surface, as kick-board 9" wide, Frame base block height 3'x9”x9”each with plinth protection 6’wide 6” thick. Total 132.8 running mtr. N) Floor: made by PCC (1:5:10)100 mm thick than CC (1:2:4) 100 mm thick and over that tiled white color ,anti-slippery hard material. Total Floor area : 1075 sq. m O) Frame base column: Galvanized channel 12mmX42mmX72mmX42mmX12mm and 3mm thick, C channel with Grouting CC (1:2:4) block, each block size 3’X1’X1’ 15 3. SEEDLING HARDENING FACILITY S. No. Technical Details of Project i. HARDENING FACILITY Area: 2112 Sq. m. (size may differ by 5 to 10 % depending on the bay width and number of bays) Bay width: 9.6 m. No. of bays: 5nos. G.H. width: 48m. G.H. length:44 m. Gutter height: 3m. Ridge height: 4.5 m. Grid size : 9.6 m x4m Shape: Gothic Hardening capacity: approximately 9,00,000 seedlings per cycle Structure detail: A) All Structures, Rafters, Perlins, Trusses are hot dip galvanized and design to take a wind load up to 120 km/h. Specification: Hot dip galvanized Steel Structure: Using galvanized tubular structure or equivalent sections. Pipe sections to be used for different Structural Member flange type will be as below or equivalent : Columns: 80 mm × 50 mm x3mm Trusses: Bottom cord 50 mm x 2mm; Truss Members 48mm x 48mm, Bracing 32 mmx2mm, B-class GI steel pipe; structural member will be fitted with zinc plated nuts & bolts without welding. Purlins: using specially designed profile 32 mm ×2mm thick. 2) Fasteners and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). Shade Cladding: Cladding on roof by 200 micron UV stabilized standard poly film having 85% light transmission, multilayer with Roof screen by 50:50 shade net UV stabilized and all sides cover by 50:50 UV stabilized shade net , This is attached with the structure by the spring & GRP profile & GRP clamps which click into it. Later on, the spring can be clipped out in order to fit new plastic. The profile does not get distorted and the profile can also be used again. Pre Entry Room & Doors: a)Ante Room/Vestibule: The hardening chamber will have a specific Pre Entry Room of size- 3m. × 3 m. × 2.43m. (L×W×H), made by polycarbonate sheet 6mm and galvanized tubular frame , where all the other spare items can be stored/ dumped out. b) Sliding Doors: 1.5 m. wide & 2m. tall single door complete with polycarbonate sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. Units 01 Complete Set c) Air curtain: auto on/off when door opening/closing. Water Applicator System: For irrigating the plants 02water boomers with 3 ways nozzles holding span rail/rod in a bay,Water boomer nozzles span is adjustable height-wise. Adjustable range of water applicator span: From Lowest 1.67 m. (up to a normal human eye height) to nearly 4.5m. qty. 01 16 Nursery Trays Holding Station for accommodation of 4684seedlings trays, nursery trays holding station made by GI frame with aluminum frame. 1 complete set Foundation wall for Hardening Chamber WIDE BASED 2' below earth's surface.2' above earth's surface, as kick-board 9" wide, Frame base block height 3'x9”x9”each with front side wall plinth protection 3’wide 6” thick. Total 144 running mtr Frame base column: Galvanized channel 12mmX42mmX72mmX42mmX12mm and 3mm thick, C channel with Grouting CC (1:2:4) block, each block size 3’X1’X1’ ii. iii. iv. v. Pathway for personnel movement except plant work station area Pathway made by PCC (1:5:10)100 mm thick than CC (1:2:4) 100 mm thick with dully plastered . complete set Seedling Tray, 99 cells: (LxWx H ), 360 mm 450mm x60 mm : made by High impact polystyrene martial. Thermal Tray, 198 cells : size : (LxWxH) 730mmx452mmx60mmmade by high impact thermo Cole material. PACKING SHED: Size: LxWxHc:s 16m x 6m x4m:3m Structure flange made by :80mmX50mm & 50mmx50mm hot dip galvanized pipe. Roof cover by pre quoted GI sheet 0.5 mm thick. Side cover by mesh SS (304 no, ) 40 mesh Door: sliding door made by aluminum frame with Polycarbonate sheet 6mm and accessories, door size 2mx1m qty. 02 Nos. Exhaust Fans: for air circulation- 2 Nos. Foundation wall for Packing room WIDE BASED 2' below earth's surface.2' above earth's surface, as kick-board 9" wide, Frame base block height 3'x9”x9”each with front side wall plinth protection 3’wide 6” thick. Floor: made by PCC (1:5:10)100 mm thick than CC (1:2:4) 100 mm thick with dully plastered floor area : 96m STORE ROOM: To accommodate the raw material like: Growing medium/Trays/ Chemicals fertilizers etc safely in this shelter. Size: LxWxHc:s 16m x 6m x4m:3m Structure made by :80mmX50mm, 50mmx50mm &38mmx38 mm hot dip galvanized pipe. Complete Pre-machined Structure and cladding with puff panel 63mm with inner/outer pre quoted GI sheet 0.5 mm thick. Window : made by aluminum frame with Polycarbonate sheet 6mm and accessories, window size : 4’x4’ Qty. 04 Door: sliding doormade by aluminum frame with Polycarbonate sheet 6mm and accessories, door size 2mx1m qty. 02 Foundation wall for Store room WIDE BASED 2' below earth's surface.2' above earth's surface, as kick-board 9" wide, Frame base block height 3'x9”x9”each with front side wall plinth protection 3’wide 6” thick. Floor :made by made by PCC (1:5:10)100 mm thick than CC (1:2:4) 100 mm thick with dully plastered , floor area 96 m 16000 7400 01set 01set 17 PROTECTED CULTIVATION OF VEGETABLES 4. Naturally Ventilated Polyhouse for cultivation of Tomato/Capsicum/Cucumber (03 No’s) S. No. Technical Details of Project 1. Poly house size 24m. × 24.2 m. (L×W) = 580 Sq. m. (size may differ by 5 to 10 % depending on the bay width and number of bays) Number of bays 02 Nos. Bays width 9.6m. Poly house length 24m. Poly house width 24.2m. Grid size 9.6m x 4m. Side Height 4m. Centre Height 6m. Corridor 2.5 m each side Ante Room 2.41m. × 