Text I, 37-42

advertisement

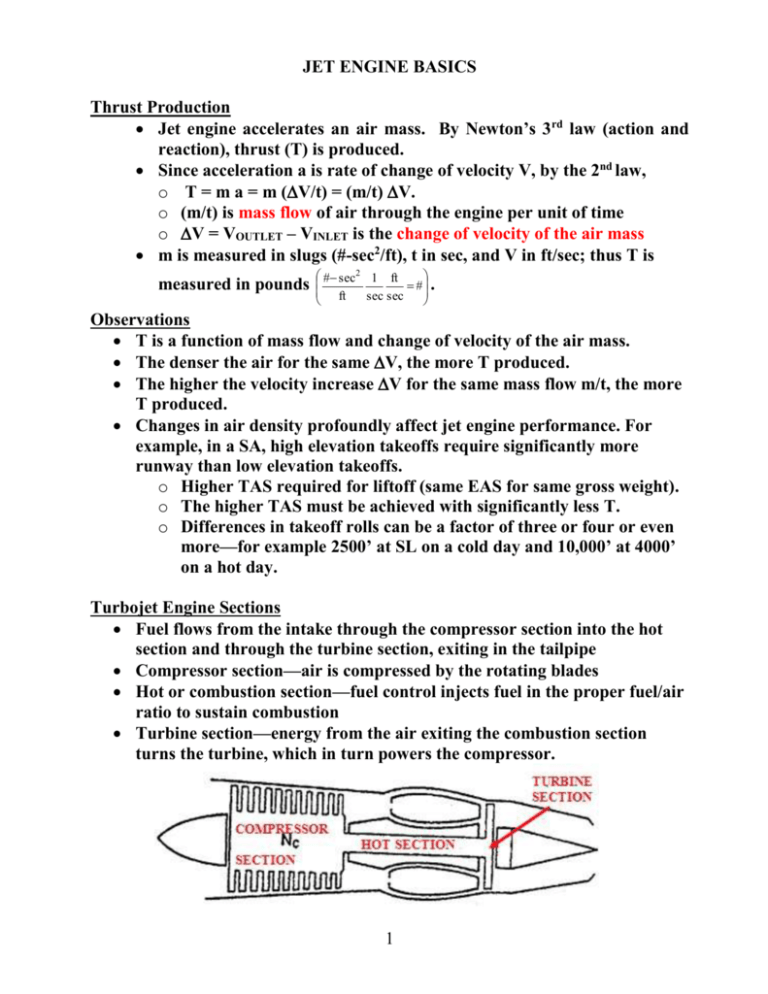

JET ENGINE BASICS Thrust Production Jet engine accelerates an air mass. By Newton’s 3rd law (action and reaction), thrust (T) is produced. Since acceleration a is rate of change of velocity V, by the 2nd law, o T = m a = m (V/t) = (m/t) V. o (m/t) is mass flow of air through the engine per unit of time o V = VOUTLET – VINLET is the change of velocity of the air mass m is measured in slugs (#-sec2/ft), t in sec, and V in ft/sec; thus T is measured in pounds # sec2 1 ft # . ft sec sec Observations T is a function of mass flow and change of velocity of the air mass. The denser the air for the same V, the more T produced. The higher the velocity increase V for the same mass flow m/t, the more T produced. Changes in air density profoundly affect jet engine performance. For example, in a SA, high elevation takeoffs require significantly more runway than low elevation takeoffs. o Higher TAS required for liftoff (same EAS for same gross weight). o The higher TAS must be achieved with significantly less T. o Differences in takeoff rolls can be a factor of three or four or even more—for example 2500’ at SL on a cold day and 10,000’ at 4000’ on a hot day. Turbojet Engine Sections Fuel flows from the intake through the compressor section into the hot section and through the turbine section, exiting in the tailpipe Compressor section—air is compressed by the rotating blades Hot or combustion section—fuel control injects fuel in the proper fuel/air ratio to sustain combustion Turbine section—energy from the air exiting the combustion section turns the turbine, which in turn powers the compressor. 1 Turbojet Multi-Stage Compressors (NC, N1, N2, are engine revolutions per minute (RPM) displayed as a percentage of rated rpm—0% to above 100%) Figures 6.10 and 6.11. Schematics of a Turbojet Engine with Single Stage and One with a Dual Stage Compressor Turbofan Engines--An initial large diameter compressor stage—called the fan—is added to a Turbojet engine. Inner portion of the fan functions as the first compressor stage, accelerating air through the engine. Outer portion of the fan accelerates air outside the engine. Fan acts as a kind of ducted “propeller” to create T. High bypass vs. low bypass turbofans: o percentage of air accelerated outside the engine o higher in high bypass than low bypass engines—can be 80% or more Figure 6.13. Schematic of Turbofan Engine with Multi-Stage Compressor. 2 Instruments to Measure Engine Performance 1. Engine Pressure Ratio (EPR). Ratio of air pressure leaving the engine to air pressure entering the engine. Measured with pitot tubes in engine inlet and tailpipe which read total pressure (P + q) High EPR reflects high T. Main instrument for setting T and for determining engine performance. 2. Exhaust Gas Temperature (EGT). Temperature of air leaving the engine—degrees Celsius. Higher EGT reflects high T, assuming the engine is operating correctly. High EGT also associated with compressor stalls, compressor or turbine failures, or engine fires. 3. Engine Revolutions per Minute (RPM). Rotational speed of fan/compressor stages displayed as percentage of allowable revolutions High RMP reflects high T. o RPM vs. T relation not linear. o Half of TA (available thrust) may lie in last 20%-25% of RPM 4. Fuel Flow Measured in pounds of fuel consumed per hour: # fuel / hour (pph) High fuel flow reflects high thrust if engine is operating correctly. Fuel control unit automatically meters fuel to the engine based on the density of air entering the combustion section. o Due to changing air density, a climb with the throttle set at 100% RPM might begin with 10,000 #/hr of fuel flow at SL and terminate at 40,000’ at 3000 #/hr. o Older turbojet engines—manual fuel control is a backup if automatic fuel control fails (pilot must manually meter fuel using the throttle). o Turbofan and newer turbojet engines—automatic fuel control backup engages if main fuel control unit malfunctions. 5. Engine instruments must agree with one another in order for their readings to be trustworthy—e.g. high EPR combined with abnormally low RPM, EGT, and FF would tell a pilot that the EPR reading might be faulty. 