risk assessments

advertisement

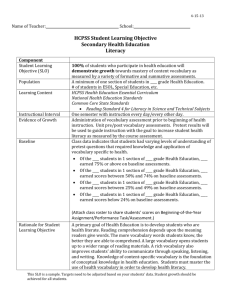

PAMPHLET Reference No: IP013 Date : January 2015 Originator: Leighton Bennett RISK ASSESSMENTS Employers are legally required to provide a safe and healthy workplace, and that the various risks associated with projects or operations or work activities have to be identified, evaluated and that suitable controls be applied to mitigate potential injury and other loss incident risks. It is generally accepted that there are three basic types of risk assessments that are in common use, are described below. However, to identify the detail necessary on certain types of risks, more sophisticated risk assessment techniques are often used, for example, HAZOP (hazard and operability analysis), FMECA (failure mode & effect criticality analysis), what-if, FTA (fault tree analysis), Bow-tie analysis, etc. 1. BASELINE RISK ASSESSMENTS For the high or strategic level of business assessment, a Baseline Risk Assessment should be performed to obtain a benchmark of the types and sizes of potential risks, which could have a significant impact on a project, an operation or even the whole business. To ensure that all the aspects needing to be risk assessed are covered all the business resources should be assessed in turn, namely the People, Equipment, Processesprocedures-practices, Materials, Environment, Legal & liability and Financial (ie. the PEPMELF resources). Depending on the scope of the baseline risk assessment the PEPMELF resources related to each of the business functions &/or operations should be assessed The outcome of a baseline risk assessment provides a risk profile, which is a histogram type of graph representation of the identified risks, where the potential high risk items identified are prioritised to highlight which risks should be mitigated first by applying risk control measures to reduce the risk magnitude to acceptable risk levels. However to obtain a more detailed insight to the nature of an important high-level risks that has been identified, it maybe necessary to perform an Issue Based Risk Assessment on the identified significant high level risks. 2. ISSUE-BASED RISK ASSESSMENTS The Issue Based Risk Assessment (or Task Based Risk Assessment) is normally focused at operational activities, process and system based business functions and is a more focused and in-depth assessment that the Baseline assessment. This is achieved by identifying the risks attached with each operational or activity step performed, with the risks being determined from proactive or reactive occurrence information, protection and safeguarding systems, change management and Baseline assessment inputs, which provides outcomes that can be risk managed by practical risk control measures being applied. Issue based risk assessments can be performed focused on any of these aspects: Job-Task (eg. welding, manual lifting, waste collection, etc work or procedures) or Process (eg, effluent discharges, blending, heating, waste treatment, engineering standards, management processes, etc) or Equipment (eg. Personal Protective Equipment (PPE), tools, machinery, fire equipment, pipe work, boilers, reactors, scrubber efficiency, etc) or on a Work Group (eg. electricians, welders, cleaners, bricklayers, plumbers, etc work or operating procedures). Risk control measures are then normally decided for each risk identified, with the aim that the control measures implemented will reduce the identified risks to an acceptable level. The effectiveness of the issue-based risk control measures is monitored on an ongoing basis using Continuous Risk Assessment methods. 3. CONTINUOUS RISK ASSESSMENTS Continuous Risk Assessments are performed at a functional operational level, where the working processes, systems and activities are monitored on an ongoing basis by the operational floor management and the front line supervision. This continuous risk monitoring is achieved through inspections, critical job or task analysis, planned job observations, pre task or toolbox talks and/or through non-conformance or defect quality reporting means and the like. This ongoing monitoring at a line management operational level permits any new, changing or poorly controlled risks to be identified and enables risk control measures to be applied. The concept of Behaviour Based Safety (BBS) is a continuous risk assessment method which facilitates monitoring the employee actions & the effectiveness of the applied risk controls and can highlight the need to re-assess new or changing risks and non-conformances. THE INSTITUTE OF SAFETY MANAGEMENT, THE PROFESSIONAL BODY OF CHOICE FOR THE DISCERNING OCCUPATIONAL SAFETY PRACTITIONER www.iosm.co.za