2.41m. ×2.43m. (L×W×H) 01 No. Doors Each Size: 2m. × 1m. (tall & wide) 02 Nos. Gutter slope:1-2% provided in civil work A) All Structures, Rafters, Perlins, Trusses are hot dip galvanized and design to take a wind load up to 120 km/h. Specification: Hot dip galvanized Steel Structure: Using galvanized tubular structure or equivalent sections. Pipe sections to be used for different Structural Member will be as below or equivalent : Columns: 80 mm x 50 mm and 3 mm thick , Arch 60mm x2mm GI and arc to arc spacing 4m Trusses: Bottom cord 50 mm x 2mm; Truss Members 32mm & Bracing 32 mmx2mm , Pillars bracings 42mmX2mm Purlins: Using speacially designed profile 42mm X2mm thick and purlin to purlin distance of 2.4m Gutter: each gutter size 4m long, 248mm wide, 150mm depth, and 1.5mm thick molding hot galvanized steel plate. Structural member will be fitted with zinc plated nuts & bolts without welding. 2) Nuts and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). 2. Cladding: Attaching the Plastic on Roof & Side walls, of Playhouse& pre entry room 200 micron UV stabilized poly film having 85% light transmission, multilayered, anti drip. This is attached with the structure by the spring/profile/clamps/SDS. 3. Side Ventilation with manually operating system: Side Ventilation- 24m. long and 3.7m. high × 4 Nos. Roll-up plastic curtains, fully open able (open from up to down) on four sides manually rollable, can rolled when not required. 40 mesh nylon insect-screen (UV stabilized) to be fixed inside the curtain on all four sides. 4. Top Ventilation :24m. long and 1m wide × 2 Nos. open with cover 40 mesh nylon insect-screen (UV stabilized) to be fixed . Arc suitably overlapped to prevent rain splash. Units Complete Set Complete Set Complete Set 18 5. 6. 7. 8. 9 10 External shading system: 50% shading net colour: white/green/black (agro shade net) fixed 1m above the polyhouse with sliding. Internal Shading System: Thermal screen (aluminized) with sliding below gutter level. Ante Room & Doors: A.Pre Entry Room/Vestibule: The Polyhouse will have a specific Pre Entry Room of size- 2.41m. × 2.41 m. × 2.43m. (L×W×H), where all the other spare items can be stored/ dumped out. B. Sliding Doors: 1m. Wide & 2m. Tall single door complete with polycarbonate sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. Drip Irrigation System – Inline lateral 16mm ,2.1 lph@30 cm emitter spacing, lateral laid out at a spacing of 0.75m, PVC pipes 4g/cm sq. Pressure rating of different sizes , Screen filter, pressure gauge, PVC valves, flush valves for flushing of sub main , connected to common pumping, filtration & fertigation unit etc. Fogging System: Four way anti-leak foggers with 28lph discharge which gives very fine droplet size, PVC pipes of 6 Kg/cm2 pressure rating of various sizes, PVC ball valves, Flush valves for flushing of sub main, disc Filter with pressure gauge, connected to common water line. Crop Support – Horizontal G.I wire at gutter level, 4mm, support to hold the crop at a spacing of 0.75m, provided with crop support bracings. Complete Set Complete Set 01 No. 02 Nos. Complete Set Complete set 11. Vertical Trailing System –crop will be trailed on twines, polypropelene, Plastic 5000 running mtr/ (or as required) in polyhouse Complete set 12. Mulching sheet – Embossed mulching sheet 1.0/1.2m wide thickness 25/30 microns 1000m/ polyhouse 13. Civil Work :Foundation Wall for polyhouse WIDE BASED 1’ below earth’s surface, 1’ above earth’s surface, 9" wide wall, duly plastered. Complete set 14 Frame base column: Galvanized channel 12mmX42mmX72mmX42mmX12mm and 3mm thick, C channel with Grouting CC (1:2:4) block, each block size 3’X1’X1’ Electrical Wiring. All wires will be of copper and desired load and switches imported make, extra switches also provided as standby. Each feature has own electric line with MCB and will be underground in PVC pipe complete set with A grade work, connected to central electricity supply UG cable. Rain water harvesting: Gutter end to be connected to 150mm PVC pipe, 4kg/cm2 with proper funnel/accessories till the ground level Complete set 15. 16 Complete Set Complete set 19 5. Greenhouse with Fan and Pad cooling system for cultivation of off-season Vegetable and Flowers (2 No’s) S. No. Technical Details of Project 1. Greenhouse house size 24m. × 24.2 m. (L×W) = 580 Sq. m. (size may differ by 5 to 10 % depending on the bay width and number of bays) Number of bays 02 Nos. Bays width 9.6 m. Poly house length 24 m. Poly house width 24.2 m. Grid size 9.6 m x 4 m. Side Height 4 m. Centre Height 6 m. Corridor 2.5 m each side Ante Room 2.41m. × 2.41m. ×2.43m. (L×W×H) 01 No. Doors Each Size: 2m. × 1m. (tall & wide) 02 Nos. Gutter slope:1-2% provided in civil work A) All Structures, Rafters, Perlins, Trusses are hot dip galvanized and design to take a wind load up to 120 km/h. Specification: Hot dip galvanized Steel Structure: Using galvanized tubular structure or equivalent sections. Pipe sections to be used for different Structural Member will be as below or equivalent : Columns: 80 mm x 50 mm and 3 mm thick , Arch 60mm x2mm GI and arc to arc spacing 4m Trusses: Bottom cord 50 mm x 2mm; Truss Members 32mm & Bracing 32 mmx2mm , Pillars bracings 42mmX2mm Purlins: Using speacially designed profile 42mm X2mm thick and purlin to purlin distance of 2.4m Gutter: each gutter size 4m long, 248mm wide, 150mm depth, and 1.5mm thick molding hot galvanized steel plate. structural member will be fitted with zinc plated nuts & bolts without welding. 2) Nuts and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). 