3 Round Gauge Jet Engine Instruments Figure 6.9/ Engine Performance Measurement in Two-Stage Turbojet Engine Figure 6.8. Cockpit Instruments to Measure Turbine Engine Performance 4 Parameters that Affect Thrust Available (TA): Airspeed and RPM 1. Variation of TA with Airspeed For fixed RPM and density altitude, TA is almost constant as airspeed increases in the airspeed operating range. T = (m/t) V o Air compresses in intake as airspeed increases, increasing mass flow (m/t) and TA. o Inlet air velocity increases faster than outlet air velocity as airspeed increases, so air mass acceleration—V = VOUTLET - VINLET decreases, decreasing TA. o The two effects offset one another, making TA close to constant across the airspeed operating range. Ram Air Effect of TA Diagram Adapted from a Figure in the AS311 Jet Engines Textbook 5 2. Variation of TA with Engine RPM T varies non-linearly with engine RPM Figure 6.2 shows that o the engine idles at about 45% producing 10% of rated T o at 80% RPM, the engine is still producing less than 50% of rated T o about 75% rated T is available only at RPM 90% What the curve doesn’t show is that the spool-up time from idle to rated T of this older turbojet engine was likely in the range 10-15 seconds! Figure 6.2. Thrust vs. Compressor Speed (N) for a 1st Generation Turbojet (The curve is exponential of the form Nx, with x ≈ 3.5 for this engine) 6 Thrust Specific Fuel Consumption (TSFC) Also called specific fuel consumption (SFC) in some AS310 text figures. The AS311 text provides different definitions for TSTC and SFC. In AS310, w use only the term TSFC in exams and quizzes. TSFC = (fuel flow in # /hour) / (# of thrust produced) = FF / T. pph is the abbreviation for # fuel/hr Often TSFC is reported in FF / 1000# thrust vice FF / # T TSFC varies with Engine RPM (throttle setting) Altitude Low TSFC is desirable (low FF for high T) Variations of TSFC with RPM Counter-intuitively, low RPM does NOT result in efficient use of fuel. Fuel efficiency increases as RPM increases. Figure 6.4 shows o TSFC decreases as RPM increases. o At idle, TSFC (3 pph) / (# T) or (3000 pph) / (1000 # T) o At 70% RPM, TSFC (1400 pph) / (1000 # T) o At 90% RPM, TSFC (1100 pph) / (1000 # T) o An airplane with four of these engines installed could substantially increase time on station by running two engines at idle and two at higher than RPM, thus getting better fuel economy at the higher RPM Figure 6.4. Specific Fuel Consumption vs. Engine RPM for Turbine Engine 7 Variations of TSFC with Altitude 1. For a turbojet engine at fixed RPM, Figure 6.3 graphs three ratios (x-axis) as a function of density altitude (y-axis): Air density ratio: ALT / SL = / 0 Thrust: TALT / TSL Thrust Specific Fuel Consumption: TSFCALT / TSFCSL 2. About Figure 6.3 To show relationships between air density, thrust, and TSFC, Figure 6.3 graphs three separate functions on one graph The density ratio plot is the same as the plot in Figure 2.2 with the x and y axes reversed. The thrust plot closely parallels the density ratio plot because jet engine TA decreases due to decreased mass flow as air density decreases. (The decrease is not quite proportional to the density ratio = / 0. A value of 0.8 is more accurate for the data given in Figure 6.3). For example, o TFL350 = 0.41 TSL while SL =0.33 SL (0.330.8 =0.412) o If TA at sea level is 10,000#, then thrust available at FL350 is 0.41 (10,000#) = 4,100#, a very substantial reduction. The TSFC plot reveals that for a turbojet engine o TSFC decreases (fuel efficiency increases) almost linearly as altitude increases up to the tropopause, where temperature stops decreasing. o After the tropopause, TSFC starts increasing. o Since TSFCFL335 = 0.80 TSFCSL, if for example TSFCSL = (800pph)/(1000# thrust), then TSFCFL335 = 0.8 (800) = (640pph)/(1000# thrust). o We don’t have corresponding graphs based on data for low and high bypass fans. However, word of mouth information from Boeing 787 test pilot Captain Bill Roberson suggests that TSFC also decreases with altitude for early generation low bypass fans. The generalization does not necessarily hold for high bypass fans, in part because these engines get much of their thrust from propeller effect, and propellers are more efficient in high density air than in low density air. 8 9