Investigating Photosynthesis with Algae Balls

Teacher Materials

Leaning Goals, Objectives, and Skills .....................................................................................2

Standards Alignments ...............................................................................................................3

Laboratory Set-Up Manual ........................................................................................................4

Instructor Laboratory Guide .....................................................................................................7

Answers to Student Questions ................................................................................................16

Post-Lab Extension Activities ..................................................................................................18

*Please consider adapting this lab to include some student-centered investigation.

Some suggestions, ideas, and tips can be found in a separate document called "Student-Centered

Investigation”

Investigating Photosynthesis with Algae Balls

Learning Goals, Objectives, and Skills

Student Learning Goals:

Students will understand the basic process of photosynthesis.

Students will understand the role of environmental factors in photosynthetic rate.

Student Learning Objectives:

Students will articulate the function of photosynthesis and identify the reactants and products of

this reaction.

Students will measure the effect of light and other factors on photosynthesis.

Scientific Inquiry Skills:

Students will pose questions and form hypotheses.

Students will design and conduct scientific investigations.

Students will make measurements and record data.

Students will use mathematical operations to analyze and interpret data.

Students will generate tables and graphs to present their data.

Students will use experimental data to make conclusions about the initial question and to support

or refute the stated hypothesis.

Students will follow laboratory safety rules and regulations.

Laboratory Technical Skills:

Students will demonstrate proper use of micropipettors.

2

Investigating Photosynthesis with Algae Balls

Standards Alignments

MA Science and Technology/Engineering Curriculum Framework (2006)

Biology

1.2 Describe the basic molecular structures and primary functions of the four major categories of

organic molecules (carbohydrates, lipids, proteins, nucleic acids).

2.4 Identify the reactants, products, and basic purposes of photosynthesis and cellular respiration.

Explain the interrelated nature of photosynthesis and cellular respiration in the cells of photosynthetic

organisms.

2.5 Explain the important role that ATP serves in metabolism.

Chemistry

7.5 Identify the factors that affect the rate of a chemical reaction (temperature, mixing, concentration,

particle size, surface area, catalyst).

Scientific Inquiry Skills

SIS1. Make observations, raise questions, and formulate hypotheses.

SIS2. Design and conduct scientific investigations.

SIS3. Analyze and interpret results of scientific investigations.

SIS4. Communicate and apply the results of scientific investigations.

Mathematical Skills

Construct and use tables and graphs to interpret data sets.

Solve simple algebraic expressions.

Perform basic statistical procedures to analyze the center and spread of data.

Measure with accuracy and precision (e.g., length, volume, mass, temperature, time)

Use common prefixes such as milli-, centi-, and kilo-.

3

DRAFT REVISED MA Science and Technology/Engineering Standards (2013)

*Please note that these are DRAFT standards that have not yet been submitted for formal review or

adoption.

Biology

HS-LS1-5. Use a model to illustrate how photosynthesis uses light energy to transform carbon

dioxide and water into oxygen and chemical energy stored in the bonds of glucose and other

carbohydrates.

[Clarification Statement: Emphasis is on illustrating inputs and outputs of matter (including ATP) and the transfer and

transformation of energy in photosynthesis by plants and other photosynthesizing organisms. Examples of models could

include diagrams, chemical equations, and conceptual models.]

[Assessment Boundary: Assessment does not include specific biochemical steps of light reactions or the Calvin Cycle, or

chemical structures of molecules.]

HS-LS2-3. Construct and revise an explanation based on evidence that the processes of

photosynthesis, chemosynthesis, and aerobic and anaerobic respiration are responsible for the

cycling of matter and flow of energy through ecosystems. Explain that environmental conditions

restrict which reactions can occur.

[Clarification Statement: Examples of environmental conditions can include the availability of sunlight or oxygen.]

[Assessment Boundary: Assessment does not include the specific chemical processes of photosynthesis, chemosynthesis, of

either aerobic respiration or anaerobic respiration.]

Chemistry

HS-PS1-5. Construct an explanation based on collision theory for why varying conditions influence

the rate of a chemical reaction or a dissolving process. Design and test ways to alter various

conditions to influence (slow down or accelerate) rates of processes (chemical reactions or

dissolving) as they occur.

[Clarification Statement: Explanations should be based on three variables in collision theory: quantity of collisions per unit time,

molecular orientation on collision, and energy input needed to induce atomic rearrangements. Conditions that affect these

three variables include temperature, pressure, concentrations of reactants, mixing, particle size, surface area, and addition of a

catalyst.]

[Assessment Boundary: Assessment is limited to simple reactions in which there are only two reactants and to specifying the

change in only one variable at a time.]

NRC Practices

Asking questions and defining problems

Planning and carrying out investigations

Analyzing data

Mathematical and computational thinking

Constructing explanations and designing solutions

Engaging in argument from evidence

Obtaining, evaluating, and communicating information

4

Investigating Photosynthesis with Algae Balls

Laboratory Set-Up Manual

Set-up assumes 30 students, working in pairs, for a total of 15 stations. Depending on the room set up

and equipment, students can work in groups of three or four.

Supply List: Basic Lab

75X 1 mL transfer pipet

75 X small beakers or disposable plastic cups

15 X tea strainers ( or 20cm x 20cm plastic screen)

60 X 2.0 mL microcentrifuge tubes

15 X plastic spoons

15X 50 mL conical

45 X 15 mL conicals

15 X test tube rack

15 X microcentrifuge rack

15 x 10X10 cm squares aluminum foil

Lamp (15 watt spiral fluorescent bulb will work)

Sodium alginate

Calcium chloride

Baking soda (sodium bicarbonate)

Cresol red

thymol blue

Ethanol

Freshly boiled distilled water (1500 mL)

Liquid freshwater algae suspension (Chlorella or Chlamydomonas)

Optional Supplies/equipment

Platform shaker

Color Standards

o 9 X 10 mL glass vials with lids

o Boric acid

o Sodium tetraborate decahydrate or sodium borate (Borax)

o dH2O

Set-up Calendar

6 weeks before the lab

Order algae suspension

4 weeks before the lab (or when the algae suspension arrives)

Inoculate 200 mL of fresh water growth media with the algae culture.

Set up culturing conditions for algae. The algae will grow well under white fluorescent light at room

temperature. If using an incandescent bulb use a beaker of water as a heat sink so the algae does

not get too hot. Continuous light is recommended. This

mixture will need to be aerated with an

air stone and pump. An alternative to the pump would be continuous shaking. The culture should be a

dark green (think pea soup!) For additional information see:

http://resources.wardsci.com/livecare/algae-cyanobacteria/

3-7 days before the lab

Prepare solutions

1. Sodium Alginate (2%) Add 2 g sodium alginate to 100 mL dH2O and shake until dissolved.

Initially all the alginate may not go into solution but if left over night at room temperature it will go

into solution. Since this is a natural product, the viscosity may vary from batch to batch. The

alginate should be fluid enough to pour slowly. If it is too viscous add dH2O to thin it. Store

covered in refrigerator. Let warm to room temperature before using. Solution will last for several

weeks if stored at 4C.

5

2. Calcium Chloride (2%): Add 8 g calcium chloride to 180 mL dH2O and stir until dissolved.

Bring volume up to 200 mL. Dispense 15 mL into 15X15 mL conicals and store at room

temperature until lab day

3. Hydrocarbonate indicator:

o Dissolve 0.1 g cresol red and 0.2 g thymol blue in 20 mL of ethanol

o Dissolve 0.85 g of baking soda in 200 mL freshly boiled (and

therefore CO2 free) dH2O

o Add the ethanol/cresol red/thymol blue solution to the baking soda

solution and bring the volume up to 1000 mL with freshly boiled dH2O

o This is the 10X stock solution. To use dilute to 1X and adjust pH to 7.4

4. Preparation of Color Standards (see attached sheet)

Copy student labs

Cut squares of aluminum foil (10 x 10 cm)

1 day before lab

Set up 15 student stations

5 X 1 mL transfer pipet

5 small beakers or disposable plastic cups

1 tea strainer

4 X 2.0 mL microcentrifuge tubes

Test tube rack

Microcentrifuge rack

1 plastic spoon

Foil

30 mL calcium chloride in 50 mL conical

6 mL sodium alginate in 15 mL conical

8 mL 1X indicator in 15 mL conical

Morning of lab

Prepare a concentrated solution of algae. There are two ways to concentrate the algae. Both

involve concentrating the algae and then resuspending it to get the volume needed.