2. Cladding: Attaching the Plastic on Roof & Side walls, of Polyhouse & pre entry room 200 micron UV stabilized poly film having 85% light transmission, multilayered, anti drip. This is attached with the structure by the spring/profile/clamps/SDS. 3. Side Ventilation with motorized operating system: Side Ventilation- 24m. long and 3m. high × 2 Nos. Roll-up plastic curtains, openable to 1.5m. in height (open from up to down) on two sides motorized can be rolled when not required. 40 mesh nylon insect-screen (UV stabilized) to be fixed inside the curtain on sides. To be used only during power failure. Side ventilations to be airtight when fan and pad is in operation. 4. External shading system: 50% shading net colour: white/green/black (agro shade net) fixed 1m above the polyhouse with motorized rolling facility. Units Complete Set Complete Set Complete Set Complete Set 20 5. 6. 7. 8. 9. 10 11 12 13 14 Internal Shading System: Thermal screen (aluminet) with motorized Complete controlled below gutter level. Set Ante Room & Doors: A.Pre Entry Room/Vestibule: The Polyhouse will have a specific Pre 01 No. Entry Room of size- 2.41m. × 2.41 m. × 2.43m. (L×W×H), where all the other spare items can be stored/ dumped out. B. Doors: 1m. Wide & 2m. Tall single door complete with polycarbonate 02 Nos. sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. Microclimate Control Panel for Temp. with manual operating option 1 set and , volt meter , RYB indicator etc. also open and close motorized system with temperature based Technical feature of Temperature Control System -Accuracy: ±1°C. -Hysteresis: 0.4°C with sensor probe Pt-100 Sensor Evaporative Cooling System : Complete 1) 5ft height x 63’ long evaporative Cellulose CELDEC Imported, Munters set make cooling pad complete with all necessary framing material of Aluminum required supporting distribution & returning piping. - Gutters, down spout end caps & drip pan, plumbing kit, pump 440 volt - 3 phase 50 cycles, Drilled PVC piping cap, pad retainer, all suspension hardware. - Metal flashings as required to seal pad to vent opening, 4" thick evaporative cooling pad material. Pad Area: 63’ × 5’ x 4’’ (w x h x Thickness) Construction Material Aluminum Profiles: Tray Sides, Top Etc. Plastic Profiles: Water Distribution tray. Cooling Media: 100mm thick celdek 7090/500 At velocities of 1 to 3 M/s to give efficiency from 60 to 95%. Filtration: 25 to 55mm viscous filter for 30 m efficiency. Miscellaneous: Fasteners, Galvanized, Rivet- Aluminum. Water storage Tank : Cemented Tank 2000 lit Pump: HP Mono block capacity as per required ( Crompton or approved equivalent) 40 Mesh Nylon: for extra protection from dust, fitted behind the pad. 2) Slow Speed Axial Flow Fan - 48" single speed belt driven exhaust fan , 440V, 50 cycles, 3 phase) with Louvers opening /closing assembly Qty. 04 Drip Irrigation System – Inline lateral 16mm ,2.1 lph@30 cm emitter Complete spacing, lateral laid out at a spacing of 0.75m, PVC pipes 4g/cm sq. Set Pressure rating of different sizes , Screen filter, pressure gauge, PVC valves, flush valves for flushing of sub main , connected to common pumping, filtration & fertigation unit etc. Crop Support – Horizontal G.I wire at gutter level, 4mm, support to hold Complete the crop at a spacing of 0.75m, provided with crop support bracings. set Vertical Trailing System –crop will be trailed on twines, polypropelene, Complete Plastic 5000 running mtr/ (or as required) in polyhouse set Mulching sheet – Embossed mulching sheet 1.0/1.2m wide thickness 1000m for 25/30 microns each Civil Work: Foundation Wall for polyhouse WIDE BASED 1’ below earth’s surface, 1’ above earth’s surface, 9" wide wall, duly plastered. Frame base column: Galvanized channel 12mmX42mmX72mmX42mmX12mm and 3mm thick, C channel with Grouting CC (1:2:4) block, each block size 3’X1’X1’ 21 15. 16 Electrical Wiring. All wires will be of copper and desired load and switches imported make, extra switches also provided as standby. Each feature has own electric line with MCB and will be underground in PVC pipe complete set with A grade work, connected to central electricity supply UG cable. Rain water harvesting: Gutter end to be connected to 150mm PVC pipe4kg/cm2 with proper funnel/accessories till the ground level Complete Set Complete set 22 PROTECTED CULTIVATION OF FLOWERS 6. Naturally ventilated Polyhouse for cultivation of Carnation, Rose and Gerbera (3 No’s) S. No. Technical Details of Project 1. Poly house size 24m. × 24.2 m. (L×W)= 580 Sq. m. (size may differ by 5 to 10 % depending on the bay width and number of bays) Number of bays 02 Nos. Bays width 9.6m. Poly house length 24m. Poly house width 24.2m. Grid size 9.6m x 4m. Side Height 4m. Centre Height 6m. Corridor 2.5 m each side Ante Room 2.41m. × 2.41m. ×2.43m. (L×W×H) 01 No. Doors Each Size: 2m. × 1m. (tall& wide) 02 Nos. Gutter slope:1-2% provided in civil work A) All Structures, Rafters, Perlins, Trusses are hot dip galvanized and design to take a wind load up to 120 km/h. Specification: Hot dip galvanized Steel Structure: Using galvanized tubular structure or equivalent sections. Pipe sections to be used for different Structural Member will be as below or equivalent : Columns: 80 mm x 50 mm and 3 mm thick , Arch 60mm x2mm GI and arc to arc spacing 4m Trusses: Bottom cord 50 mm x 2mm; Truss Members 32mm & Bracing 32 mmx2mm , Pillars bracings 42mmX2mm Purlins: Using specially designed profile 42mm X2mm thick and purlin to purlin distance of 2.4m Gutter: each gutter size 4m long, 248mm wide, 150mm depth, and 1.5mm thick molding hot galvanized steel plate. Structural member will be fitted with zinc plated nuts & bolts without welding. 2) Nuts and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). 