Design Constraint Analysis

advertisement

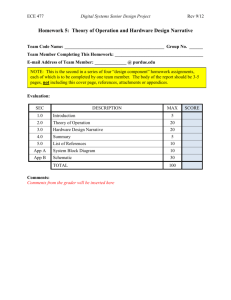

ECE 477 Digital Systems Senior Design Project Rev 8/12 Homework 3: Design Constraint Analysis and Component Selection Rationale Team Code Name: ___Doodle Drive__________________________ Group No. 6__ Team Member Completing This Homework: ___Jun Pan_________________________ E-mail Address of Team Member: ___pan19_______ @ purdue.edu NOTE: This is the first in a series of four “professional component” homework assignments, each of which is to be completed by one team member. The body of the report should be 3-5 pages, not including this cover page, references, attachments or appendices. Evaluation: SEC DESCRIPTION 1.0 Introduction (including updated PSSC) 2.0 Design Constraint Analysis MAX 10 - 2.1 Computational Requirements 10 2.2 Interface Requirements 5 2.3 On-Chip Peripheral Requirements 10 2.4 Off-Chip Peripheral Requirements 5 2.5 Power Constraints 5 2.6 Packaging Constraints 5 2.7 Cost Constraints 5 3.0 Component Selection Rationale 20 4.0 Summary 5 5.0 List of References 10 App A Parts List Spreadsheet 5 App B Updated Block Diagram 5 TOTAL Comments: Comments from the grader will be inserted here. 100 SCORE ECE 477 Digital Systems Senior Design Project Rev 8/12 1.0 Introduction Our design is Android tablet/phone application used to move a small vehicle. There will two modes: indoor and outdoor mode. Paths will be drawn on the Android device while Google Maps is displayed in outdoor mode. The vehicle will follow that drawn path using GPS. Indoor mode will be a simple direction/speed control mode. PSSCs 1.An ability to send and receive encoded data to an Android Device via Bluetooth 2.An ability to make a turn without stopping 3.An ability to navigate to a designated GPS coordinate with some approximation (GPS uncertainty of about ~5m) 4.An ability to monitor the battery power level 5.An ability to detect distance to an obstacle and stop to avoid crashing 2.0 Design Constraint Analysis Since our design is a mobile vehicle, the major constraint of it is the power component. The power design should be small, efficient, rechargeable and reasonably durable, which requires our circuit to have less power consumption than of the AC power design. The second important constraint is that the wireless range should be reasonably large, a class 1 Bluetooth could be used to compensate/extend the communication range between vehicle and the short range class 2 Bluetooth in the tablet [10]. Due to the navigation calculation, the microcontroller should have floating point math library supported. Cost is not a major concern of our design since no comparable design occurs in the market. . 2.1 Computation Requirements Although the whole design does not include graphic display, which is normally considered very computational intensive, the geometrical calculation with floating point for GPS coordinates transformation and route calculation inside microcontroller will be the major computation parts in our design. Although the GPS coordinates and compass data will be sent back as a string of characters, the library provided will store them in floating point -1- ECE 477 Digital Systems Senior Design Project Rev 8/12 format. Also geometric operation such as sine, cos, tan, etc might be used in our program. Floating point calculation is not supported by hardware but software library in most of the microcontrollers. One floating point operation uses about 50 cycles in software versus 2 cycles in hardware. The intensity of the computation also depends on how frequent the vehicle wants to check the GPS and compass, recalibrate the route. Higher recalibrating frequency could increase the accuracy of the route. But the calibrating frequency is limited by the refresh rates of GPS and compass, and the respond time of mechanical part. GPS, which has the slowest refresh rate among all the electronic components that we need, has a refresh rate of 10 HZ [2]. In worst case, the microcontroller has to finish 1 round of computation in 0.1s, which is sufficient. In addition, the microcontroller is responsible for communicating with Bluetooth module and GPS module periodically. Different kinds of interrupts will be utilized in the program very frequently. Fast interrupt handle is required by the architecture of the microcontroller. 