Concentrate the algae

1) let the algae settle out overnight and slowly pour off the liquid—leaving concentrated algae

solution at bottom. Save both the algae and the decanted liquid.

2) add 45 mL of algae solution to 50 mL conicals and centrifuge at low speed for 5 minutes. Pour

off and save the supernatant

Making the final solution

Each pair of students will need 2 mL of algae solution. Using the concentrate from either method

above, bring the volume up to 20 mL (if you have 15 pairs). The supernatant or the decanted liquid

should be used to resuspend the algae. This solution should be stored at room temperature until

the lab period.

Set out the color standards (if using)

At the beginning of the lab

As students start the lab, they should come up with their small beaker and get 2 mL algae solution.

A graduated transfer pipet can be used for this transfer.

A spectrophotometer may be used to determine the color change. For further information, see

http://www.saps.org.uk/secondary/teaching-resources/235-student-sheet-23-photosynthesis-using-algaewrapped-in-jelly-balls

6

Investigating Photosynthesis with Algae Balls

Instructor Laboratory Guide

The purpose of this lab is for students to lead their own investigations on environmental factors that affect

the rate of photosynthesis in the microalgae. Briefly, students will immobilize defined quantities of algae in

gelatinous balls of calcium alginate. The balls are formed when sodium alginate is added to a solution of

calcium chloride. A double replacement reaction occurs, replacing the sodium ions with calcium ions. The

crosslinking that occurs stabilizes the compound, creating the balls. These balls will be immersed in

solutions that allow for controlled testing of an independent variable. The pH of this solution over time

serves as a proxy for photosynthetic rate. pH changes result from uptake of CO2 during photosynthesis or

production of CO2 during cellular respiration, via the reaction:

CO2 (g) + H2O (l) <=> H+ (aq) + HCO3- (aq)

We provide sample protocols for examining the effects of the color of light, type of light source, external

carbon sources, and light intensity on photosynthetic rate. Methods for manipulating the independent

variable are intentionally omitted from the student manual. Each student or group of students will choose

one of these variables to test with a rigorous, self-designed experiment, drafting an experimental design

based on the provided guidelines. They should have enough background knowledge of photosynthesis

and producer physiology to form educated hypotheses. We encourage you to assign this as pre-lab

homework and to review their protocols in advance of the lab. This manual will help you assess whether a

student’s design is logical and feasible.

You will monitor pH changes in the reaction vials by the striking changes in the color of the

hydrocarbonate indicator solution. This is due to dye molecules therein that exist in an equilibrium of

different protonation states, with each species bearing its own color. A more acidic solution shifts the

equilibrium in favor of the protonated form, while a basic solution favors the unprotonated state. Small

changes in pH are therefore reflected by the color of the indicator.

You have two options for measuring pH. The first is to compare your solution of interest against color

standards titrated to known pH values. The indicator is highly sensitive from pH 7.6 to 9.2. The Color

Standards Preparation section of the Laboratory Setup Manual describes how to prepare these. The

second option, which is more quantitative, is to measure the absorbance of your solution at 550 nm using

a Vernier UV-vis spectrophotometer. Absorbance at this wavelength is linear with pH in the range of 7.6

to 9.2. This allows you to generate a standard curve of absorbance vs. pH from which you can interpolate

data.

An excellent reference for technical support and for ideas about additional experiments is

http://www.saps.org.uk/secondary/teaching-resources/235-student-sheet-23-photosynthesis-using-algaewrapped-in-jelly-balls. We encourage you to adapt this lab to your vision and your curricular needs once

you become comfortable with the physical manipulations. For instance, it is easily modified to test the

effects of different factors on cellular respiration, or to compare photosynthetic rates between different

microalgae.

Detailed Procedure:

Making the algae balls (20 minutes)

Refer to the directions in the student manual. You may need to optimize the ratio of algae to sodium

alginate depending on your solution’s viscosity. Be sure to alert students of any change.

Note that the concentration of algae in the balls will affect the rate of photosynthesis. Therefore, it is

essential that each group make all the balls they need in a single batch. If your class compares data

between groups, bear in mind that this will be a source of variability.

This is a convenient stopping point in the protocol. You can store the algae balls for a few months

submerged in distilled H2O in the refrigerator.

7

Reaction Setups for Each Independent Variable

Although we offer the following guidelines for obtaining robust results, factors such as ambient

temperature and the inherent activity of your microalgae culture will affect photosynthetic rate. We

encourage your students to be flexible and creative in adjusting various features of the setup.

The algae vial should be placed close to a 60W equivalent (or brighter) light bulb in order to

visualize changes within a class period. With the exception of the investigation of different light

sources, we recommend compact fluorescent bulbs because they output little heat.

A. Color filters provide a simple but powerful illustration of the absorption properties of photosynthetic

pigments. Each filter transmits the color that it appears to our eyes and absorbs other visible wavelengths

to varying degrees. Ask your students to consider the absorption spectrum of chlorophyll and minor

photosynthetic pigments. Which filter should allow the greatest activity? the least?

1. Gather red, blue, green, and transparent color filters. Which is your experimental control?

2. Add 35 algae balls to each of four vials and 35 H2O/alginate balls to another vial. With which

sample will you compare your H2O control?

3. Prepare 20 mL of 1X hydrocarbonate indicator solution. Dispense 3.0 mL to each vial. Invert the

vial gently and allow the solution to equilibrate for 3 minutes.

4. Determine the initial pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, transfer 1.5 mL from each vial to a cuvette for an initial absorbance

reading. Be sure to keep track of the sample to which each cuvette corresponds. Then

re-pour the solution from the cuvette back into its corresponding sample vial.

5. For each filter setup, place the vial at an angle into a paper cup. Sit the filter over the mouth of

the cup.

6. Shine a CFL bulb over all setups. Be sure that all vials are equidistant from the light source.

7. Record the final pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, remove 1.5 mL of the indicator solution from each vial and transfer to

a cuvette. Be sure to keep track of which sample each cuvette corresponds to. Record

the absorbance of each sample.

Sample

abs at time 0 (absinitial)

abs at 30 minutes (absfinal)

H2O/alginate control

transparent filter

red filter

green filter

blue filter

B. Different light sources highlight other factors that affect photosynthesis when the overall brightness

remains constant. Can algae detect differences between light emitted by LED vs. CFL bulbs? What is a

side effect of incandescent bulbs?

1. Gather LED, CFL, and incandescent bulbs of 1200 lumens.

2. To 18 mL distilled H2O, add 2 mL 10X hydrocarbonate indicator solution.

3. Label each of three vials LED, CFL, and incandescent. Add 35 algae balls to each.

4. Label another vial H2O/alginate. Add 35 H2O/alginate balls. Decide on which light source you

would like to test this control.

5. Dispense 3.0 mL 1X indicator solution to each. Allow to equilibrate for 3 minutes.

6. Determine the initial pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, transfer 1.5 mL from each vial to a cuvette for an initial absorbance

reading. Be sure to keep track of the sample to which each cuvette corresponds. Then

re-pour the solution from the cuvette back into its corresponding sample vial.

7. Place all vial at the same distance from their respective light sources for 30 minutes. To reduce

contaminant light, consider placing cardboard barriers between the setups.

8

8. Record the final pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, remove 1.5 mL of the indicator solution from each vial and transfer to

a cuvette. Be sure to keep track of which sample each cuvette corresponds to. Record

the absorbance of each sample.