2. Cladding: Attaching the Plastic on Roof & Side walls, of Polyhouse& pre entry room 200 micron UV stabilized poly film having 85% light transmission, multilayered, anti drip. This is attached with the structure by the spring/clamp/profile/SDS 3. Side Ventilation with manually operating system: Side Ventilation- 24m. long and 3.7m. high × 4 Nos. Roll-up plastic curtains, fully open able (open from up to down) on four sides manually rollable, can rolled when not required. 40 mesh nylon insect-screen (UV stabilized) to be fixed inside the curtain on all four sides. 4. Top Ventilation :24m. long and 1m wide × 2 Nos. open with cover 40 mesh nylon insect-screen (UV stabilized) to be fixed . Arc suitably overlapped to prevent rain splash. Units Complete Set Complete Set Complete Set Complete set 23 5. 6. 7. 8 9 10 11 12 13 14 External shading system: 50% shading net colour: white/green/black (agro shade net) fixed 1m above the polyhouse with sliding. Internal Shading System: Thermal screen (aluminized) with sliding below gutter level. Ante Room & Doors: A. Pre Entry Room/Vestibule: The Polyhouse will have a specific Pre Entry Room of size- 2.41m. × 2.41 m. × 2.43m. (L×W×H), where all the other spare items can be stored/ dumped out. B. Doors: 1m. Wide & 2m. Tall single door complete with polycarbonate sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. Complete Set Complete Set Drip Irrigation System – Inline lateral 16mm ,2.1 lph@30 cm emitter spacing, lateral laid out at a spacing of 0.75m, PVC pipes 4g/cm sq. Pressure rating of different sizes , Screen filter, pressure gauge, PVC valves, flush valves for flushing of sub main , connected to common pumping, filtration & fertigation unit etc. Fogging System: Four way anti-leak foggers with 28lph discharge which gives very fine droplet size, PVC pipes of 6 Kg/cm2 pressure rating of various sizes, PVC ball valves, Flush valves for flushing of sub main, disc Filter with pressure gauge, connected to common water line. Mulching Sheet - Embossed mulching sheet 1.0/1.2m wide thickness 25/30 microns Crop Support – Special support arrangement for carnation fabricated by use of 20mmX20mmX20mm not galvanized angle iron and 4 levels of GI wire grid, totaling to 120cm height. For rose as directed at the time of installation. For gerbera may not be necessary. Civil Work: Foundation Wall for polyhouse WIDE BASED 1’ below earth’s surface, 1’ above earth’s surface, 9" wide wall, duly plastered. Frame base column: Galvanized channel 12mmX42mmX72mmX42mmX12mm and 3mm thick, C channel with Grouting CC (1:2:4) block, each block size 3’X1’X1’ Rain water harvesting: Gutter end to be connected to 150mm PVC pipe, 4kg/cm2 with proper funnel/accessories till the ground level Complete Set 01 No. 02 Nos. Complete set Complete set Complete set Complete set Complete set 24 7. Greenhouse with Fan and Pad cooling system for cultivation of Chrysanthemum with lighting arrangements (1 No) S. No. Technical Details of Project 1. Greenhouse house size 24m. × 24.2 m. (L×W) = 580 Sq. m. (size may differ by 5 to 10 % depending on the bay width and number of bays) Number of bays 02 Nos. Bays width 9.6m. Poly house length 24m. Poly house width 24.2m. Grid size 9.6m x 4m. Side Height 4m. Centre Height 6m. Corridor 2.5 m each side Ante Room 2.41m. × 2.41m. ×2.43m. (L×W×H) 01 No. Doors Each Size: 2m. × 1m. (tall & wide) 02 Nos. A) All Structures, Rafters, Perlins, Trusses are hot dip galvanized and design to take a wind load up to 120 km/h. Specification: Hot dip galvanized Steel Structure: Using galvanized tubular structure or equivalent sections. Pipe sections to be used for different Structural Member will be as below or equivalent : Columns: 80 mm x 50 mm and 3 mm thick , Arch 60mm x2mm GI and arc to arc spacing 4m Trusses: Bottom cord 50 mm x 2mm; Truss Members 32mm & Bracing 32 mmx2mm , Pillars bracings 42mmX2mm Purlins: Using speacially designed profile 42mm X2mm thick and purlin to purlin distance of 2.4m Gutter: each gutter size 4m long, 248mm wide, 150mm depth, and 1.5mm thick molding hot galvanized steel plate. Structural member will be fitted with zinc plated nuts & bolts without welding. 2) Nuts and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). 2. Cladding: Attaching the Plastic on Roof & Side walls, of Greenhouse & pre entry room 200 micron UV stabilized poly film having 85% light transmission, multilayered, anti drip. This is attached with the structure by the spring/profile/clamps/SDS. 3. Side Ventilation with motorized operating system: Side Ventilation- 24m. long and 3m. high × 2 Nos. Roll-up plastic curtains, open able to 1.5m. in height (open from up to down) on two sides motorized can be rolled when not required. 40 mesh nylon insect-screen (UV stabilized) to be fixed inside the curtain on sides. To be used only during power failure. Side ventilations to be airtight when fan and pad is in operation. 4. External shading system: 50% shading net colour: white/green/black (agro shade net) fixed 1m above the polyhouse with motorized rolling facility. Units Complete Set Complete Set Complete Set Complete Set 25 5. 6. 7. 8. 9. 10. 11. 