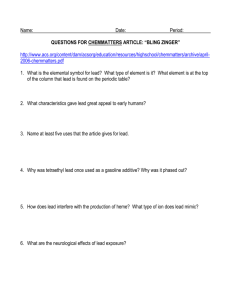

Dirty Business - American Chemical Society

advertisement