Sample

abs at time 0 (absinitial)

abs at 30 minutes (absfinal)

H2O/alginate control

LED

CFL

incandescent

C. External carbon sources test the ability of carbohydrates to feedback inhibit enzymes required for

photosynthesis. The glyceraldehyde-3-phosphate produced in the Calvin-Benson cycle has two fates:

conversion into starch or into the disaccharide sucrose, which subsequently is hydrolyzed into glucose

and fructose. Ask your students to hypothesize how external carbon sources affect photosynthesis rate.

They can compare equal concentrations of two different sugars, such as sucrose and glucose, or varying

concentrations of a single sugar. The following protocol was optimized for the latter investigation, but can

be modified to test equimolar glucose and sucrose.

1. Prepare 9 mL of 0.5M glucose and 9 mL of 0.1M glucose. Add 1 mL 10X hydrocarbonate

indicator solution to each.

2. To 18 mL distilled H2O, add 2 mL 10X hydrocarbonate indicator solution.

3. Label each of three vials –glucose, 0.1M glucose, and 0.5M glucose. Add 35 algae balls to each.

Add 3.0 mL 1X indicator solution to the –glucose vial and 3.0 mL of the corresponding solutions

into the glucose vials.

4. Add 35 H2O/alginate balls to a fourth vial. Label it H2O/alginate. Dispense 3.0 mL 1X indicator

solution into this vial.

5. Invert all vials gently and allow to equilibrate for 3 minutes.

6. Determine the initial pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, transfer 1.5 mL from each vial to a cuvette for an initial absorbance

reading. Be sure to keep track of the sample to which each cuvette corresponds. Then

re-pour the solution from the cuvette back into its corresponding sample vial.

7. Place all vial equidistant from the light source for 30 minutes.

8. Record the final pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, remove 1.5 mL of the indicator solution from each vial and transfer to

a cuvette. Be sure to keep track of which sample each cuvette corresponds to. Record

the absorbance of each sample.

Sample

abs at time 0 (absinitial)

abs at 30 minutes (absfinal)

H2O/alginate control

- glucose algae control

0.5 M glucose

0.1 M glucose

9

D. The intensity of light opens a deeper consideration of the properties of chlorophyll and can also be

well quantified. Ask your students to hypothesize how photosynthetic rate alters with intensity. Have them

apply the inverse square law to calculate the intensity at various distances from the light source. Will the

brightest light necessarily induce the most photosynthesis? Because chlorophyll is a dye with electrons

that can be promoted to higher energy states, it may react with other molecules in the cell or else absorb

photons in a way that causes permanent structural damage. This phenomenon is called photobleaching.

At the other extreme, what is the lowest level of light that can still support photosynthesis?

1. To 18 mL distilled H2O, add 2 mL 10X hydrocarbonate indicator solution.

2. Label each of four vials 5, 10, 20, and 30 cm. Add 35 algae balls to each. Label a fifth vial

H2O/alginate. Decide where you will place it and label it accordingly. Add 35 H 2O balls.

3. Dispense 3.0 mL of 1X indicator solution to each vial and invert gently. Allow to equilibrate for 3

minutes.

4. Determine the initial pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, transfer 1.5 mL from each vial to a cuvette for an initial absorbance

reading. Be sure to keep track of the sample to which each cuvette corresponds. Then

re-pour the solution from the cuvette back into its corresponding sample vial.

5. Place all vial equidistant from the light source for 30 minutes.

6. Record the final pH:

a. If comparing against color standards, estimate pH to the nearest tenth.

b. If using the UV-vis, remove 1.5 mL of the indicator solution from each vial and transfer to

a cuvette. Be sure to keep track of which sample each cuvette corresponds to. Record

the absorbance of each sample.

Sample

Intensity of light (W)

abs at time 0 (absinitial)

abs at 30 minutes

(absfinal)

H2O/alginate control

5 cm

10 cm

20 cm

30 cm

Measuring pH (50 minutes)

Students will measure the pH of their reaction solutions immediately after adding the balls and again

30 minutes later. In the meantime, they will work in groups to generate standard curves of

absorbance vs. pH.

You can connect the Vernier UV-vis spectrophotometer either to a LabQuest device or to a computer

with LoggerPro. Below are step-by-step directions for how to configure and take measurements with

either. We also explain how to generate and use a standard curve.

With a computer and LoggerPro software:

1. Plug in the UV-vis to a USB port on your computer.

2. Open LoggerPro. The software will automatically recognize the UV-vis (you will see a rainbow

spectrum on the main screen).

3. You will first need to calibrate the UV-vis before your students begin taking measurements. In

LoggerPro, go to Experiment -> Calibrate -> Spectrometer: 1. The “Calibrate Spectrometer”

dialog box will appear. Allow 90 seconds for the lamp to warm up.

4. Fill a clean cuvette with 1.5 mL of distilled H2O. Insert the cuvette into the UV-vis so that the

clear panel faces the arrow. Make sure the water level is visible above the slot. Press the Finish

Calibration button; wait for it to turn grey, which signals that the machine is done calibrating.

Press OK.

a. Note: The dialog box prompts you to insert a blank cuvette. You should calibrate with a

cuvette filled with distilled H2O.

10

5. To take absorbance measurements at a single wavelength, press the

button. Under

Collection Mode, select the Absorbance vs. Concentration ratio button. Under Column Name,

Short Name, and Units, type “pH.” Click the arrow of the drop-down menu and select Individual

Wavelengths. There will be a list of discrete wavelengths in the middle of the dialog box. Press

Clear Selection, then select 550.3 nm. The right of the Clear Selection button should read “1

selected wavelengths.” Press OK.

6. A real-time panel of the absorbance reading should appear in the lower left panel. Immediately

above it, there will be a two-column data table of pH as the left header and Abs-550.3 as the right

header. The empty plot in the main screen should have “Absorbance at 550.3 nm” as the y-axis

and “pH (pH)” as the x-axis.

7. You are now ready to collect your t0 data point. Dry off the outside of your sample cuvette and

place it in the slot, ensuring that the clear panel faces the arrow. The lower left box will report the

absorbance value.

With a LabQuest device:

1. Press the red power button to turn on the device.

2. Plug the UV-vis into the USB port on the device. The screen should read “USB: Abs.”

3. Go to Sensors -> Calibrate -> USB: Spectrometer. Wait 90 seconds for the lamp to warm up.

4. Fill a clean cuvette with 1.5 mL distilled H2O and insert it into the slot. Press the Finish Calibration

button. Once the screen reads “Calibration completed,” press OK. You should be back at the

Meter screen.

a. Note: The interface prompts you to insert a blank cuvette. You should calibrate with a

cuvette filled with distilled H2O.

5. To take absorbance measurements at a single wavelength, tap “Mode” to configure the

instrument. At the top of the new screen, there will be a drop-down menu next to “Mode:.” Select

“Events with Entry.”

6. Next to “Name” and “Units,” enter “pH.” Tap OK to return to the Meter Screen.

7. The screen should now read “USB: Abs @ 0 nm.” Tap the red box and select “Change

Wavelength…”

8. Next to “Selected Wavelength:,” enter 550. Deselect the “Report average of wavelength band”

box. Tap OK. The red box will now display the real-time absorbance reading.

9. You are now ready to collect your t0 data point. Wipe down your sample cuvette and place it in

the slot, ensuring that the clear panel faces the arrow. Record the absorbance value.

Generating a standard curve

A standard curve is a plot of absorbance versus the known pH values of your color standards. Its

purposes are:

o 1) To reveal the range of pH values in which absorbance varies linearly with pH. In this

range, one is confident that changes in absorbance accurately reflect changes in pH.

o 2) To allow one to calculate pH from absorbance in this range. You will be able to fit a

line of the form y = ax + b, where y is the absorbance and x is the pH. By substituting y

with the absorbance of a sample, you can determine its pH by solving for x.

If many groups are sharing one UV-vis, it is recommended that they manually record absorbance

values and generate linear fits using Excel rather than storing data on the device.