12. Internal Shading System: Thermal screen (Aluminet) with motorized Complete controlled below gutter level. Set Ante Room & Doors: A.Pre Entry Room/Vestibule: The Polyhouse will have a specific Pre 01 No. Entry Room of size- 2.41m. × 2.41 m. × 2.43m. (L×W×H), where all the other spare items can be stored/ dumped out. B. Doors: 1m. Wide & 2m. Tall single door complete with polycarbonate 02 Nos. sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. Microclimate Control Panel for Temp. and Light with manual 1 set operating option and , volt meter , RYB indicator etc. also open and close motorized system with temperature based Technical feature of Temperature Control System -Accuracy: ±1°C. -Hysteresis: 0.4°C with sensor probe Pt-100 Sensor Technical feature of Light Control System Photoperiods control -Accuracy: ±5% High luminous PAR lamp 400 Wt LED light (for horticulture use) with 06 complete fittings Evaporative Cooling System : Complete 1) 5ft height x 63’ long evaporative Cellulose CELDEC Imported, set Munters make cooling pad complete with all necessary framing material of Aluminum required supporting distribution & returning piping. - Gutters, down spout end caps & drip pan, plumbing kit, pump 440 volt - 3 phase 50 cycles, Drilled PVC piping cap, pad retainer, all suspension hardware. - Metal flashings as required to seal pad to vent opening, 4" thick evaporative cooling pad material. Pad Area: 63’ × 5’ x 4’’ (w x h x Thickness) Construction Material Aluminum Profiles: Tray Sides, Top Etc. Plastic Profiles: Water Distribution tray. Cooling Media: 100mm thick celdek 7090/500 At velocities of 1 to 3 M/s to give efficiency from 60 to 95%. Filtration: 25 to 55mm viscous filter for 30 m efficiency. Miscellaneous: Fasteners, Galvanized, Rivet- Aluminum. Water storage Tank : Cemented Tank 2000 lit Pump: HP Mono block capacity as per required ( Crompton or approved equivalent) 40 Mesh Nylon: for extra protection from dust, fitted behind the pad. 2) Slow Speed Axial Flow Fan - 48" single speed belt driven exhaust fan , 440V, 50 cycles, 3 phase) with Louvers opening /closing assembly Qty. 04 Drip Irrigation System – Inline lateral 16mm ,2.1 lph@30 cm emitter Complete spacing, lateral laid out at a spacing of 0.75m, PVC pipes 4g/cm sq. Set Pressure rating of different sizes , Screen filter, pressure gauge, PVC valves, flush valves for flushing of sub main , connected to common pumping, filtration & fertigation unit etc. Crop Support – Special support arrangement for chrysanthemim Complete fabricated by use of 20mmX20mmX20mm not galvanized angle iron and set different levels of GI wire grid, totaling to 120cm height. Civil Work :Foundation Wall for polyhouse WIDE BASED 1’ below Complete earth’s surface, 1’ above earth’s surface, 9" wide wall, duly plastered. set Complete 26 13 14. 15 Frame base column: Galvanized channel 12mmX42mmX72mmX42mmX12mm and 3mm thick, C channel with Grouting CC (1:2:4) block, each block size 3’X1’X1’ Electrical Wiring. All wires will be of copper and desired load and switches imported make, extra switches also provided as standby. Each feature has own electric line with MCB and will be underground in PVC pipe complete set with A grade work, connected to central electricity supply UG cable. Rain water harvesting: Gutter end to be connected to 150mm PVC pipe4kg/cm2 with proper funnel/accessories till the ground level Set Complete Set Complete set 27 8. Installation of Open field Sprinkler (Plastic) Irrigation System for 1000 sq.m Item Description UNITS Sprinkler System:- It Consist of Over head Plastic Sprinkler 5022 Israel make at spacing 9 m x 10 m with 75 mm x 4 kg/cm2 PVC pipe as main, 63 Complete mm x 4 kg/cm2 as submain, 32 mm LLDPE lateral, Sand filter, Screen filter, Set pressure gauge, control valve, flush valve, PVC Fittings etc, connected to common pumping and fertigation unit. 9. Installation of Open field Drip Irrigation System for 1000 sq. m. Item Description UNITS Drip System:- It Consist of Inline 16 mm strip dripper 2.4 lph x 30 cm spacing with 75 mm x 4 kg/cm2 PVC pipe as main, 63 mm x 4 kg/cm2 as Complete submain, Use two laterals per bed and bed size will be 90 cm, Screen filter, Set control valve, flush valve, PVC Fittings etc., connected to common pumping and fertigation unit. 10. Installation of Insect Proof Net Houses (2 nos) of area 580 Sq. mtr. S. No. Item Description 1 Structure:- It consists of Galvanized Flenge structure Poly house size 24m. × 24.2 m. (L×W) = 580 Sq. m. (size may differ by 5 to 10 % depending on the bay width and number of bays) Number of bays 02 Nos. Bays width 9.6m. Poly house length 24m. Poly house width 24.2m. Grid size 9.6m x 4m. Side Height 4m. Centre Height 6m. Corridor 2.5 m each side Ante Room 2.41m. × 2.41m. ×2.43m. (L×W×H) 01 No. Doors Each Size: 2m. × 1m. (tall & wide) 02 Nos. Gutter slope:1-2% provided in civil work A) All Structures, Rafters, Perlins, Trusses are hot dip galvanized and design to take a wind load up to 120 km/h. Specification: Hot dip galvanized Steel Structure: Using galvanized tubular structure or equivalent sections. Pipe sections to be used for different Structural Member will be as below or equivalent : Columns: 80 mm x 50 mm and 3 mm thick , Arch 60mm x2mm GI and arc to arc spacing 4m Trusses: Bottom cord 50 mm x 2mm; Truss Members 32mm & Bracing 32 mmx2mm , Pillars bracings 42mmX2mm Purlins: Using speacially designed profile 42mm X2mm thick and purlin to purlin distance of 2.4m Gutter: each gutter size 4m long, 248mm wide, 150mm depth, and 1.5mm thick molding hot galvanized steel plate. UNITS 28 Structural member will be fitted with zinc plated nuts & bolts without welding. 2) Nuts and other metallic parts: Includes all the elements required for joining and water tightens components (such as fittings, clamps, screws and nuts plated against corrosion). 2 Covering Material:- Nylon U. V. Stabilized, Insect proof net 40 mesh for roof and side covering buried in ground with ante room Ante Room & Doors: A.Pre Entry Room/Vestibule: The Polyhouse will have a specific Pre Entry Room of size- 2.41m. × 2.41 m. × 2.43m. (L×W×H), where all the other spare items can be stored/ dumped out. B. Doors: 1m. Wide & 2m. Tall single door complete with polycarbonate sheet glazing, top & bottom tracks, jambs, flashings & installation hardware. 3 Locking Profiles:- GI locking profile with zig zag spring for fixing of nylon net for roof & Sides . 4 Shade Net: Thermal net (Aluminet), U. V. Stabilized, 50 % underneath the Net House with manual collapsible mechanism. 