092613_L13-08032-sup-revised

Thermopower in quantum confined La-doped SrTiO

3

epitaxial heterostructures

K. Kerman, 1, a S. Ramanathan 1 , J.D. Baniecki, 2, b M. Ishii, 2 Y. Kotaka, 2 H. Aso, 2 and K.

Kurihara

2

, R. Schafranek

3

, A. Vailionis

4

1

Harvard University, School of Engineering and Applied Sciences, Cambridge, MA, USA

2

Fujitsu Ltd., Environmental and Energy Materials Laboratories, Atsugi, Kanagawa, Japan

3

University of Bordeaux, IMS, UMR 5218, F-33400 Talence, France

4

Geballe laboratory for Advanced Materials, Stanford University, Stanford, CA, USA

SUPPLEMENTARY INFORMATION

All films were grown by pulsed laser deposition (PLD) at 600 °C in ~10

-8

torr on (100) single crystal pseudocubic (La

0.3

Sr

0.7

)(Al

0.65

Ta

0.35

)O

3

(LSAT), having an RMS roughness of < 2

Å, which has a lattice parameter of 3.865 Å. Films were cooled from the growth temperature in

10

-8

torr and ex-situ annealed in 1 atm flowing O

2

for 1 hour at temperatures ranging from 600

°C to 700 °C. LSAT was used since it remains insulating for the given deposition conditions and is sufficiently lattice matched with La

0.05

Sr

0.95

TiO

3

(LSTO), having a lattice parameter essentially unchanged from that of un-doped SrTiO

3

(STO) of 3.905 Å, to yield high structural quality epitaxial films. Ablation was carried out using a q-switched Nd:YAG laser with a pulse rate of

10 Hz. In all cases, the target to substrate distance was 5 cm. The LSTO layers were deposited with a laser fluence of 0.4 J/cm 2 using a single crystal La doped (3.37 wt%) SrTiO

3

target while the SZO thin film layers were deposited using a laser fluence of 0.2 J/cm

2

and a polycrystalline stoichiometric SZO ceramic target.

Deposition rates were 0.89 (0.27) nm/min for LST (SZO) with film thickness determined by scanning transmission electron microscopy (STEM). Inductively coupled plasma optical a correspondence to K. Kerman, electronic mail: kkerman@fas.harvard.edu

b

correspondence to J.D. Baniecki, electronic mail: john.d.baniecki@jp.fujitsu.com

emission spectroscopy (ICP) indicated, within measurement accuracy (coefficient of variation of

5% and detection limits of 0.03 ppm for Ti and Sr, and 0.01 ppm for La), stoichiometric cation composition ratios for the LST and SZO films and a La film concentration of 4.6 at% for LST.

For ICP measurements, films were grown on MgO substrates. Surface A to B site stoichiometry was confirmed by using X-ray photoelectron spectroscopy (XPS) before and after annealing samples at 600°C ex-situ in air. Structural characterization was studied using a Phillips X’Pert diffractometer with Cu Kα radiation. High-angle annular dark field-scanning transmission electron microscopy (HAADF-STEM) observation was performed using a JEM-2100F microscope (JEOL) with a probe corrector (CEOS) equipped with an electron energy loss spectroscopy (EELS) system (Gatan Enfina) at 200 kV acceleration voltage. Elemental mapping of Ti was obtained by column-by-column STEM-EELS measurement on the Ti-L2,3 edge (456 eV). The spatial resolution of STEM-EELS was less than 1.6 Å. Figs. 1S-3S show additional structural characterization supporting our analysis. We note here, that while strain induced structural distortion in epitaxial SZO/STO superlattices has been shown to cause artificial

Ferroelectricity, our SZO cap is structurally relaxed (Fig. 3S) reducing the likelihood of such phenomena in the SZO layer.

Electrical properties were measured using Au/Cr electrodes deposited by DC sputtering.

Hall measurements were made with square shaped samples in van der Pauw geometry. Structures were fabricated with circular electrodes contacting only the top STO or SZO surface at the four corners of the sample or triangular shaped electrodes contacting simultaneously the top surface and sample edge (defined by a metal mask during growth or by cleaving the sample post growth) at each corner, providing a direct contact to the LSTO layer. Seebeck measurements were made using a steady state differential method. Hall and conductivity measurements were performed at

room temperature in air using a 0.5 T electromagnet. S measurements were made using a steady state differential method in an evacuated chamber at ~10 -8 torr. Samples were characterized as grown and after ex-situ annealing at 600 o

C in 1 atm of flowing O

2

for 1 hour. Subsequent anneals in 1 atm flowing O

2

at temperatures ranging from 600 o

C to 700 o

C, yielded no significant changes in Hall or S properties. Fig. 4S shows the temperature dependence of carrier concentration as a function of temperature, confirming sample stoichiometry and minimal defect centers as discussed in the main text.