With Excel:

1. Connect the UV-vis either to a computer or to a LabQuest device. Calibrate and set up the

instrument as described above.

2. Fill a clean cuvette with 1.5 mL of the pH 7.6 color standard. Manually record the absorbance in

the following data table:

pH

7.6

7.8

8.0

8.2

8.4

8.6

8.8

9.0

9.2

Abs (550 nm)

3. Using a clean cuvette each time, repeat step 2 for each of the color standards until your table is

complete.

4. Enter the data into Excel to fit a linear regression.

11

With LoggerPro:

1. Calibrate and set up the UV-vis as described above.

2. Press the

button at the top of the screen. Fill a clean cuvette with 1.5 mL of the

pH 7.6 color standard and insert into the UV-vis. The real-time absorbance reading will be

displayed in the lower left corner. Once it stabilizes, press

. You will be prompted to

enter the pH value. Enter 7.6.

3. Using a clean cuvette each time, repeat step 2 for each color standard. Enter the corresponding

pH value when prompted. The raw data will appear in the table on the left.

4. Once you have measured all standards, press

. Go to Analyze -> Linear Fit. The

program will implement a linear regression. To adjust the axes, go to Options -> Graph Options ->

Axes Options. “Top” and “bottom” correspond to minimum and maximum values.

With LabQuest:

5. Calibrate and set up the UV-vis as described above.

6. Press the green play button at the bottom left of the Meter screen. The screen should now display

a plot with Abs @ 550 nm on the y axis and pH (pH) on the x-axis.

7. Fill a clean cuvette with 1.5 mL of the pH 7.6 color standard and insert into the UV-vis. The realtime absorbance reading will be displayed on the right under Abs @ 550 nm. Once it stabilizes,

tap the Keep button in the bottom left corner. Enter 7.6 as the pH value and press OK.

8. Using a clean cuvette each time, repeat step 3 for each color standard. Enter the corresponding

pH values.

9. Once you have finished measuring all standards, press the red stop button in the lower left

corner.

10. To fit a line, go to Analyze -> Curve Fit -> Abs @ 550 nm. Under the Fit Equation drop down

menu, select linear. The coefficients of the equation y = mx + b should be displayed. Tap OK.

11. For the purposes of the lab report, students can either configure the device to email the data

to themselves or copy it manually to process in Excel. For the latter option, click the X|Y icon

to view the raw data.

12. Sample standard curve (generated in LoggerPro):

For sample data tables and examples of how to use the standard curve, see the section following

“Reaction setups for each independent variable.”

12

Sample Data Analysis

The following example illustrates how to calculate pH from absorbance.

From the sample standard curve above of absorbance vs. pH,

abs = 0.76 (pH) – 5.61

for absorbance values between 0.24 and 1.4.

If an absorbance measurement equals 0.84,

0.84 = 0.76 (pH) – 5.61

pH = (0.84 + 5.61) / 0.76 = 8.5

Students should then be able to complete the following table:

Sample

pH at time 0 (pHinitial)

pH at 30 minutes

(pHfinal)

ΔpH (pHfinal – pHinitial)

H2O/alginate control

algae control

independent variable –

instance 1

independent variable –

instance 2

pH change after 30 minutes (final initial)

A concise visual representation of such data is a bar graph of ΔpH vs. the independent variable. For

instance, the experiment with exogenous glucose may look like the following:

Effect of glucose on photosynthetic

reactions

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

H2O/alginate

algae without

glucose

algae in 0.1 M algae in 0.5 M

glucose

glucose

condition

13

Investigating Photosynthesis with Algae Balls

Color Standards Preparation

Recipe makes up to 10 sets of 10 mL color standards.

1. Dissolve 3.1 g boric acid in 240 mL dH2O and stir until dissolved. Bring volume to 250 mL.

2. Dissolve 2.9 g of sodium tetraborate decahydrate in 140 mL of dH2O and stir until dissolved.

Bring volume to 150 mL.

3. For each pH color standard, add the boric acid solution and the borax solution in the

amounts in the table below to a small flask or beaker and bring the solution to 100 mL final

volume with dH2O. Use a clean container to make each pH standard to avoid contamination.

pH Color Standards – Recipe Chart

pH

7.6

7.8

8.0

8.2

8.4

8.6

8.8

9.0

9.2

Boric

Acid

25 mL

25 mL

25 mL

25 mL

25 mL

25 mL

25 mL

25 mL

25 mL

Borax

1.00 mL

1.55 mL

2.45 mL

3.60 mL

5.70 mL

8.70 mL

15.00

mL

29.50

mL

57.50

mL

Add dH2O

to Total

Volume

100 mL

100 mL

100 mL

100 mL

100 mL

100 mL

100 mL

100 mL

100 mL

4. Label one of each of 9 X 10 mL clean glass vials with one of the following pH values: pH 7.6,

pH 7.8, pH 8.0, pH 8.2, pH 8.4, pH 8.6, pH 8.8, pH 9.0, pH 9.2. Repeat to generate the

desired number of standards sets.

5. Dispense 9 mL of each pH color standard into the corresponding 10 mL glass vial. Store at

room temperature until ready to use. Four to six sets of standards is sufficient for a class of

30 students (~ 1 set of standards/3 groups). Repeat to generate the desired number of

standards sets.

6. Just prior to the start of class you will need to add 1 mL of 10X hydrocarbonate indicator

solution to each color standard vial. Refer to Set-Up Manual for instructions. See example

standards below.

Color Standards and Corresponding pH values

pH 7.6

pH 7.8

pH 8.0

pH 8.2

pH 8.4

pH 8.6

pH 8.8

pH 9.0

pH 9.2

Photo by Debbie Eldridge. Copyright Science & Plants for Schools (www.saps.org.uk). Photosynthesis with Algal Balls: Technical notes

(Revised 2012).

14

Recipe for one set of 5 mL standards

The boric acid and borax solutions can be made in larger volumes and stored indefinitely.

1. Dissolve 3.1 g boric acid in 240 mL dH2O and stir until dissolved. Bring volume to 250 mL.

2. Dissolve 2.9 g of sodium tetraborate decahydrate (borax) in 140 mL of dH2O and stir until

dissolved. Bring volume to 150 mL.

3. For each pH color standard, add the boric acid solution, the borax solution and the 10X

hydrocarbon indicator in the amounts in the table below to a 5 mL tube and bring the solution

to 5 mL final volume with dH2O.

pH Color Standards – Recipe Chart

pH

7.6

7.8

8.0

8.2

8.4

8.6

8.8

9.0

9.2

Boric

Acid

1250 uL

1250 uL

1250 uL

1250 uL

1250 uL

1250 uL

1250 uL

1250 uL

1250 uL

Borax

50 uL

77.5 uL

122.5 uL

180 uL

285 uL

435 uL

750 uL

1475 uL

2.875 uL

500 uL

500 uL

500 uL

500 uL

500 uL

500 uL

500 uL

500 uL

500 uL

10X

Indicator

Add dH2O

to Total

Volume

5 mL

5 mL

5 mL

5 mL

5 mL

5 mL

5 mL

5 mL

5 mL

15

Investigating Photosynthesis with Algae Balls

Answers to Student Questions

Protocol-embedded:

p. 2:

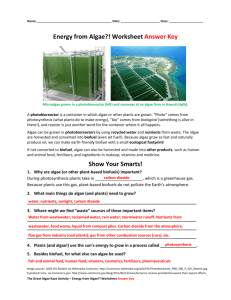

The biological process is photosynthesis. The energy for photosynthesis comes from

sunlight. The carbon for production of biofuel comes from CO2.

(sample answers): Photosynthesis fixes CO2 into glucose, Photosynthesis uses

chlorophyll, Photosynthesis has light dependent and light independent reactions,

Photosynthesis requires ATP and NADPH, green plants and other primary producers are

the only organisms the can photosynthesize, etc.

p. 3:

The tube on the left, the one that is more yellow will have more H+ ions. Not much

photosynthesis has occurred, so there is lots of carbon dioxide is dissolved in water,

which produces carbonic acid, H2CO3, and lowers the pH.