5 Trellis System: Trellis arrangement includes side support 48 mm GI pipe 2 mm thick, GI wire 4 mm/ wire rope 4 mm, bracings 48mm OD 2 mm thick for crops like Capsicum, Tomatoes, Cucumber, Plastic 5000 running mt ( or as required in net house) Civil Work: S. No. Item Description 1 Construction of foundation with ratio 1:2:4 PCC of size 0.45 m x 0.45 m x 0.9 m Drip and Fogger Systems: S. No. Item Description 1 Drip System- It consist of Inline lateral 16mm 2.1 lph @ 30 cm spacing, 4 kg/cm2 PVC sub main pipes, 16 mm LLDPE Laterals, PVC Valves, connected to Common Pumping & fertigation Unit. 2 Fogging System: Four way anti-leak foggers with 28lph discharge which gives very fine droplet size, PVC pipes of 6 Kg/cm2 pressure rating of various sizes, PVC ball valves, Flush valves for flushing of sub main, disc Filter, pressure gauge etc connected to common pumping and fertigation unit. UNITS UNITS 11. Automation Fertigation and Irrigation System (Common facility for all units) S. No. PRODUCT TECHNICAL SPECIFICATIONS UNITS 1 FERTIGATION SYSTEM: Automation and Fertigation System: It consists of Fertigation Machine with EC/Ph Control- 1nos., Irrigation Controller 20 station- 1nos., with complete hardware and software, BAFO cable for connect, within controller and computer, control and safety valves, Sol. Valve Plastic 2” and 1.5”, Pressure Relief Valve Plastic 2”, Auto Electric Panel For Irrigation Pumps, 1.5 mm & 2.5 mm Single Core Multi strand Wire. Housing for fertigation unit Open well submersible pump of suitable size to run all the units in the facility with all plumbing and electrical accessories. Filtration unit consisting of sand and disc filter (50m3 each) with necessary plumbing 01 2 3 4 01 01 01 29 COMMON FACILITY FOR ALL UNITS Sl. No 12 13 14 15 16 17 Detail Units OVER HEAD COVERED WATER TANK: CAPACITY: 25000 ltr (10’X10’9’), at height of 10’ from ground level with complete plumbing work etc. Made by RCC as per standard civil work, guide line. (For auto filling Syntax tanks) COMPLETE MAIN ELECTRICAL AND PLUMBING WORKS: Feeder pillars, Junction boxes, control panels switches, MCBs and UG cabling interconnecting all the units from main electricity receiving point of the facility. Similarly water supply from main pumping, filtration and fertigation site to all the units of the facility. SECURITY & PROTECTION: By chain link fencing with 2’’x’2’’x6mm, angle iron pole , fencing height up to 5’, pole to pole distance 7.5’ with proper RCC grouting and one main gate for entire unit POWER BACK-UP UNIT: Generator operating capacity 63 KVA make Kirlosker/Mahindra or equivalent make with Automatic on/off panel. Shelter with platform for Generator Housing for generator unit (12’X15’) 01 set Packing shed (20’X40’) (Top covered with precoated GI sheet. Structure raised on Flenge type side 10' centre 12' and 1' height with cemented floor) Complete set Complete set 01 Nos. one one Production module for Centre for Research and Development at Venkataramannagudem, West Godavari District Operational charges of the entire Centre for Research and Development including Automated plug type seedling production and other auto machine units as per the following units for a period of one year which includes skilled and unskilled man power S. No. Detail 18 Supervision and operational charges for plug type seedlings unit (for 10 million plants) Includes skilled and un skilled manpower and supervision by horticulture expert’s team. Growing media- Coco peat ,Vermiculite, & perlite Fertilizers – Water soluble NPK & micronutrient and others. Chemicals- pesticides/fungicides & any other items. Protected cultivation of Vegetable: Tomato, Capsicum and Cucumber Cultivation Module including Fan & Pad polyhouse systems (Five polyhouses of 580sq.m) Fertilizers – Water soluble NPK & micronutrient and others. Chemicals- pesticides/fungicides & any other items. Seed Cost Protected cultivation of flowers (Carnation , Roses ,Gerbera & Chrysanthemum ) Module (four houses of 580 sq.m) Fertilizers – Water soluble NPK & micronutrient and others. Chemicals- pesticides/fungicides & any other items. Planting material Duration One year One year One year 30 SCOPE OF WORK FOR UNIVERSITY: Electricity three phase 440 w without interrupt shall be provided by the university. Running water supply shall be provided by the university. Leveled site shall be provided by the university. Seeds for nursery production is based on crop/variety as per the farmers choice or crop/variety as recommended by the University/State Horticulture Department. Type & variety of planting material should be approved by the University. 31 Annexure – III (General Conditions) Submission of Tender and Deposit of earnest money 1. Quoted rate should be written legibly in ink or type written. No alterations should be made to any of the terms and conditions of the tenders by scoring out, altering or overwriting; similarly no alterations are permitted in the rates quoted by them. No alterations will be allowed after this Office receives the tender. Ambiguity must be avoided in filling the tenders. However, any corrections etc., made will have to be duly attested with dated signatures and official seal. The tenders not complying with these conditions will be rejected summarily. 2. The tenders not conforming to the prescribed terms and conditions of the Horticultural University or conditional Tenders or Tenders which cannot adhere to the prescribed time schedule are liable for rejection. Validity of rates and other Conditions 1. The defect liability period for the constructing of naturally vented polyhouses, fan and pad system and automated seedling production unit shall be given for 12 months or more from the date of installation. In the event of any correction or defects or replacement of defective material is to be done during this period, it should be corrected/ replaced at the cost of the bidder/ agency. 