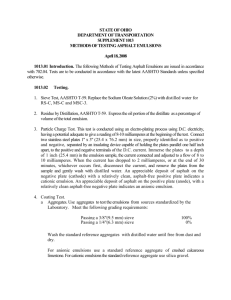

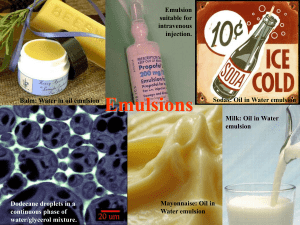

Chapter 2: Emulsions - Performance Chemical Company

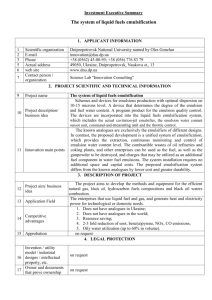

advertisement