Investigations on Mineral Liberation by Transgranular and

INVESTIGATIONS ON MINERAL LIBERATION BY TRANSGRANULAR AND

INTERGRANULAR FRACTURE AFTER MILLING

Thomas Leißner a ; Hoang Huu Duong a,b ; Martin Rudolph c , Thomas Heinig c , Kai Bachmann c , Heinrich

Schubert a and Urs Alexander Peuker a a Institute of Mechanical Process Engineering and Mineral Processing, Technische Universität

Bergakademie Freiberg, Agricolastraße 1, 09599 Freiberg, Germany b Department of Mineral Processing, Faculty of Mining, Hanoi University of Mining and Geology, Duc

Thang, Bac Tu Liem, Hanoi, Vietnam c Helmholtz-Zentrum Dresden-Rossendorf, Helmholtz-Institute Freiberg for Resource Technology,

Halsbrücker Straße 34, 09599 Freiberg, Germany

ABSTRACT

In comminution minerals can be liberated by random fracture of particles into smaller fragments or by detachment along phase boundaries. These two mechanisms represent borderline cases. When ores get crushed and milled the liberation of minerals is achieved to some extent by both mechanisms. This article describes a method to determine the extent of transgranular and intergranular fracture of minerals based on

2-dimensional liberation analysis from automated mineralogy.

The approach uses the non-biased surface information like phase specific surface area (PSSA), phase specific free surface (PSFS) and phase specific locked surface (PSLS) of minerals and their change through comminution. The parameters are discussed related to the normalized grain size, which is the ratio of mineral grain size of the milled product to mineral grain size of the feed material. Finally the amount of transgranular and intergranular fracture can be calculated using the phase specific surface parameters.

An apatite ore (sedimentary origin), a rare earth mineral containing nepheline-syenite and a porphyrycopper ore (both igneous origin) were ground to different fineness using a ball mill. Based on the mineral liberation analysis (MLA, device FEI Quanta 650 MLA-FEG) of feed and products, the extent of phase boundary fracture on the surface exposure of the minerals is studied.

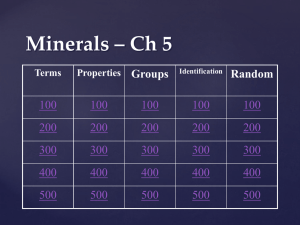

100 100 a b

80 80

60

40

20

60

40

20

0

0 20 40 60 80 100 normalized grain size / (%)

0

0 20 40 60 80 100 normalized grain size / (%)

Apatite Calcite Dolomite Silicates Aegirine Eudialyte Feldspar Nepheline

Figure 1 – Percentage of detachment (grain boundary fracture) on the generation of free surface for the (a) apatite ore and (b) the nepheline-syenite

It is found, that the extent of transgranular and intergranular fracture on surface exposure differs for different types of ores. For sedimentary rocks, intergranular fracture (detachment) plays a major role in the liberation of the minerals (cf. Fig. 1 a). Surface exposure of minerals from the nepheline-syenite (cf. Fig. 1,

b) has to be discussed more differentiated. Feldspar shows a small percentage of detachment on surface exposure whereas the aegirine is liberated in equal proportions by both mechanisms.

The presented method of liberation analytical calculations using phase specific surface information will be useful for the better understanding of ore specific fracture events with different comminution strategies.

Consequently, it will lead to a more economical way to successfully liberate minerals by the energy intense processes of comminution.

KEYWORDS

Mineral liberation analysis, preferential breakage, transgranular fracture, intergranular fracture, random fracture, grain boundary fracture

TEMPLATE FOR AUTHORS FOR THE PREPARATION OF ABSTRACTS TO BE SUBMIIITED

TO IMPC 2016

ABSTRACT

You are invited to submit your abstract (maximum 300 words plus two graphs). Authors whose abstracts are selected will be invited to submit a full paper for peer review. The Theme of the Congress is Processing for All: Meeting Technical, Environmental and Social Challenges. For online technical program consistency, this Abstract Template must be used for abstract submission . The abstract must include these details: title, objective of the paper, results and its contribution to the development of mineral processing. The title should include the full contact information of each author.

Abstracts of a maximum of 300 words must be submitted online by August 1, 2015 and may include up to two graphs. Authors will be notified of abstract acceptance by October 1, 2015 and must submit their full paper by January 1, 2016. Authors must register by May 1, 2016 and have paid in full to have their paper in the Proceedings and in the final program. The final revised paper submission deadline is March 15, 2016.

100

80

60

40

20

0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Fe Concentration (mol/L)

Figure 1 – Effect of iron concentration on the amount of precipitate formed during hydrolytic precipitation from waste processing solutions

KEYWORDS

Instructions, Authors, CIM conference, Template for authors, How to guide