Responsible Leadership Impact Initiatives Update Q1 2012 MOVING

advertisement

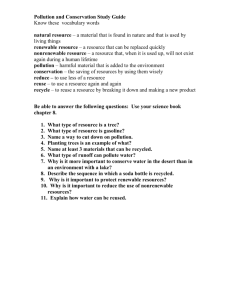

MOVING THE ENVIRONMENT FORWARD: ENVIRONMENTALLY SUSTAINING PRODUCTS & FACILITIES People are meant to move and New Balance designs footwear and apparel to serve the body in motion and inspire people to move further, faster and more frequently. New Balance is reducing the environmental impact of all of our footwear, apparel and accessories without sacrificing performance. Our focus is in the following areas: Environmentally Preferred Materials (EPMs) Waste Reduction Chemical Management Sustainable Design Eco- Indexing Collaboration and Industry Involvement ENVIRONMENTALLY PREFERRED MATERIALS (EPMs) Footwear product management, designers and developers all have quarterly and SBU specific goals in place for use of Environmentally Preferred Materials (EPMS) for uppers. New Balance defines EPMs as: o o o o o Textiles, laces and webbings with a minimum of 25% recycled polyester. Materials made from sustainable/renewable resources such as hemp or organic cotton. Leathers made by tanneries that meet strict industry standards for environmental impact (minimum of Bronze rating from BLC Leather Working Group) Non-PVC synthetic leather with reduced solvent/energy use and/or with recycled polyester backer “Zero waste” thermoplastic heel counters which are manufactured in a manner that produces little wasted material. New Balance has specified more than 2,500 EPM items to use in our products. We have sourced common shoe parts (strobel sock liners, shoe laces) with recycled content and they are used routinely by all product teams. New Balance has instituted a material supplier certification process and narrowed down our vendor base to better control raw material sourcing and create more eco-preferred materials. newSKY footwear for men and women made from recycled PET bottles debuted in October 2011. newSKY”s upper material utilizes 95% post-consumer recycled PET plastic bottles and is adhered to the outsole with water-based glue. The average pair of newSKY uses the equivalent of eight 20-ounce PET bottles, keeping them from landfill. The shoes are built with less material than traditional New Balance athletic shoes through thoughtful upper pattern design. WASTE REDUCTION A successful pilot in 2010 that analyzed 5 styles from predecessor to prototype, and identified methods to use less material, and minimize the waste of the material that was used. Over 109,000 square yards of material were saved with the learnings from the small five style pilot test in 2010. We continue to leverage these learnings in design and development of future styles to minimize the waste we generate. CHEMICAL MANAGEMENT New Balance is committed to operating its business in an environmentally sustainable manner to protect the consumer, worker, environment, and the brand. The New Balance Restricted Substance List (“RSL”) and Manual is an integral part of this commitment. The goal of the New Balance RSL program is to have a strong program in place to aggressively reduce the amount of or substitute for chemicals used in our products. Our objective is to minimize the use of hazardous substances in our products that affect the: o Worker during production Responsible Leadership Impact Initiatives Update Q1 2012 o o Consumer during normal use Environment’s waste stream in product sourcing and upon end of product life New Balance has instituted a Restricted Substance Program to ensure compliance to all global legislation regarding chemicals and has quickly reached some major milestones: o Incorporated CPSIA/REACH/Proposition 65 into Restricted Substance program beginning in October 2008. o Began deployment of the RSL program for Apparel, Domestic Footwear, Licensees and Equipment (Warrior/Brine) in 2009 o Released Restricted Substance List Manual – Version 7 in Jan 2012 which is currently online at newbalance.com. o The NB RS team collaborated with industry brands to create the RSL Supplier toolkit (released Nov. 2011), which demonstrates how a brand can build a successful RS program. Footwear factories globally are submitting monthly environmental data with a goal to convert from solvent based adhesives to water based adhesives whenever performance criteria for the shoes will allow. Noteworthy: All New Balance footwear is made without the use of PVC (Polyvinyl chloride), a substance considered to contaminate the environment and be harmful to humans and animals. COLLABORATION & INDUSTRY INVOLVEMENT New Balance is an active member of three major industry associations working toward environmental improvement: the BLC Leather Working Group, the Outdoor Industry Association Eco-Working Group and the Sustainable Apparel Coalition (SAC). As a founding member of the SAC, the New Balance apparel team is taking part in a pilot-test of the SAC Index. The SAC Index was created as a combination of existing ecoindexing tools, methodologies, and frameworks to create a single method for rating the responsible compliance and sustainability efforts behind a footwear or apparel product. PACKAGING New Balance’s primary shoe boxes are made from 100% recycled materials and are 100% recyclable. The glue, inks, and varnishes used are all non-toxic and environmentally-preferred. The structure of the box is designed to create minimal waste throughout the production process. All stuffing, molded toe forms and tissue wrap are made from 100% recycled materials and are 100% recyclable. Integrated carrying handles were incorporated in boxes rolling out in 2011 to reduce the need to use a shopping bag. Product Design Goals Include EPM – Measure and Achieve SBU Specific Goals Quarterly regarding EPM use in our products. Waste – Achieve 10% Reduction in wasted materials with a positive or neutral impact on performance Eco-indexing – Pilot test SAC version 1 in Apparel, Participate in SAC development of Version 2 across New Balance. 2 Responsible Leadership Impact Initiatives Update Q1 2012 NEW BALANCE FACILITIES In 2011, New Balance reduced total energy use in our domestic factories by 8.7% over the prior year. NB engaged in an energy usage reduction campaign seeking opportunities to eliminate waste. Upgrades in utility systems, re-tooling of building equipment and adjusting building energy management systems saved approximately 1.2 Million KWH for our New England Facilities. This campaign led to the reduction of 1477 metric tons of green house gas (GHG) of carbon dioxide. NB recycled or burned for energy almost 98% (92% fully recycled + 6% burn to energy) of solid waste which includes cardboard, metal, plastic, paper and wood. More than 3402 tons of waste (1351 tons in cardboard and paper) were recycled or burned for energy. The resources saved by recycling are equivalent to 9,233,917 KWH of energy; 15,765,225 gallons of water; 135,130 pounds of air emissions; 6,757 cubic yards of landfill space; and 38,287 mature trees. The remaining 2% of our solid waste was sent to landfill (mostly leather material). Hazardous and Universal Waste trend data continues to drop year over year. New Balance continues to focus on supporting domestically produced renewable energy. New Balance expanded its commitment to clean renewable energy in 2011 by making a voluntary purchase of 5,483 MWH of renewable energy credits (REC’s). For 2011, 55% of New Balance’s annual electrical consumption is supported by Massachusetts and Maine’s Renewable Portfolio Standards and voluntary purchases. NB Sales recycled old retail fixtures in 2011 and saved one ton of debris from going to landfill NB IT Datacenter reduced paper usage by 91% over the last 8 years. In 2010, NB demolished the Skowhegan Distribution Center. It was a ‘green’ building demolition with 2300 tons of debris being generated, but ultimately 98% of it was recycled. 2200 tons of debris was saved from landing in a landfill. New Balance Corporate Services Management Goals Reduce total energy use year over year. Offset 100% of New England energy usage with renewable energy sources. Fully recycle our solid waste. Drive recycling programs for footwear in our retail and associate facilities. 3