2.2 Interface Requirements The microcontroller is required to interface with Bluetooth and GPS module via UART interface. The compass could be interfaced via I2C. The H-bridge is connected to PWM pins. Either GPIO pins or ADC could interface Ultrasonic. Multiple status LEDs for debugging could be directly driven by the GPIO pins of the microcontroller based on the LPC 17xx datasheet ([1],page 45). The motors are controlled directly by H-bridge. The Hbridge includes optical isolation, which isolates the motor and microcontroller. 6 GPIO pins(interrupt output, output A, output B for each encoder[3]) will be connected to 2 optical encoders for measure the speed of both sides of the motors. All I/O interfaces will be operated on 3.3V level. The logic part of H-bridge is powered by 5V but it is 3.3V input tolerant. 2.3 On-Chip Peripheral Requirements The design will require minimum of 2 UART, 12 GPIO pins 2 8-bits PWM and 1 I2C. 2 channels of UART are required for communicating with Bluetooth module and GPS Module. DMA controller could help reduce overhead of MCU on data transfer between -2- ECE 477 Digital Systems Senior Design Project Rev 8/12 UART and SRAM. But it is not required. 2 PWM channels are for interfacing with Hbridge. 1 I2C master is required for configuring and reading from digital compass. The reading of each of 3 ultrasonic sensors could be done via 3 GPIO pins. 3 Input capture timer channels are also required to collaborate with ultrasonic sensors. Finally, 2 pulse counter channels are needed for measuring the motor speed via optical encoder. 2.4 Off-Chip Peripheral Requirements The design will require several off-chip peripherals. A Bluetooth module will be used to communicate with tablet via UART. A GPS module with 2.5~5 m accuracy will be used to receive GPS coordinates of the vehicle location. Digital compass module is used for determining the head direction of the vehicle. 3 ultrasonic sensors are used for detecting the obstacles to the front and side. A H-bridge motor driver will be used for controlling the motor of the left side wheels and right side wheels. Finally, 2 optical encoders are needed to measure the speed of the motors. 2.5 Power Constraints Since our design is portable, it will be a battery-powered vehicle. The battery pack that we choose should be rechargeable. An IC for charging will be integrated to our design. In addition, the battery pack should be small enough to fit in a 20cm*20cm area, which is the approximate size of our vehicle. It has to be light enough not to contribute much weight to the vehicle. Based on the DC motor that we choose, a battery pack with 7 to 12 Volts voltage could be considered. Voltage regulator is needed to convert unregulated battery voltage to 5V and 3.3V. All the components except H-bridge requires 3.3V supply. The Hbridge requires 5V supply but can be driven by 3.3V logic output from microcontroller ([4], page 5). Here is current estimation of each component ([1][3][4][5][6][7][8][9]): Component Voltage (V) Current (mA) Power (mW) Micro 3.3 50 165 Bluetooth 3.3 30 99 -3- ECE 477 Digital Systems Senior Design Project Bluetooth Antenna Rev 8/12 32 (15dBm) Compass 3.3 0.83 2.7 GPS 3.3 Ultrasonic 3.3 20x3 198 Motor 9 210*2 3780 75 Total 4351.7 The major power-draining component in our design is definitely the motor. The battery pack needs to be selected such that it could support minimum of this amount of power listed above. Heat dissipation should not be a big problem in our case. The total power dissipation is not very large. The vehicle should have large enough space for this amount of heat dissipation. 2.6 Packaging Constraints Due to limited torque provided by the motors, the weight of the vehicle could not be too large. The whole PCB should be fit in the tray inside the vehicle kit. Additional space needs to be left for placing the ultrasonic sensor. The wheels of the vehicle need to be strong enough to spin on the bumpy road. 2.7 Cost Constraints Since there is no comparable product in the market, no price competition needs to be concerned. The microcontroller could be sampled from manufacturer directly. The major parts of the cost will be the vehicle kit, GPS module and Bluetooth module. The vehicle kit would be the major cost of the design. For easy prototyping purpose, breakout board will be bought. It will cost much more than chip itself. The costs are listed in Appendix A. 3.0 Component Selection Rationale Since we will be using floating point in our program, a 32-bits microcontroller with enough peripherals and floating point math library will be our best choice. We decide to pick from two different microcontroller from different