Pre-lab:

1. Photosynthesis uses energy from the sun to drive the reaction: CO2 + 6H2O C6H12O6 + 6O2

2. An experimental control is an experiment designed to minimize the effects of variables other than the

single independent variable being tested. This increases the reliability of the results, often through a

comparison between control measurements and the other measurements.

3. The tube containing the water balls was our control.

4. The water balls should not have photosynthetic organisms, so the the reaction above should not

occur, and we should not see a change in pH. If something else in the experiemtn, other that the

photosynthesis of the algae is influencing the pH, we would be able to detet that with the water ball

control.

5. Algae ball tube:

30 minutes: Some of the CO2 will be converted to glucose, which will decrease the amount of

carbonic acid, and thus the pH will increase and the color of the indicator solution will

begin to change from yellow to orange or red.

24 hours: Most of the CO2 will be converted to glucose, which will decrease the amount of

carbonic acid, and thus the pH will increase and the color of the indicator solution will be

purple.

Water ball tube:

30 minutes and 24 hours: The CO2 will NOT converted to glucose, the amount of carbonic acid,

and thus the pH will remain the same and the color of the indicator solution will not

change.

16

6. The dyes in the indicator are sensitive to pH. When CO2 is present, the level of carbonic

acid is high and the pH is low. Photosynthesis consumes CO2 so a color change associated

with a decrease in CO2 can be detected.

Post-Lab and Analysis:

1. (Sample answer) The results from the algae ball tube and the control tube matched my

prediction. The water ball tube did not change color, but the algae ball tube became more

purple with time.

2. Answers will vary depending upon the measurement tools used.

3. Answers will vary depending upon the design of each indivduals student’s experiment.

4. (Sample answer) If the algae was boiled before making algae balls, the I would expect the

cells to be dead and unable to photosynthesize. If the algae was unable to photosynthesize,

then the algae ball and water ball tubes should look the same.

5. (Sample answer) If the water used to make the water balls was contaminated with

bacteria, the results would probably be the same as the uncontaminated control. Bacteria

do not photosynthesize so the CO2 that is present will remain. When given glucose or

another carbon source to consume, bacteria do respire, which produces CO2. But, in the

absence of glucose or another carbon source to consume the bacterial contaminated water

balls would probably behave much like the normal control water balls.

17

Investigating Photosynthesis with Algae Balls

Post-Lab Extension Activities

Student Oral Presentation:

Students can report the findings of their student-centered investigations to the class using a PowerPoint

presentation that includes the following information:

Experimental question—what you hope to learn from performing the experiment.

Hypothesis—a testable, proposed answer to the experimental question based on prior

knowledge.

Experimental system and data collection methods—flowchart of how the experiment was

performed and how data was collected. This should NOT include a detailed summary.

Results—observations, data tables, figures, etc.

Conclusions—should the hypothesis be accepted or rejected as supported by key data.

Online resource for effective PowerPoint presentations:

http://office.microsoft.com/en-us/powerpoint-help/tips-for-creating-and-delivering-an-effectivepresentation-HA010207864.aspx

Student Lab Report:

Students can report the findings of their student-centered investigations through a written lab report. Your

school may have its own lab report format, but generally lab reports include the following information:

Title—brief summary reflecting the factual content of the investigation.

Introduction—includes questions being answered, hypothesis and background information.

Materials—list of supplies needed to perform the lab.

Procedure—step-by-step procedure (with enough detail so someone could repeat the

experiment).

Results—observations, data tables, figures, etc. and a brief narrative summary of results.

Conclusion—explanation supported by evidence for whether the hypothesis should be accepted

or rejected.

Online resources for writing lab reports:

http://www.mhhe.com/biosci/genbio/maderinquiry/writing.html

http://www.ncsu.edu/labwrite/

Student Writing Exercise:

Ask students to read a current newspaper or journal article related to biofuels and write a paragraph

answering a series of prompts. For example, students could read the online article, As Algae Bloom

Fades, Photosynthesis Hopes Still Shine (http://www.nytimes.com/gwire/2011/03/29/29greenwire-asalgae-bloom-fades-photosynthesis-hopes-stil-54180.html?pagewanted=print) and answer the following

questions:

Why did scientists have such hope for algae as a biofuel?

What were some of the reasons that GreenFuel Technologies did not succeed in their attempt to

develop algae as a biofuel?

What could they or should they have done differently?

Do you think the government should invest money in the development of algae as a biofuel? Why

or why not?

What are the benefits of using cyanobacteria vs. microalgae for biofuel?

How has sequencing technology helped biofuel technology to progress?

What kinds of genes would you put into cyanobacteria to enhance biofuel production? (possible

answers: faster growth, resistance to fungus/water flea infection, ability to grow in brackish water,

carbon fixation).

18

As Algae Bloom Fades, Photosynthesis Hopes Still Shine

March 29, 2011 by Paul Voosen of Greenwire

BOSTON -- Bioengineer Jeff Way has seen what happens when the claims of algae biofuel companies

get ahead of the science, when their promises of "renewable diesel" slam into the realities of engineering.

He's been to the bankruptcy auction.

Once the standard-bearer for the algae revolution, GreenFuel Technologies failed almost two years ago.

Spun out of the Massachusetts Institute of Technology, the company promised to convert waste carbon

dioxide into fuel-producing algae. It opened a celebrated -- and, it turns out, expensive -- pilot plant in

Arizona. It raised more than $70 million in private funds. Then it went bust.

A former biotech pharmaceutical developer, Way hunted for deals at GreenFuel's equipment auction.

"It was a very sobering experience to see the death of a biotech company," said Way, who works on

bioenergy at Harvard University's Wyss Institute for Biologically Inspired Engineering. "This company just

went belly up. And I was buying their light bulbs for pennies on the dollar."

Few stories in the energy business are as seductive as that of algae biofuels. Using sunlight, CO2 and

little else, many varieties of fast-growing pond scum, when starved of nutrients, quickly build up oil in their

cells. They need no external sugar from corn or cane to grow, so they don't compete with food crops.

Farmed in ponds or translucent reactors, microalgae can be raised on cheap, sun-splashed land that is

unsuitable for crops or much of anything else.

That was the idea, anyway, of a host of startups that launched into algae fuels over the past half decade.

Often ignorant of algae's biology, these companies stumbled into major physical and engineering hurdles

that can derail most of their lofty goals, industry and government experts say.

Even the most promising approaches are a decade or more away, experts say. By then, many firms will

have failed.

Most of these problems were predicted -- and ignored. Algae are speedy growers, but they are also

greedy, preventing sunlight from penetrating even moderately dense concentrations. The most popular

algae varieties, which resemble single-celled plants, remain difficult to bioengineer. Water requirements

are vast. And while pond scum are prolific in building up oily fats, they surrender their dearly built energy

stores only if they are killed and broken apart.

With investors wary, the algae bloom seems to be dissipating.

But before the green tide completely turns red, several groups of scientists and a few controversial

startups are calling for what they say amounts to a shift in focus. By fixating, they say, on what was

bleeding-edge technology in the 1970s -- tortured, plump microalgae -- many have missed what could

prove the most promising path to algae fuels: photosynthetic bacteria.

That's the pitch of Joule Unlimited, one of the most-watched biofuel companies to emerge in recent years.

Backed by a group of high-profile biologists -- including Boston University's James Collins and Harvard's

George Church -- Joule has raised a racket with its grandiose claims.

Using heavily engineered photosynthetic bugs called cyanobacteria, Joule promises to produce hundreds

of barrels of fungible diesel fuel per acre a year at the cost of $50 a barrel, a productivity that would

outstrip nearly any other biofuel, including corn ethanol.

Joule is not alone in its cyanobacteria work. Synthetic Genomics, the bioengineering firm begun by Craig

Venter, the enterprising biologist famous for being one of the first to sequence the human genome, is also

investigating the bugs in its $300 million algae collaboration with Exxon Mobil Corp. Flush with cash, the

company operates in relative silence.