2. Bids shall remain valid for a period of 90 days from the date of opening of the bid prescribed. In exceptional circumstances, the University may solicit the bidder’s consent for an extension of the period of validity. The request and response shall be made in writing / cable / telex / fax / e-mail. 3. The validity of the tender will extend for a period of three months from the date of placing the initial order and it shall be open to Dr.YSRHU to place the orders with the suppliers on the same rates, terms and conditions for any additional quantities likely to be recurred during that period. 4. The Technical Bid (Annexure I (Part I & II), Annexure III should be taken in to consideration) and Financial Bid (Annexure II (Part I & II should be included) should be sealed individually in separate covers and both these covers should be kept in a single cover. 5. The inner and outer envelops shall bear the following address: THE PRINCIPAL INVESTIGATOR & UL O/o DIRECTOR OF RESEARCH ADMINISTRATIVE OFFICE, Dr. Y. S. R. HORTICULTURAL UNIVERSITY VENKATARAMANNAGUDEM-534101, WEST GODAVARI Dist. ANDHRA PRADESH 6. The inner envelopes should also contain the name and address of the bidder. 32 7. Telex, cable, e-mail or facsimile bids will be rejected. 8. Bidding Documents must be received by the University at the address specified not later than the time and date specified in the invitation (Notification) for bids. In the event of the date specified being declared as a holiday for the University, the bids will be received up to the appointed time on the next working day. 9. The Bidder’s representatives who are present shall sign in the register evidencing their attendance. 10.During evaluation of bids subsequent to opening, the University may at its discretion, to ask the bidder for clarification of its bid. The request for clarification and the response shall be in writing and no change in the bid will be entertained. 11.The evaluation of the bid will take into account, the past experience in addition to the bid price. Such price should include all duties and taxes to be paid or payable on components of works. 12. The bidder may present the project on power point presentation to Committee on the following. a) constructing of naturally vented polyhouses, fan and pad system and automated seedling production unit specifications b) Operation and maintenance 13. The successful tenderer (s) will be intimated by letter (s) or other means of communication and the tenderer (s) so informed shall be bound from the time of transmission of such acceptance by the University. Formal acceptance of the tender (s) will be forwarded to successful tenderer (s) in due course but it will serve merely as a confirmation of the initial information and shall not affect the time from which the offer is/are is bound by the contract(s). 14. The University is not bound to accept the lowest tender. Any or all the quotations may be rejected without assigning any reasons. It reserves the right of acceptance in whole or part of the offer made. The decision of the Dr.YSR Horticultural University in the matter shall be final and binding on the tenderers. 33 TENDER EVALUATION The evaluation and comparison of the bids shall be done for the technical as well as financial aspects. a) Technical Bid Evaluation: While power point presentation or the examination of the documents submitted by the tenderer, the committee shall have the right to verify the claims of experience made by the bidders. Based on the bid evaluation, only technically qualified bidders shall be short listed (power point presentation). After thorough evaluation of the technical bid by the committee, the financial bid of only technically qualified Bidders shall be opened in due course. b) Financial Bid Evaluation: The total cost of the project (landed cost) quoted by the bidder would be considered for financial bid evaluation. Committee: a. The committee shall do the above evaluation. The committee shall determine the approach and methodologies for the issues, which may arise during the above, referred evaluation process and their decision is final. The decision of the committee to reject or accept shall be final and binding on all the bidders. b. The successful bidder shall be responsible for the operation and maintenance of the naturally vented polyhouses, fan and pad system and automated seedling production unit for a period of one year from the date of commissioning and trial run. The bidder shall deploy at least one experienced person from time to time for advising any doubts regarding operation and maintenance besides troublshooting whenever required. 34 Other contractual obligations 1. The contract shall not be deferred/ modified except by written consent by both the Dr. YSRHU and the Bidder. 2. The Bidder shall not sublet or delegate this contract or part thereof without the written consent of the Horticultural University. Consequence of non-supply and damages 1. All risks of loss, damage or depreciation to material and structure shall be upon the supplier until the material is delivered at the addresses specified and in accordance with the provision of the contract. Till the material is received at the respective destination indicated by the university, the property continues to be at the risk of the Bidder. The mere fact that the material is delivered to transporter is no defense to the Bidder and the Bidder will be squarely held responsible for any delayed receipt of the material by the University or for loss or damage of any kind to the material in transit. 