manufacturer with different architecture: LPC1768, an ARM Cortex-M3 based microcontroller and PIC32MX360F128L, a PIC32 based microcontroller. Firstly, the cost is not a problem since -4- ECE 477 Digital Systems Senior Design Project Rev 8/12 we can sample them for free. Both of them have enough on chip peripherals, but LPC1768 has 1 addition UART for us to use as on board debugging feature. Also LPC1768 has more timer module than PIC32MX360F128L. LPC1768 includes an 8-channel DMA controller that we can use to efficiently transfer data to UART. From programming environment perspective, ARM provides better library support. It provides optimized floating point library. The printf command to terminal will run quicker in LPC1768. Consider the facts above, we choose LPC1768 as our microcontroller [1][9]. For Bluetooth module, we have Bluetooth USB dongle, RN42 and RN41 in our list. Bluetooth USB dongle is easy to interface, but it doesn’t have any IO pin to indicate the status of the Bluetooth. RN41 and RN42 are virtually the same thing. But RN41 provides longer range connection than RN42, which is the reason we choose RN41 as our Bluetooth module. The third important part is GPS module, We decide to choose from UP501 and LS20031. After comparing the features and specifications, UP501 has faster update rate(10 hz) and more accuracy reading(2.0~2.5m with SBAS enabled). These two parameters are very important to our design. Most importantly, LS20031 is out of stock. Thus we choose UP501 as our GPS module. 4.0 Summary This project could be one of the conceptual prototypes, which redefine the world of driving. The process of choosing between the microcontroller has been discussed. The microcontroller we choose is sufficient to finish the task. All the peripherals chosen are suitable for the design. The power constrains will guide our future power design. -5- ECE 477 Digital Systems Senior Design Project Rev 8/12 5.0 List of References [1] LPC1769/68/67/66/65/64/63, 32-bit ARM Cortex-M3 microcontroller[Online] http://www.nxp.com/documents/data_sheet/LPC1769_68_67_66_65_64_63.pdf [Accessed: Jan. 27, 2013] [2] Sparkfun GPS Buying guide[Online]: https://www.sparkfun.com/pages/GPS_Guide [Accessed: Jan. 27, 2013] [3] How to use a quadrature encoder[Online]: https://www.http://letsmakerobots.com/node/24031[Accessed: Jan. 27, 2013] [4] L293, L293D QUADRUPLE HALF-H DRIVERS[Online]: http://www.datasheetcatalog.org/datasheet/texasinstruments/l293d.pdf[Accessed: Jan. 27, 2013] [5] RN-41/RN-41-N Class 1 Bluetooth Module [Online]: http://dlnmh9ip6v2uc.cloudfront.net/datasheets/Wireless/Bluetooth/rn-41-dsv3.3r.pdf[Accessed: Jan. 27, 2013] [6] LSM303DLHC [Online]: http://www.st.com/internet/com/TECHNICAL_RESOURCES/TECHNICAL_LITERATU RE/DATASHEET/DM00027543.pdf [Accessed: Jan. 27, 2013] [7] UP501 Fastrax GPS antenna module [Online] http://www.ublox.com/images/downloads/Product_Docs/UP501_PS.pdf [Accessed: Jan. 27, 2013] [8] Dagu Rover 5 Tracked Chassis with 2 Encoders 2WD robot chassis[Online] http://www.mhobbies.com/dagu-rover-5-tracked-chassis-with-encoders.html [Accessed: Jan. 27, 2013] [9] PIC32MX Family [Online] http://ww1.microchip.com/downloads/en/devicedoc/pic32mx_datasheet_v2_61143b.pdf [Accessed: Jan.28, 2013] [10] Class 1 Bluetooth Dongle Test [Online]:http://www.amperordirect.com/pc/r-electronicresource/z-reference-bluetooth-class1-myth.html[Accessed: Jan.28.2013] IMPORTANT: Use standard IEEE format for references, and CITE ALL REFERENCES listed in the body of your report. -6- ECE 477 Digital Systems Senior Design Project 8/12 Appendix A: Parts List Spreadsheet Vendor Manufacturer Part No. Description Unit Cost Qty $35 $45.34 $79.95 $33.27 Sample $14.95 Roving networks Roving networks Dagu ST 740-1007-ND 740-1034-ND RPDR5D 511-STEVAL-MKI106v1 RN-41 class 1 Bluetooth RN-41 class 1 Bluetooth breakout board Robot Chassis and motors/Encoders LSM303DLHC adapter for prototyping NXP sparkfun Mouser ST NXP sparkfun Fastrax ST LPC1768 ROB-10555 916-UP501 497-2940-5-ND 32-Bits Cortex M3 based microcontroller wheels UP501 GPS module with antenna $31.35 L298HN Hbridge Sample 2 $31.35 $0 Maxim Maxim Maxim Maxim Maxim Maxim MAX17502E MAX17502F DS2782 Buck DCDC Converter (to 3.3V) Buck DCDC Converter (to 5V) Stand-Alone Fuel Gauge IC 1 1 1 $0 $0 $0 Sample Sample Sample TOTAL -7- 1 1 1 1 1 Total Cost digikey digikey Mhobbies mouser 2 1 $35 $45.34 $79.95 $33.27 $0 $29.90 $254.82 ECE 477 Digital Systems Senior Design Project Appendix B: Updated Block Diagram -8- 8/12