Government-funded scientists are pushing the limits of using the bacteria as mini-factories. And smaller,

private companies like Easel Biotechnologies and Proterro have put forward innovative, if far removed,

applications for the bugs.

Unlike microalgae fuels, cyanobacteria have not received buckets of government cash. But Joule has

attracted attention from a few influential figures inside the Beltway, most notably John Podesta, the CEO

of the left-leaning Center for American Progress and former co-chairman of President Obama's transition

19

team; Podesta was added to the company's board of directors early this year. And late last year, Sen.

John Kerry (D-Mass.) dropped by the firm's Cambridge, Mass., lab to praise the company's "gamechanging" technology.

At Joule's office, just blocks from MIT, the company's chief executive -- and chief fundraiser -- Bill Sims

said he cannot blame people for being suspicious of Joule's claims.

The company has taken to decorating its office with models of winged pigs, seen reclining on a

conference table or, during a tour, snuggled next to a researcher's computer, a few rooms away from the

clichéd-but-hypnotic sight of emerald-blue bacteria swirling in incubating flasks.

"We respect that it's a big idea," Sims said. "And with big ideas comes skepticism. That's fine. If there

wasn't skepticism, it probably wasn't a big enough challenge to be in this."

As history makes clear, there are no certain bets in harnessing photosynthesis. Joule could be on a path

to -- as Obama would put it -- "win the future," and jump-start the United States on the path to a bio-based

economy, independent of oil.

Or, like GreenFuel's light bulbs, Joule's winged pigs could end up in a few years at a bankruptcy auction,

having never flown.

'Tremendous achievement'

At first glance, cyanobacteria and traditional microalgae seem alike. Both are green and single-celled,

forming the blooms that provide an estimated half of the world's oxygen. In fact, cyanobacteria used to be

known as blue-green algae -- just another kind of pond scum. It is suspected that in the planet's murky

past, a cyanobacteria ancestor merged with microalgae, providing the genetic tools used to tap the sun's

rays.

Those tools, the machinery of photosynthesis, remain similar in both bugs.

The sun's light streaks into tiny chlorophyll-dyed antenna on the cell's membrane, creating energy that

strips water into oxygen and hydrogen. The oxygen is released -- we can be thankful for that -- while the

charged hydrogen creates the chemical energy needed to convert CO2 into sugars, oils and other

molecules, a process known as carbon fixation.

Despite these similarities, microalgae and cyanobacteria belong to different domains of life.

Microalgae have an intricate cell machinery, wrapping most of their DNA in a tightly bound nucleus;

cyanobacteria hold their DNA in easily accessible, circular chromosomes. Zoomed in, they have starkly

different sizes, algae running 1,000 times cyanobacteria's volume. And, most importantly to biofuel

dreamers, microalgae naturally store oily fats in their cells; cyanobacteria do not.

Microalgae's oil production meant that, for the past century, they have trumped cyanobacteria in industrial

labs.

During World War II, German scientists first attempted to produce oil from the microbes, discovering that

green algae, when deprived of nutrients, devoted more than two-thirds of their weight to oils. The oil built

up slowly, though, and the algae, investing their energy in survival, grew at a tepid rate -- a problem to

this day.

After the war, mass cultivation of algae began in a few modest, translucent bags on an MIT rooftop,

focusing on protein-rich food production. The 1950s soon saw a bubble similar to the past few years, with

companies saying they could rapidly expand algae production in three years with drastic drops in price,

said Rene Wijffels, an engineer at Wageningen University in the Netherlands. Those claims amounted to

little, he added.

Given this precedent, it was natural that the Department of Energy's Aquatic Species Program, which was

launched in response to the 1970s oil crisis and ran from 1978 to 1996, focused on fat-producing

algae (pdf).

Scientists collected some 3,000 strains, several of which seemed ripe for biodiesel. Ponds were built in

Roswell, N.M., to demonstrate that the algae could be, in effect, farmed. (The researchers soon

discovered, to their chagrin, that wild algae had overtaken the ponds.) The program ended in the face of

persistent low oil prices, but in an influential final report, its leaders prophesied algae's eventual return.

20

Meanwhile, out of DOE's sight, academic scientists were busy discovering that many varieties of

cyanobacteria could easily integrate foreign DNA, much like E. coli, another industrial workhorse. Since

the bugs did not produce oil, researchers tweaked them to study photosynthesis.

There was little emphasis on application.

That industrial agnosticism changed this past decade, as scientists saw the results achieved by labs

heavily modifying bacteria to produce malaria drugs or clothing fabrics.

Cyanobacteria, they realized, are ideal fuel candidates, said Wim Vermaas, a microbiologist at Arizona

State University who recently received a grant to develop fuel-producing cyanobacteria from DOE's

Advanced Research Projects Agency-Energy (ARPA-E).

"You don't have a nucleus," he said. "You don't have mitochondria. You don't have all the infrastructure to

worry about. The volume is a thousand-fold smaller. The diameter is tenfold smaller. You really have

properties you like."

Until a few years ago, using cyanobacteria would have seemed a pipe dream, given the work needed to

get them producing fuels. But in the past three years, DNA sequencing costs have crashed, allowing

researchers to spell out a parade of bug genomes.

The decline in costs is staggering. Today, a moderate-sized microbe costs $5,000 to sequence. A few

years ago, it would have taken $100,000 and many months, said Donald Bryant, a microbiologist at Penn

State University.

By year's end, Bryant estimates, close to 100 cyanobacteria strains will be sequenced, yielding a bounty

of data.

Bryant, a Joule adviser, is sequencing four close relatives of his favorite cyanobacteria, hoping

comparisons will reveal important functions hidden in its genes. Similar work has revealed dieselproducing pathways in E. coli by LS9, a corporate peer of Joule.

"The power of these genome databases is really quite remarkable," Bryant said.

The price drops in DNA sequencing and synthesis make a startup like Joule possible, if not necessarily

viable. The company can now send a gene out to be sequenced at 5 o'clock in the afternoon and receive

it at 8 in the morning, said Dan Robertson, Joule's chief biologist and first employee. It can then tweak the

gene in software and contract it out for synthesis.

"In two weeks we can have a gene synthesized that has all of the decorations on it that you need to be

able to incorporate it into your organism," he said. "That is a tremendous achievement."

Major technical challenges

While sequencing costs have dropped for microalgae, too, these oil-producing bugs have lagged behind

cyanobacteria in advanced labs. Only a few species have had their genome sequenced, and even the

best-understood species, a green algae, remains troublesome to manipulate.

The types of heavy-duty alteration used in bacteria -- and likely required for viable fuel production -- are,

in a rosy scenario, more than a few years off for most microalgae.

This lag in genetic tools is an overplayed problem, though, according to Stephen Mayfield, a founder of

Sapphire Energy, which plans to grow algae in open ponds. The company has received more than $100

million in grants and loan guarantees from the federal government to develop its first biorefinery in

Columbus, N.M.

While the company plans to bioengineer algae, it also maintains that modern selective breeding can

produce viable fuel candidates, said Mayfield, who also directs the San Diego Center for Algae

Biotechnology (Greenwire, Sept. 17, 2009).

"If I have a single [breeding] event, one in a million, I'll find it in one day," Mayfield said. "I can cross it with

another algae in a week. ... I bet we can do in the next four to five years what [they] did in agriculture in

50 years."

21

Microalgae's model should be agriculture, Mayfield added. Like in farming, scientists need to improve the

productivity of algae, and they need to protect it from predators like water fleas and fungus. The algae

need to produce appropriate products, and an efficient way is needed to harvest algae oil.

"If we had an algae combine right now, we'd be done," he said.

This list of improvements was clear to the oldest operating algae fuel company, Solazyme.

Unlike bankrupt GreenFuel, another pioneer, Solazyme remains solvent and has scored several small

coups, including a contract providing the Navy with algae-derived jet fuel. GreenFuel's founder, Isaac

Berzin, declined to comment for this article.