2. Assuming that the bidder fails to deliver any or all the material covered by the contract, the Horticultural University reserves the right in addition to other legal remedies, to cancel the contract or any portion thereof and hold the Bidder liable for all damages sustained by the university by virtue of the Bidder failing to perform the contract and consequent cancellation of the contract. 3. The time allowed for delivery of goods shall be deemed to be the essence of the contract. The University also reserves the right to cancel the purchase order in case supplies are delayed beyond the scheduled date of delivery and to make such arrangements as it may think fit for the completion of supplies on account and at the risk of the suppliers (s). The additional expenses thus incurred together with the consequential losses and also the liquidated damages shall be recovered from the supplier out of his / their security deposit / earnest money deposit and any other amount due to him / them. The balance still, if any, payable by the supplier shall be paid by him/them within 7 days of notice by the Dr.YSR Horticultural University FORFEITURE/REFUND OF THE EARNEST MONEY DEPOSIT (EMD) 1. In case the selected Tenderers (s) does not construct the naturally vented polyhouses, fan and pad system and automated seedling production unit at the quoted rates within the period of contract and commits any breach of any one or more of these terms and conditions, the Earnest Money Deposit deposited by the Tenderers (s) will be forfeited. 2. Earnest Money of the unsuccessful Tenderer (s) shall be refunded within three months from the date of decision regarding the tenders. No interest is payable by the University on such deposit. 35 3. On due performance and satisfactory completion of the order in all respects during the contract periods, the Earnest Money Deposit (Security Deposit) will be refunded to the Contractor(s) without interest within a period of 3 months with effect from the date of receipt of a request to this effect from the Bidder . SETTLEMENT OF DISPUTES 1. Any difference or dispute arising out of or in connection with this tender or acceptance thereof or the contract that may be entered in consequence thereof, shall be decided by arbitration. The Chairman of the committee for purchase of the equipment, Dr YSR Horticultural University or his nominee shall be the sole arbitrator and the arbitrator’s decision shall be final and binding on the parties. The Tenderer (s) will have no objection to such appointment on any ground whatsoever including that such nominee, in his official capacity dealt with this matter at any stage. 2. The parties hereby agree that in the event of any dispute no cause of action shall arise in their favor to approach any court unless they have restored to and exhausted the remedy of arbitration as envisaged above. 3. The parties also do hereby agree that the contract envisaged by these terms and conditions shall be deemed to have been entered into at DrYSRHU, V R Gudem and the courts at Eluru, West Godavari District alone will have jurisdiction to try and legal proceedings which may arise out of this contract. Neither party shall file any proceedings in any other Court. 36 TENDER FORM (Should be included in Financial bid only) From : To The Principal Investigator & UL O/o Director of Research, Administrative Office, Dr YSR Horticultural University Venkataramannagudem – 534 101. (A.P) . Ref: 1.Your tender Notice No: NIT NO.1/Dr YSRHU/2015-16 Dated........... 2. EMD – D.D. No. ...................Dated..........................for Rs ............................ I/We have read the contents of the terms and conditions mentioned in your tender schedule and its enclosures and agree to abide by the same. I/We hereby offer to construct of naturally vented polyhouses, fan and pad system and automated seedling production unit prescribed in the schedule (or such portion thereof as you may specify on the acceptance of tender) at the price given below. I/We agree to hold this offer open for a period of 90 days from the date of acceptance of tender and shall be bound by communication of acceptance dispatched within a period of 15 days from the date of accepting the tender of the bidder. I/We have also examined the requisite specifications of the material to be supplied and my / our offer is to supply the required material in accordance with the requisite specifications. I/We have carefully considered all terms and conditions in Annexure I, II and III and particulars regarding settlement of disputes and we have signed the same in token of consciously accepting the same and do hereby state that we accept them without any reservations and accordingly I/We quote the rates inclusive of all taxes, duties, transportation, insurance etc., as below. Name of the item Unit Unit price The articles will be ready for delivery within ..........................days from the date of receipt of firm orders. Yours faithfully, Proprietor (Signature and stamp of the Tenderers State legal status, whether Prop./ Partner / Registered firm / Company etc.) Encl: Samples enclosed EMD-DD No.......................................dated............................for Rs........................... 37 Dr. YSR HORTICULTURAL UNIVERSITY ADMINISTRATIVE OFFICE, VENKATARAMANNAGUDEM, WEST GODAVARI DISTRICT-534 101 E-mail: universitylibrarian@drysrhu.edu.in TENDER NOTICE NIT No:1/Dr YSRHU/2015-16 Dated: Bids are invited from firms to Supply structures for poly houses & automated plug type seedling production under Centre for Research and Development. For details visit the www.drysrhu.edu.in. PRINCIPAL INVESTIGATOR & UL O/o Director of Research Administrative Office Dr. Y. S. R. Horticultural University Venkataramannagudem 38