The Hall mobility ( 𝜇

𝐻

) at 300K for the as-deposited sample series is plotted in Fig. 5S. In contrast to the uncapped LSTO/LSAT structures, 𝜇

𝐻 measurements were possible to significantly thinner layers, of approximately 12-16 Å for the SZO/LSTO/LSAT series. Below 30 Å, 𝜇

𝐻 appears to decrease as a function of thickness. Such behavior has also been recently observed in

GdTiO

3

/STO/LSAT heterostructures, with proposed explanations stemming from interface proximity carrier scattering owing to polar interface charge and disorder.

1

However, the samples studied here do not have an inherently polar interface owing to ionic charge balance at atomic lattice planes.

The conduction band off-set at the LSTO/LSAT interface is not known at present to the best of our knowledge. As a rough estimate, LSAT is a mixture of LaAlO

3

and Sr

2

AlTaO

6

which have indirect band gaps of 5.6 eV and 4.6 eV respectively.

2,3

LSTO, at these dilute doping concentrations has band gap similar to that of STO, namely 3.2 eV. If the common anion rule holds for the LSTO/LSAT interface one would expect a band offset at least as large as 1.4 eV.

Using a finite square well model with a width of 8 Å and well depth of 1.9 eV leads to an effective well width (including wave function attenuation outside the well walls) of 9.3 Å, or about 0.6 Å on either side of the well. Using a constant effective mass (4.5 m e

) and changing the

well depth to 1.4 eV makes this width to 9.6 Å. The true well depth will fall somewhere between these values as the SZO/LSTO conduction band off-set is 1.9 eV and the LSTO/LSAT conduction band off-set if on the order of 1.4 eV.

References

1

P. Moetakef, C.A. Jackson, J. Hwang, L. Balents, S.J. Allen, S. Stemmer, Phys. Rev. B 86 ,

201102(R) (2012)

2

P.W. Peacock, J. Robertson, J. Appl. Phys. 92 , 4712 (2002)

3 R.F. Berger, J.B. Neaton, Phys. Rev. B 86 , 165211 (2012)

Figure Captions

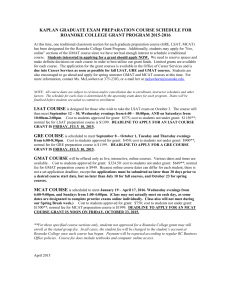

Fig. 1S

(a) θ-2θ scan of LSTO/LSAT, (b) φ scan around (101) confirms in plane coherence between film and substrate, (c) bright field STEM and (d) HRSTEM image of the interface

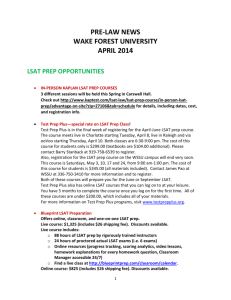

Fig. 2S

HRSTEM image with a line scan indicating the average out of plane lattice parameter of LSAT and LSTO in a 2 u.c. SZO/LSTO/LSAT structure.

Fig. 3S

A reciprocal space map of SZO/LSTO (250 Å)/LSAT showing coherence in LSTO and a fully relaxed SZO.

Fig. 4S

An approximately constant temperature dependence of total carriers in LSTO/LSAT films indicates a lack of compensating defects. Minor variations are due to ±3 K temperature fluctuations during measurement.

Fig. 5S

The Hall mobility of as-deposited samples measured at 300 K with electrodes in van der Pauw geometry simultaneously contacting the top surface and LSTO layer.

Fig. 1S

100000

(a)

10000

(c)

1000

100

10

1

20 30

(b)

LSTO film

LSAT substrate

40 50

2 (deg.)

60

LSTO

70

(d)

0 50 100 150 200 250 300 350

(deg.)

5 nm

LSAT

2 nm

Fig. 2S

average

0 2 4

0.387 nm

6 8 10

Distance [nm]

12 14 16

0.403 nm

6

LSAT

7

La-STO

8

Distance [nm]

9 10

Fig. 3S q (Å -1 )

Fig. 4S

10

21

8x10

20

6x10

20

4x10

20

2x10

20

224 nm

112 nm

56 nm

28 nm

Bulk single xtal

50 100 150 200

Temperature (K)

250 300 350

Fig. 5S

10

2

STO/LSTO/LSAT

SZO/LSTO/LSAT

SZO/LSTO/SZO/LSAT

LSTO/LSAT

10

1

10

0

10

-1

10 100 t

LSTO

(Å)

T = 300 K

1000