Solazyme's success is tied to one fateful decision, said Harrison Dillon, the firm's founder.

It ditched photosynthesis.

"We grew ponds of algae for about two years," Dillon said. They tried it in translucent reactors, too. But in

both situations, he said, "we couldn't come up with a scenario where we weren't making ridiculous

assumptions."

Solazyme instead cultivates its algae in large, dark vats, feeding them sugar -- a process nearly identical

to current ethanol production. In effect, the firm bought into the dominant biofuel system, substituting

diesel and jet fuel for ethanol as a final product. (Matching yeast's hyper-efficient conversion of sugar to

ethanol is another story.) Given the uncertainty facing its algae peers, Solazyme's choice seems at least

a wise short-term decision.

The Department of Energy has remained a strong proponent of algae's potential, but as its senior officials

have stressed in the past year that potential remains far from being realized.

Currently, algae fuels cannot be grown in large scale, and compared to gasoline prices, they are "off by at

least a factor of two right now," Steve Koonin, DOE's undersecretary for science, said last month at the

annual meeting of the American Association for the Advancement of Science in Washington.

Serious research needs to be done before costs can come down further -- for example, researchers at

Los Alamos National Lab are working on that combine, exploring the use of high-frequency sound waves

to extract algae oil.

"It is these nitty-gritty engineering-type issues that are as important and maybe more important than the

biology in bringing things to scale," Koonin said.

These technical challenges seem well beyond the scope of many algae startups, prompting widespread

expectation in the industry that a surge of quiet algae failures is imminent, according to Andrew Soare, an

analyst at Lux Research, a technology research firm.

Soare recently examined 24 algae fuel companies in a report aimed at investors. Three firms warranted

a positive rating; one was sun-adverse Solazyme. Most of the firms lacked proof of their technology and

exaggerated their abilities. Their future looks grim, Soare said.

"A lot of these companies are going to fail," he said.

'The chart'

Many realities and hopes melded to form the algae bloom.

As public awareness of global warming increased, oil prices began to soar, spurring interest in energy

independence. Rising food prices sent researchers hunting for fuel alternatives, and the long-expected

breakthrough in converting non-food crops like grass to fuels refused to become reality.

And then there was "the chart."

The most aggravating myth about algae, for Solazyme's Dillon and others, stems from a simple chart

comparing the oil yields of common crops. One version (pdf) was published by Yusuf Chisti, a biochemist

in New Zealand, in 2007. It portrays algae, conservatively, as 130 times more productive than soybeans.

Over the past five years, no other algae fuel paper has been as widely cited.

It is the chart that launched a thousand overheated stories.

22

"That chart perpetuates one of the biggest myths out there," Dillon said. "Everybody has seen versions of

that chart. [But] I've never seen what I'd say to be proof that algae has even made as much oil as

soybeans."

There was a fundamental mistake people outside the algae business made when looking at the chart.

They extrapolated speedy growth rates from open waters and ideal conditions to the industrial setting

necessary for commercial cultivation, said Greg Stephanopoulos, a biochemical engineer at MIT and a

longtime expert in bacterial manipulation.

"They make fuels from free CO2," Stephanopoulos said. "It's a no-brainer, right? They've got it all. So

where's the problem with that? The problem is that you cannot cultivate [algae] at high enough densities

to make this a worthwhile process."

For every gallon of oil made from algae in a pond, hundreds of gallons of water need to be circulated, he

said. The algae cannot grow in dense concentrations, because they do an excellent job of blocking

sunlight, even when they don't use it for energy, instead wasting it as heat.

"The issue is not one of designing a better reactor," Stephanopoulos said. "That's not going to solve this

problem. The issue is not of doing better molecular biology. Even if you make all the algal cell full of oil,

still you're going to have a [low] concentration of oil."

A frank assessment (pdf) of algae fuel ponds released last fall by researchers at Lawrence Berkeley

National Laboratory found that the only economically viable route for algae ponds would be for use in

wastewater treatment, creating oil on the side. Without such a dual use -- and several regions do use

algae for this purpose -- oil costs from the pond would run between $240 to $330 a barrel, more than

double current crude prices.

"There are just a lot of things that have to come together to bring the cost down," said Nigel Quinn, an

author of the study and water-resource engineer. "You need adequate light, adequate temperatures, a

source of CO2 and you need water."

Chisti, for his part, remains convinced that algae are the only option for producing renewable fuels at a

large scale but admits that the economics remain far off. Much of the initial effort on fuels ignored algae

biology, Chisti said. Algae fuels will need sustained investment to become a mature technology, he said.

"Several algae companies have gone bust, and others will go bust in the future," he said. "The quest for

algal fuels has been characterized by 'irrational exuberance.' ... [A] science-based long-term strategy is

needed for delivering on algal fuels."

Confronted with high operating costs, many algae firms are looking to produce fish feed, dietary

supplements and cosmetics to support their business. Soare, the energy analyst, suspects many of these

companies will stay stuck producing fish feed. Some, like Sapphire, have higher ambitions, and Mayfield

expects the firm to spin out production of expensive, protein-based pharmaceuticals in the next few years,

he said.

"A lot of these companies were simply naive," Mayfield said. "They had this naive assumption that they

were going to grow up algae and miraculously be producing at $2 a gallon."

When Sapphire opens its first biorefinery, Mayfield expects it will be producing replacement fuels at a

price between $10 and $20 a gallon. It's a good start, he said. "We don't have to make 100 percent of our

improvements every day."

'We can deploy at a large scale'

At Joule's offices, the firm can make it seem like they have surpassed microalgae's hurdles.

The company's bugs grow in brackish water. (Many microalgae first targeted by startups required

freshwater.) They will be cultivated in flat, translucent panels that can scale up in size, much like solar

panels. Flue gas from power plants can provide the needed CO2. And the bugs secrete a diesel-like fuel

that can be separated from water and piped to a central processing refinery.

The company has run a pilot plant in Leander, Texas, just north of Austin, for a couple of years. The plant

has been producing ethanol, a technology Joule plans to license. This year, the firm began testing parts

of its diesel process at the facility. The project has provided Joule with enough data to ramp up its

operations, said David Berry, one of Joule's co-founders, at ARPA-E's annual conference this month.

23

"We know from our pilot," he said, "that we can deploy at a large scale."

What irks Joule's competitors and scientific peers is that the company remains vague in backing up its

claims, even in its patent applications. No hard economic or production rates have been released -- not

an uncommon trait for a private firm -- and even theoretical papers assessing the cost of industrial

photosynthesis, including one recently published in Photosynthesis Research, provide little to the

technically inclined reader.

Joule's secrecy is simply caution, said Harvard's Church, who has long collaborated with the venture

capital firm, Flagship Partners, behind Joule. Flagship, where Berry serves as a partner, has created a

series of biomedical companies but has had limited success in energy.

"Obviously the stakes are quite high and they've put a lot of effort into this organism," Church said. "And

it's not a totally obvious organism and they've changed it pretty radically, so it's not clear they can protect

everything by patents."

Independent scientists find the short path to commercial production proposed by Joule to be optimistic at

best. It is more likely that cost-competitive fuel production won't arrive for another 10 or 15 years, if at all.

But the ultimate model proposed by Joule, the use of bacteria as fuel-producing mini-factories, is exactly

right, they say.

Think of dairy cows, said Arizona State's Vermaas. Farmers do not harvest milk by grinding the cows up

and extracting the milk, which is pretty much how oil is currently taken from microalgae. Instead, they let

the heifers secrete the milk at their own pace, incrementally improving the cows' genetics and their

lactating environment. It should be the same with photosynthetic bugs.

While Robertson, Joule's chief biologist and photosynthesis guru, remained cautious on details, he did

outline what the company has done to modify its bacteria. It is not about redoing photosynthesis, he said,

since nature has had millions of years to work on it. Rather, the company has gained control over the

metabolism of its bug, in a way similar to how oxygen deprivation is used to control fermenting microbes,

like ethanol-producing yeast.

