Lab #1 WriteUp Guidance - Mechanical Engineering : University of

advertisement

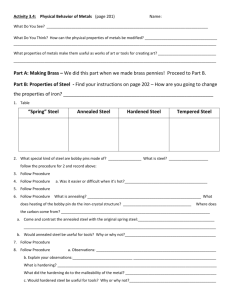

Lab Writeup Guidance Prepare your shared data sheets with names from all 6 people. This should be as an electronic document so that each group can have a copy. Turn in a printed copy in the plain folder marked Shared Data Sheets when the color coded homework folders are circulated on Thursday TOMORROW. What should be there? Load vs Displacement data for the mechanical tests of the 1010 annealed steel, including tensile test data for both 700 and 900 degree annealed samples, along with dimension measured for thickness, width, and gage length. In your lab reports, mark the slope of the initial linear region and discuss why you don't expect this to agree with the known value of Young's Modulus. Include the load displacement data of the 700 and 900 degree annealed samples with indications of the specific load at which the Luders marks were first observed near the hole on each side. Include an angle of the Luders bands during propagation on the tensile sample for comparison. There should be data sheets for weights of the samples and the foil pouches that can help you determine if you can make sense of the weight changes. Clearly now that we have done the diffusion discussion, you understand that the carbon in the steel might have evaporated if we did not include the burning toothpicks to consume the oxygen in the pocket and provide CO and CO2 as a source of surface C in the steel. x=rootDt lets you estimate how deep the effects might have been. In your reports, you should attempt to determine if all of the carbon left and if it went in, how much went in and how far in did it go. This data may or may not be useful....use your engineering judgment but make sure you have the data in the shared data. Your individual reports will analyze the data obtained from the sample with the circular hole. Take a picture of the luders strain that starts at the edge of a hole. For the second part of the experiment, include a data sheet of the superficial hardnesses of the samples to assess if any changes in hardness result from the electrochemical effects of the battery and the Mg sheet. You should include data on the voltage-current plot obtained from the battery and from the open circuit voltage and the closed circuit current caused by the Mg sheet in electrical contact with the spring steel. You will be asked to discuss why these behave the way they do. Include the load-displacement plots of the spring steel samples that were used as anode and cathode in the battery driven charging experiment and that was used as the cathode when coupled to the Mg alloy. Include any photos you intend to use, particularly those showing the luders markings that develop around the hardness indentations. You should be able to determine the size of the luders zone relative to the apparent mark left by the indenter. You should have taken images with the microscope. Next week, when your group writes up the experiment, you will use this data and include this data as an appendix to your report. Looking ahead to the due date for the lab write ups...that is Labs #1 are due Next Thursday, October 24. What to include in the Lab write up.--this lab write up is to be modeled after a technical report for a company. Thus, it is NOT A TERM PAPER where you would describe your entire known knowledge with a substantial background section. Rather each of these two experiments is unique and represents the type of experiment you might perform as a working engineer to accomplish some purpose at your place of employment. The technical report then documents the outcome. In the spirit of YOU ARE THE ENGINEER, create a scenario where your supervisor has asked you to look into something....or even better, you have taken the initiative to learn more about the particular systems your company makes or that you are planning on using in an upcoming design. I have created the lab to provide learning opportunities. In writing it up, pretend that this is a project you have initiated and actively integrate the knowledge you have accumulated from all of your courses and life experience. This is likely to be the first corporate technical report you write so it will form a template for how you write up these types of documents. I will suggest some formats below. Keep it short so that it will actually be read by others and will inform them. It is intended to record the outcome for others in your company that follow you so they will not need to redo the experiment. They can just read what you have done and reported. Now because this lab is really two topics glued together, I believe it will be easier to write two shorter reports that are modeled on a technical report for a company rather than mixing the topics. In planning for this experiment, I began experiments this summer thinking that I could overdrive the hydrogen embrittlement and MAKE the annealed steel samples embrittle so that the samples of the same geometry could be made to fail at very low stresses, but found that these samples were impervious to hydrogen embrittlement. That is so important I want to repeat it because there is a chance in the years ahead you will be designing structures to deal with hydrogen as a fuel, if the hydrogen economy becomes a reality. SOFT STEEL IS NOT EMBRITTLED BY HYDROGEN so it would probably be the favored material to contain hydrogen, covered, perhaps, by some coating that might slow down diffusion. But I also want you to know about embrittlement for the same reason. Hence, to show the embrittlement phenomena and let you experience it first hand, it was necessary to find a high strength steel where embrittlement rears its ugly head. I used the same general sample size so the grip set up would work and, as you have noticed, produced a situation where there were NO LUDERS strains in the spring steel. It would be only natural for you to notice the similar sample sizes and shapes with very different outcomes. Once the little region near the stress concentration fails at relatively low ductility, the geometry is (or soon becomes) cracklike, introducing huge stress concentrations, forcing the material to fracture without much local yielding. You will notice alternating shear lips as the material yields through its thickness. This type of failure is characteristic of thin sheet failure. You would not see this by testing round tensile bars. Your report(S) each should have: Title page with authors, contact information as of the date of writing, date, and an executive summary Objective/Background. Why you are doing this....in the spirit of what the experiment is designed to show and why it is useful enough to spend time and $ Experimental Protocol or Procedure.....the what you did part in enough detail to allow others to reproduce your work Results. The facts that were determined (notice how the results and discussion separate FACTS from THINKING ABOUT THE FACTS which belongs in the discussion) Discussion. Interpretation of the facts that may include assumptions. The meaning of the results in the circumstances at hand. The IMPLICATIONS of the results is the most important part and you should strive to actively state them. Conclusions. Figures Appendices The Luders band experiment lets you answer the question: Can stress concentrations be used to estimate the yield load of engineering structures. How, and with what accuracy? Can this experimental method be used to convince management about the reality of the effects of stress concentrations. That is stress concentrations actually reduce the failure loads of engineering structures so that drilling a hole can drop the strength of a tension member all by itself. The hydrogen charging experiment lets you answer the question: Does the electrochemical creation of nascent hydrogen on hardened steel modify the mechanical properties of the steel? Can we determine if the steel strength is reduced, or is the ductility reduced, or both? Hardness can help you answer this. What precautions must be taken when designing system that utilize high strength steel? Can this be used to convince any non-believers in the engineering team about the importance of hydrogen effects on high strength steels. The goal of having you write this engineering technical report style of write up is to give you a little real world experience. Remember that you are forming a template for yourself in how you will write up your engineering findings.