"These organisms are controlled by light," he said. "And the light changes every day. They have to go

through a diurnal cycle, and these organisms have circadian rhythms. Their level of metabolic control is

circadian and diurnal. And that's what you have to gain control over. ... [They] have to be based on light

and this clock mechanism, as opposed to oxygen."

After lashing down these controls -- again, an unverified claim -- Joule has also stripped out many

metabolic functions that would normally use carbon in the bug, the equipment it would need to survive in

wild settings. And Robertson has built an inexpensive trigger into the bacteria so that, after they spend

three days growing to an optimal density for light, the bugs shift entirely toward fuel production.

"We say, 'OK, stop growing and now send all the carbon to our product,'" Robertson said. "And so this

allows you to then continuously fix CO2, absorb light and make product. The diesel separates and you

can physically harvest it. That allows you to radically increase your productivity over algae."

At its pilot plant in Texas, Joule has had these cyanobacteria producing fuel "productively" for eight weeks

before the microbes exhausted themselves. After exhaustion, the panels housing the bacteria would be

cleaned and restocked at night, to begin producing again in three days.

Joule is not alone in achieving fuel secretion, though. Turns out, it is not terribly hard to do in

cyanobacteria. Once the cells are rigged to produce fuel components, they have no idea what to do with

the chemicals -- they have no instinct to store fat -- and so they shunt the fuel out of the cell. Vermaas

and Jim Liao, a bioengineer at the University of California, Los Angeles, have had similar success.

(Synthetic Genomics has also quietly announced on its website that it has engineered algae to secrete oil

continuously. The company makes little distinction between cyanobacteria and microalgae in its public

releases, so it is difficult to interpret its claim.)

UCLA's Liao has become a bit of a household name in biofuels. His expertise lies in microbial production

of butanol, an energy-packed alcohol that, unlike ethanol, can be used in existing oil pipelines. Liao

imported genes from three different bugs into his cyanobacteria, which produces and secretes a butanol

precursor. Liao, whose work is also behind the growing biofuel company Gevo, began a startup, Easel

Biotech, to move ahead with the bug.

24

The cost of creating photoreactors for the bacteria remains a problem. But if somebody finds a way of

doing it cheaply, then direct conversion of CO2 to fuels could finally take off, Liao said.

"If we can do it in a cost-effective way, of course we'll go that way," he said.

Joule proposes to have solved these cost problems, currently on its fifth-generation design for its

reactors, which it developed in concert with its wet work. The reactors are large sheets of thin plastic, 7

feet by 4 feet, that line up in attached rows. At their base, CO2 bubbles in -- the company requires CO2

concentrations typically found in flue gas from burning fossil fuels -- and product separation occurs at the

top.

"This device is capturing the sunlight," Sims said. "Extinguishing all the photons. Taking in the CO2. The

product is synthesized there. Initial product separation takes place. Thermal management is occuring. ...

This device is unlike any that has been created before."

It had better be, many in the algae game say, because photoreactors have failed before for microalgae.

Digging holes in the ground? Much cheaper. The capital investments are high, Sims admitted, but Joule's

productivity and low operating costs, lacking any need to add biomass to its mix or break apart algae cells

to recover fuel, make up for the cost, he added.

Wait and see

Despite their easy genetic modification, much about cyanobacteria remains mysterious.

Scientists do not know why some grow quickly and others slowly. (Penn State's Bryant suspects it has to

do with differing ratios between the two photosynthesis complexes that power the bacteria.) Their

metabolism is not well understood. Scientists are "picking it up on the fly," said Harvard's Way.

Way does see cyanobacteria as a strut holding up the future of biofuels -- he recently published

a paper to that effect and has collaborated on work rigging them to produce sugars and lactic acid -- but

companies targeting fuel production with the bugs are making a fundamental economic mistake, he said.

Oil companies have never had true competition for their product, and they can ruthlessly trim their profit

margins if need be.

"If there's a competition issue, they can make it cheaper," he said.

Rather, photosynthesis companies should be targeting chemicals and other products, like the amino acid

lysine, that are already widely made by genetically modified bugs that feed on corn. Sugar can only get so

cheap, and its cost has risen in the ethanol era. Compete against the sugar baseline, Way said, and

eventually you move into fuel, not the other way around.

Joule plans to license its technology for chemical and ethanol production, but it is retaining diesel for

itself, Sims said. It sees a future that, at times, seems hard to separate from some past algae dreams.

Fleets of bugs, customized to local solar and climate conditions, will begin stretching across the American

plains, churning out fuel that can seamlessly power existing heavy trucks or jets. What can go wrong?

"The reality is," Sims said, "people have seen it. People are pretty blown away at what they hear."

Joule may have done it. It may have broken past the incremental progress that has long typified energy

innovation. Its pigs may fly. But if they don't, Joule has positioned itself to fail spectacularly and publicly.

Time will tell.

Copyright 2011 E&E Publishing. All Rights Reserved.

25

Websites:

http://www.saps.org.uk/secondary/teaching-resources/235-student-sheet-23-photosynthesis-using-algaewrapped-in-jelly-balls

http://www.algaebiomasssummit.org/ema/DisplayPage.aspx?pageId=About

http://www.pbs.org/wgbh/nova/nature/photosynthesis.html

Videos:

https://www.youtube.com/watch?v=QP_HbQ5cWSk

https://www.youtube.com/watch?v=N5snbafLV40

https://www.youtube.com/watch?v=0Yt-uAf2By8

https://www.youtube.com/watch?v=g78utcLQrJ4

Games:

http://earthguide.ucsd.edu/earthguide/diagrams/photosynthesis/photosynthesis_game.html

http://www.ellenjmchenry.com/homeschool-freedownloads/lifesciencesgames/photosynthesisformula.php

Related Experiments:

http://www.biologyjunction.com/5b-photoinleafdiskslesson.pdf

http://www.phschool.com/science/biology_place/labbench/lab4/intro.html

26

Practice MCAS Questions:

The following multiple choice questions from the spring 2013 and spring 2010 Biology MCAS test probe

student understanding of the interconnectedness of photosynthesis and cellular respiration.

Which of the following statements describes a difference between photosynthesis and cellular respiration

in plants?

A. Photosynthesis occurs only during the day, whereas cellular respiration occurs only at night.

B. Photosynthesis involves only one reaction, whereas cellular respiration involves many steps.

C.

Photosynthesis occurs only in cells containing chlorophyll, but cellular respiration occurs in all

cells.

D. Photosynthesis converts light energy into chemical energy, but cellular respiration converts light

energy into heat energy.

Which of the following statements correctly describes the processes of photosynthesis and cellular

respiration?

A. Photosynthesis and cellular respiration occur in the same organelle.

B. Photosynthesis and cellular respiration are performed by all organisms.

C.

Photosynthesis produces carbon dioxide, and cellular respiration uses carbon dioxide.

D. Photosynthesis stores energy for cells, and cellular respiration releases energy for cells.

The following open response question from the spring 2012 Chemistry MCAS test probes student

understanding of photosynthesis.

Sample student responses can be found at:

http://www.doe.mass.edu/mcas/search/answer.aspx?questionid=23790

• BE SURE TO ANSWER AND LABEL ALL PARTS OF THE QUESTION.

• Show all your work (diagrams, tables, or computations) in your Student Answer Booklet.

• If you do the work in your head, explain in writing how you did the work.

Glucose (C6H12O6) is formed in plants by the process of photosynthesis. The net equation for

photosynthesis is shown below.

sunlight

6CO2 + 6H20 --------- C6H12O6 + 6O2

a. Calculate the molar mass of glucose. Show your calculations and include units in your answer.

b. Explain how the amount of carbon dioxide consumed by a plant can be determined from measuring the

amount of oxygen released by the plant. Assume excess water is available.

c. Calculate the amount of glucose, in grams, formed when 100 mol of O 2 is released. Show your

calculations and include units in your answer.

27